Positioning tool for welding of vertical beams of cabinet

A technology for welding positioning tooling and cabinets, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low welding precision, improve work efficiency and avoid temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

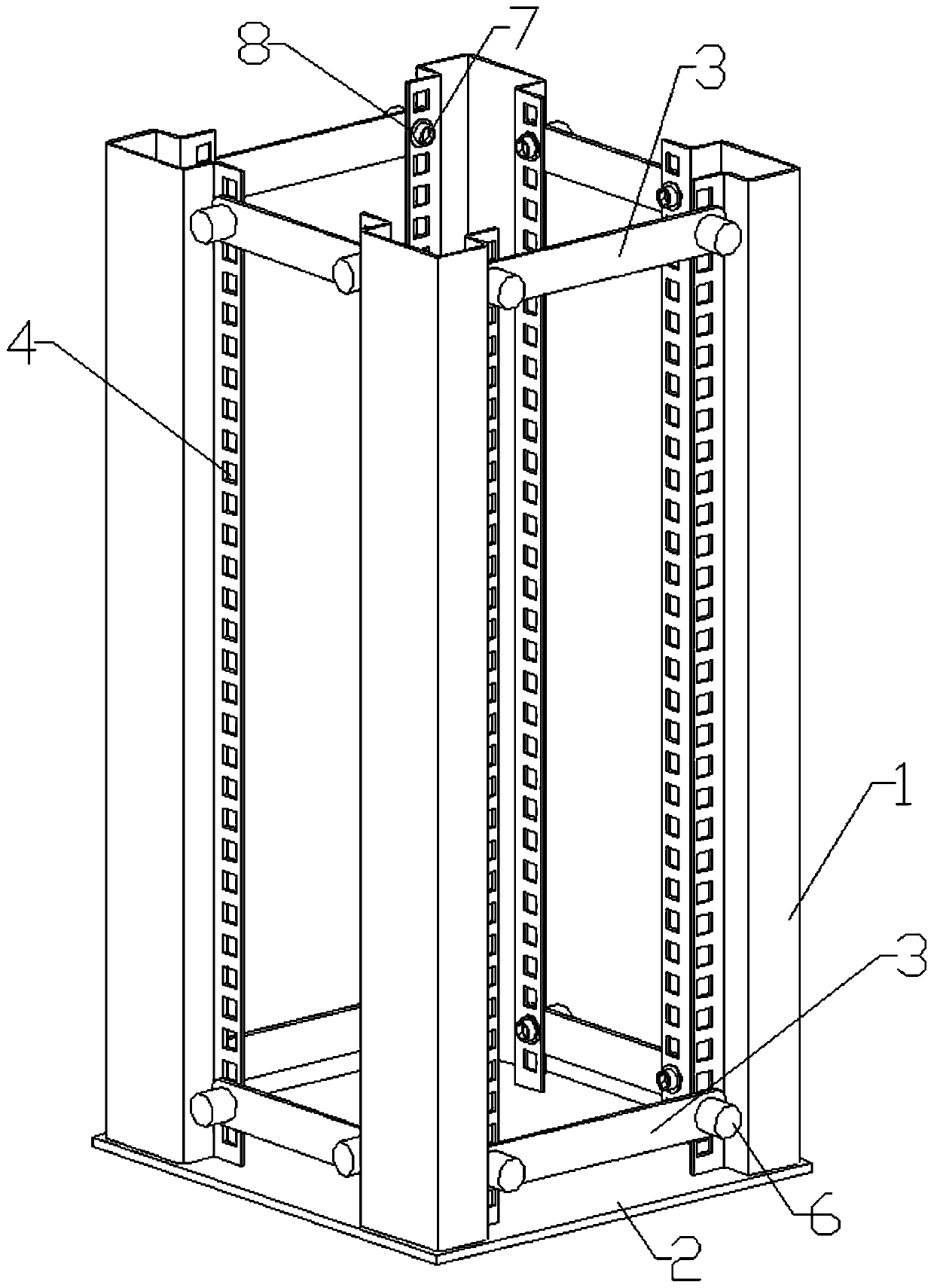

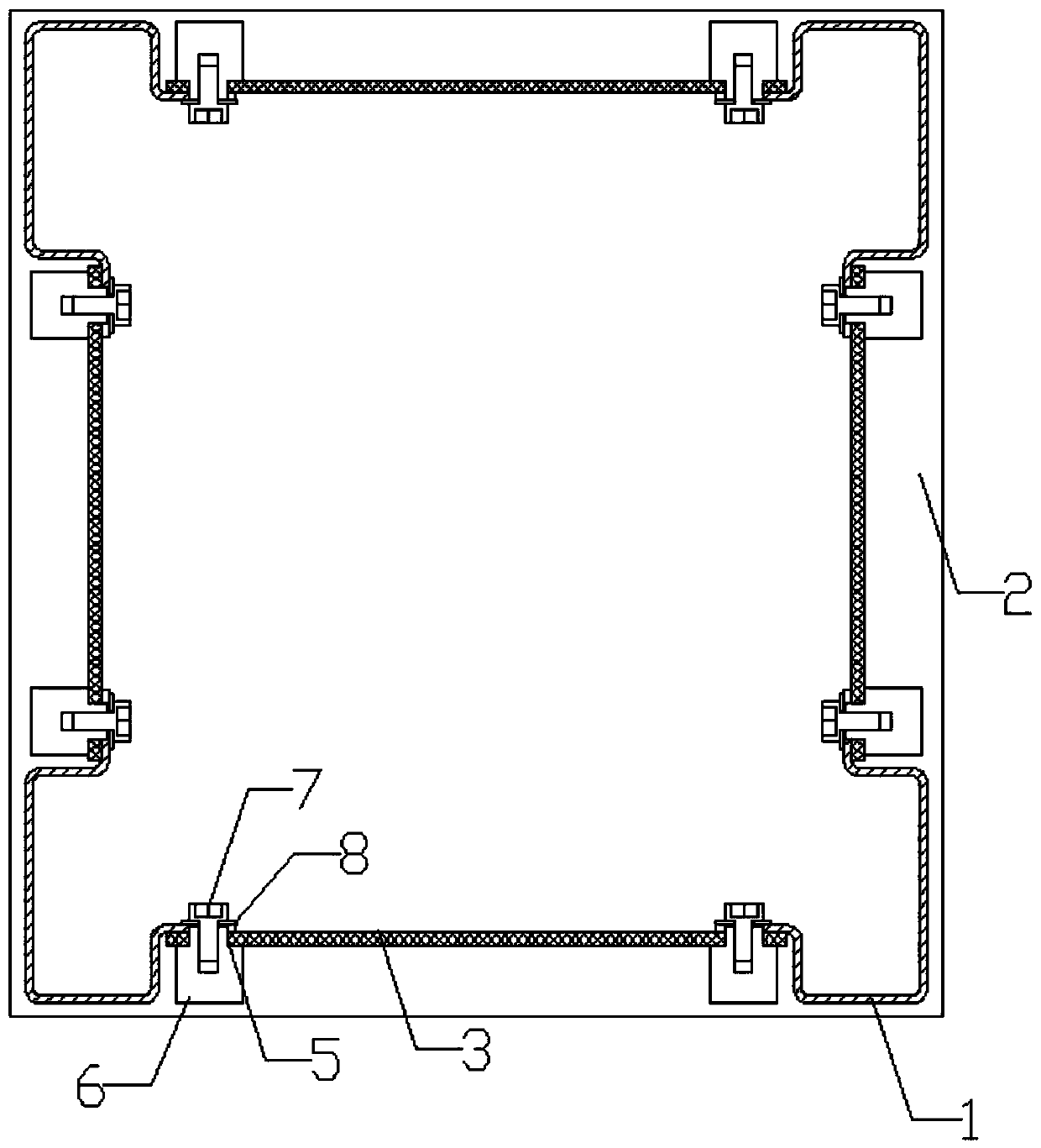

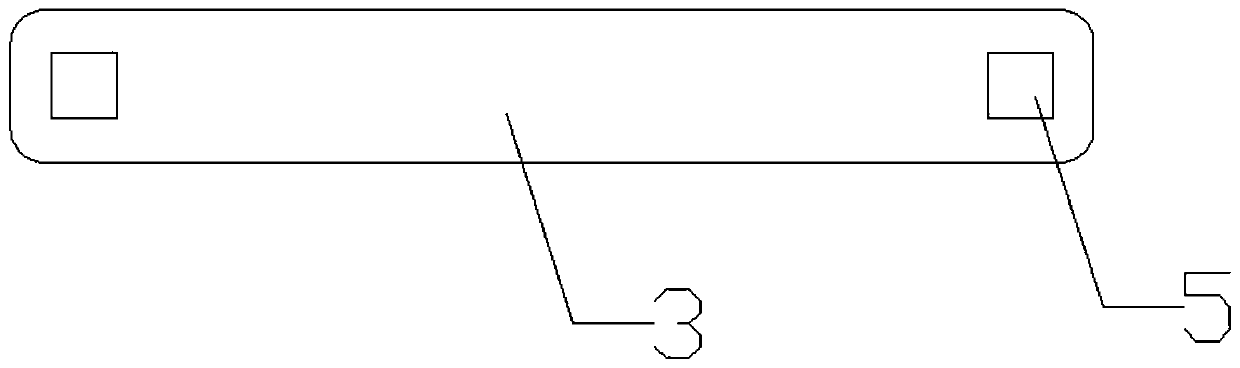

[0018] Such as Figure 1 to Figure 3 As shown, a cabinet vertical beam welding and positioning tooling includes a vertical beam 1, a base 2, a positioning plate 3, and a positioning pin 6. The vertical beam 1 is provided with a plurality of square holes A4, and the square holes A4 are along the length of the vertical beam 1. The directions are equidistantly distributed on the upright beams 1, and there are four upright beams 1, and the upright beams 1 are connected to each other through the positioning plate 3, and placed on the upper end surface of the base 2, and the two ends of the positioning plate 3 are provided with square holes B5, the size of the square hole B5 is the same as the size of the square hole A4, one end of the positioning pin 6 passes through the square hole B5 and the square hole A4 sequentially from the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com