Dust removal and slag removal mechanism for lithium battery laser welding

A laser welding and lithium battery technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting the laser passing area, affecting the heat sealing effect of the tab side when the battery is packaged, and affecting the welding area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

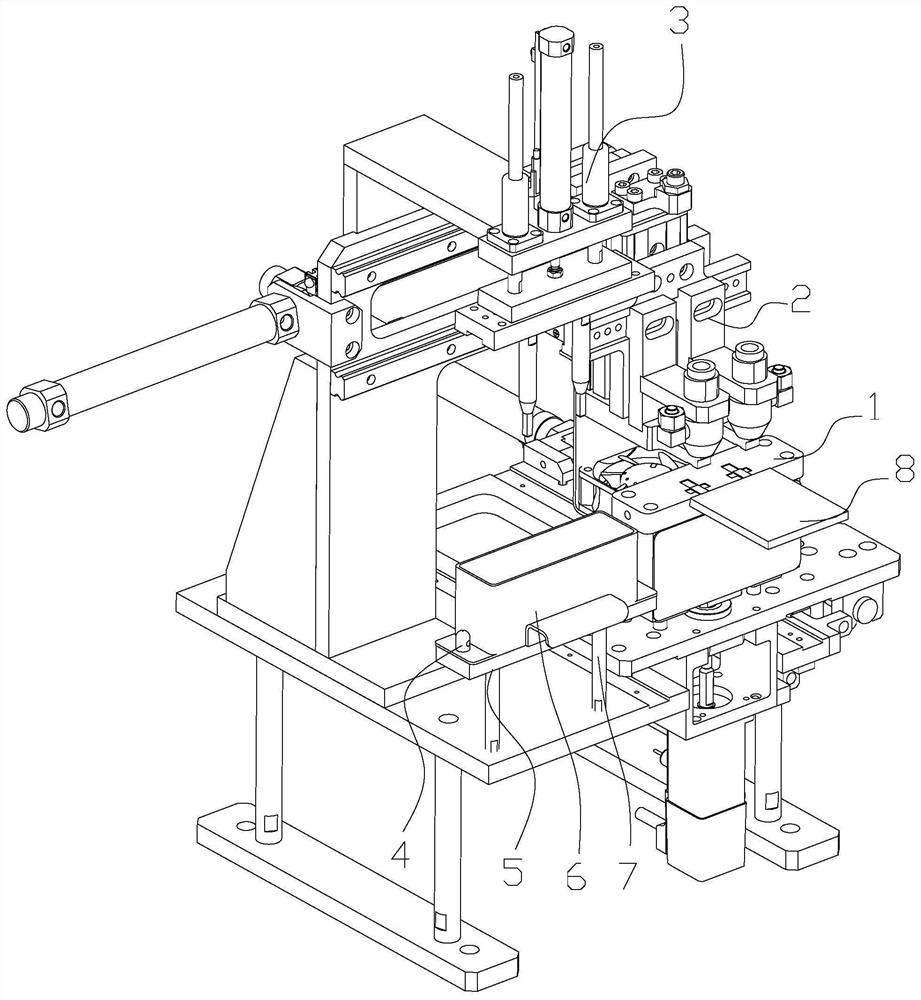

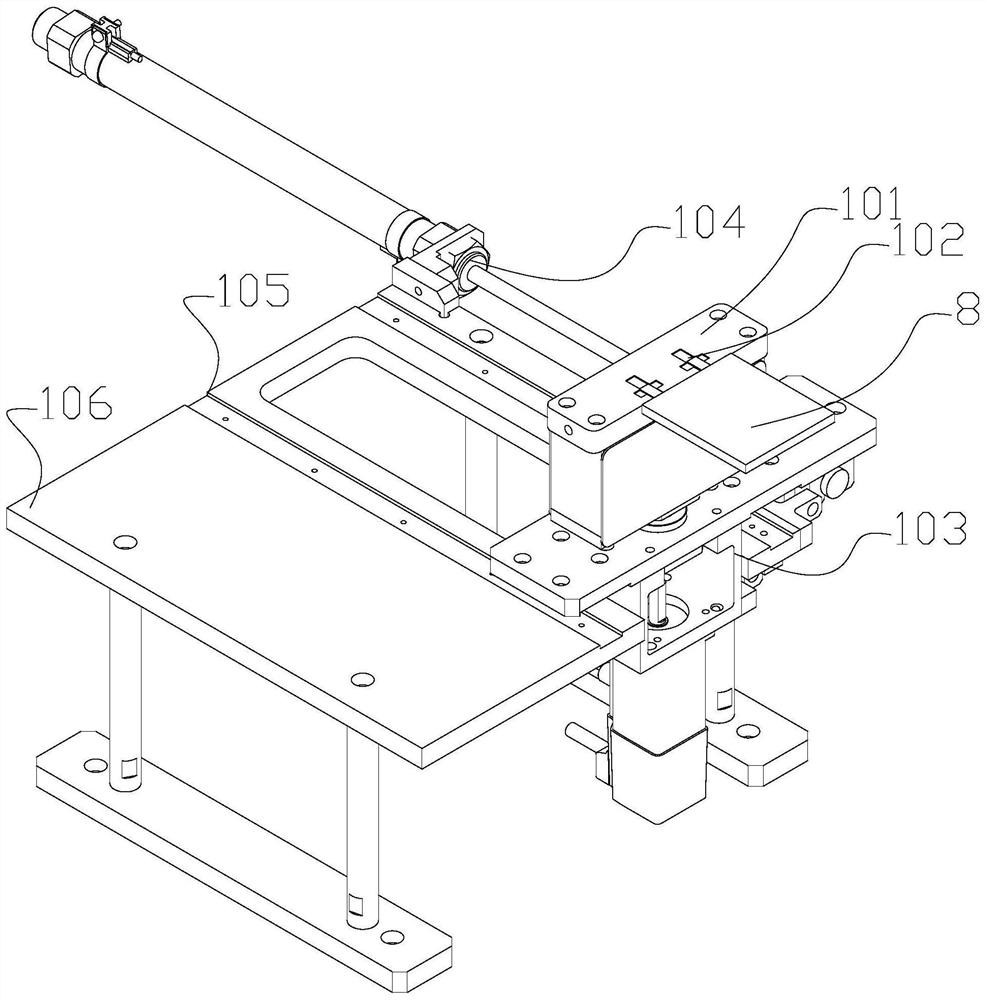

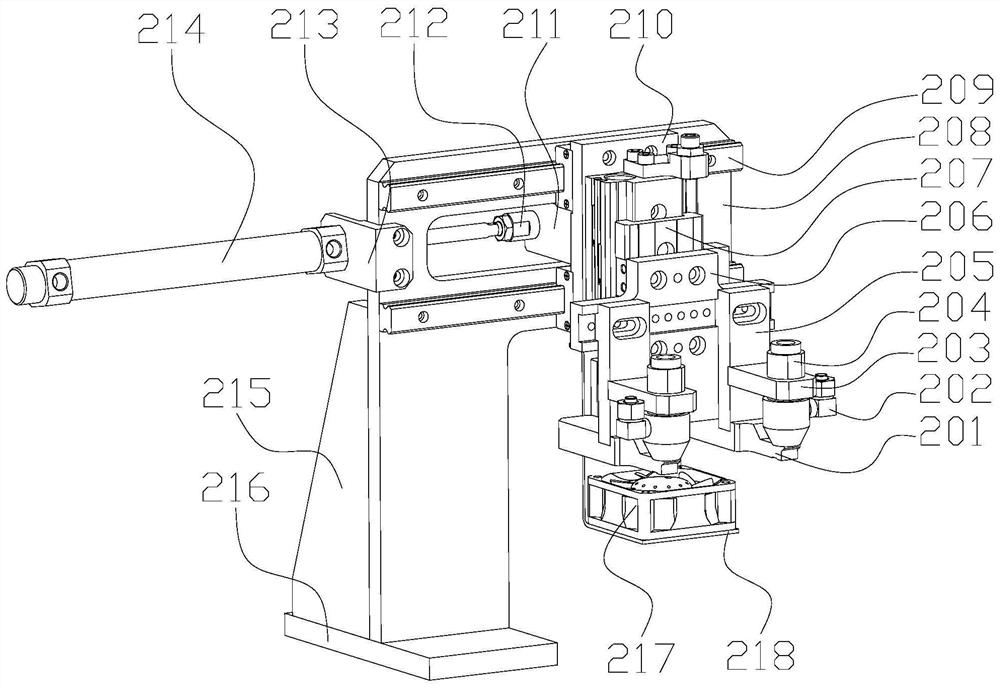

[0020] refer to Figure 1 to Figure 4 , which is a dust removal and slag removal mechanism for laser welding of lithium batteries, including a tab transfer mechanism 1, a welding head pressing mechanism 2, a welding slag cleaning mechanism 3 and a welding slag collection box 6; the welding head pressing mechanism 2 is installed on the tab On the transfer mechanism 1, the welding head pressing mechanism 2 is provided with two stations on the left and right, which are the slag cleaning station on the left and the welding station on the right; a welding slag cleaning mechanism 3 is installed above the slag cleaning station. Below the slag station is a welding slag collection box 6; below the welding station is a lug transfer mechanism 1; Light hole, when laser welding the tab 102, the tab 102 is transferred to the welding station through the tab transfer mechanism 1, pressed by the welding pressure head 201 and laser welded with the cell 8, after the laser welding is completed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com