Patents

Literature

31results about How to "Uniform tightening force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for adjusting housings outside single stand reversible rolling mill

ActiveCN101664760AHigh adjustment accuracyMeet the acceptance criteriaMetal rolling stand detailsMeasuring devicesEngineeringRoll center

The invention relates to a method for adjusting a single stand reversible rolling mill, in particular to a method for adjusting housings outside the single stand reversible rolling mill, which comprises the following steps: a, determining that a housing base reaches assembly accuracy, and suspending the housings to correct positions; b, hanging a steel wire, checking vertical and transverse central lines of the rolling mill; c, connecting earphones to the vertical and transverse central lines of the rolling mill by lead wires; d, moving housings on a transmission side and an operation side towards the housing base direction on a discharge side respectively by a hydraulic jack to ensure that a bracket side of the housings is close to the lateral surface of the base on an outlet side, and moving a rail rest on an inlet side towards the outlet side; e, adjusting sizes of the housing rolling center and the transverse center of the rolling mill, and fastening a foundation bolt by 70 percentof a design torque; and f, hanging steel wires on housing windows and the rolling directions of the housings, and measuring the verticality and the horizontality of the windows and the rolling directions of the housings of the rolling mill. The method uses the steel wires and the earphones to ensure numerical reading, eliminates reading errors caused by visual errors of staff, and improves the assembly accuracy of equipment.

Owner:CHINA MCC20 GRP CORP

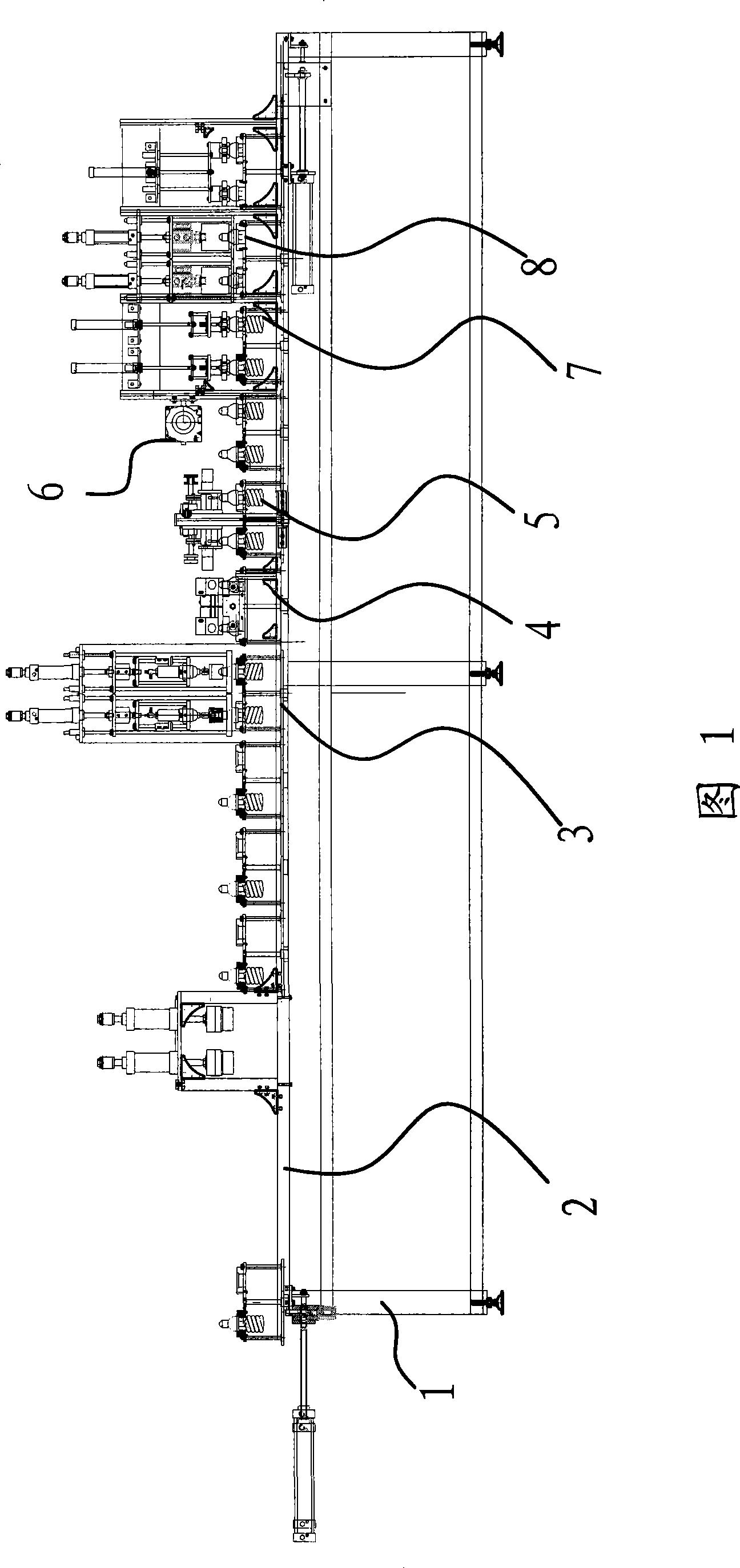

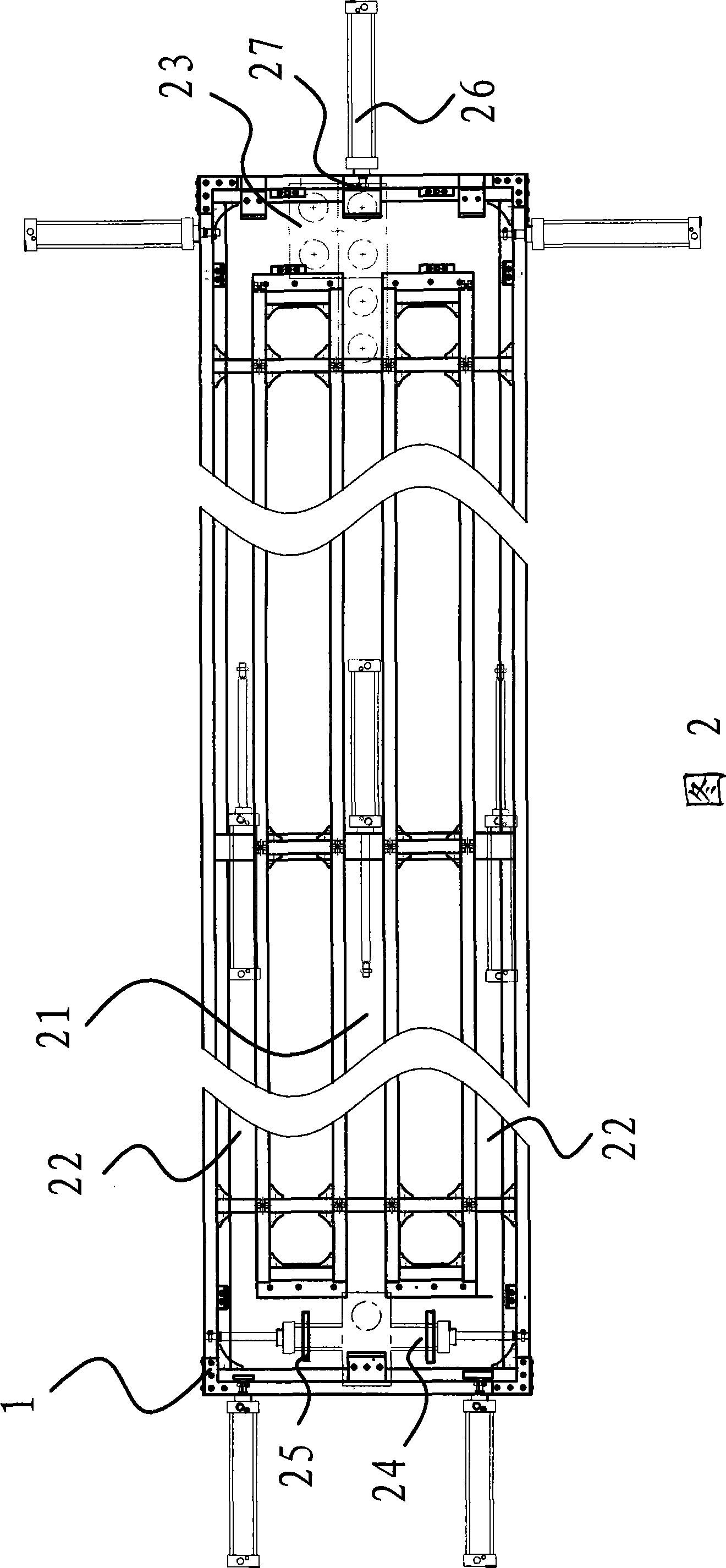

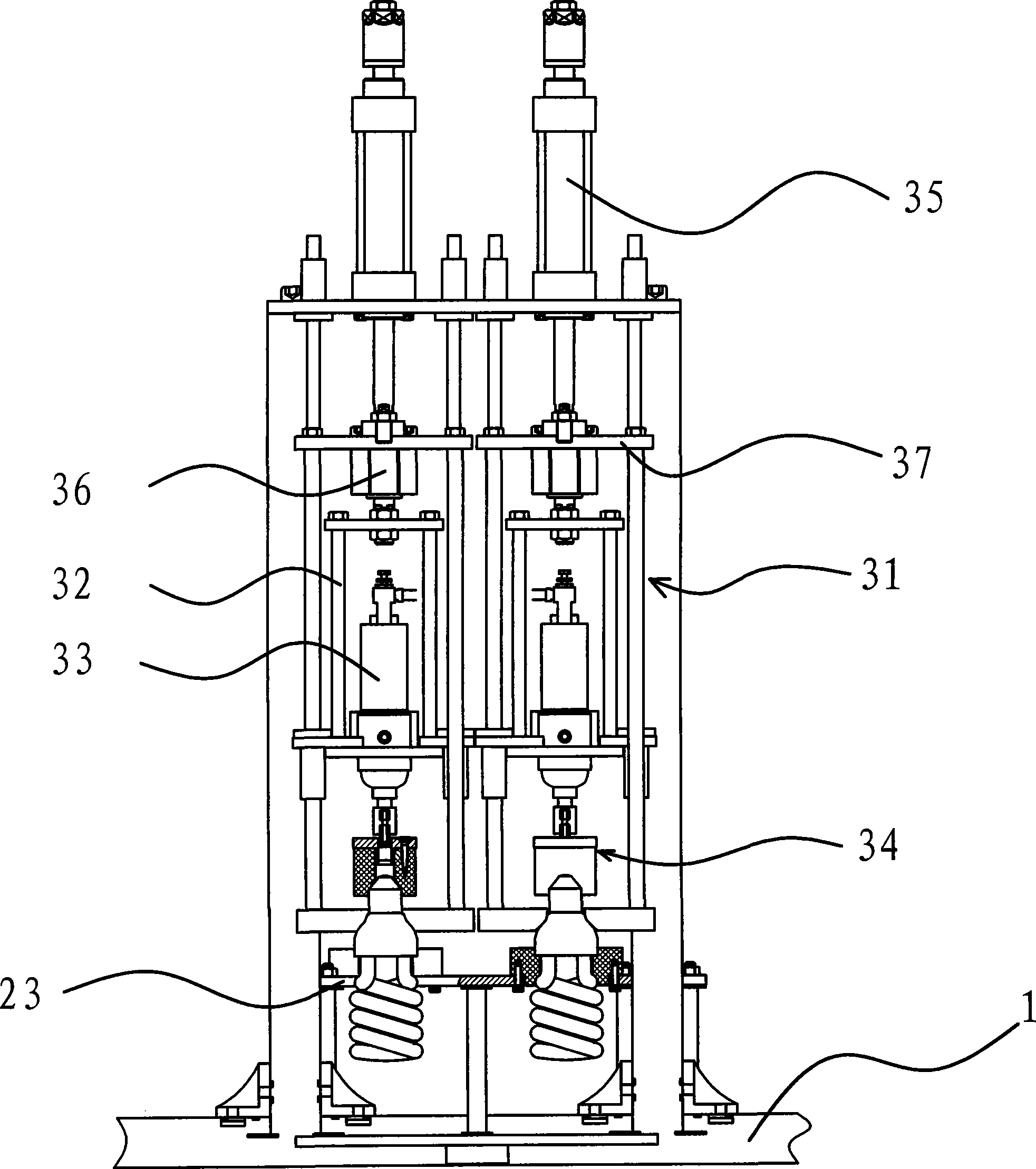

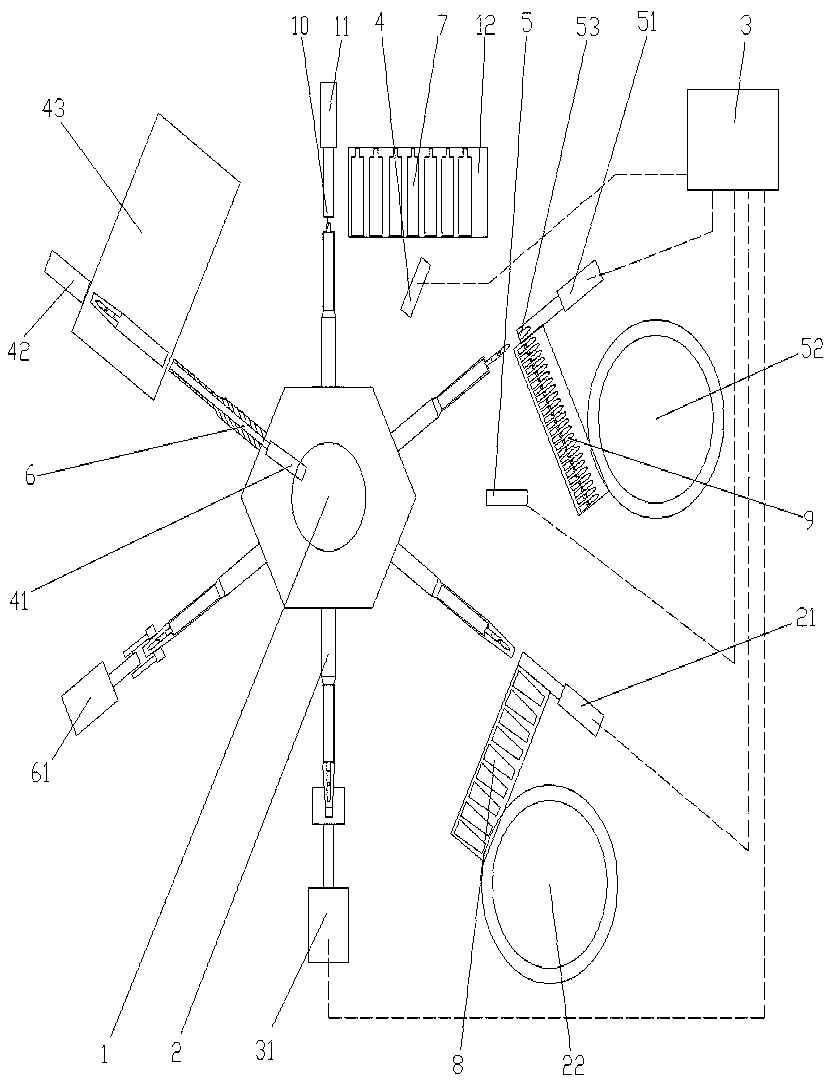

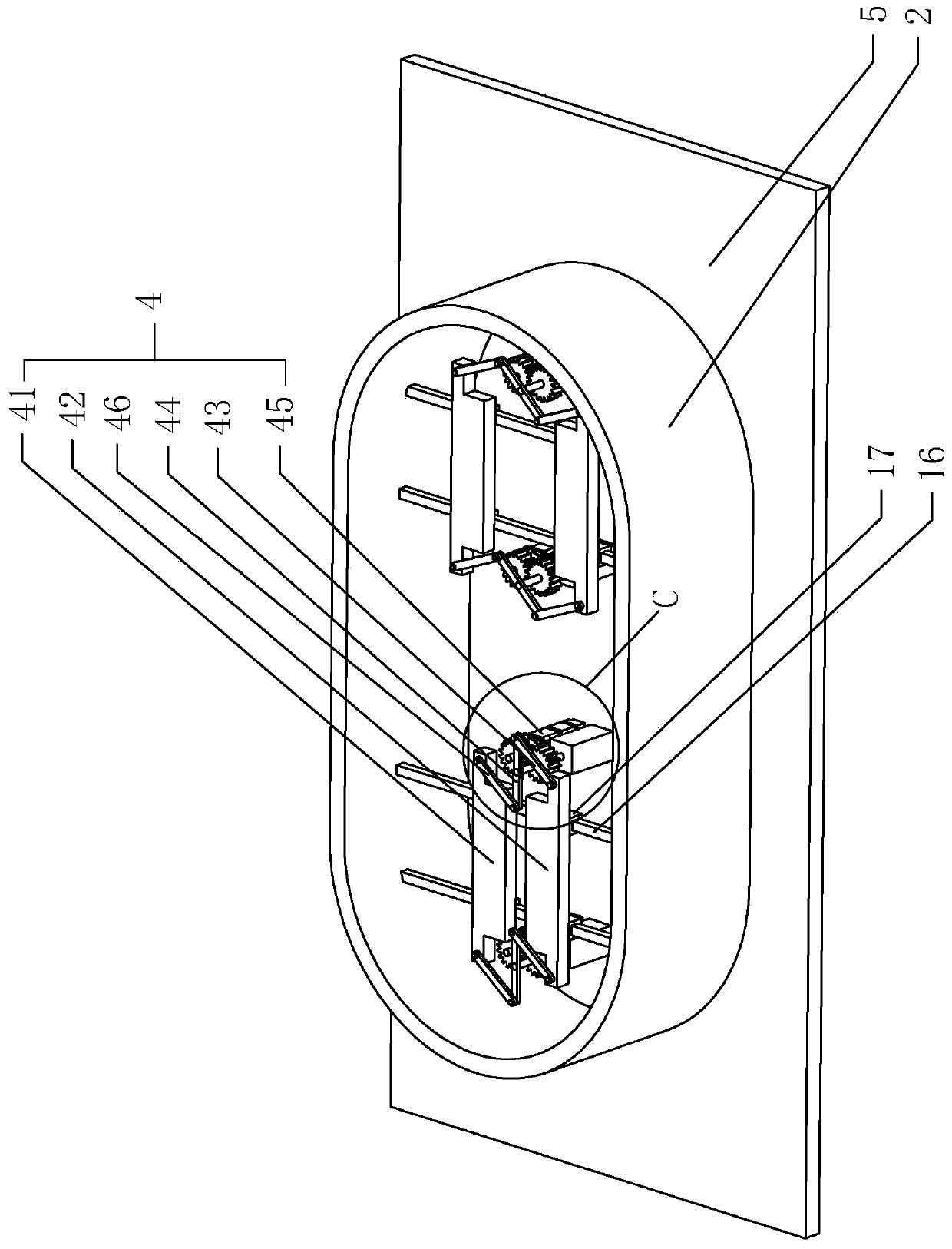

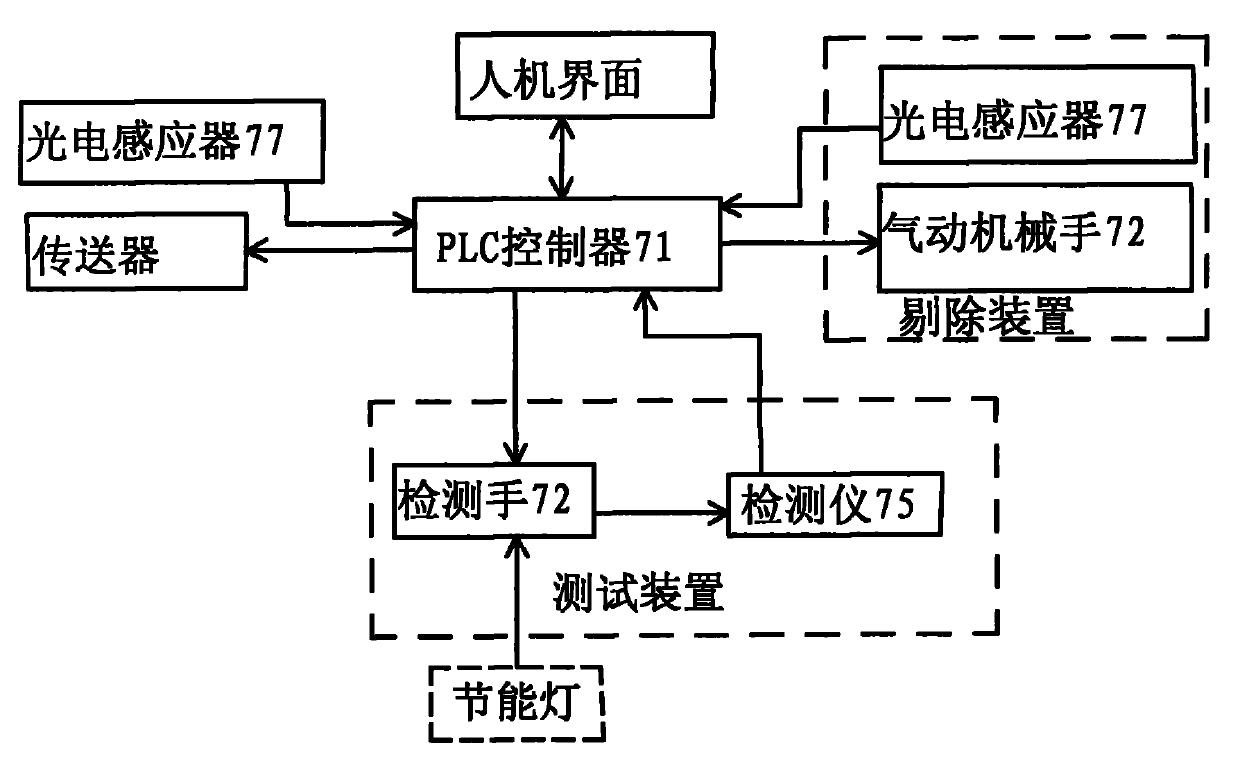

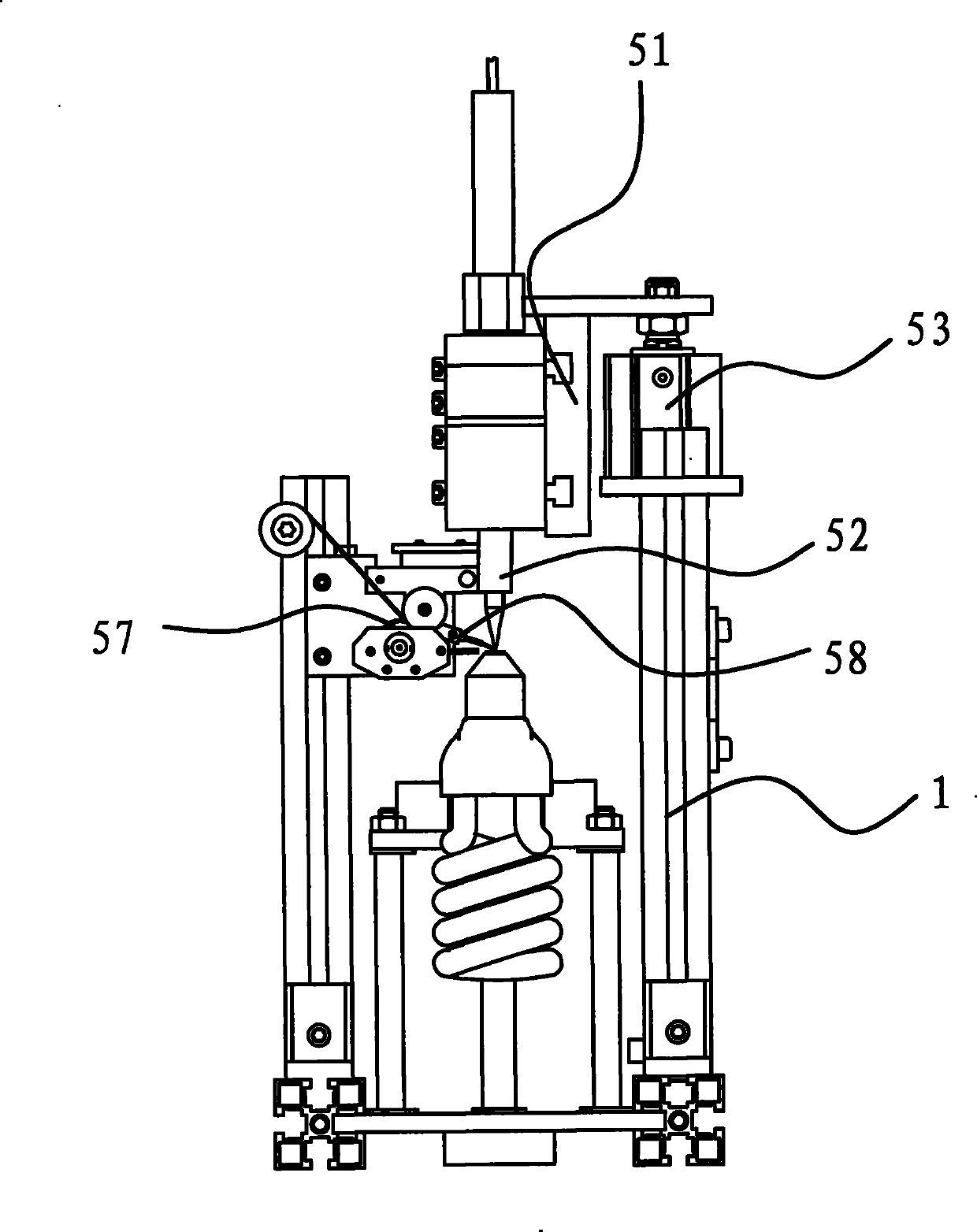

Energy-saving lamp automatic assembly line

InactiveCN101447382AReduce labor costsReduce manufacturing costSequential operation station machinesAutomatic transmissionControl system

The invention provides an energy-saving lamp automatic assembly line which belongs to the technical field of machine. The energy-saving lamp automatic assembly line solves the problem that the existing energy-saving lamp automatic assembly line adopts manual assembly and has low production efficiency. The energy-saving lamp automatic assembly line is provided with an energy-saving lamp assembly transmission system on a frame. The energy-saving lamp assembly transmission system comprises a middle transmission track and branch transmission tracks. Joint parts of one end of the middle transmission track with two branch transmission tracks are provided with distributing mechanisms which can distribute energy-saving lamps at the middle transmission track to two branch transmission tracks. Each branch transmission track is respectively provided with an automatic rotating energy-saving lamp cap device, an energy-saving lamp automatic filament-cutting device, an energy-saving lamp automatic tin soldering device, an energy-saving lamp automatic detecting and controlling system and an energy-saving lamp automatic nailing device. The energy-saving lamp automatic assembly line is equipped with two sets of assembly devices and realizes the advantages of automatic transmission and assembly, etc.

