Multifunctional SAW type iron tower welding robot

A welding robot and multi-functional technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of single welding process method, no benchmark for workpiece positioning, poor welding environment, etc., and achieve a good working environment for workers and stable movement. Good, the effect of reducing ineffective working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

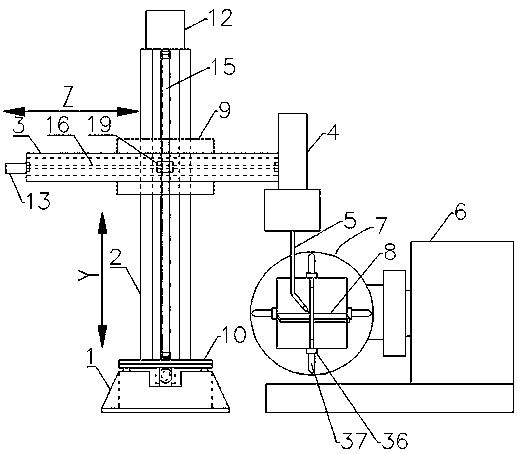

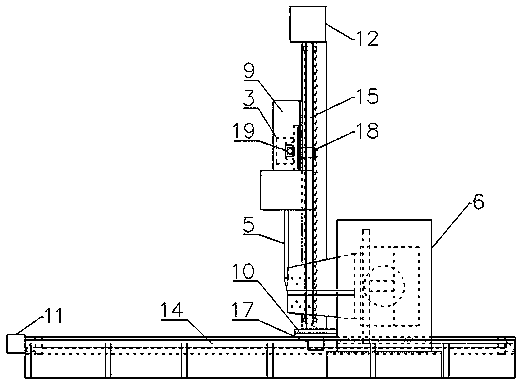

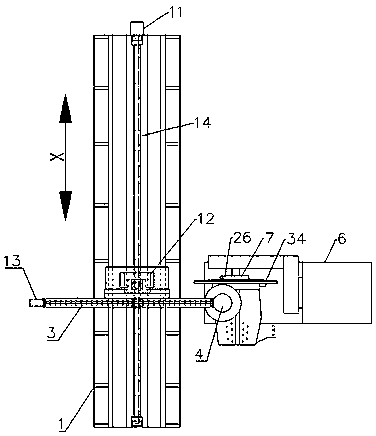

[0066] see Figure 1-3 , a multifunctional SAW-type iron tower welding robot, including a base 1, is characterized in that: a curved neck gun body 5 for welding workpieces is installed above the base 1, and the curved neck gun body 5 can move and rotate in multiple directions through an azimuth adjustment device One side of the azimuth adjustment device is provided with an L-shaped servo numerical control positioner 6 for driving the multi-directional rotation of the welded part, and the output end of the L-shaped servo numerical control positioner 6 is fixedly connected with a device for fixing the position of the welded part Self-locking four-point positioning mechanism7.

[0067] see Figure 7-8 , the lower end of the neck gun body 5 is bent at a certain angle and extends downward, and the bending angle is 140°≤α≤170°.

[0068] The inside of the bent neck gun body 5 is provided with a through hole running through the upper and lower ends of the bent neck gun body 5 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com