Battery jig and battery assembly method

A technology of battery fixtures and components, which is applied in battery assembly machines, secondary battery manufacturing, climate sustainability, etc. It can solve the problems of low assembly efficiency of soft-pack lithium batteries, save positioning time, improve compatibility, and improve assembly efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

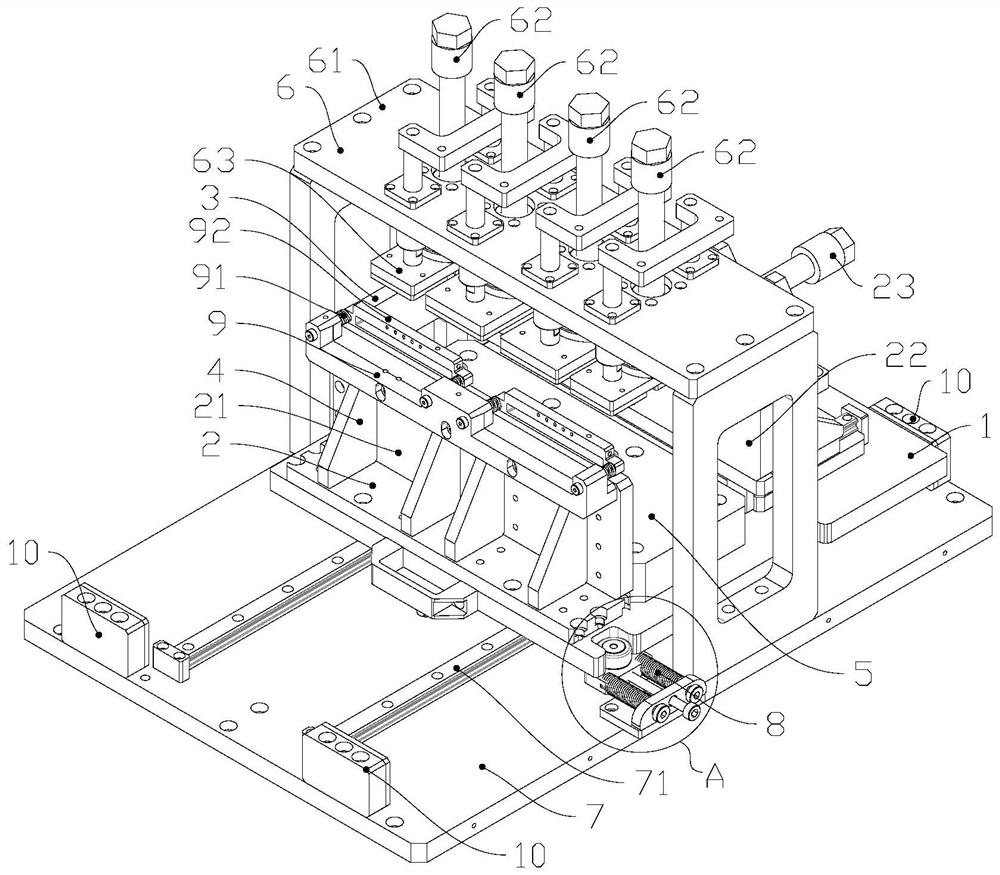

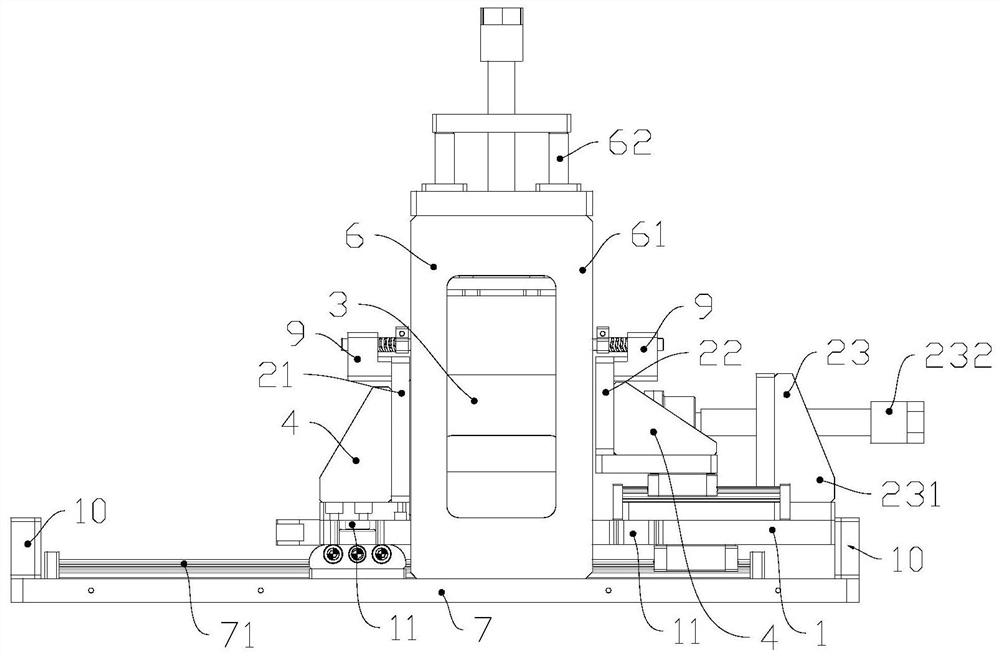

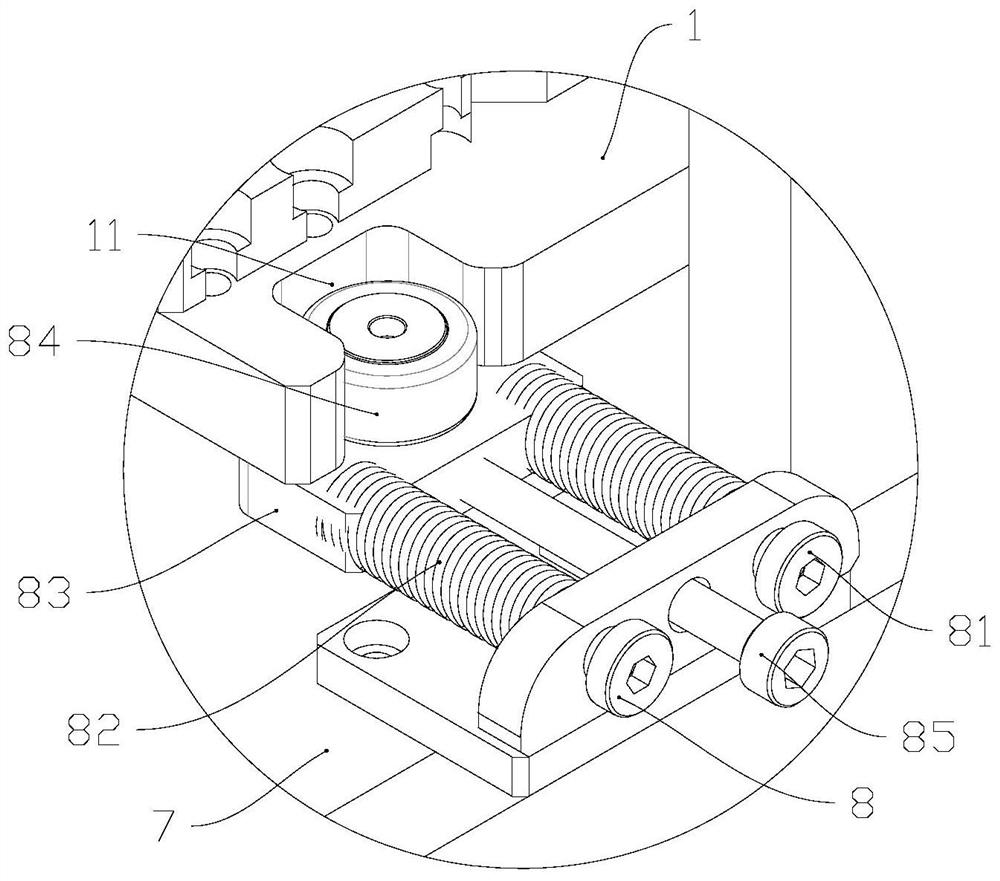

[0052] Further, see figure 1 and image 3 , as a specific embodiment of the battery clamp provided by the present invention, also includes a positioning component 8;

[0053] The positioning assembly 8 includes a first guide shaft 81, a first spring 82, a movable block 83 and a roller 84, the first guide shaft 81 is movably connected to the fixed seat 7, the movable block 83 is fixed on the first guide shaft 81, and the roller 84 Set on the movable block 83, the first spring 82 is sleeved on the first guide shaft 81 and can push the movable block 83 close to the moving seat 1; Extend into the positioning groove 11 under action or withdraw from the positioning groove 11 under the action of external force.

[0054] The first guide shaft 81 can ensure that the moving direction of the movable block 83 is constant; the first spring 82 provides a reset thrust for the movable block 83, so that the movable block 83 is pushed toward the moving seat 1; Seat 1 is locked to ensure that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com