Owner:ZHEJIANG SHENDU OPTOELECTRONICS TECH

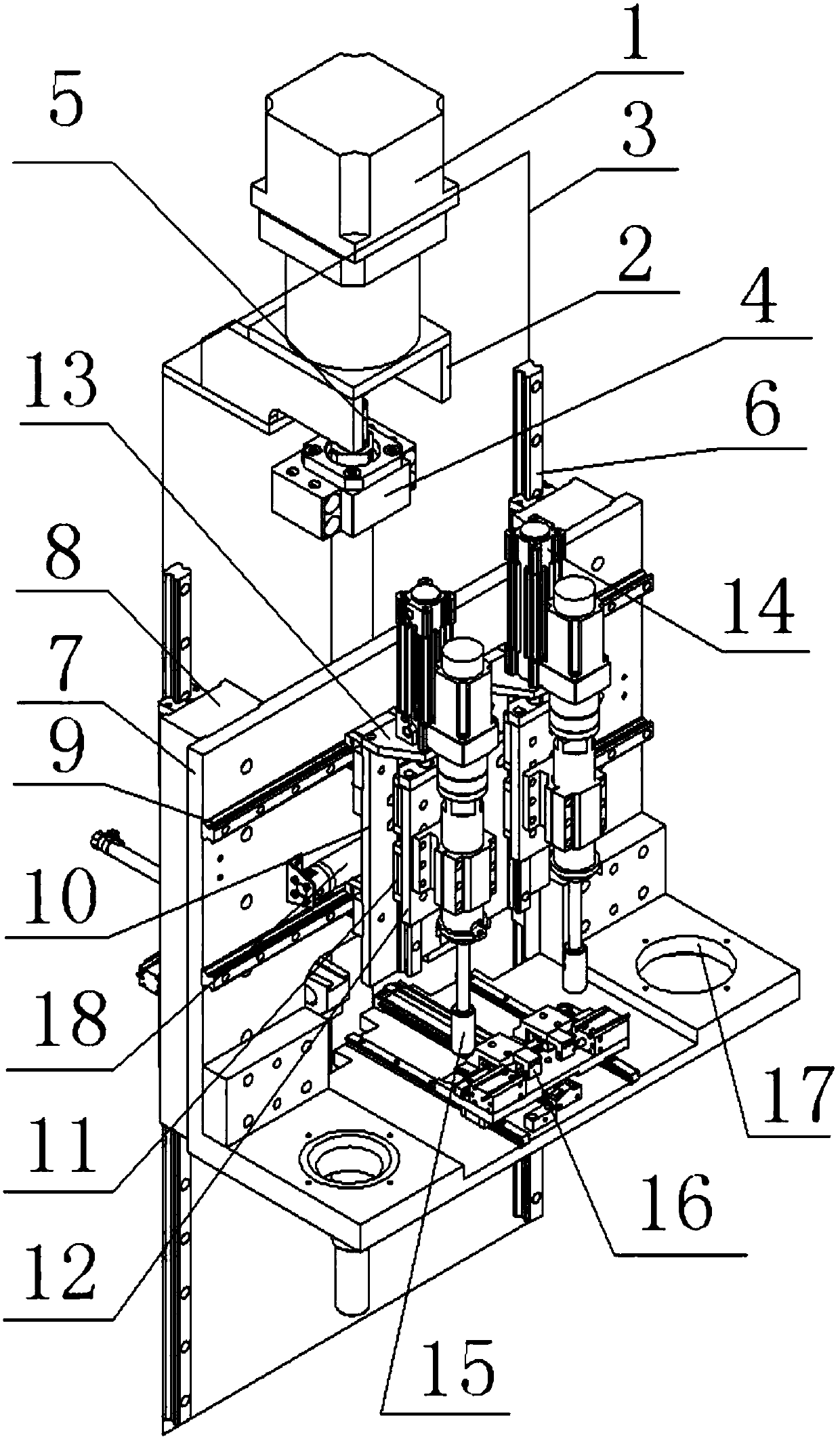

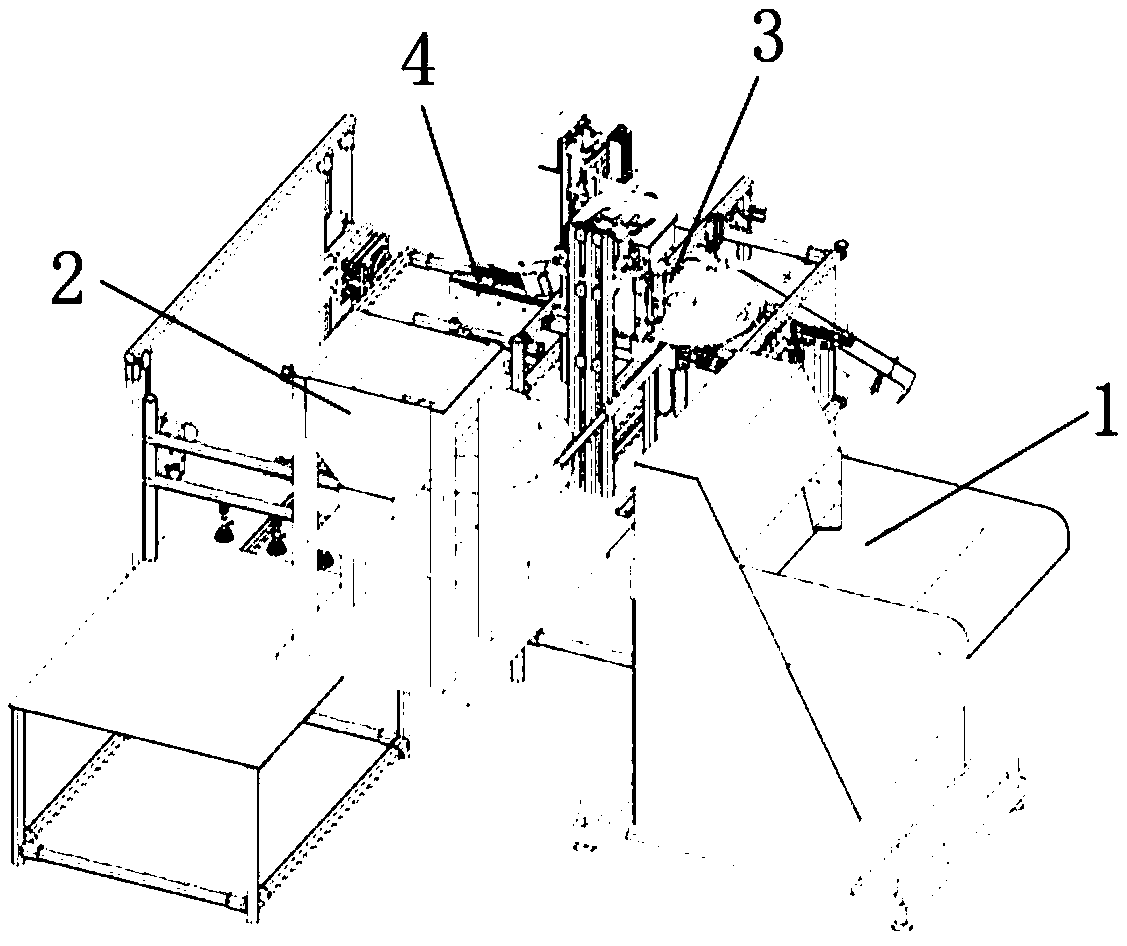

Full-automatic nut pre-loading machine

InactiveCN108015529AImprove efficiencyReduce labor costsMetal working apparatusTransverse planeMechanical engineering

The invention discloses a full-automatic nut pre-loading machine. A mounting back plate is in longitudinal sliding connection with a Z-axis lifting plate, the Z-axis lifting plate is of an L-shaped structure, a nut of a screw assembly is connected with a vertical plate of the Z-axis lifting plate, the vertical plate of the Z-axis lifting plate is in transverse sliding connection with two X-axis moving plates, a second air cylinder is arranged on the vertical plate of the Z-axis lifting plate, the second air cylinder is connected with the X-axis moving plates, the X-axis moving plates are in longitudinal sliding connection with tightening shaft mounting plates, the tops of the tightening shaft mounting plates are connected with first air cylinders, the first air cylinders are arranged on the tops of the X-axis moving plates, tightening nuts are vertically mounted on the tightening shaft mounting plates, a nut material way is arranged on a transverse plate of the Z-axis lifting plate andlocated below the tightening shafts, and workpiece fixing rings are arranged at the positions, on the two sides of the nut material way, of the transverse plate of the Z-axis lifting plate. Automaticscrewing of the nut can be achieved, time and labor are saved, efficiency is extremely high, manual cost is saved, tightening force is balanced, quality is ensured, and safety and reliability are achieved.

