Fluorine butterfly valve

A technology of fluorine-lined butterfly valve and valve body, which is applied in the field of valves, can solve problems such as structural feature restrictions, and achieve the effects of preventing medium leakage, uniform tightening force, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

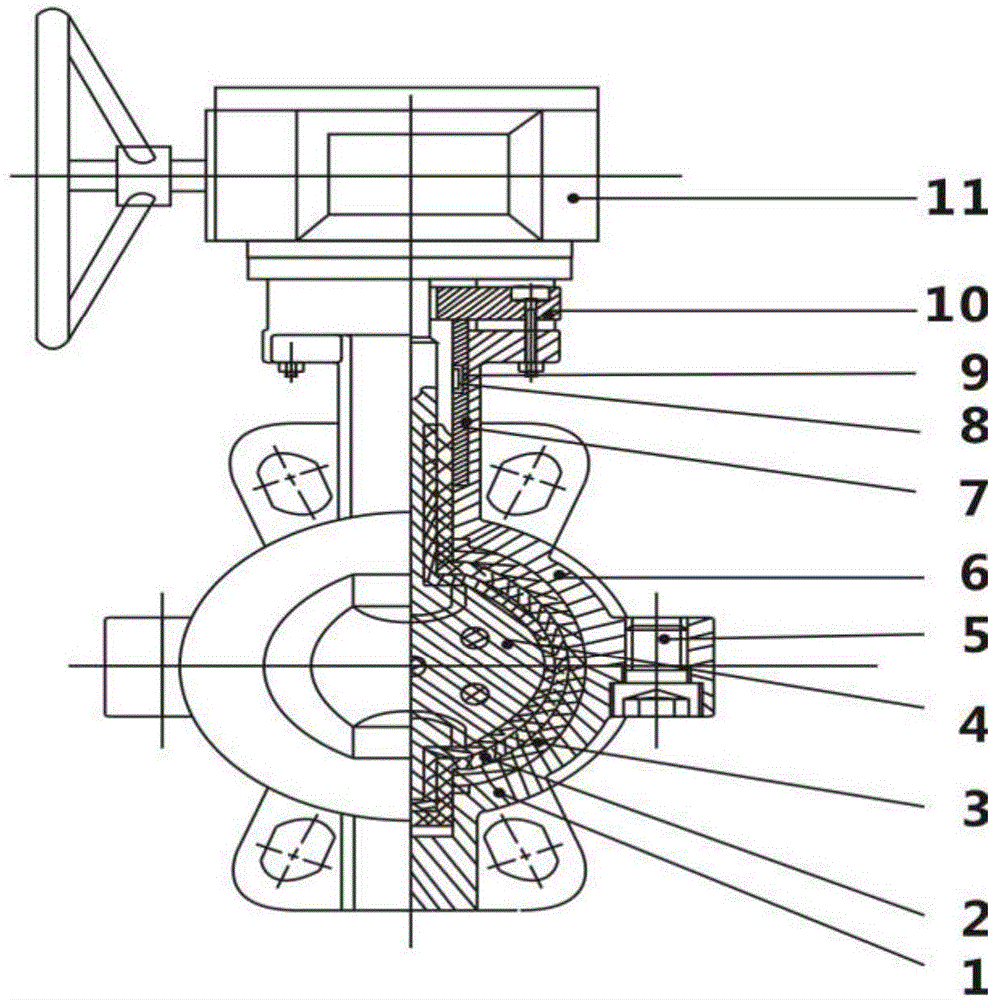

[0015] A fluorine-lined butterfly valve, including a lower valve body 1, a valve seat 2, a gasket 3, a butterfly plate 4, bolts 5, an upper valve body 6, a gland 7, valve body positioning teeth 8, gland positioning grooves 9, and a pressure plate 10 , the driving device 11, wherein the lower valve body 1 and the upper valve body 2 are fixed and tightened together by bolts 5, the valve seat 2 is embedded in the valve body, the gland 7 is welded to the upper part of the upper valve body 6, and the valve body positioning teeth 8 Set on the inner side of the gland positioning groove 9, the gland positioning groove 9 and the valve body positioning teeth 8 are welded to the side wall of the gland 7, the pressure plate 10 is fixed to the upper end of the gland 7 by bolts, and the driving device 11 is welded to the upper end of the pressure plate 10. The inner wall and outer surface of the upper valve body 6, the lower valve body 1 and the butterfly plate 4 are lined with polytetrafluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com