Intelligent welding method for electric smelting pipe fitting based on position detection, storage medium and terminal

A welding method and a technology of electric fusion pipe fittings, which are applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of whether the pipe fittings cannot be inserted in place, etc., and achieve the effect of improving welding quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

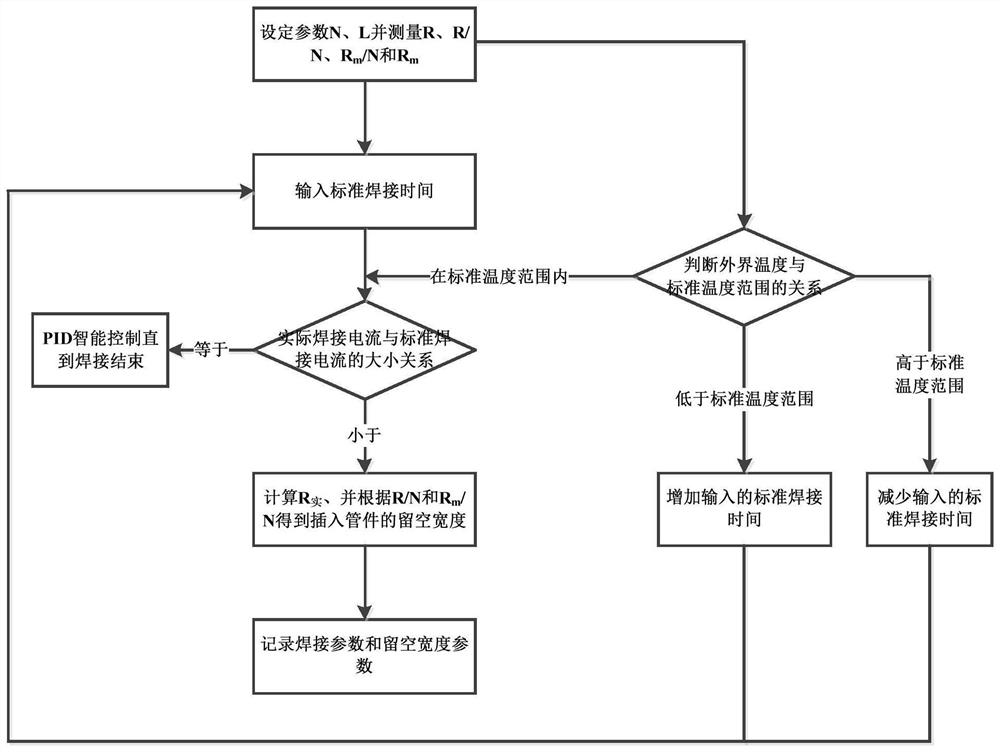

[0033] Such as figure 1 As shown, the embodiment of the present invention relates to an intelligent welding method for electrofusion pipe fittings based on position detection, and the intelligent welding method includes:

[0034] Parameter setting steps: set one end of the electrofusion pipe to be equipped with N coils of resistance wire and the layout width is L, and then calculate the cladding width of each coil of resistance wire as L / N;

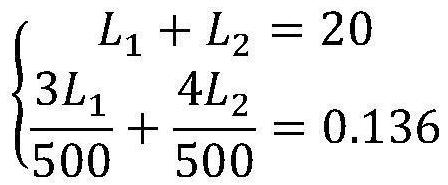

[0035] Specifically, assuming that one end of the electrofusion pipe fitting is provided with 50 turns of resistance wires of the same direct size, and the laying width is 20 cm, it can be calculated that the cladding width of each turn of resistance wire is 4 mm.

[0036] When the relationship between the actual current and the maximum output power is measured, the total resistance of the resistance wire is R when the requirements are met, and the average resistance value of each turn of the resistance wire is calculated as R / N at this t...

Embodiment 2

[0060] Another embodiment of the present invention includes a storage medium on which a computer control program is stored, and when the computer control program is executed by a processor, the intelligent welding of electric fusion welding pipes based on position detection in Embodiment 1 of the present invention is realized method steps.

Embodiment 3

[0062] Another embodiment of the present invention includes a terminal, including a processor and a memory; the memory is used to store a computer control program; the processor is used to execute the computer control program stored in the memory, so that the The terminal executes the steps of an intelligent welding method for electric fusion welding pipes based on position detection in Embodiment 1 of the present invention.

[0063] The invention realizes the measurement of the resistance of the gap width and insertion depth through the change of the current calculated by the temperature and resistance changes in the resistance wire welding process, and then calculates the specific values of the gap width and insertion depth, and determines the insertion of the pipe fitting Whether it is inserted in place, it can also be accurately calculated how many turns of the resistance wire the heat from cannot be transmitted because it is not in contact with the inserted pipe fitting,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com