Owner:DALIAN RUIFENGDA MACHINERY MFG

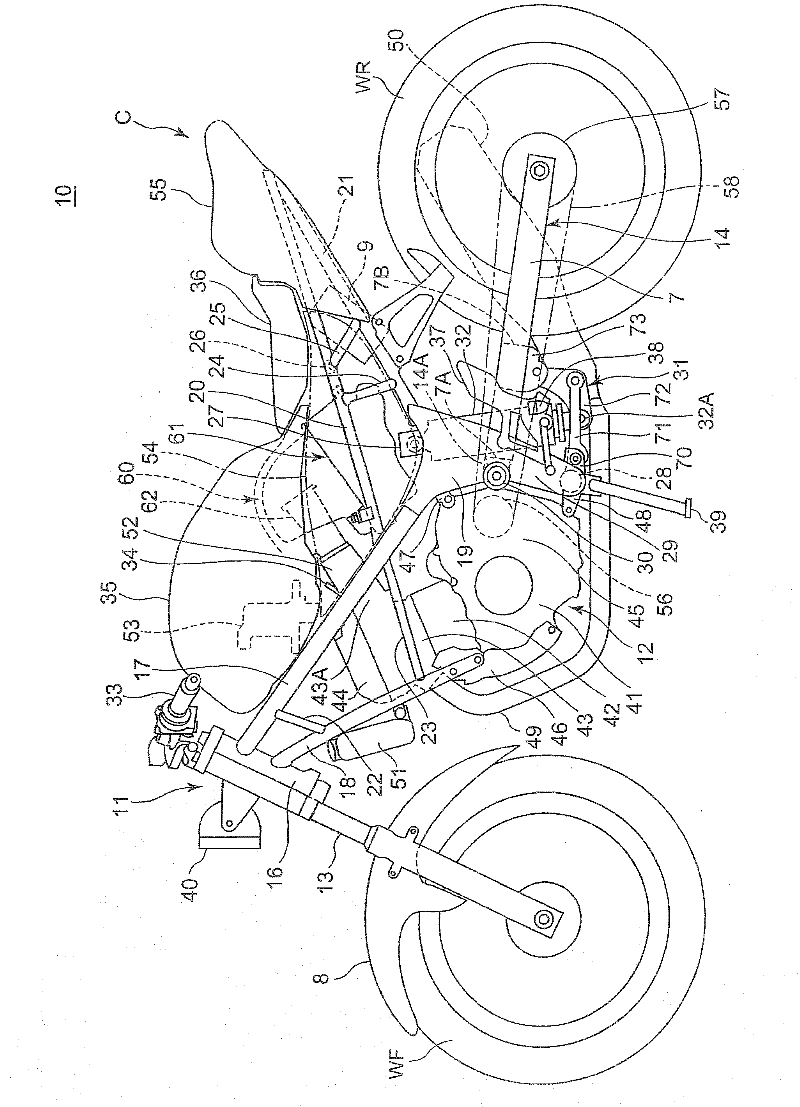

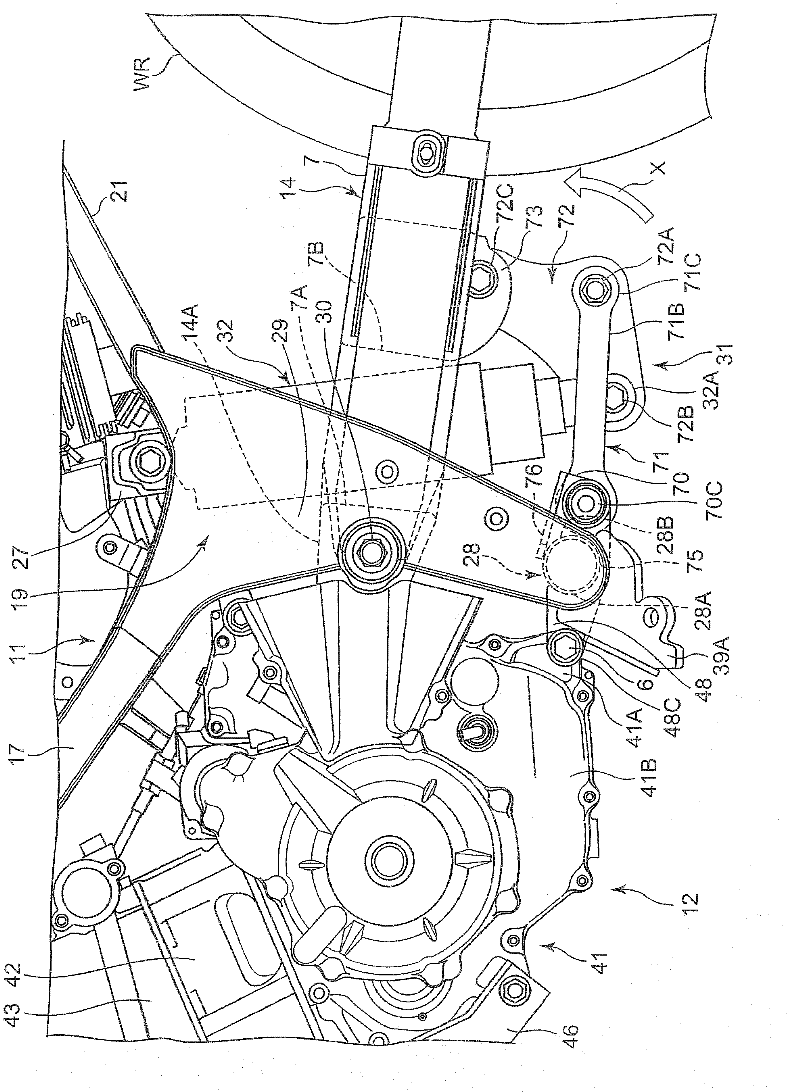

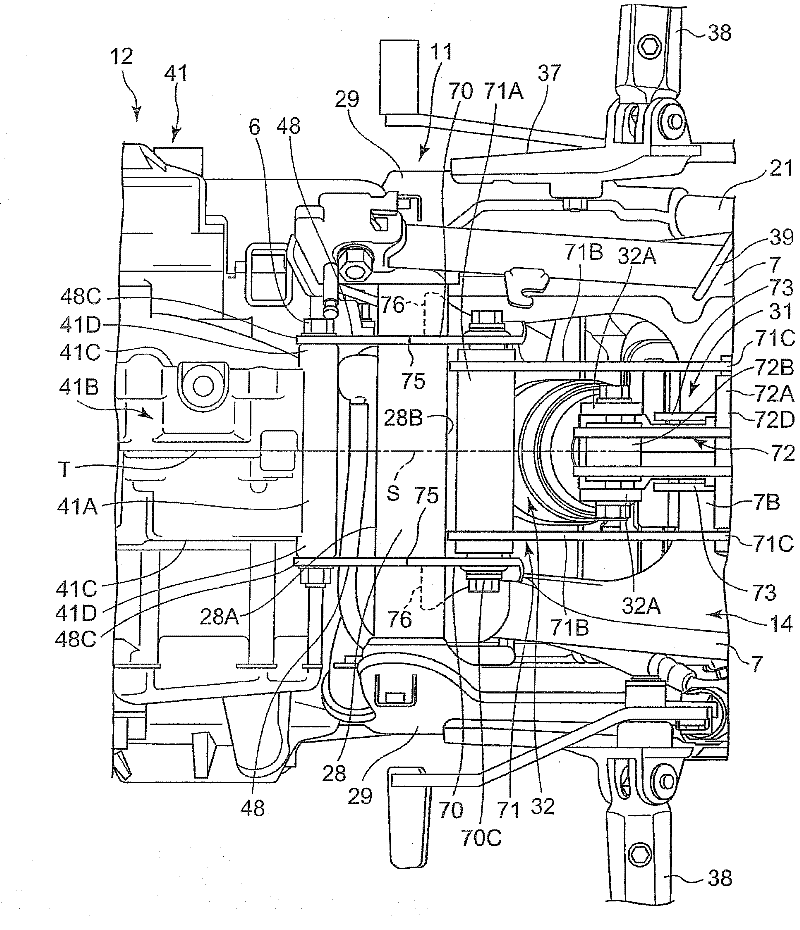

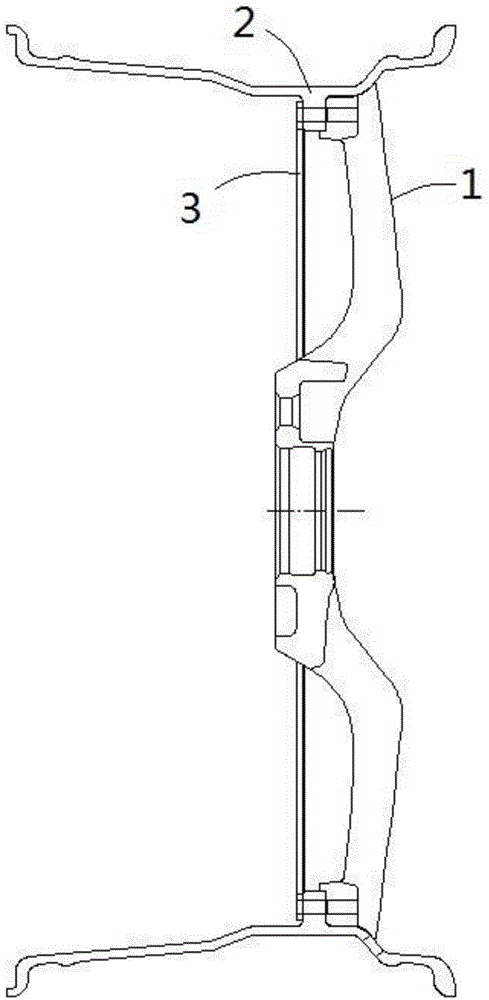

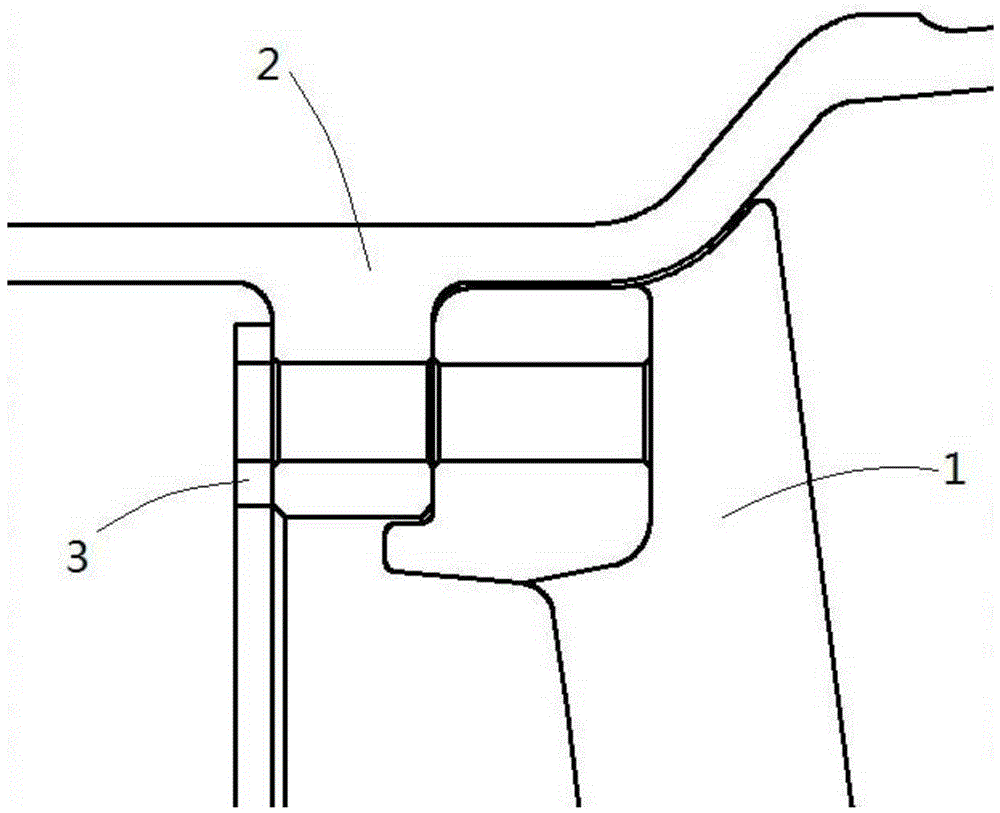

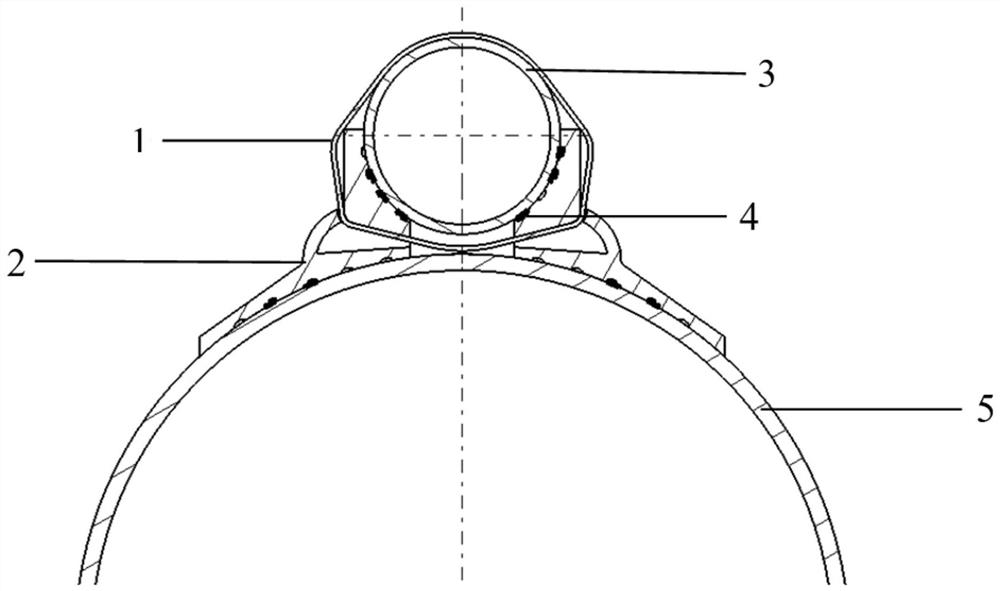

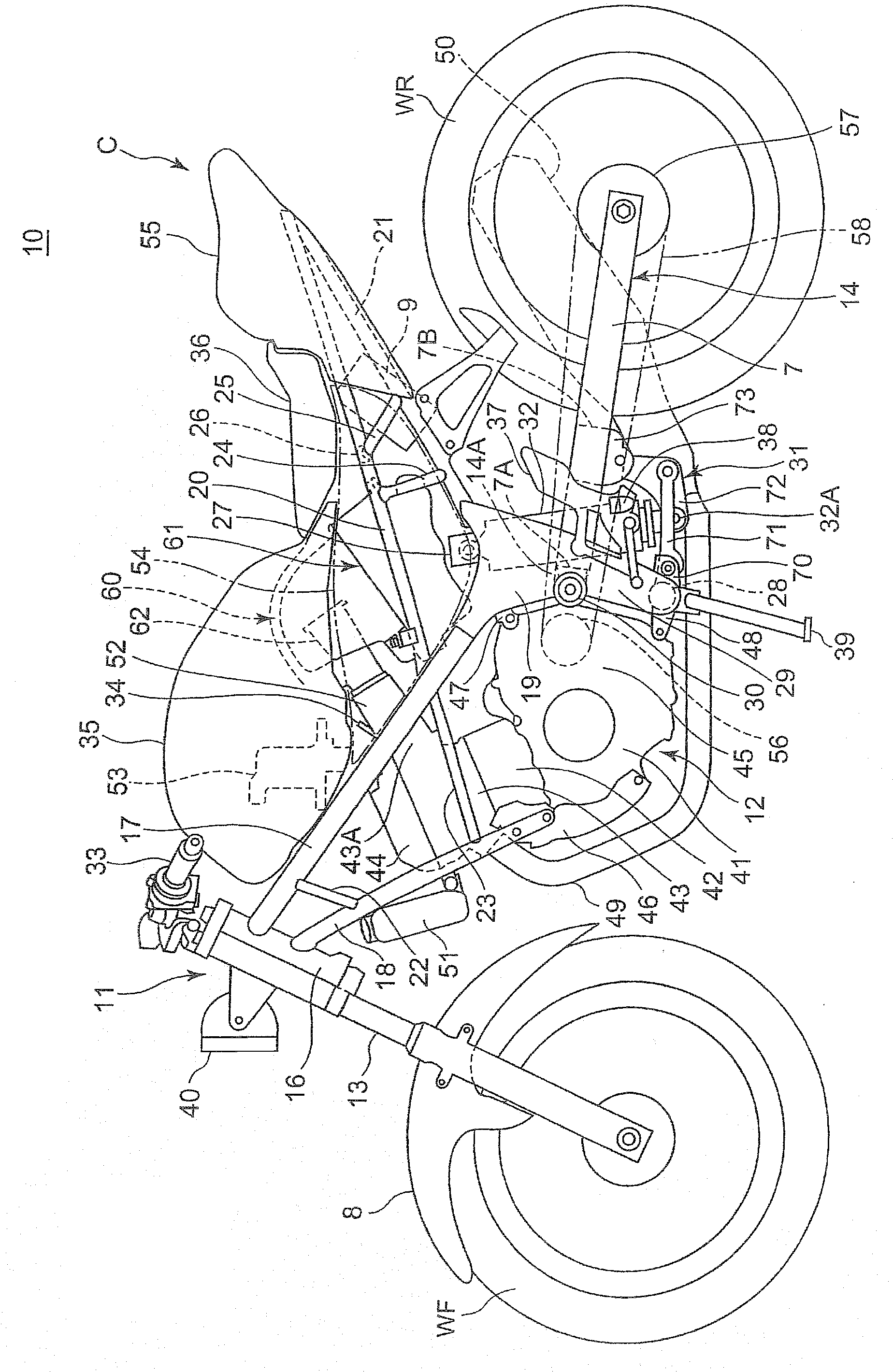

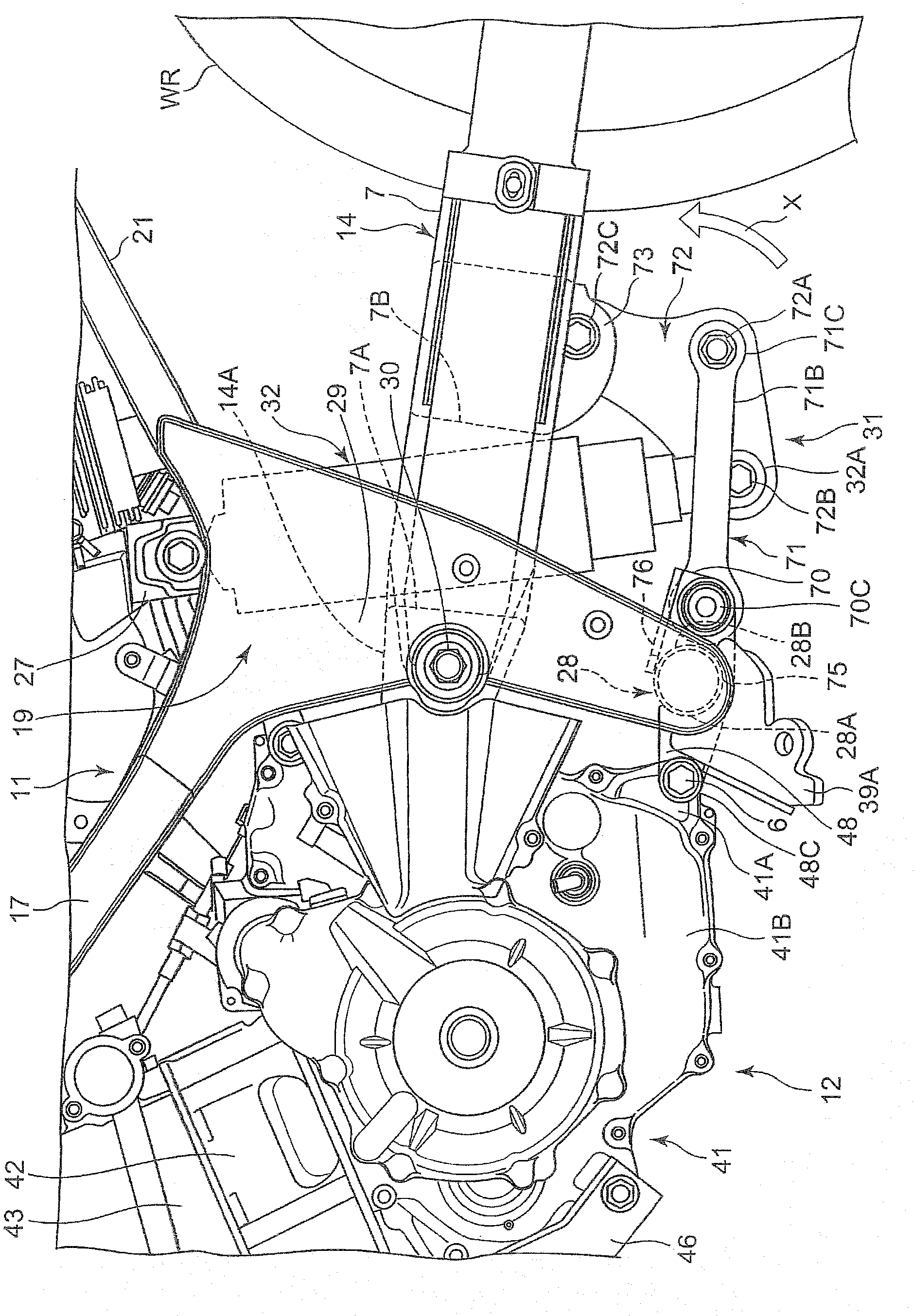

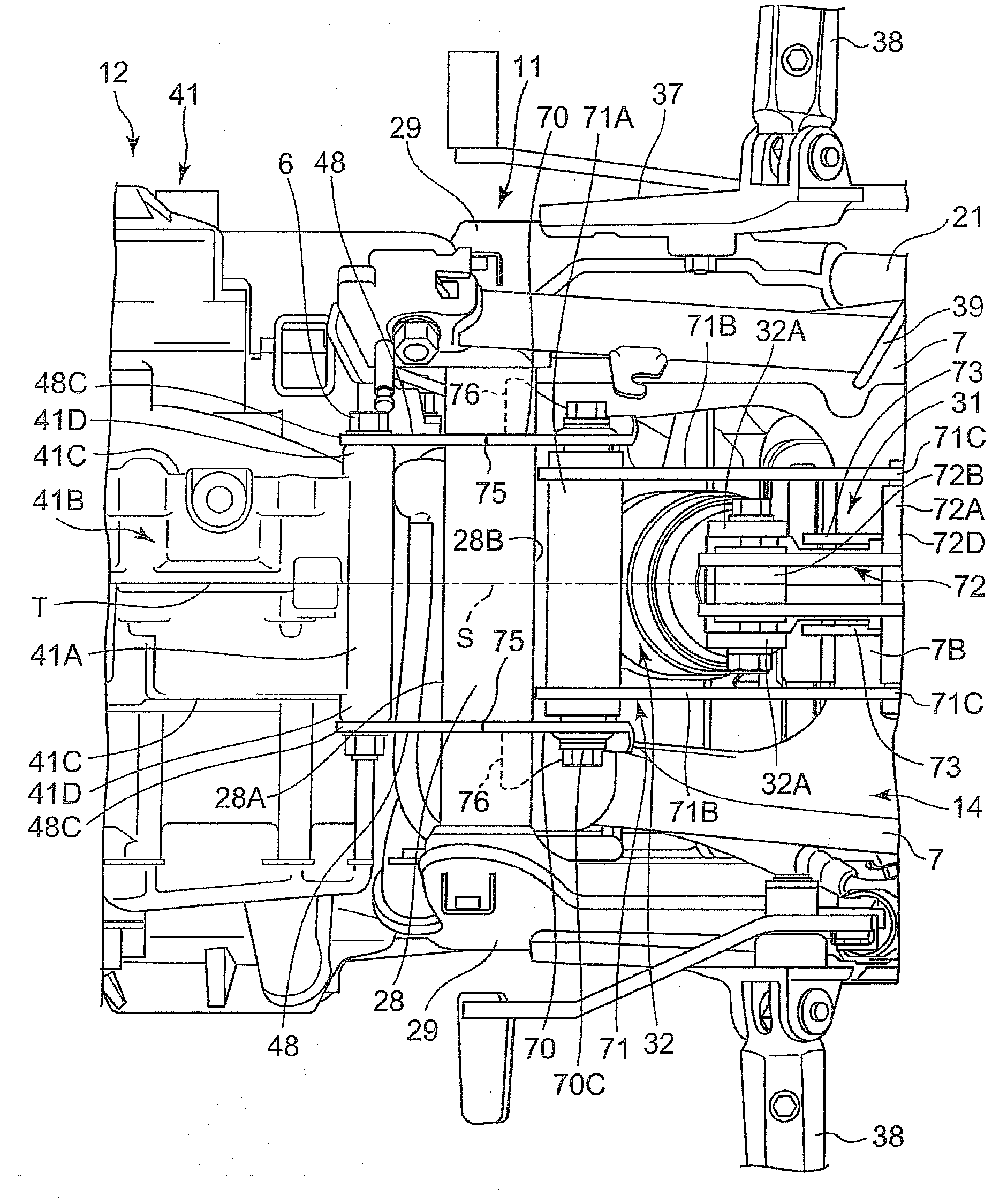

Saddled vehicle

ActiveCN102481967ANo need to increase intensityThe case of loads that prevent deformationAxle suspensionsMotorcyclesVehicle frameBody frame

A saddled vehicle having a cross-member which is reduced in weight by preventing a non-uniform load from acting on the cross-member. A saddled vehicle provided with: a vehicle body frame (11) for suspending an engine (12); a swing arm (14) for pivotably suspending a rear wheel (WR); a pair of left and right pivot sections (29) for forming a part of the vehicle body frame (11) and pivotably supporting the swing arm (14); a lower cross-member (28) for connecting the pivot sections (29); a rear cushion (32) for applying an elastic force to the swing arm (14); a link mechanism (31) to which the lower end (32A) of the rear cushion (32), the swing arm (14), and the pivot sections (29) are connected; link connection stays (70) which are formed behind the lower cross-member (28) and to which the link mechanism (31) is connected; and lower hangers (48) which are formed in front of the lower cross-member (28) and to which the engine (12) is affixed. The link connection stays (70) are formed at the same position in the widthwise direction of the vehicle, and so are the lower hangers (48).

Owner:HONDA MOTOR CO LTD

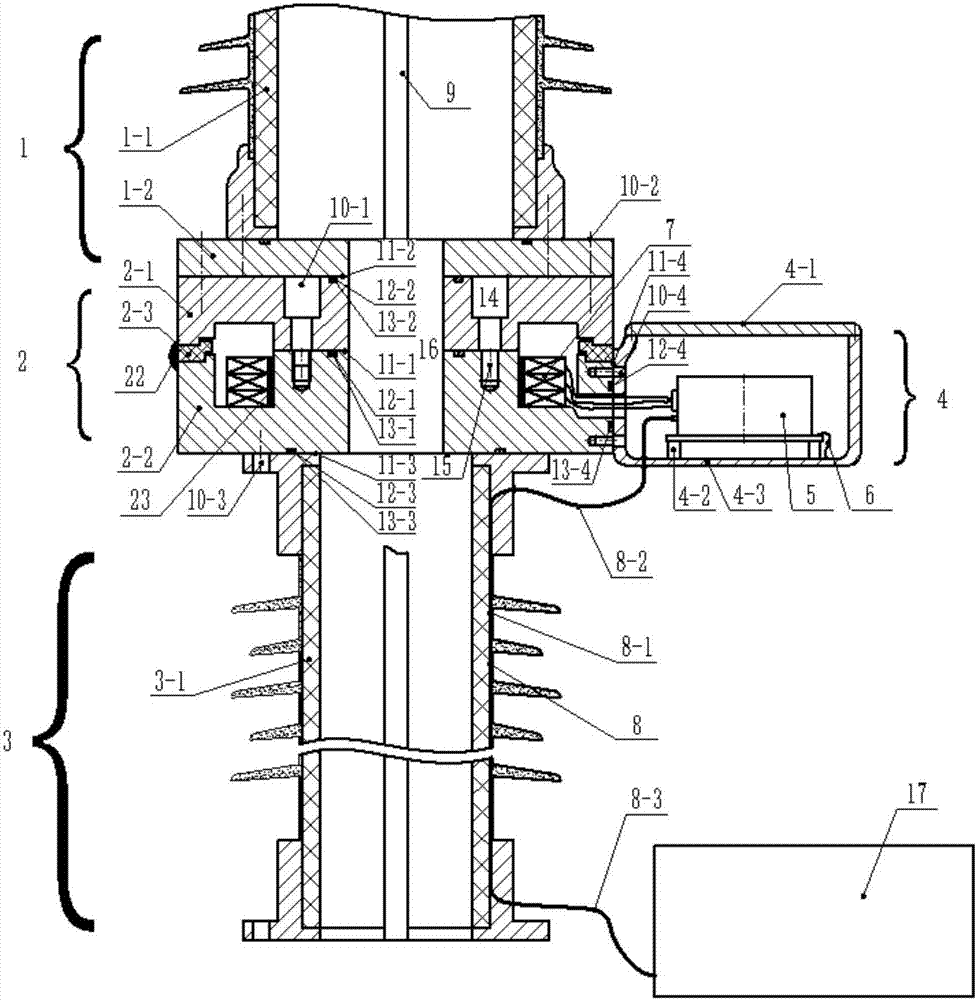

Power battery pack thermal management system air tightness detection tool and detection system

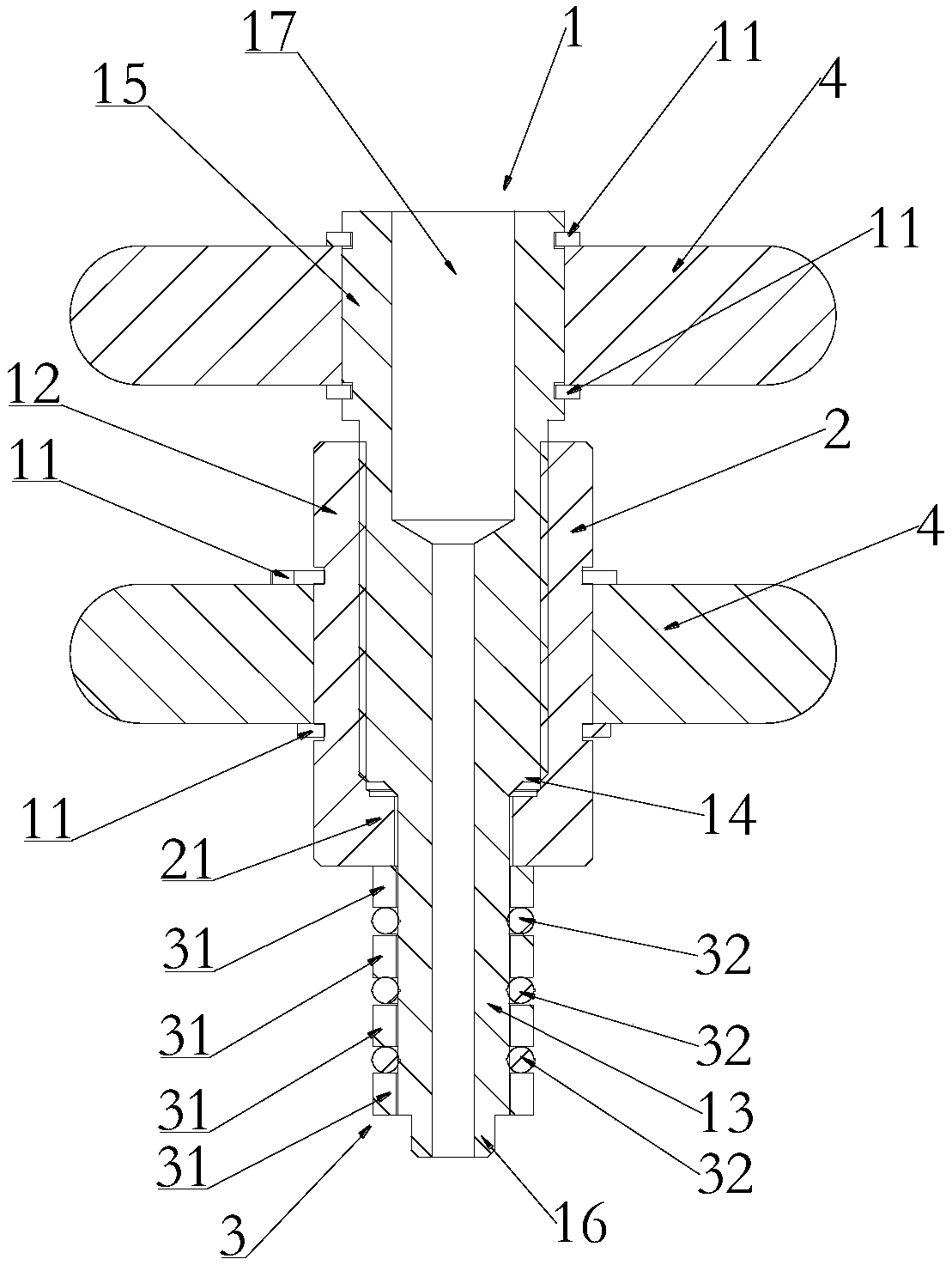

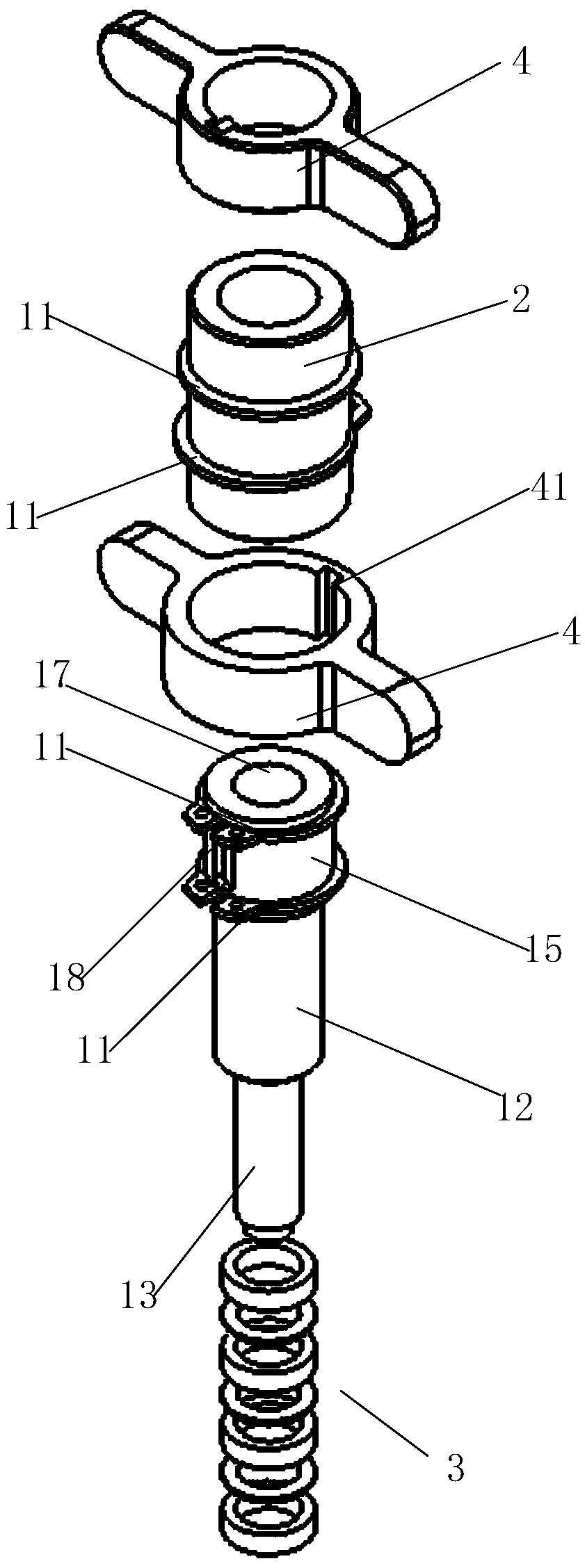

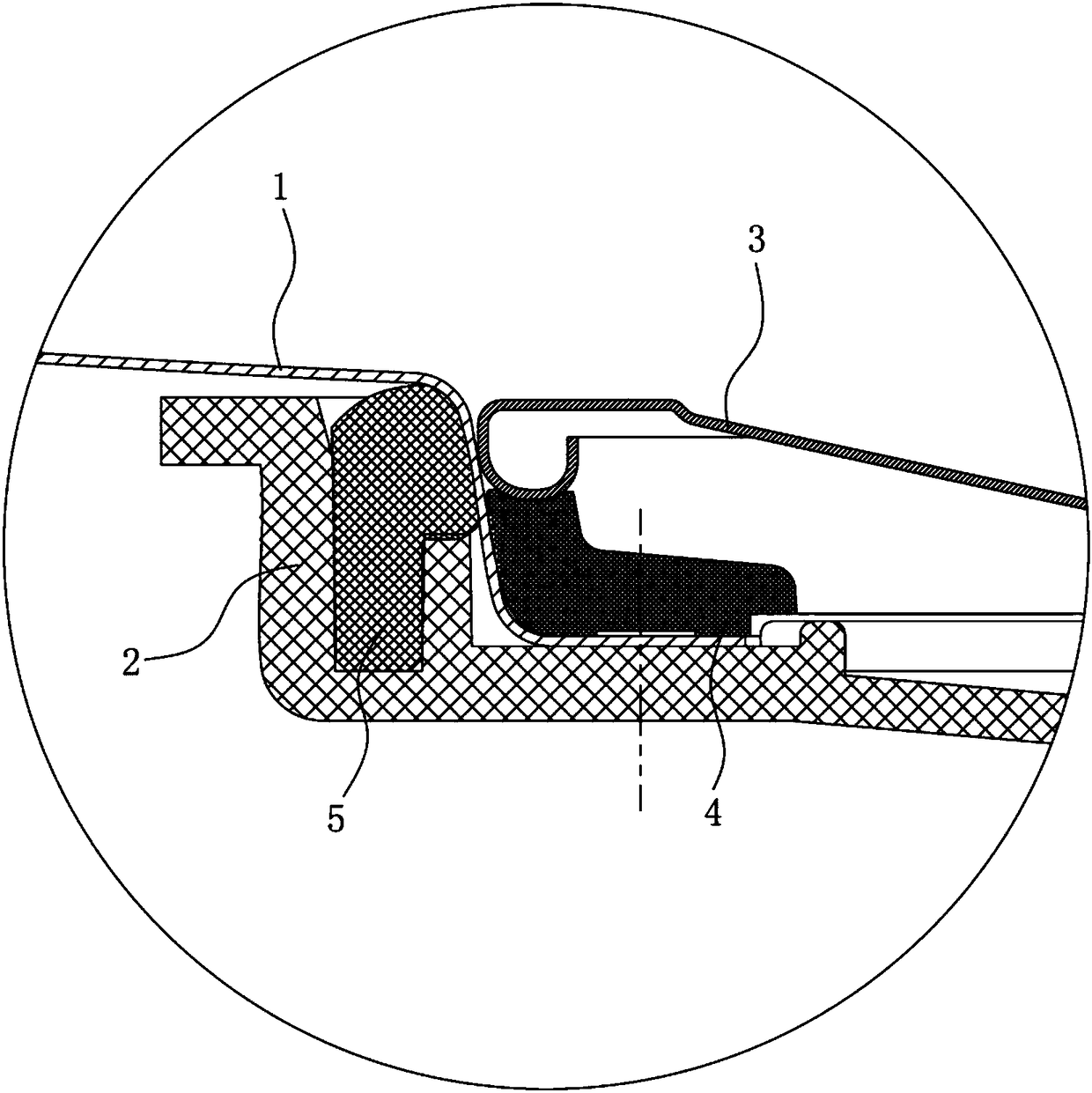

PendingCN109060255ASimple structureEasy to operateFluid-tightness measurement using fluid/vacuumPower batteryElectrical battery

The invention relates to a power battery pack thermal management system air tightness detection tool and detection system. The detection tool comprises a vent rod, a swelling rod and an elastic swelling part; and the elastic swelling part is arranged on the outer side wall of one end of the vent rod in a sleeving mode, the swelling rod is connected to the outer side wall of the middle of the ventrod in a threaded mode, and one end of the swelling rod is arranged to be close to the elastic swelling part. According to the air tightness detection tool, by arranging the elastic swelling part on the outer side wall of the vent rod, a connection piece can achieve seal connection with a power battery pack management system through the elastic swelling part when being connected to the power battery pack management system, and the detection tool is simple in structure and convenient to operate and maintain.

Owner:江苏和中普方新能源科技有限公司

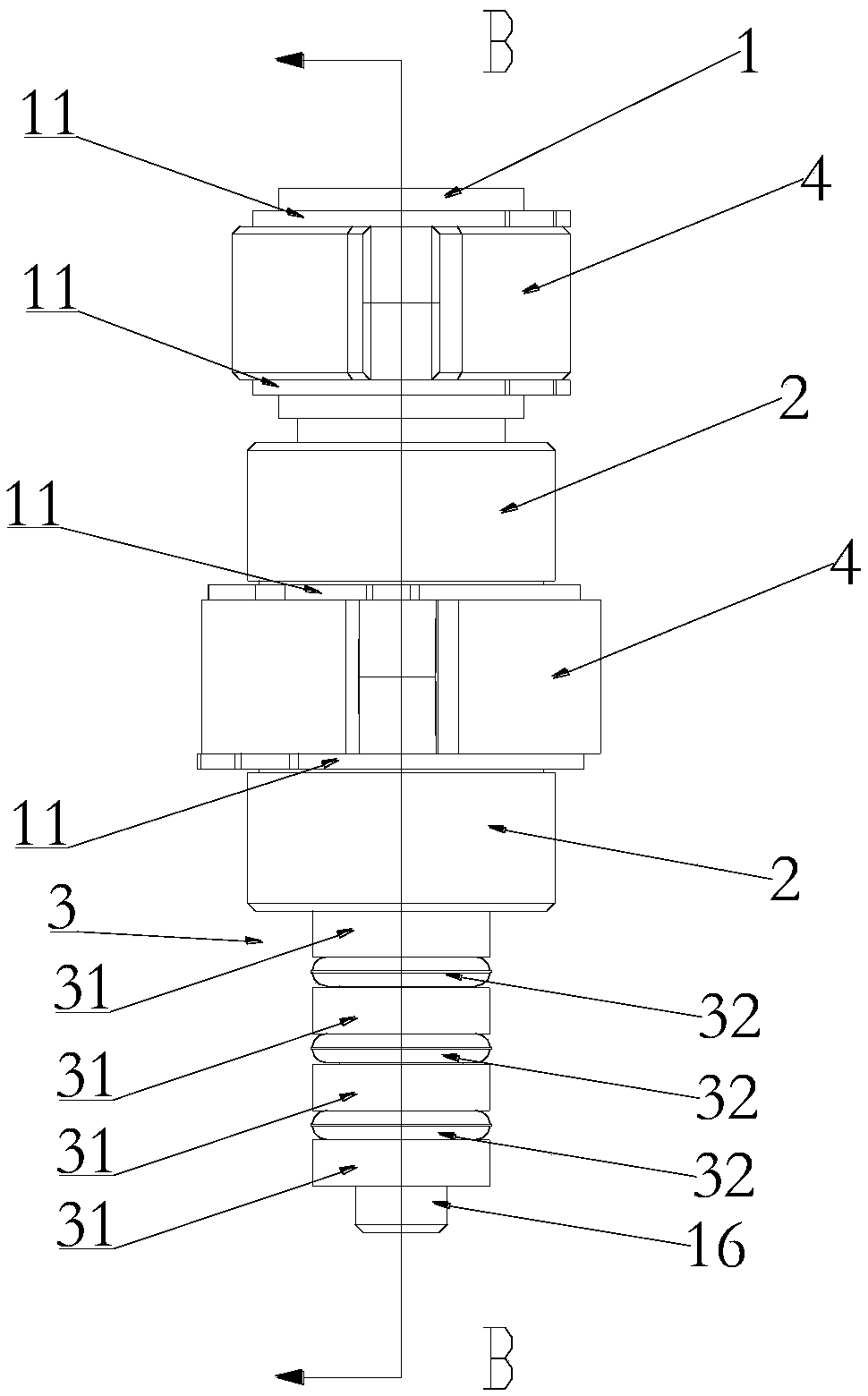

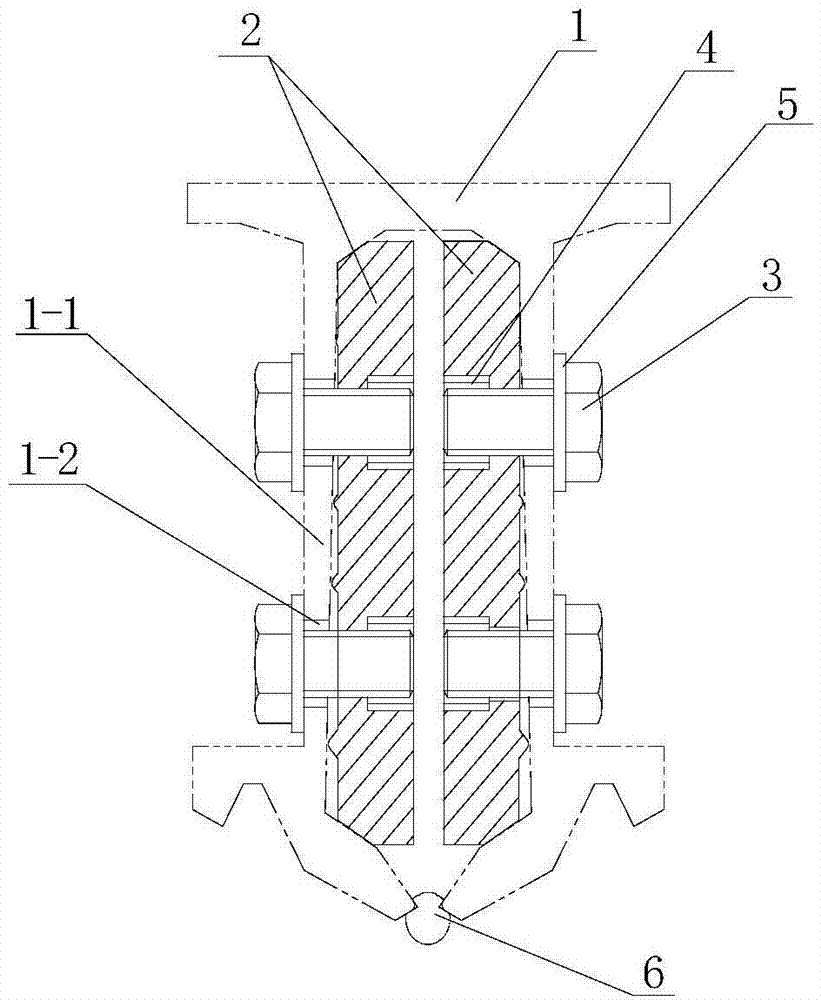

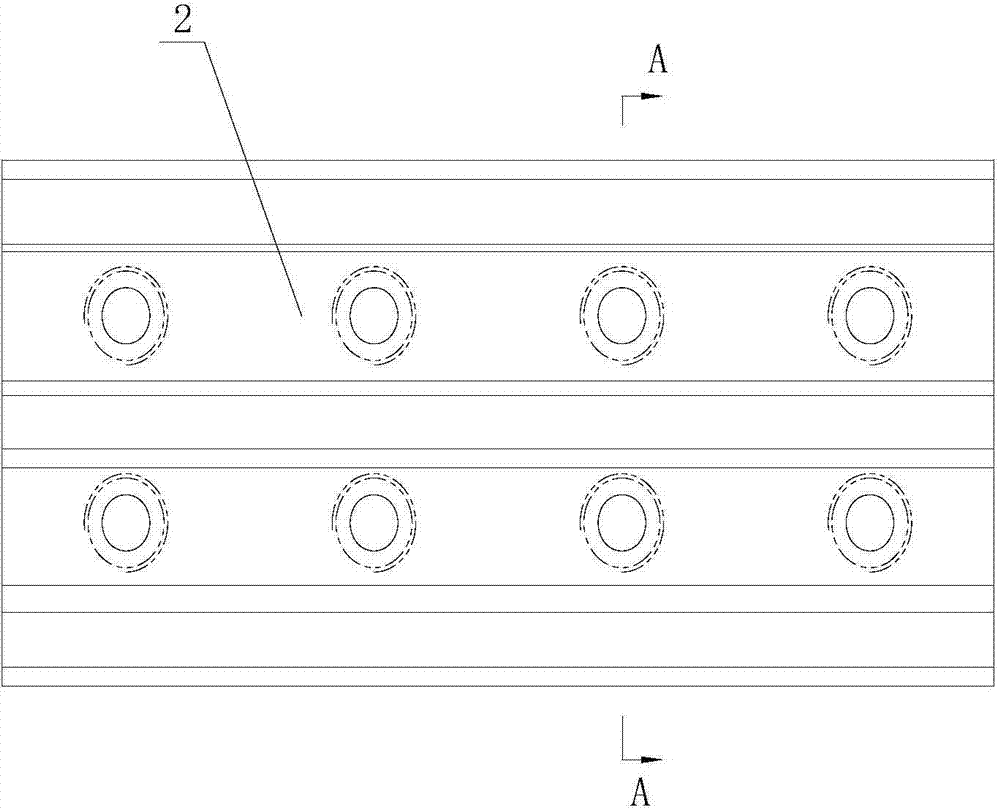

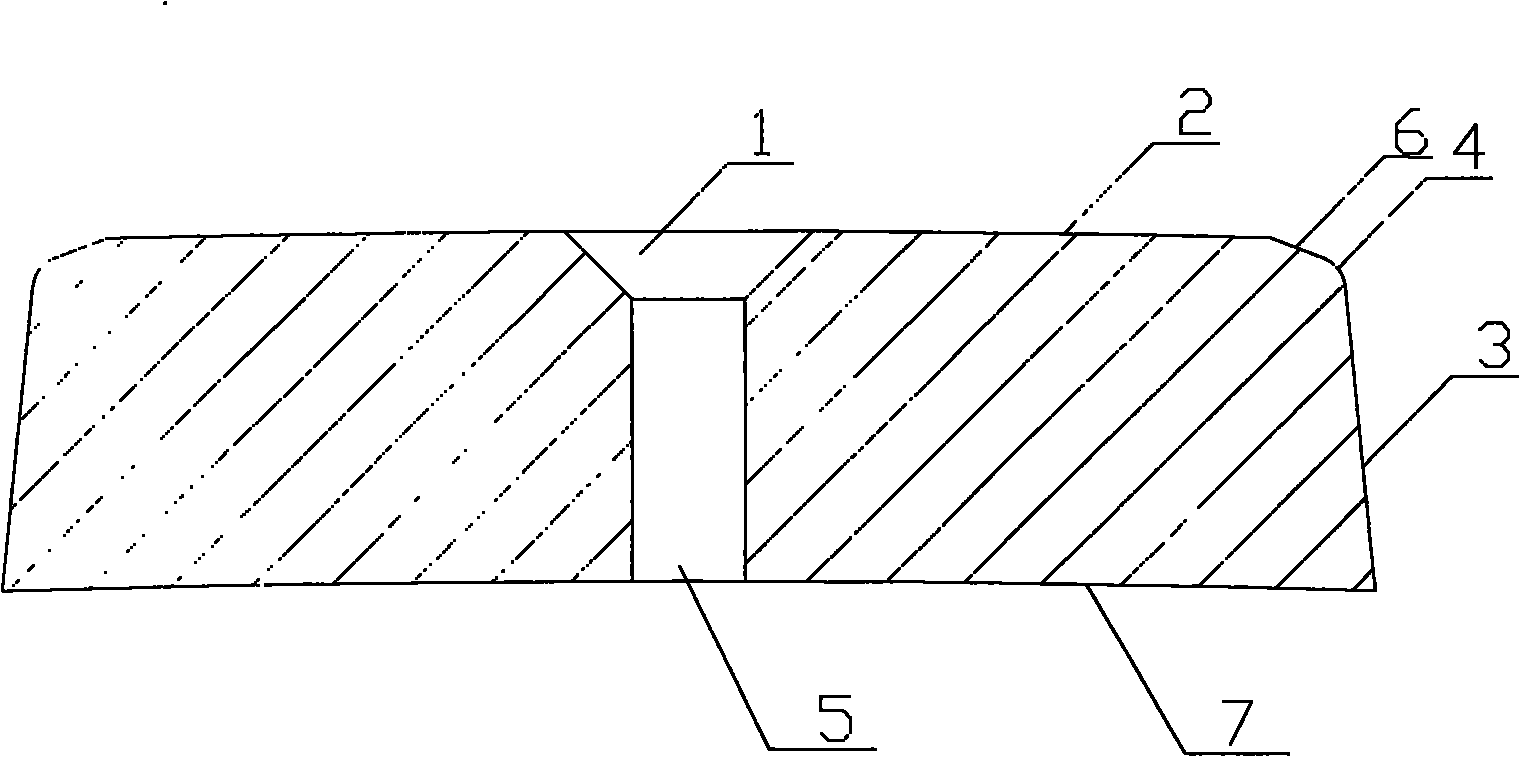

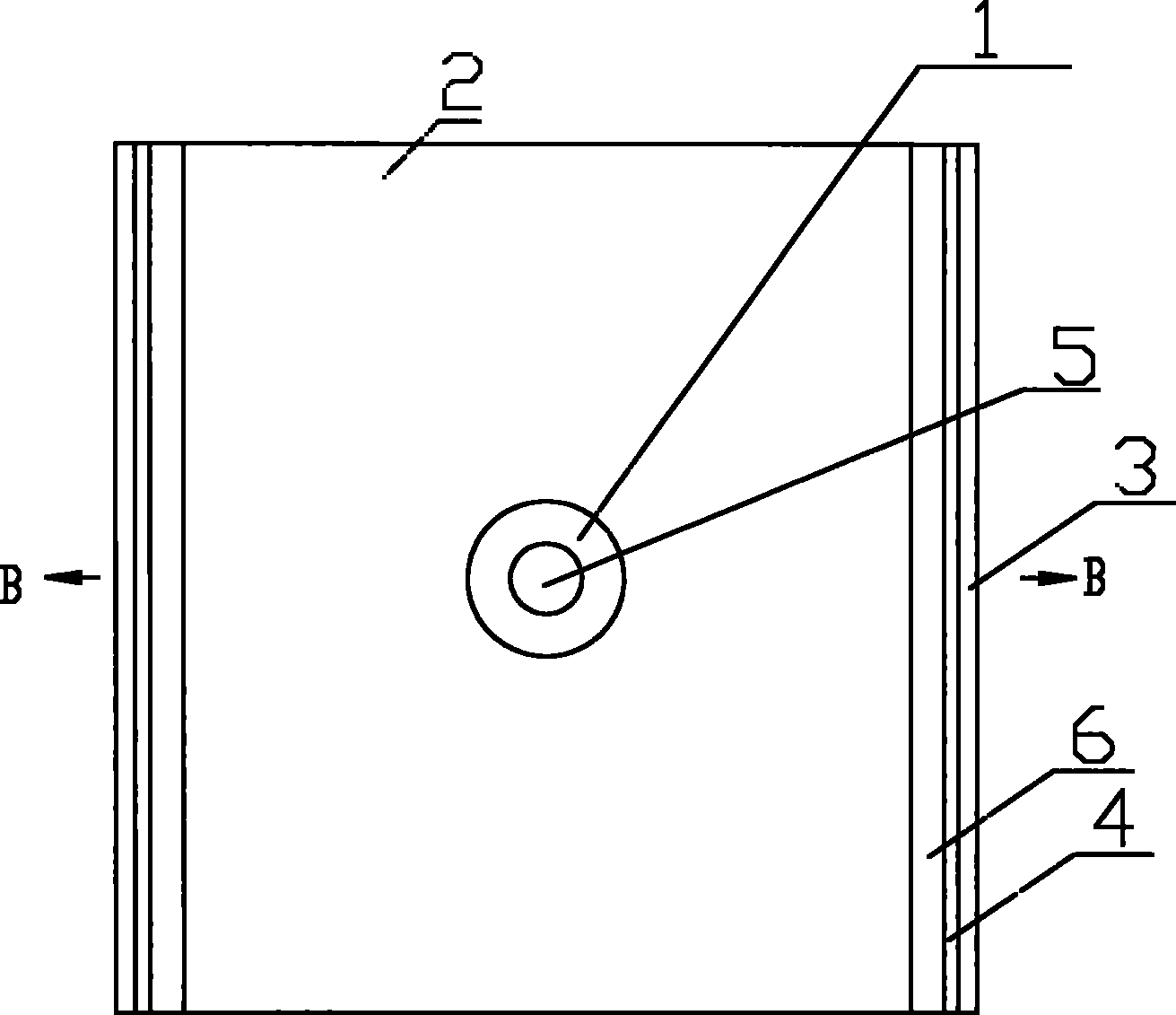

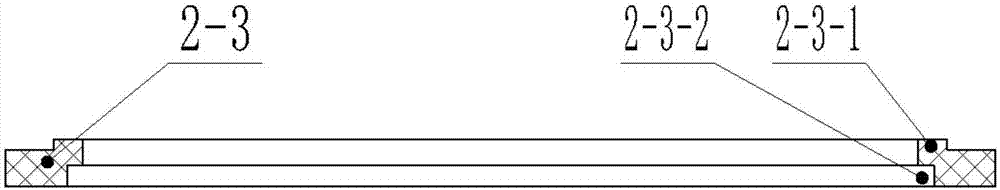

Improved split wheel

The invention provides a split wheel. The split wheel comprises a turntable part 1, a rim part 2 and a metal fastening ring 3, wherein the turntable part 1 is made of an aluminum alloy; the metal fastening ring 3 is made from 65Mn steel; the rim part 2 is made from a carbon fiber composite material; the rim part 2 and the metal fastening ring 3 are fixed to the turntable part 1 through a bolt or a rivet together. The technical scheme provided by the invention has the following advantages that the contact area of the place where the rivet or the nut and a composite material rim are connected is effectively increased by the metal fastening ring, fastening force is dispersed and is more uniform; under the action of the metal fastening ring, the pre-tightening torque can be increased. The problems that the tightening torque is reduced and the wheel fails are effectively solved.

Owner:CITIC DICASTAL

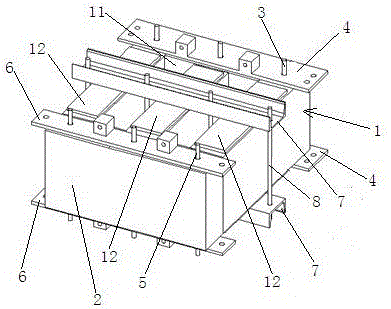

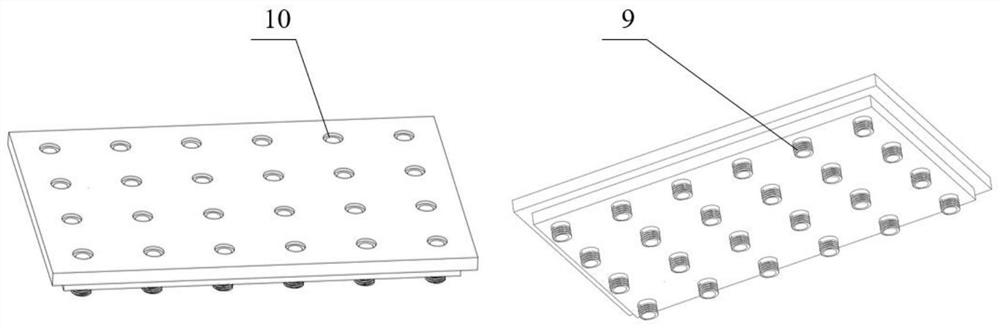

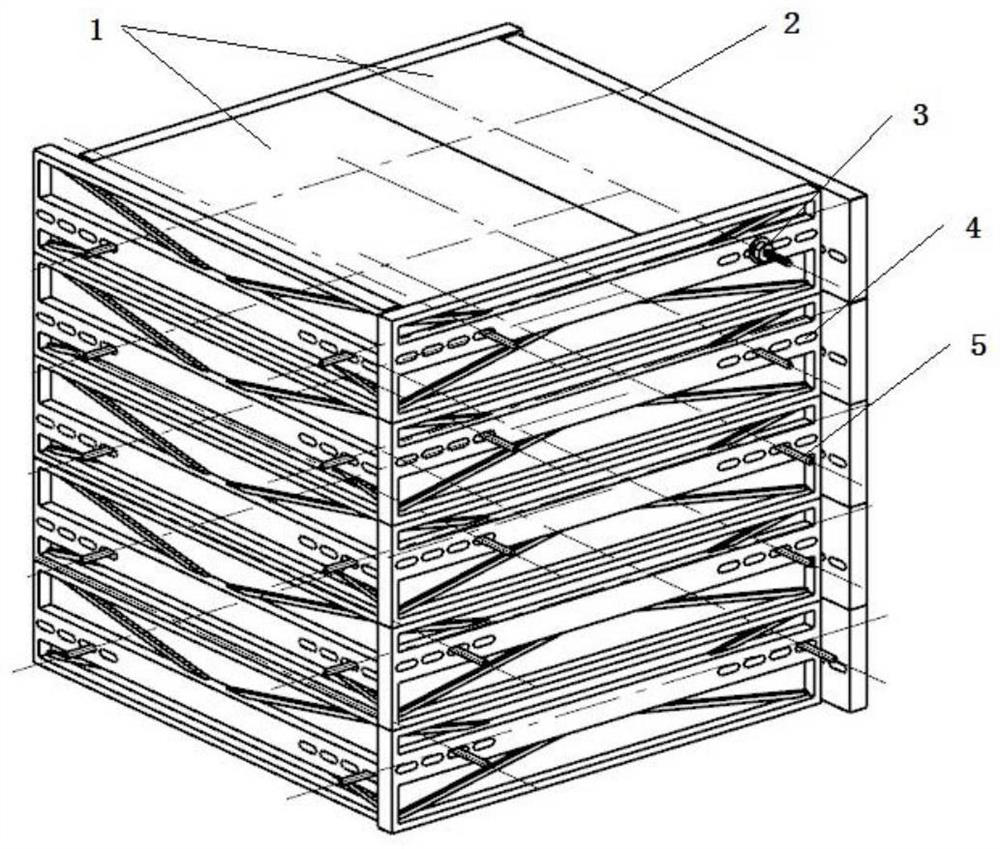

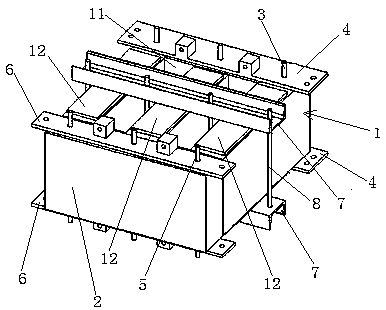

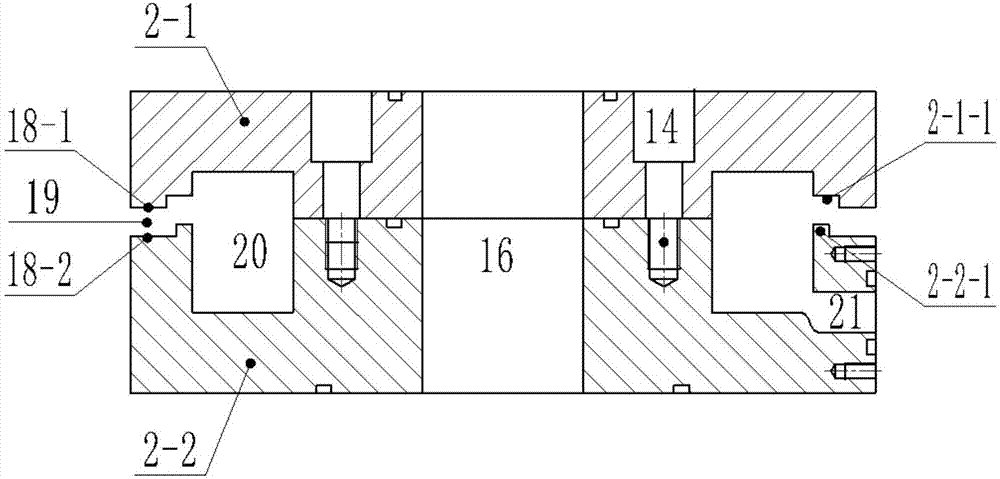

Laminated combination tooling for transformer

ActiveCN106024369AUniform tightening forceEasy to operateTransformers/inductances detailsInductances/transformers/magnets manufactureTransformerEngineering

The invention discloses a laminated combination tooling for a transformer. The laminated combination tooling comprises a group of mountain-shaped stacks and a group of upper iron yoke stacks; the mountain-shaped stacks are provided with a lower iron yoke part and three stem parts; the upper iron yoke stacks are arranged on the three stem parts of the mountain-shaped stacks; the upper iron yoke stacks and the mountain-shaped stacks form closed structures; first positioning steel poles are arranged in the lower iron yoke parts of the mountain-shaped stacks in a penetrating manner; first positioning sheets are respectively arranged at the front side and the rear side of the lower iron yoke part; the end parts of the first positioning steel poles penetrate through the first positioning sheets; second positioning steel poles are arranged in the upper iron yoke stacks in a penetrating manner; second positioning sheets are respectively arranged at the front and rear sides of the upper iron yoke stacks; the end parts of the second positioning steel poles penetrate through the second positioning sheets; one clamping channel steel crossing over the three stem parts is arranged on each of the front and rear sides of the mountain-shaped stacks; the two clamping channel steels are connected by screws. The laminated combination tooling disclosed by the invention has the advantages of higher convenience in operation, time saving, labor saving, cost saving and high production efficiency; in addition, the formed laminated structure meets the requirements and no joints are generated.

Owner:SUZHOU WUBIAN ELECTRICAL TECH CO LTD

Bus-bar middle joint for rigid suspension catenary

The invention relates to the technical field of a high-speed electric railway catenary, in particular to a bus-bar middle joint for a rigid suspension catenary, and solves the problem that looseness can be easily generated among the existing catenary bus-bars under the frequent impact condition. The bus-bar middle joint has the scheme that the middle joint is provided with a pair of threaded clamp plates and screw bolts, the clamp plates are respectively arranged in clamp walls at two sides of the bus-bars and are internally connected with two bus-bars, the screw bolts pass through holes formed in the bus-bars and are used for fixing the two ends of the threaded clamp plates with the two bus-bars, an installing hole formed in each threaded clamp plate is provided with a contractive unthreaded hole section positioned at the opening part and a threaded section positioned at the bottom, the middle joint is also provided with an annular steel threaded sleeve provided with screw threads at inside and outside, the external screw threads of the threaded sleeve are suitable for the threaded section of the corresponding threaded clamp plate to be screwed in, the internal screw threads of the threaded sleeve are suitable for the screw bolts to be screwed in, the inner diameter of the contractive unthreaded hole section arranged on the each threaded clamp plate is greater than that the screw diameter of each screw bolt, and the middle joint is also provided with flat pads which sheath the screw bolts and are positioned outside the bus-bar holes.

Owner:中铁建电气化局集团轨道交通器材有限公司

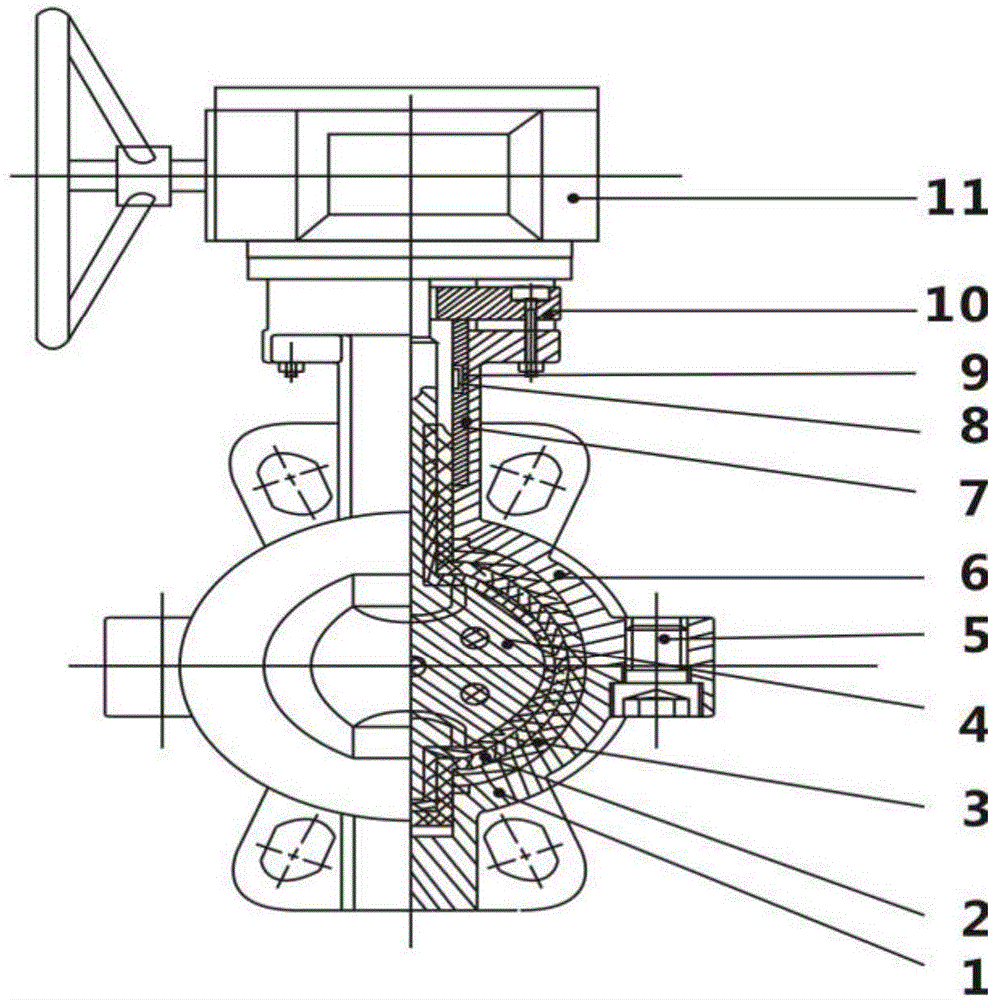

Fluorine butterfly valve

The invention provides a fluorine butterfly valve. The fluorine butterfly valve comprises a lower valve body, a valve seat, a butterfly plate, bolts, an upper valve body, a gland, a valve body positioning tooth, a gland positioning groove, a pressing plate and a driving device, wherein the lower valve body and the upper valve body are fixed and tightened into a whole through the bolts; the valve seat is arranged on the inner chamber wall of the valve body; the gland is arranged at the upper part of the upper valve body; the gland positioning groove and the valve body positioning tooth are formed in the gland; the pressing plate is arranged at the upper end of the gland; the driving device is arranged at the upper end of the pressing plate. The fluorine butterfly valve is convenient to mount, excellent in sealing performance and high in acid, alkali and corrosion resistance, the valve body guarantees firm and accurate positioning of the valve seat, the valve seat and the gland are fixed on the valve body through the bolts, uniform fastening of the valve seat is guaranteed, the gland positioning groove improves the sealing performance of the valve body and a medium is effectively prevented from leakage.

Owner:天津市精沃阀门科技有限公司

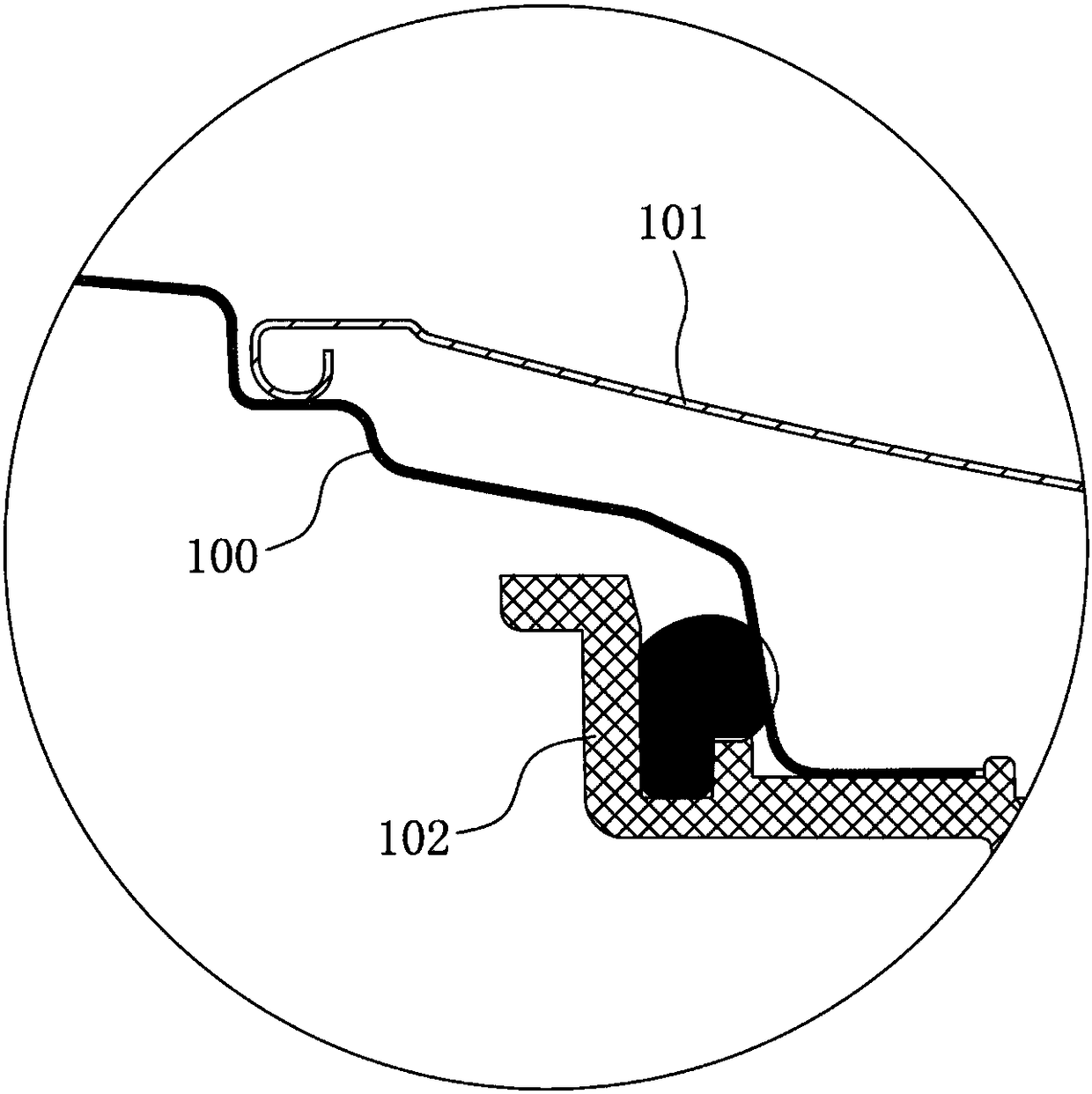

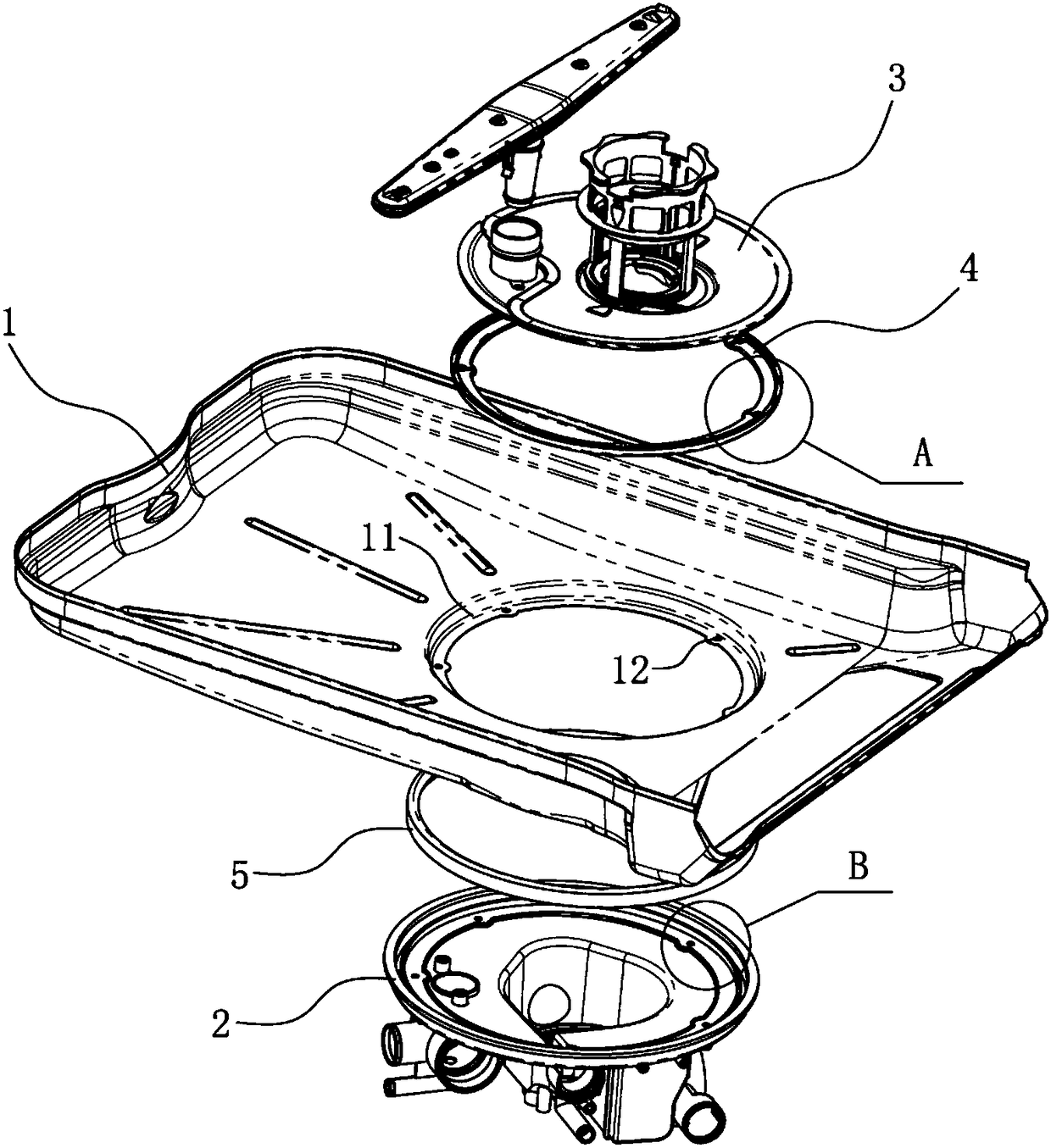

Dish-washing machine

InactiveCN108652558ASmall footprintImprove space utilizationTableware washing/rinsing machine detailsManufacturing cost reductionWater leakage

The invention belongs to the field of dish-washing machines, and discloses a dish-washing machine. The dish-washing machine comprises a liner and a water channel. The connecting part of the liner andthe water channel is sunken downwards in a cylindrical shape. A planar filtering net is placed in the sunken part of the liner. A supporting piece is annularly arranged between the planar filtering net and the bottom face of the sunken part and used for supporting the planar filtering net. According to dish-washing machine, the connecting part of the liner and the water channel is sunken downwardsin the cylindrical shape, the planar filtering net is placed in the sunken part, thus compared with that of an existing liner structure with two steps, the space occupied by a water way can be reduced, and accordingly, the space utilization rate of the bottom of the liner is increased; through the liner structure, the manufacturing cost can be reduced; and by arranging the supporting piece, fastening force between the water channel and the liner is more balanced, the probability of water leakage is decreased, and meanwhile, a gap between the planar filtering net and the bottom face of the sunken part of the liner is enlarged, so that the water flow is smoother.

Owner:QINGDAO HAIER DISHWASHER

Pipeline heat tracing device

PendingCN112856106AReduce your weightClarify on-site installation standardsThermal insulationPipe protection by thermal insulationEngineeringMechanical engineering

The invention relates to a pipeline heat tracing device which is arranged between a heat tracing pipeline and a heat-traced pipeline and tightly attached to the heat tracing pipeline and the heat-traced pipeline. According to the pipeline heat tracing device, the heat tracing device and the heat tracing pipe are fastened through a metal binding belt so that the fastening force between the heat tracing pipe and the heat tracing device is more uniform, the installation is more convenient, slight deformation can be conducted while the strength is guaranteed, the heat tracing device and the heat tracing pipe are perfectly attached, heat cannot be lost in the heat transfer process, and the heat tracing effect is achieved. The self weight of the pipeline heat tracing device is reduced structurally, and the cost is reduced. The pipeline heat tracing device has a clear on-site installation standard which is completely attached to an acceptance standard.

Owner:徐正强

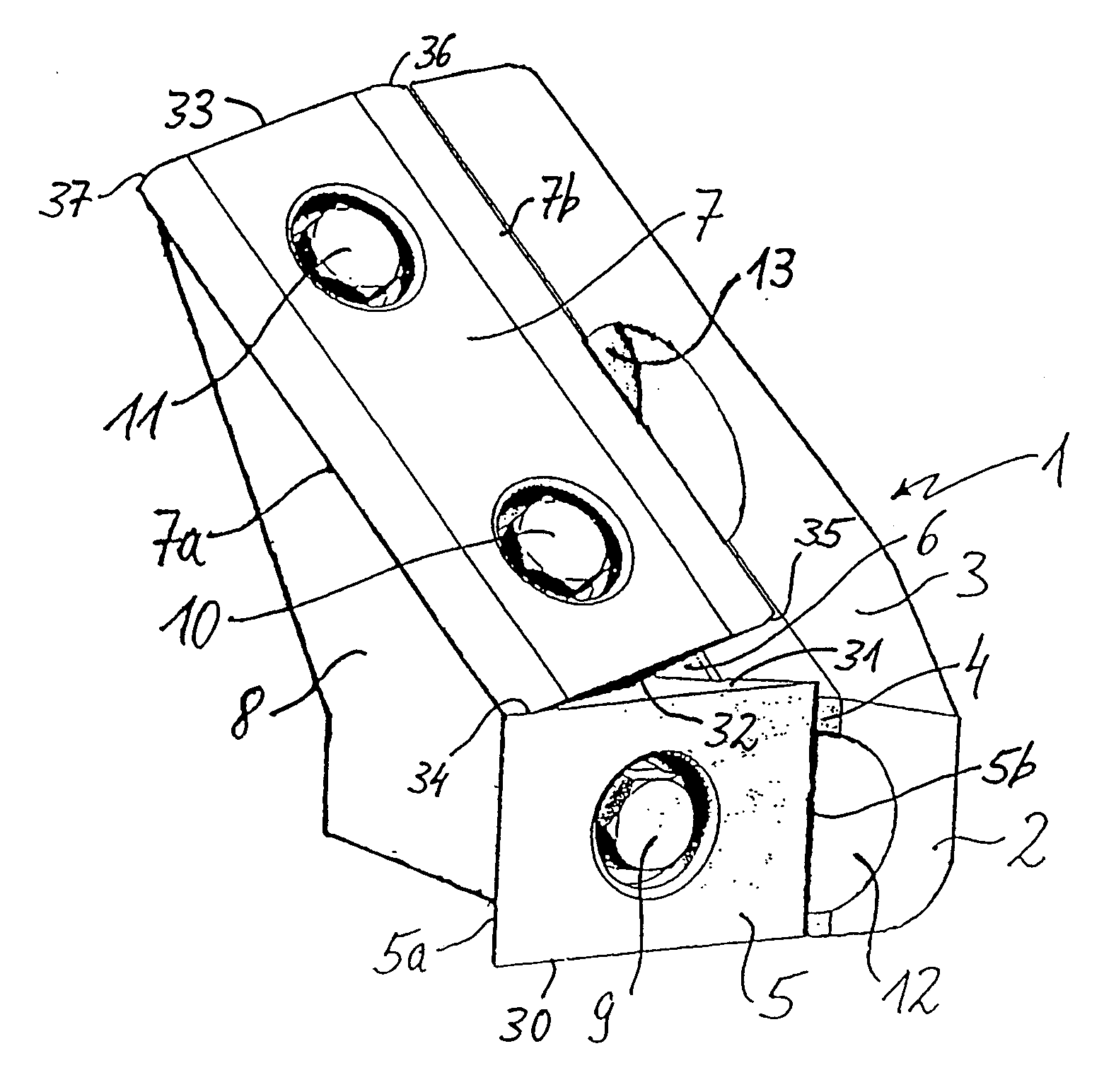

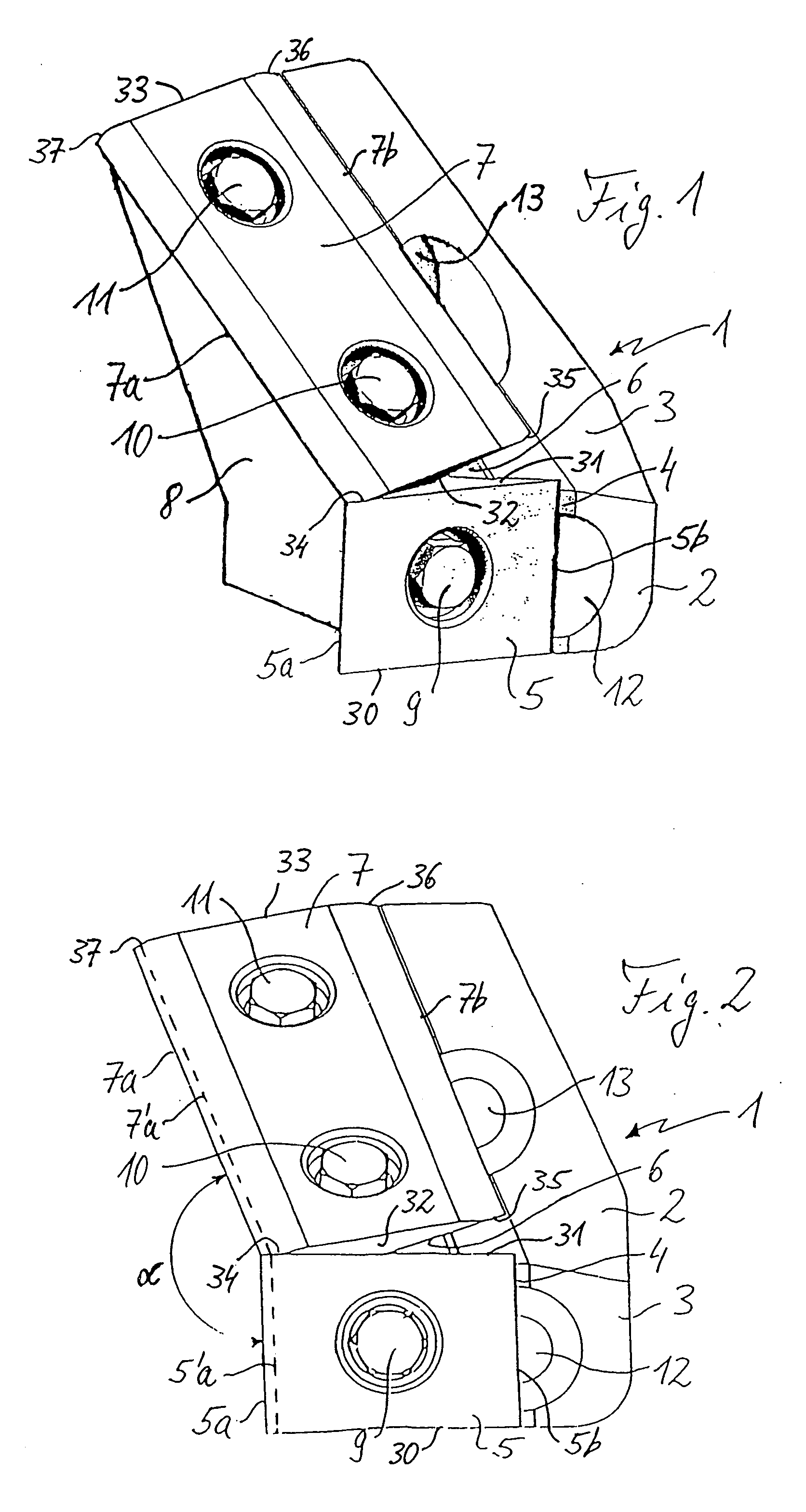

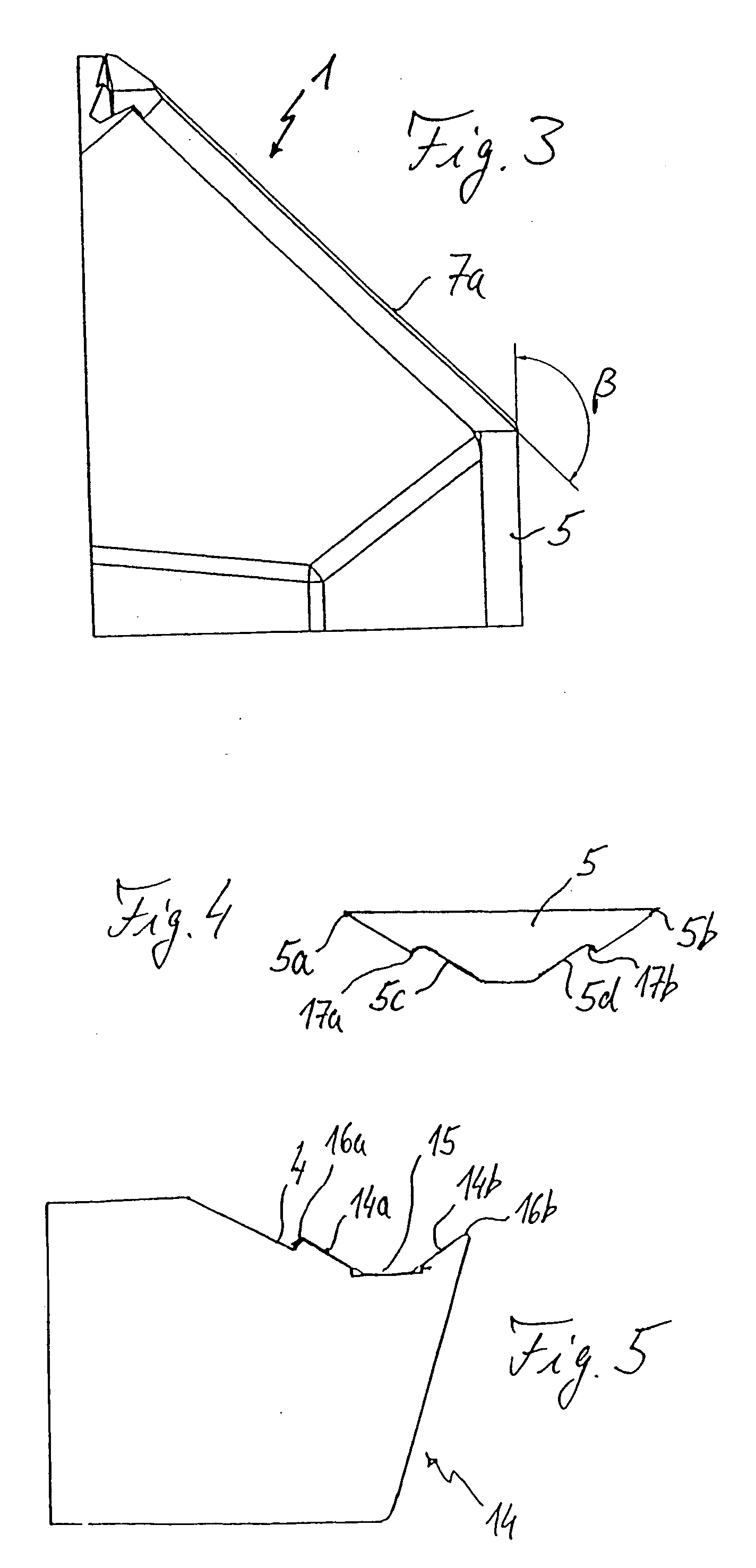

Blade holder, blade and blade tool head

InactiveUS20060151064A1Easy to replaceQuick installationMulti-purpose machinesProfiling/shaping machinesEngineeringKnife blades

Owner:LINDEX CHIPPING SYST

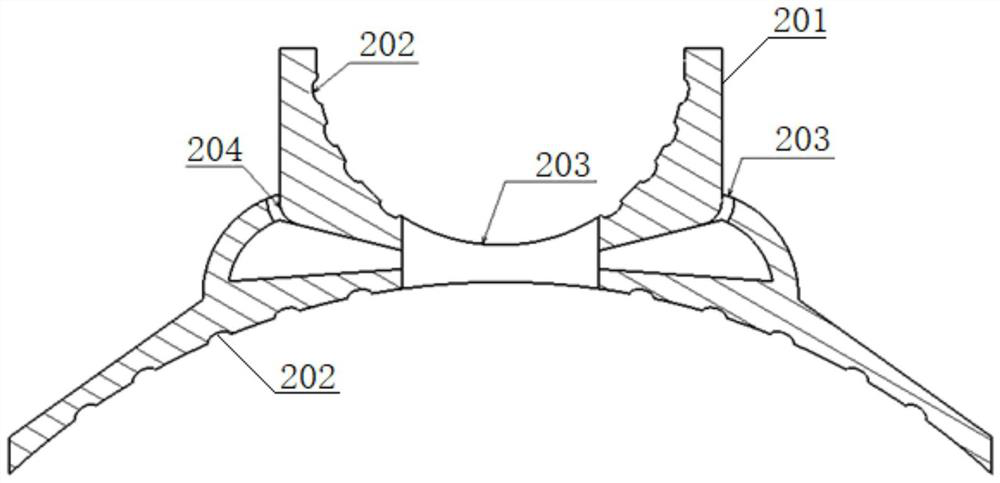

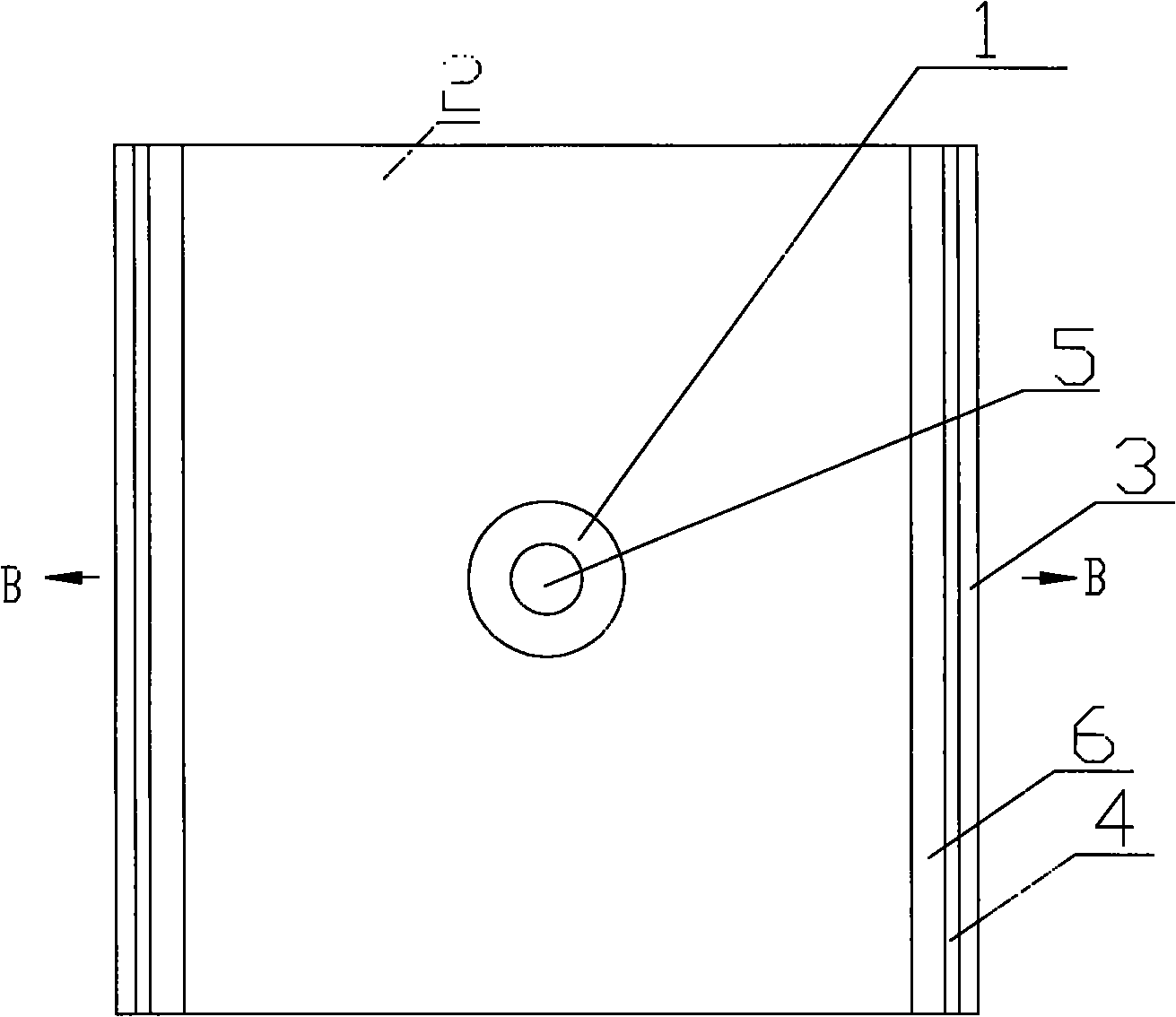

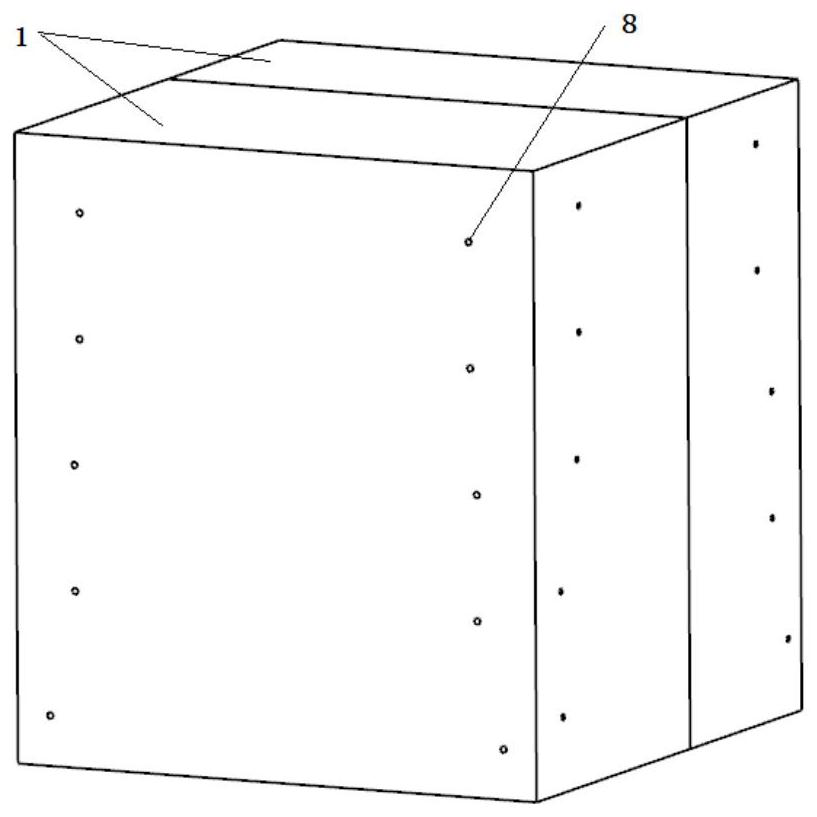

Magnetic steel used for permanent-magnet direct drive wind power generator

InactiveCN102340188ASimple structureGood workmanshipMagnetic circuit rotating partsWind energy generationEngineeringMagnet

The invention relates to magnetic steel used for a permanent-magnet direct drive wind power generator. A transverse section of the magnetic steel is in a shape of a rectangle. A through hole is arranged in a center of the transverse section. An upper surface and a lower surface are in a shape of an arc. Side surfaces comprise an upper side surface, a middle side surface and a lower side surface. Compared to the prior art, the magnetic steel of the invention possesses a simple structure, good manufacturability, low costs and the like.

Owner:SHANGHAI WANDE WIND POWER

Automatic valve assembling equipment

PendingCN114273916AReduce demandAutomate assemblyAssembly machinesMetal working apparatusAutomatic transmissionDrive by wire

The invention relates to the technical field of valve assembling, and provides automatic valve assembling equipment which comprises a rotary driving assembling mechanism, a driving assembly mechanism, a driving assembly mechanism, a driving assembly mechanism, a driving assembly mechanism and a driving assembly mechanism. The rotary driving assembling mechanism comprises a rotary driving device, a main rotary supporting piece and a plurality of branch rotary supporting pieces; the linear driving assembly mechanism comprises a plurality of linear driving devices; the automatic screwing mechanism is matched with at least one of the rotary driving assembling mechanism and the linear driving assembling mechanism; the automatic feeding mechanism is arranged corresponding to the rotary driving assembling mechanism and the linear driving assembling mechanism; the automatic transmission device is arranged between the rotary drive assembling mechanism and the linear drive assembling mechanism; the valve accessories comprise a single accessory and an assembly formed by a plurality of accessories. The automatic valve assembling equipment can achieve assembling automation of products containing the multiple accessories, the requirement for assembling personnel is reduced, the labor cost of production is reduced, and the production efficiency is improved.

Owner:国泰达鸣精密科技集团有限公司

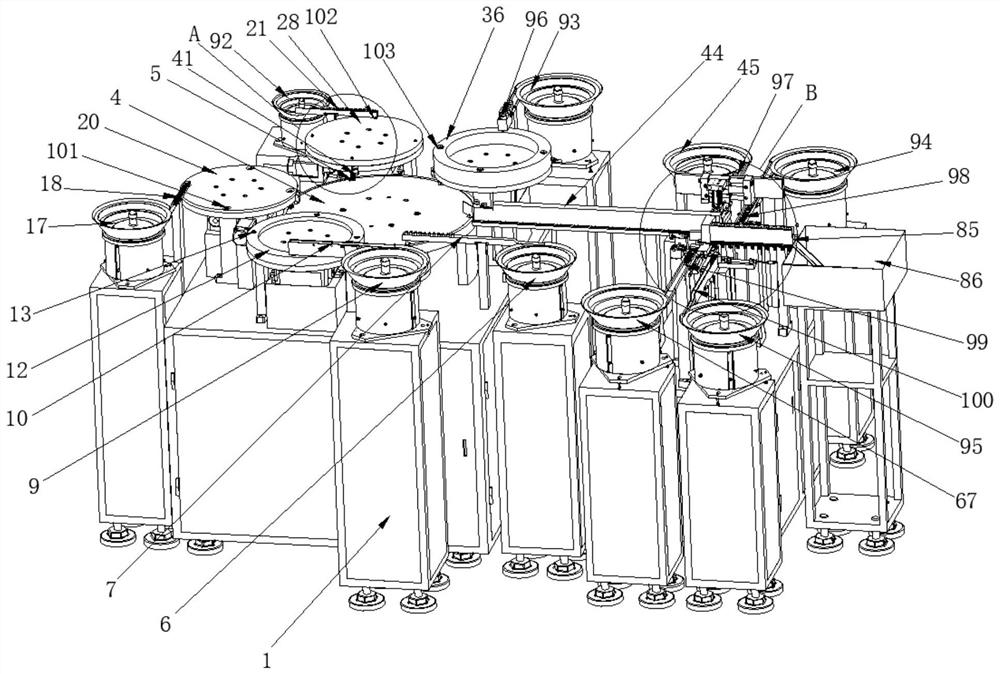

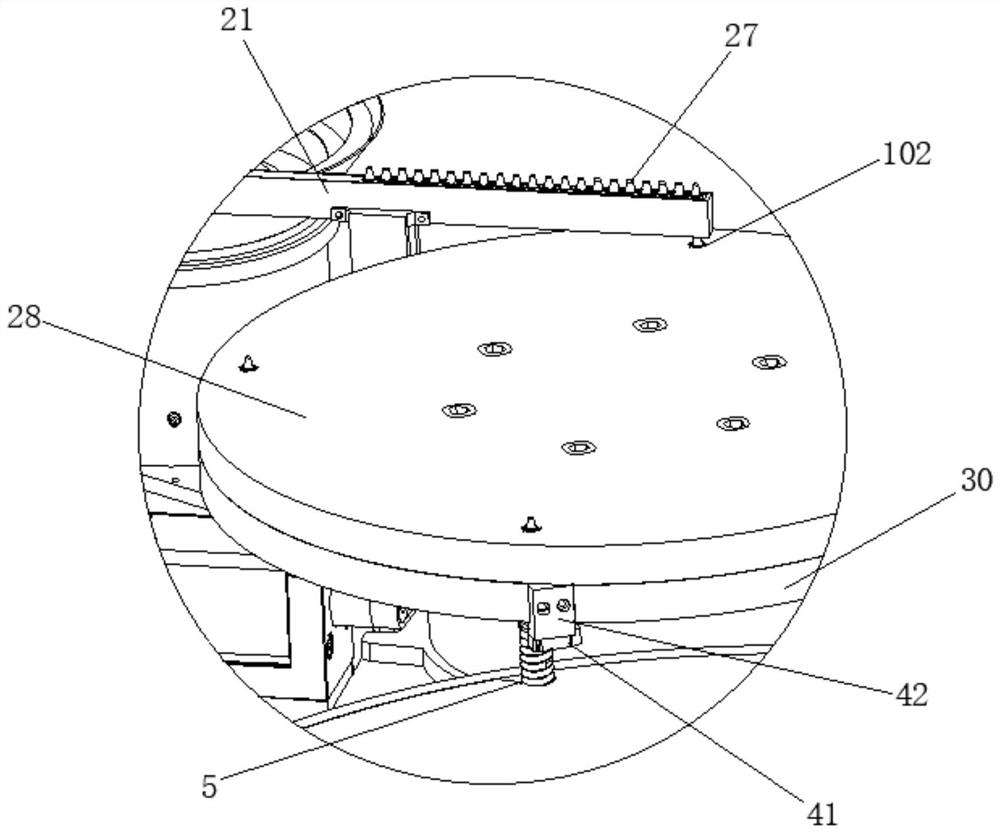

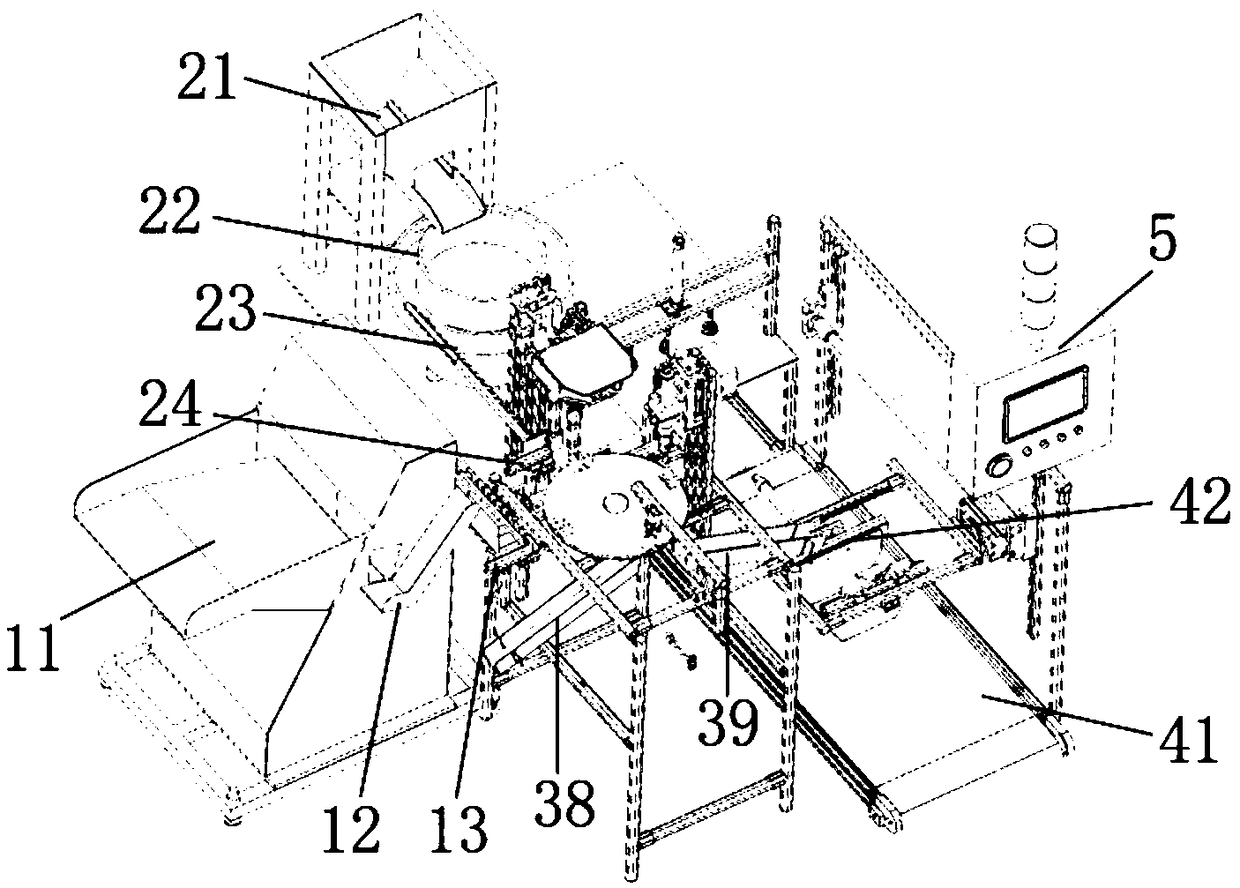

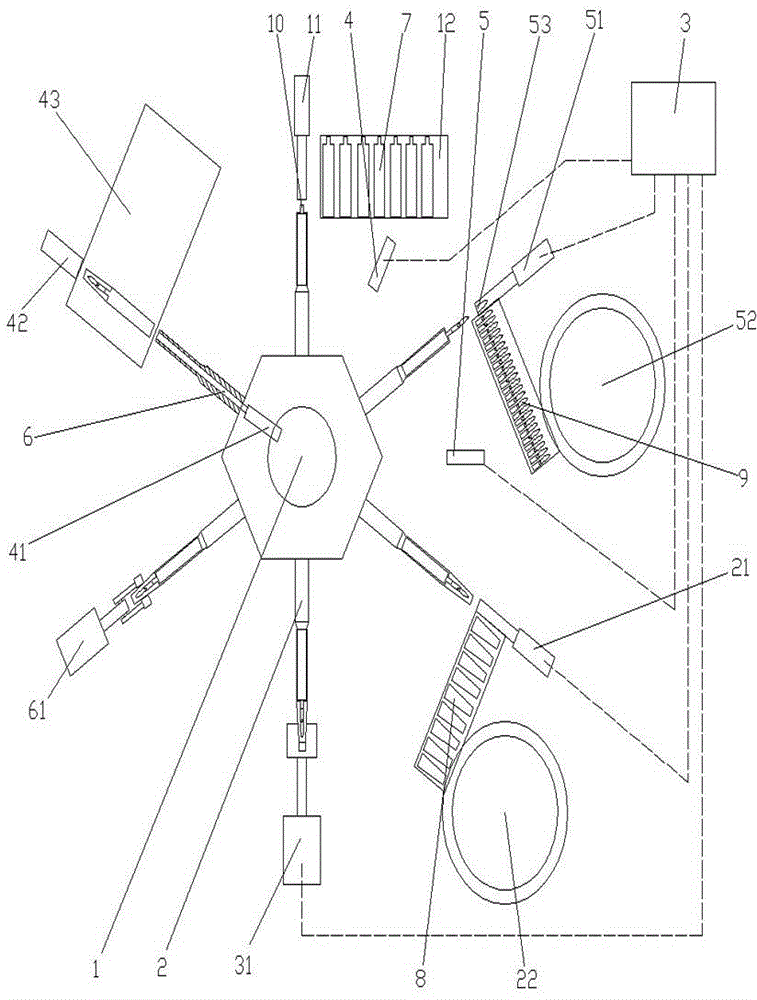

Assembly machine provided with brush hose

InactiveCN103072280AGuaranteed assembly qualityUniform tightening forceAssembly machineConstant torque

The invention discloses an assembly machine provided with a brush hose. The assembly machine comprises a rotary table, a plurality of sleeve rods are arranged on the periphery of the rotary table, a pipe sleeving mechanism, a brush embedding mechanism, a pipe cap sleeving mechanism, a pipe cap screwing mechanism, a constant-torque cap screwing mechanism and a tube removing mechanism are further arranged on the periphery of the rotary table successively. According to the assembly machine provided with the brush hose, the brush embedding mechanism is further arranged between the pipe sleeving mechanism and the pipe cap sleeving mechanism, so that prior manual brush embedding is changed into machine assembly, and accordingly, not only is the production efficiency greatly improved, but also the assembly quality of the brush is guaranteed; and simultaneously, the constant-torque cap screwing mechanism is further arranged behind the pipe cap screwing mechanism, so that screwed pipe caps have uniform tightening force.

Owner:SHANGYU WANHONG PLASTIC CO LTD

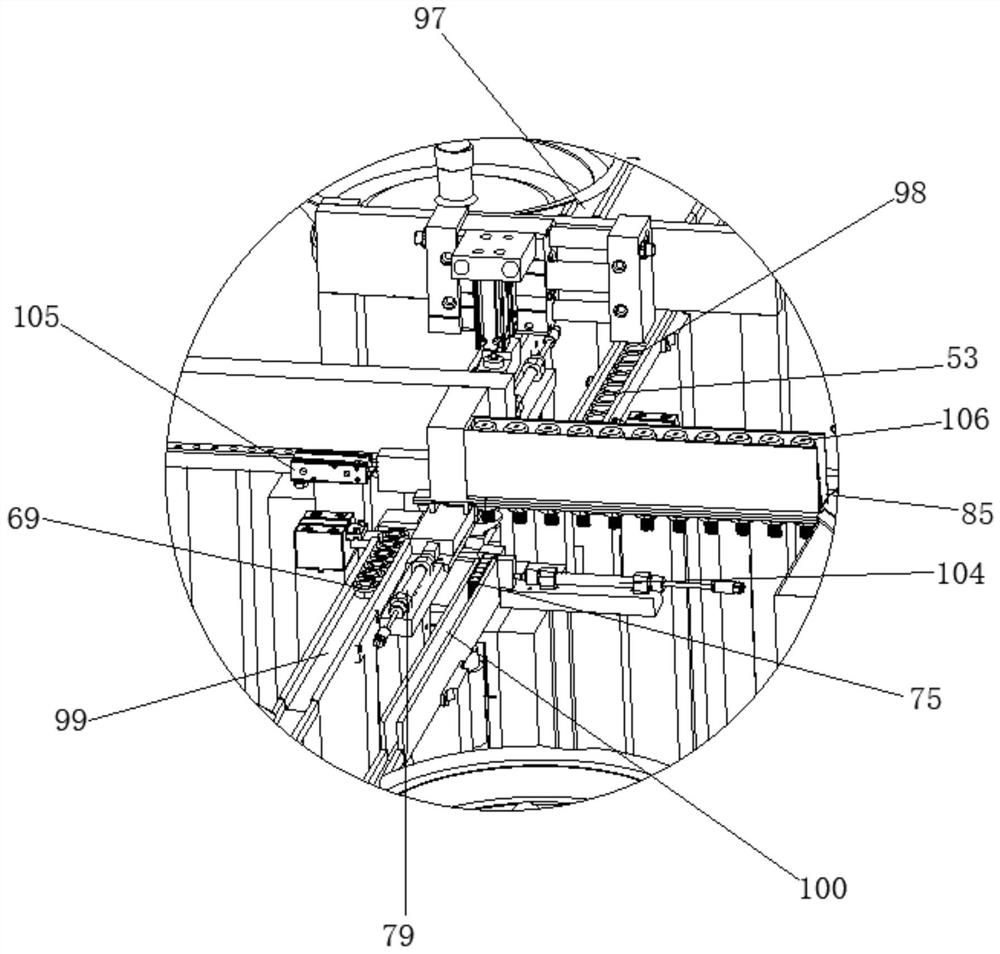

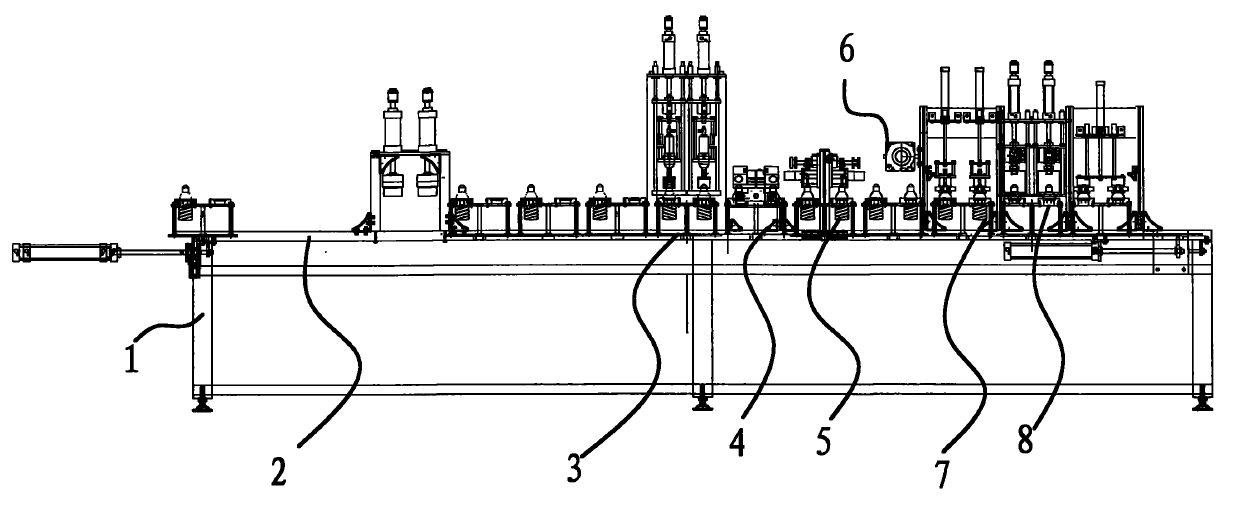

Automatic foot pad nut assembling and packaging automatic production line

PendingCN109014883AOvercome efficiencyOvercome strengthPackaging automatic controlMetal working apparatusControl systemEngineering

The invention discloses an automatic foot pad nut assembling and packaging automatic production line, and belongs to the technical field of automatic assembling equipment. The automatic foot pad nut assembling and packaging automatic production line comprises a rack, a foot pad conveying system, a nut conveying system, a nut tightening system and a bagging system. The foot pad conveying system andthe nut conveying system are connected with the nut tightening system. The nut tightening system is connected with the bagging mechanism. The foot pad conveying system, the nut conveying system, thenut tightening system and the bagging system are all connected with a PLC control system. Through the automatic foot pad nut assembling and packaging automatic production line, the assembling efficiency can be improved, the counting and packaging procedures are finished together, the work efficiency is improved, and the labor intensity and the manufacturing cost are reduced.

Owner:南京金三力橡塑有限公司

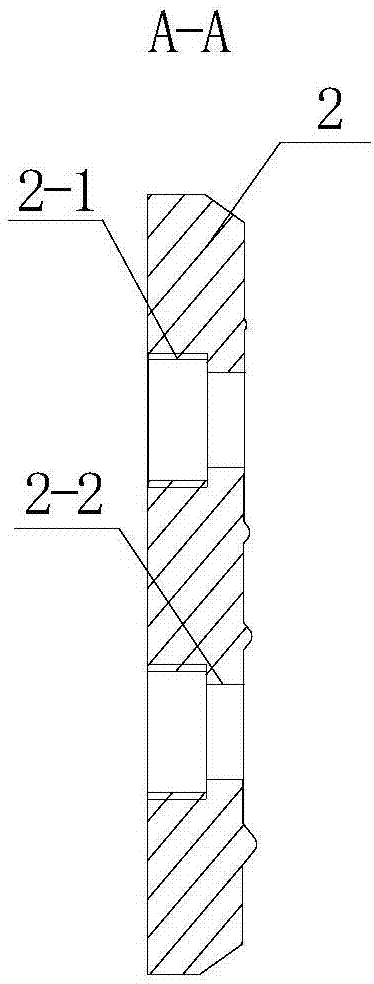

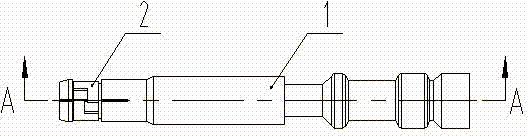

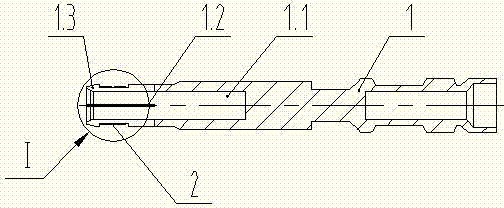

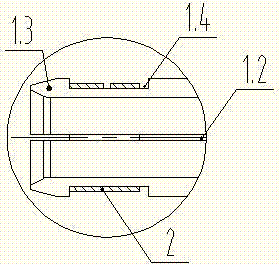

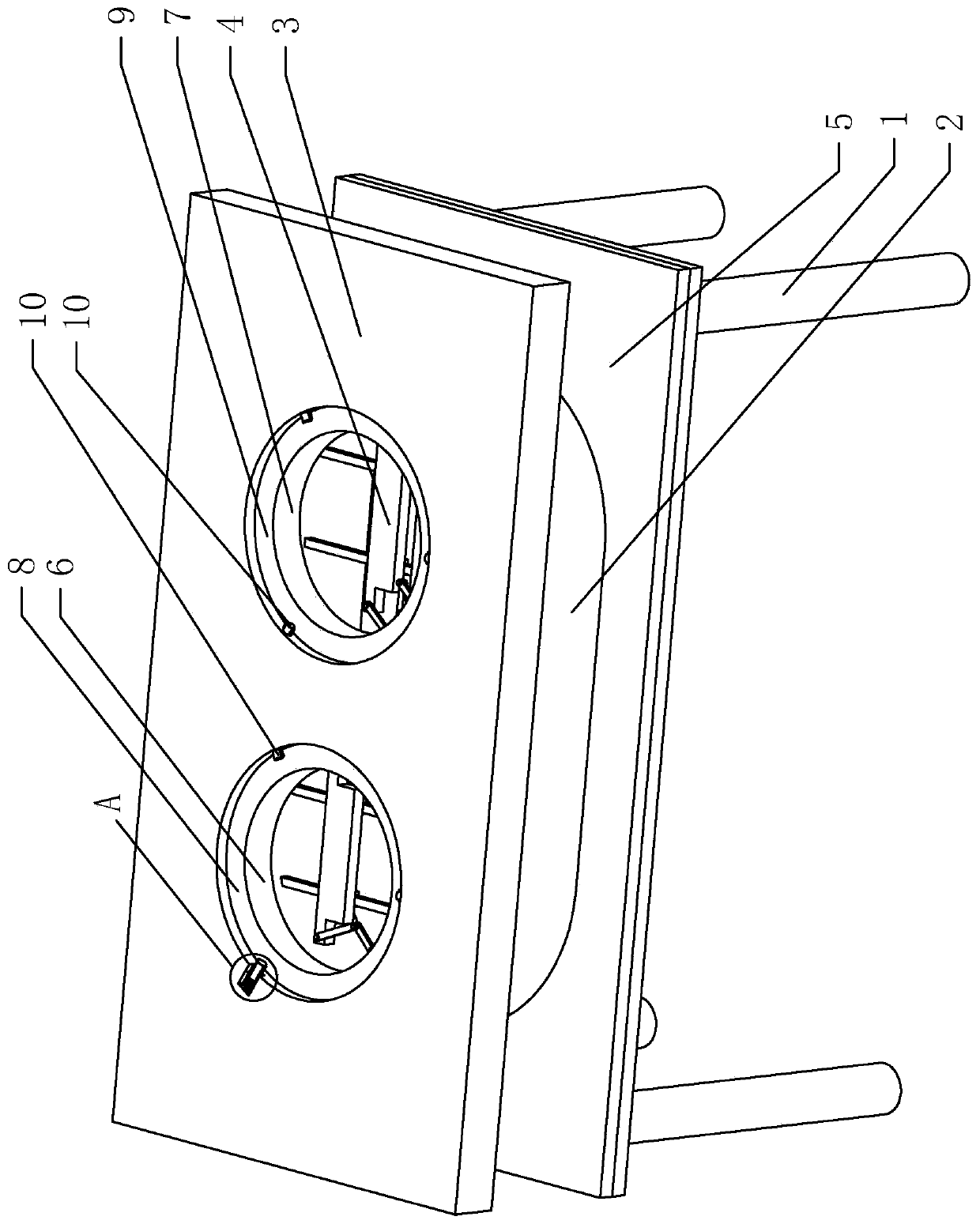

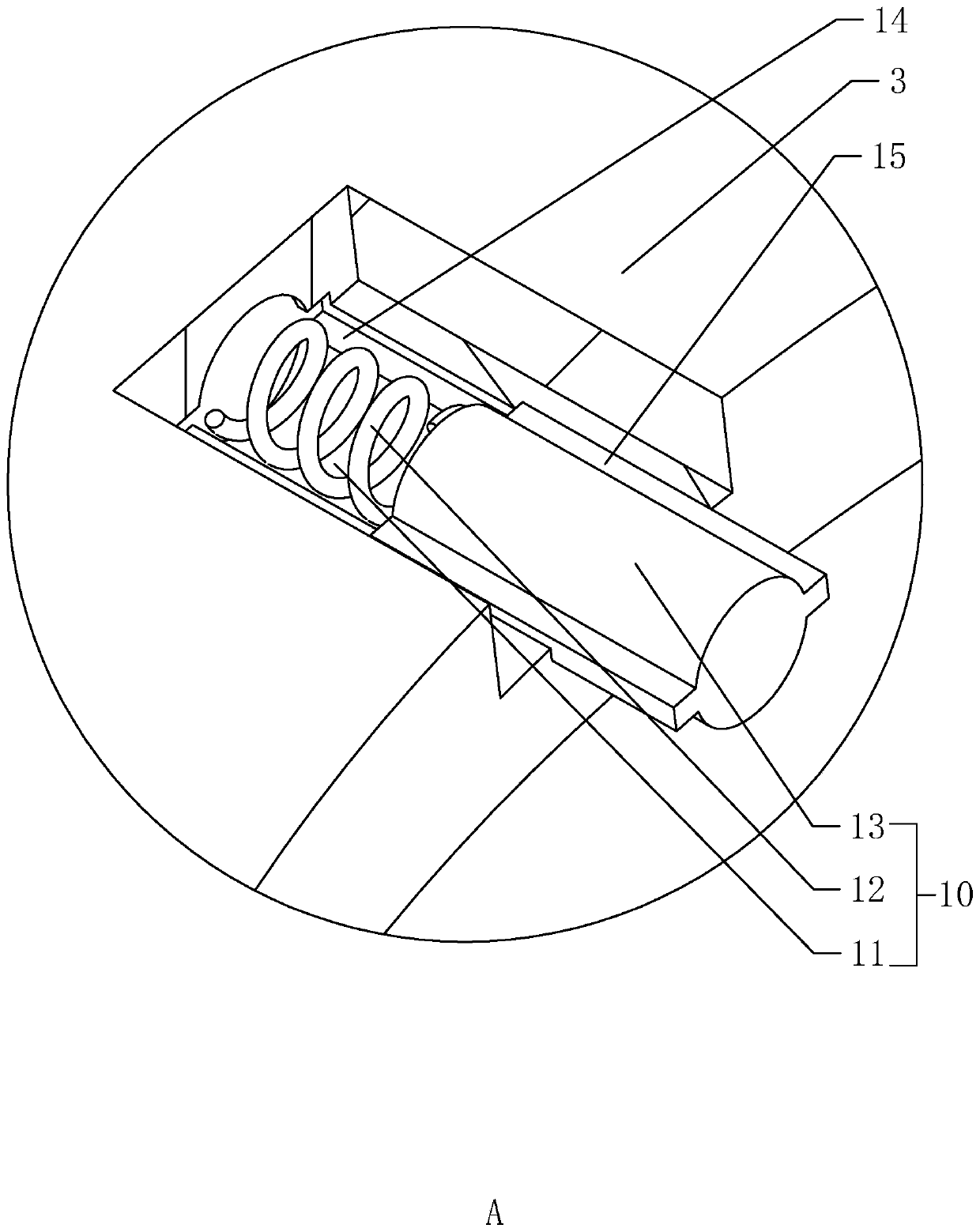

Female pin for cable connector

InactiveCN104505619AKeep tightIncrease contactCoupling contact membersMechanical engineeringEngineering

The invention discloses a female pin for a cable connector. The female pin for the cable connector comprises a cylindrical terminal body and an elastic tightening device; an inner hole is formed in the end part of the terminal body; a plurality of axial straight slots are formed in the wall of the inner hole from the end part to form clamping claws in the circumferential direction; annular slots are formed in the outer wall of the clamping claws; the elastic tightening device sleeves the outer walls of the annular slot to tighten the clamping claw. The female pin for the cable connector is characterized in that an elastic sleeve or an elastic ring is used as the elastic tightening device; the elastic sleeve is an opened elastic metal sleeve of which the sidewall is opened. With the adoption of the female pin for the cable connector, the tightening force of the clamping claws can be remained for a long term; when in use, a good contact can be kept with a cylindrical male pin, and therefore, the phenomena of bad contact and sparking occurring in contact with the cylindrical male pin can be avoided.

Owner:SAIYANG ELECTROMECHANICAL

Saddled vehicle

ActiveCN102481967BNo need to increase intensityThe case of loads that prevent deformationAxle suspensionsMotorcyclesVehicle frameEngineering

Owner:HONDA MOTOR CO LTD

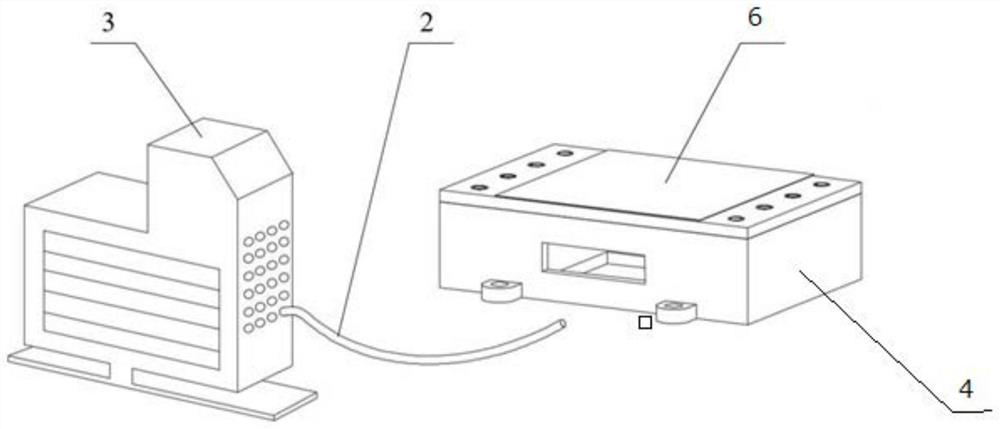

Rotor cage bar and end ring welding bench and welding method

InactiveCN109848502AImprove welding efficiencyUniform tightening forceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRotor cage

The invention relates to the technical field of motor welding, and aims to provide a rotor cage bar and end ring welding bench. According to the key points of the technical scheme, the rotor cage barand end ring welding bench comprises a support, a welding barrel and a workbench. A first welding hole, a second welding hole, a first limiting groove and a second limiting groove are formed in the workbench, and the first welding hole and the second welding hole communicate with the welding barrel. Limiting components are arranged on the side wall of the first limiting groove and the side wall ofthe second limiting groove, and each limiting component comprises a limiting hole, a spring and a limiting rod. The limiting holes are formed in the side wall of the first limiting groove and the side wall of the second limiting groove, one end of each spring is connected with the corresponding limiting hole, and the other of the spring is connected with the corresponding limiting rod. When the spring is under compression, the end, back from the spring, of the corresponding limiting rod is outside the corresponding limiting hole. The rotor cage bar and end ring welding bench can weld two groups of rotor cage bars and end rings at a time, and the welding efficiency is high.

Owner:西安阿尔斯通永济电气设备有限公司

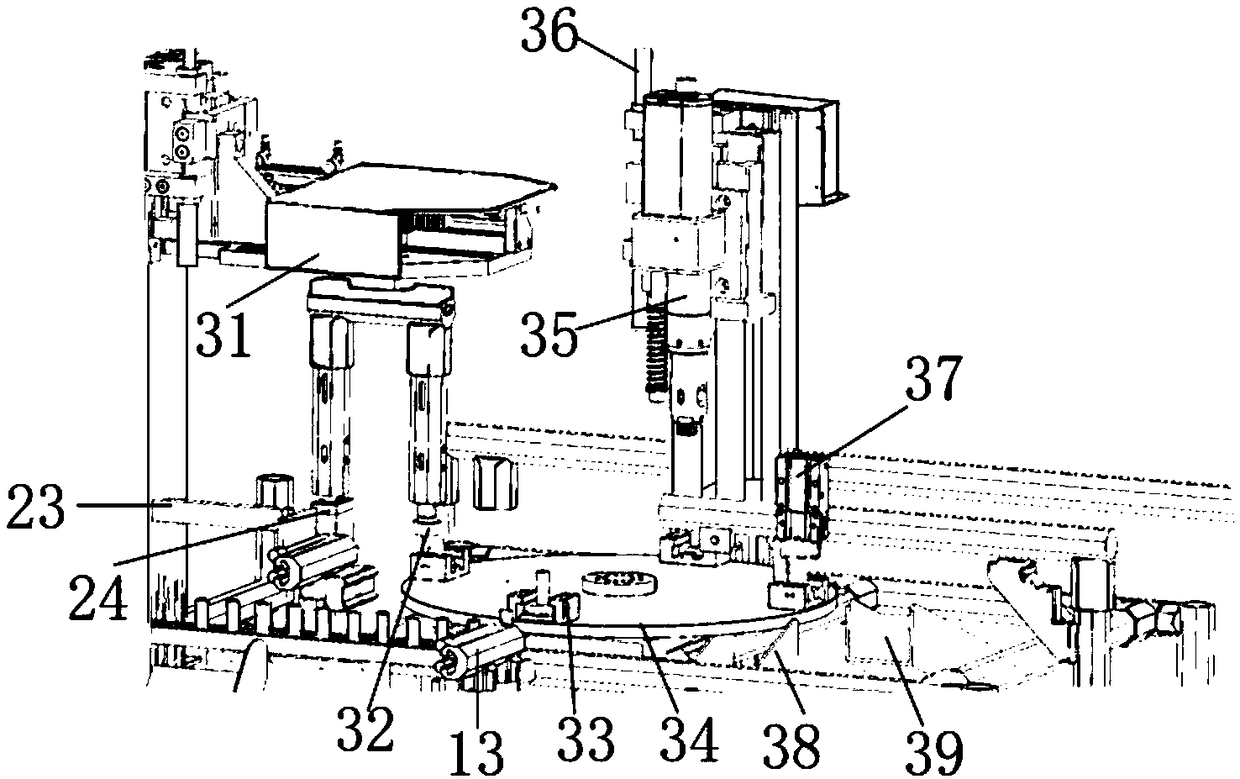

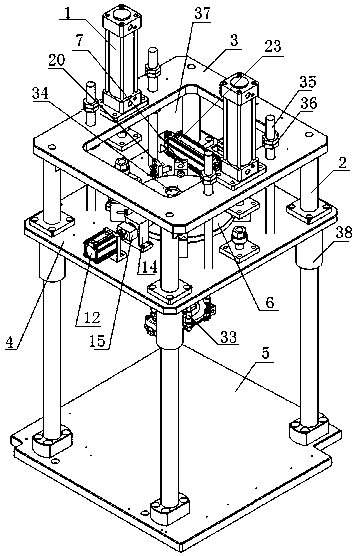

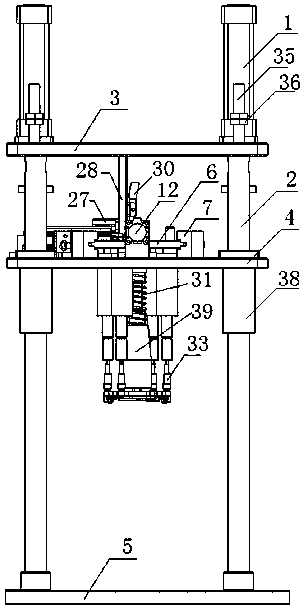

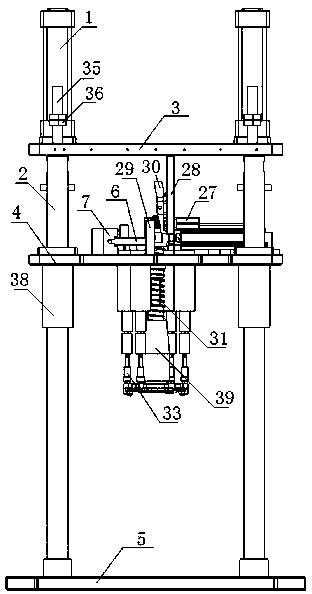

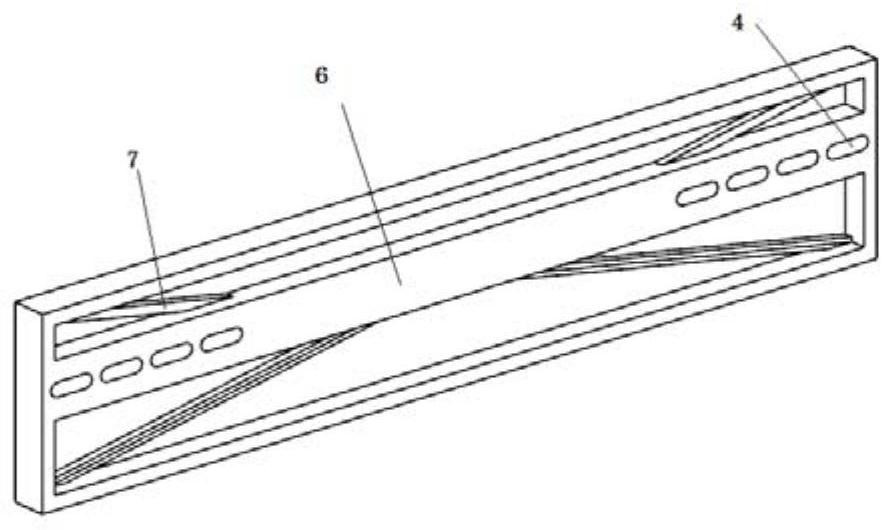

A bolt fastening machine

ActiveCN105965247BReduce in quantityPrecise control angleMetal working apparatusMechanical equipmentEngineering

The invention relates to the field of mechanical equipment, in particular to a bolt fastening machine. The bolt fastening machine comprises a lifting plate and a fastening device positioned on the lifting plate, wherein the middle part of the lifting plate is provided with an opening for allowing the fastening device to move up and down; the fastening device comprises a tray which is positioned in a middle opening of the lifting plate, a floating mechanism which penetrates through the tray, a plurality of dowel pins positioned on the upper surface of the tray, a plurality of rotary positioning mechanisms which are positioned on the upper surface of the lifting plate and are arranged at the periphery of a circular opening, a locking device which is positioned on the upper surface of the lifting plate and is matched with the plurality of the dowel pins for use, and a rotary pushing mechanism which is positioned on the upper surface of the lifting plate and is connected to the side surface of the tray; the tray is embedded into an area which is defined by the plurality of the rotary positioning mechanisms and the locking device; the tray is circular; and the plurality of the rotary positioning mechanisms are distributed at equal spacing at the periphery of the tray. The bolt fastening machine can realize precise control on a bolt while reducing number of wrenches, so that tightness of a mechanical device is ensured.

Owner:山东中际钇嘉智能装备有限公司

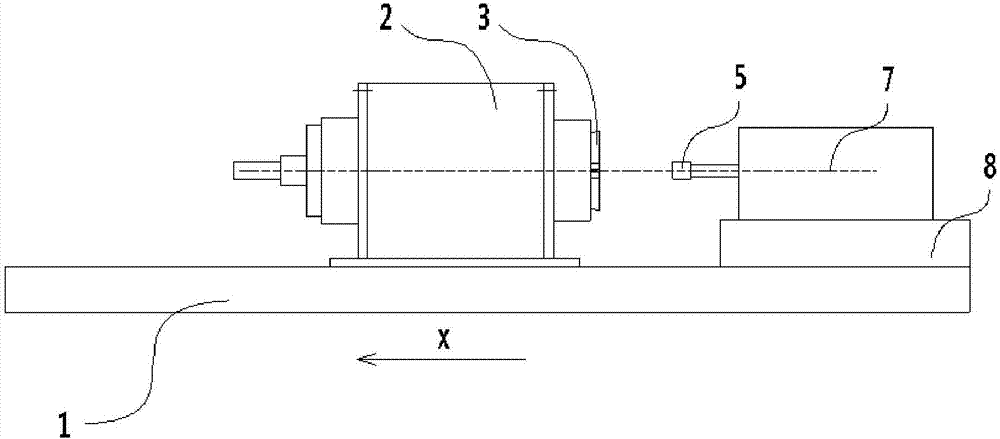

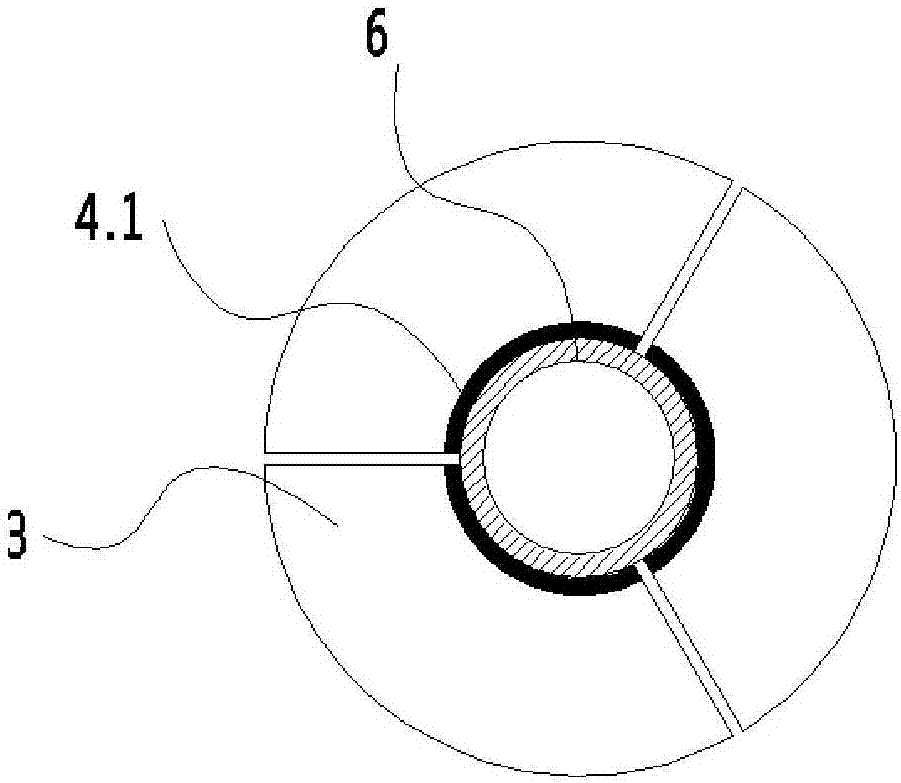

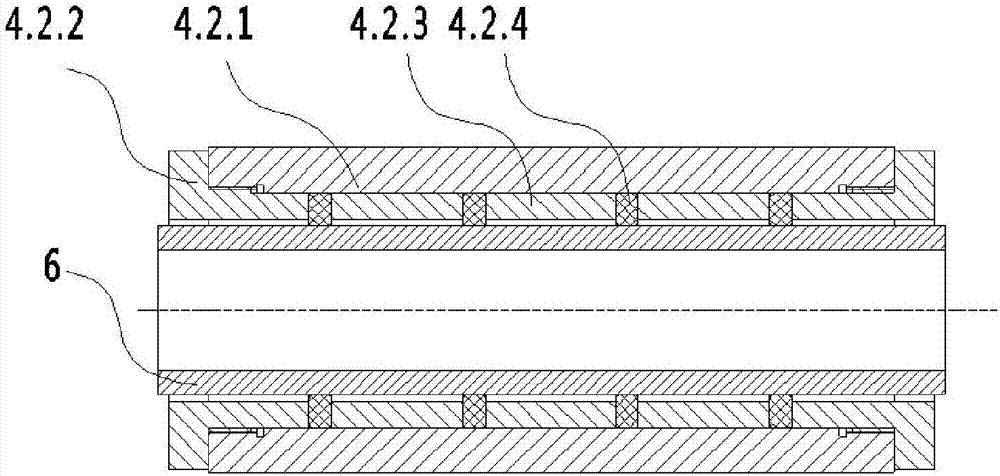

Machining method and equipment for inner circle of circular tube magnet

ActiveCN107877274AUniform tightening forceAvoid chippingGrinding carriagesRevolution surface grinding machinesElastomerLocking mechanism

The invention provides machining equipment for the inner circle of a circular tube magnet. The machining equipment comprises a base, wherein a rotation mechanism is installed on the left part of the base; a drive table capable of moving on the three coordinates X, Y and Z is installed on the right part of the base; the centre of the rotation mechanism is sleeved with a chuck with a locking mechanism, and the chuck is used for clamping the hole tube magnet for machining; a ring of elastomers is added around the hole tube magnet; a high-speed rotation mechanism is arranged on the drive table; and a detachable elastic grinding head used for avoiding the shock of the hole tube magnet during grinding machining is installed at the centre of the high-speed rotation mechanism. According to the machining equipment provided by the invention, breakage in a machining process of the thin-wall hole tube magnets is avoided, so that the yield is increased; and on the other hand, the phenomenon of large heads and small heads of the inner holes of hole tubes is avoided, and the inner hole machining accuracy for the products is improved.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

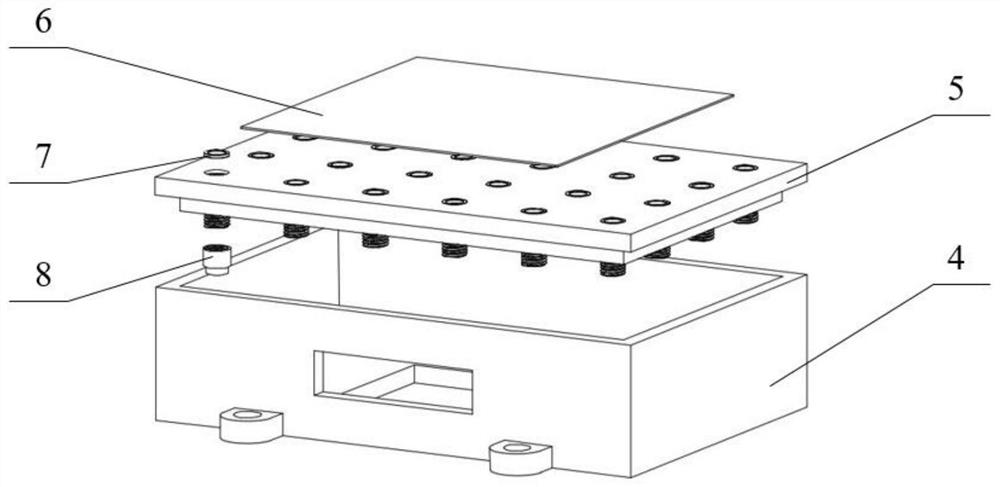

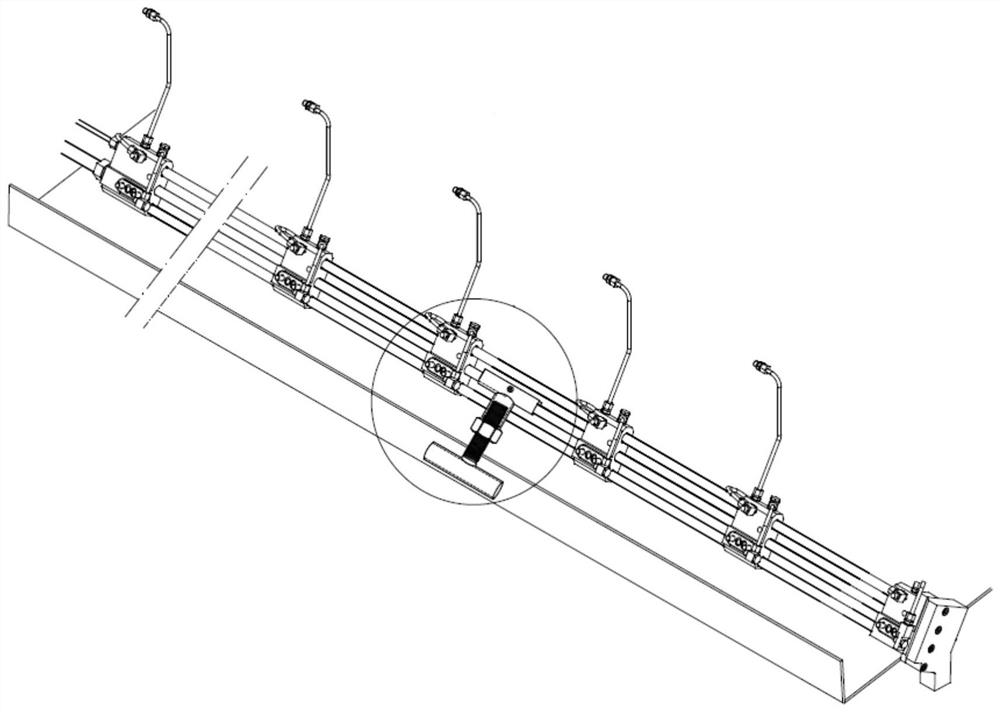

Device and method for reducing machining deformation of heat exchange fin

PendingCN113319628AReduce processing deformationUniform tightening forcePositioning apparatusMetal-working holdersMachining deformationPumping vacuum

The invention relates to the field of heat exchangers, and discloses a device and method for reducing machining deformation of a heat exchange fin. The device comprises a base, a supporting plate and a vacuumizing device, wherein the supporting plate is arranged above the base, and a plurality of pipelines are arranged on the supporting plate; one end of each pipeline is flush with the plate face of the supporting plate, and the other end of each pipeline extends out of the supporting plate and is hermetically connected with the vacuumizing device. The method comprises the following steps of: (1) conducting finishing treatment on a heat exchange fin blank before machining; (2) mounting the device for reducing machining deformation of the heat exchange fin, placing the heat exchange fin blank on the supporting plate, connecting the pipelines to the vacuumizing device, and starting the vacuumizing device; (3) conducting milling machining of pouring cooling liquid on the heat exchange fin blank; and (4) after milling is completed, closing the vacuumizing device, conducting vacuum breaking, and taking down the part. The device solves the problem that the heat exchange fin is very easy to deform during clamping and machining is effectively solved, and has the advantages of being easy to operate and low in cost.

Owner:航天科工哈尔滨风华有限公司

Resin-sand combined mold protection device and method

ActiveCN110405149BRealize standardization and serializationGuaranteed not to deformFoundry mouldsFoundry coresCasting moldGeotechnical engineering

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Assembly machine provided with brush hose

Owner:SHANGYU WANHONG PLASTIC CO LTD

A transformer lamination assembly tooling

ActiveCN106024369BUniform tightening forceEasy to operateTransformers/inductances detailsInductances/transformers/magnets manufactureTransformerMechanical engineering

The invention discloses a laminated combination tooling for a transformer. The laminated combination tooling comprises a group of mountain-shaped stacks and a group of upper iron yoke stacks; the mountain-shaped stacks are provided with a lower iron yoke part and three stem parts; the upper iron yoke stacks are arranged on the three stem parts of the mountain-shaped stacks; the upper iron yoke stacks and the mountain-shaped stacks form closed structures; first positioning steel poles are arranged in the lower iron yoke parts of the mountain-shaped stacks in a penetrating manner; first positioning sheets are respectively arranged at the front side and the rear side of the lower iron yoke part; the end parts of the first positioning steel poles penetrate through the first positioning sheets; second positioning steel poles are arranged in the upper iron yoke stacks in a penetrating manner; second positioning sheets are respectively arranged at the front and rear sides of the upper iron yoke stacks; the end parts of the second positioning steel poles penetrate through the second positioning sheets; one clamping channel steel crossing over the three stem parts is arranged on each of the front and rear sides of the mountain-shaped stacks; the two clamping channel steels are connected by screws. The laminated combination tooling disclosed by the invention has the advantages of higher convenience in operation, time saving, labor saving, cost saving and high production efficiency; in addition, the formed laminated structure meets the requirements and no joints are generated.

Owner:SUZHOU WUBIAN ELECTRICAL TECH CO LTD

Method for adjusting housings outside of single stand reversible rolling mill

ActiveCN101664760BHigh adjustment accuracyMeet the acceptance criteriaMetal rolling stand detailsMeasuring devicesEngineeringRoll center

Owner:CHINA MCC20 GRP CORP

Energy-saving lamp automatic assembly line

InactiveCN101447382BReduce labor costsReduce manufacturing costSequential operation station machinesAutomatic transmissionControl system

The invention provides an energy-saving lamp automatic assembly line which belongs to the technical field of machine. The energy-saving lamp automatic assembly line solves the problem that the existing energy-saving lamp automatic assembly line adopts manual assembly and has low production efficiency. The energy-saving lamp automatic assembly line is provided with an energy-saving lamp assembly transmission system on a frame. The energy-saving lamp assembly transmission system comprises a middle transmission track and branch transmission tracks. Joint parts of one end of the middle transmission track with two branch transmission tracks are provided with distributing mechanisms which can distribute energy-saving lamps at the middle transmission track to two branch transmission tracks. Eachbranch transmission track is respectively provided with an automatic rotating energy-saving lamp cap device, an energy-saving lamp automatic filament-cutting device, an energy-saving lamp automatic tin soldering device, an energy-saving lamp automatic detecting and controlling system and an energy-saving lamp automatic nailing device. The energy-saving lamp automatic assembly line is equipped with two sets of assembly devices and realizes the advantages of automatic transmission and assembly, etc.

Owner:ZHEJIANG SHENDU OPTOELECTRONICS TECH

Integrated system of electronic current transformer and breaker

InactiveCN107332112AReasonable structureIngenious designTransformersTransformers/inductances coils/windings/connectionsEngineeringInterrupter

Owner:CHINA XD ELECTRIC CO LTD

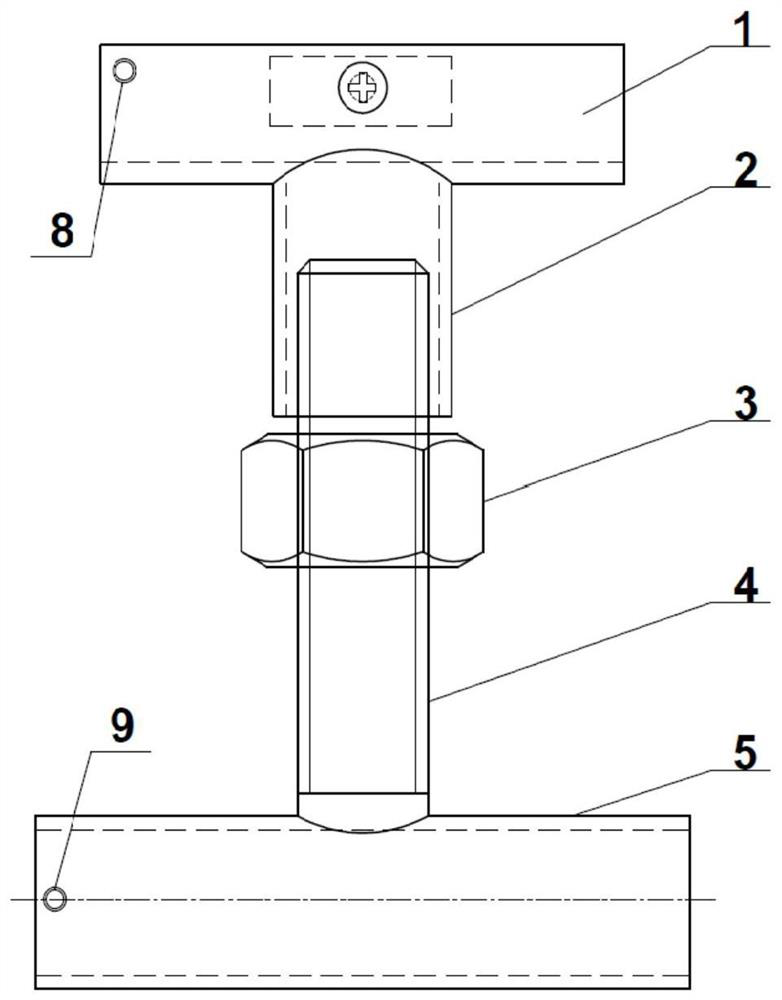

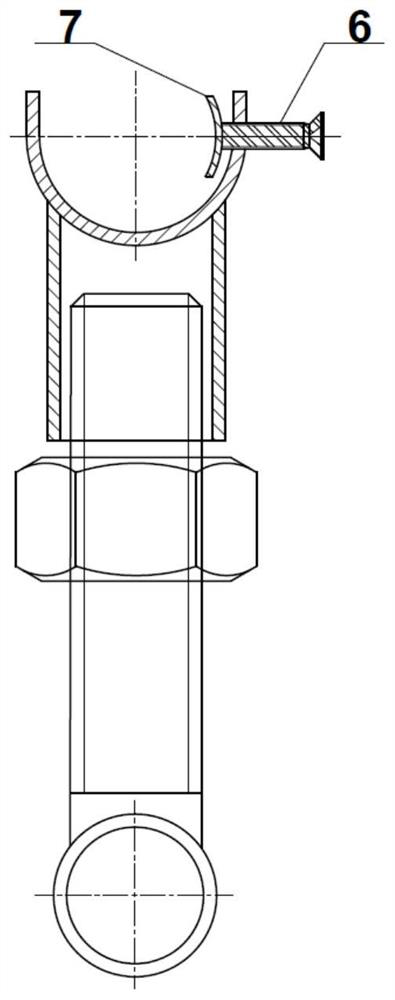

Oil inlet and return pipe maintenance tool and method for diesel engine body at nuclear power station

PendingCN112238408AUniform tightening forceConvenient self-lockingWork holdersNuclear energy generationMarine engineeringNuclear power

The invention belongs to the technical field of diesel engine maintenance at nuclear power stations, and discloses an oil inlet and return pipe maintenance tool and method for a diesel engine body ata nuclear power station. The oil inlet and return pipe maintenance tool comprises a clamping device and a jacking device, wherein the clamping device comprises a clamping pipe, a sleeve, a clamping screw and a clamping piece; the jacking device comprises a nut, a bolt and a bottom support; the clamping pipe is fixedly connected with the sleeve; a through hole is formed in the clamping pipe and inthreaded connection with the clamping screw; the end, close to the clamping pipe, of the clamping screw is fixedly connected with the clamping piece; the bottom of the bolt is fixedly connected with the bottom support; the nut matched with the bolt sleeves the bolt; and the bolt is inserted into the sleeve and connected with the sleeve in a matching manner. The oil inlet and return pipe maintenance tool is simple in structure and small in size, can adapt to onsite narrow maintenance space, and has rapid positioning and jacking functions; the uniform stress of an entire oil inlet and return pipe assembly can be guaranteed; the deformation of an oil inlet and return pipe as well as the sealing surface and thread damage can be avoided; the labor cost can be effectively reduced; the risk caused by human errors can be reduced; and the maintenance operation on the oil inlet and return pipe can be safely and efficiently performed.

Owner:JIANGSU NUCLEAR POWER CORP

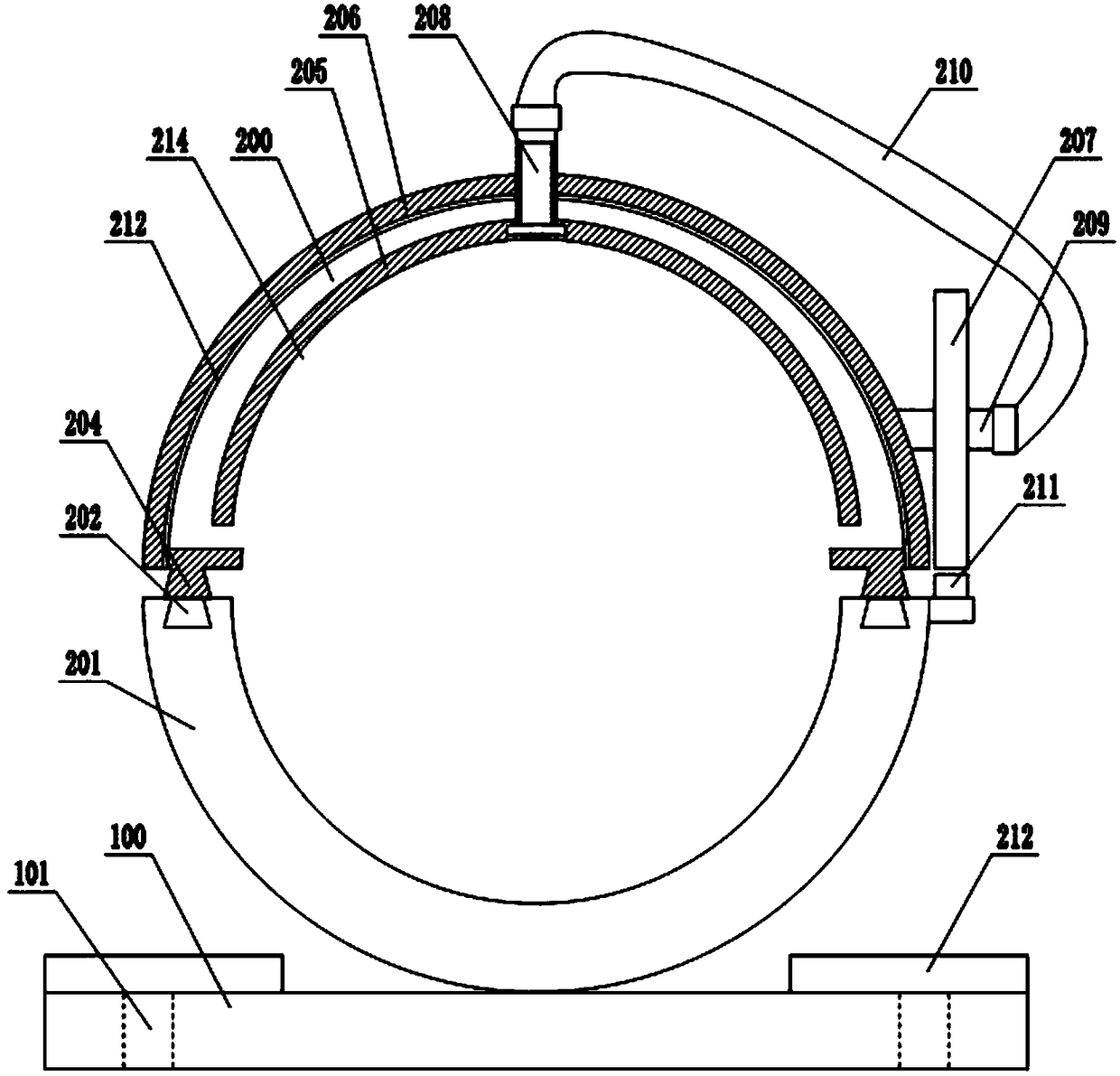

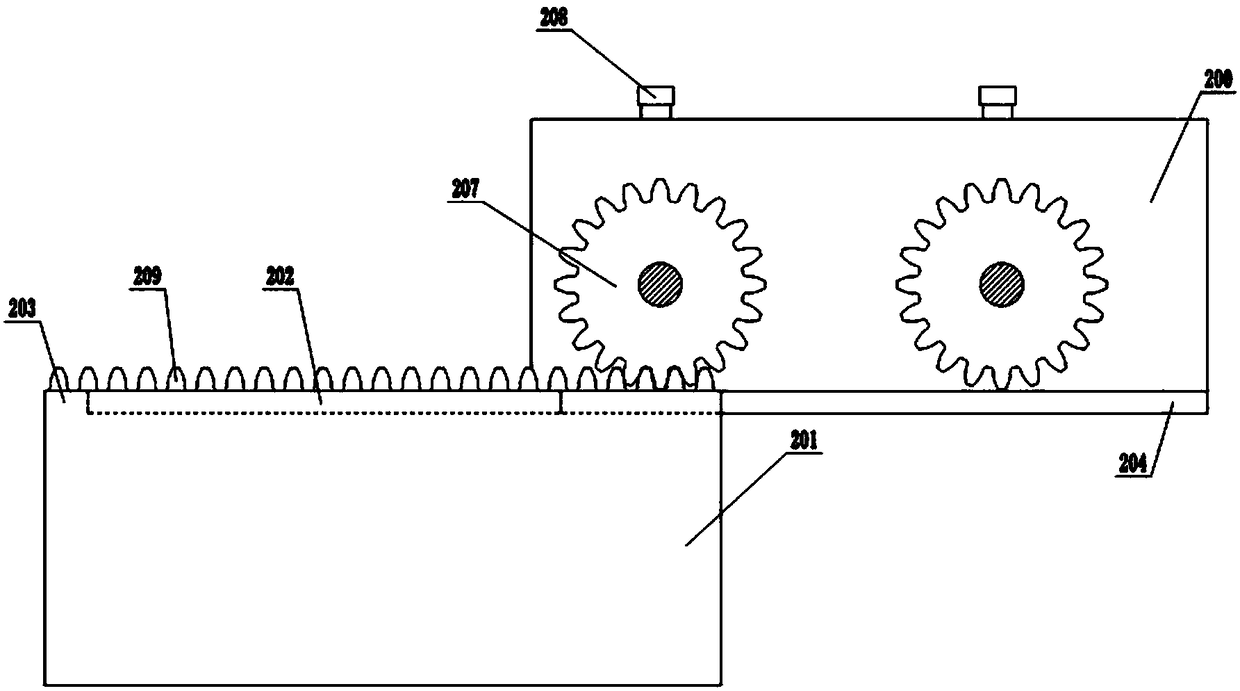

High-voltage cable supporting protector

ActiveCN108306242ASolve opening difficultiesUniform tightening forceCable installations on groundEngineeringHigh pressure

The invention discloses a high-voltage cable supporting protector. The high-voltage cable supporting protector includes a pedestal and support columns, wherein the support columns are hollow and are arranged horizontally by the central axis; the support columns include an upper cylinder and a lower cylinder which are symmetrical in design; the upper end surface of the lower cylinder is equipped with dovetails in the axial direction; the lower end surface of the upper cylinder is equipped with guide rails in the axial direction, and the guide rails are connected with the dovetails; each of theupper cylinder and the lower cylinder includes a cylinder outer wall and a cylinder inner wall; the cylinder inner wall of the upper cylinder is movably connected with the cylinder outer wall of the upper cylinder; the high-voltage cable supporting protector also includes a compaction structure; the compaction structure includes gears and screws; the screws penetrate through screwed holes and thenare rotatably connected with the cylinder inner wall of the upper cylinder; the gears are fixedly connected with gear shafts; the gear shafts are rotatably connected with the cylinder outer wall of the upper cylinder; soft shafts are connected between the gear shafts and the screws; a tooth bar is arranged on the cylinder outer wall of the lower cylinder; the length of the tooth bar is identicalto the axial length of the lower cylinder; and each gear is engaged with the tooth bar when the upper cylinder is connected with the lower cylinder. When the high-voltage cable supporting protector isarranged in a narrow pipe or obstructions exist around high voltage cables, the high-voltage cable supporting protector is convenient to mount and dismount.

Owner:重庆博创知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com