Automatic foot pad nut assembling and packaging automatic production line

An automatic production line and automatic assembly technology, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc., can solve the problems of low manual assembly efficiency and high manual packaging strength, and achieve the purpose of overcoming the low efficiency of manual assembly, shortening the working time, and pre-tightening Uniform force and tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

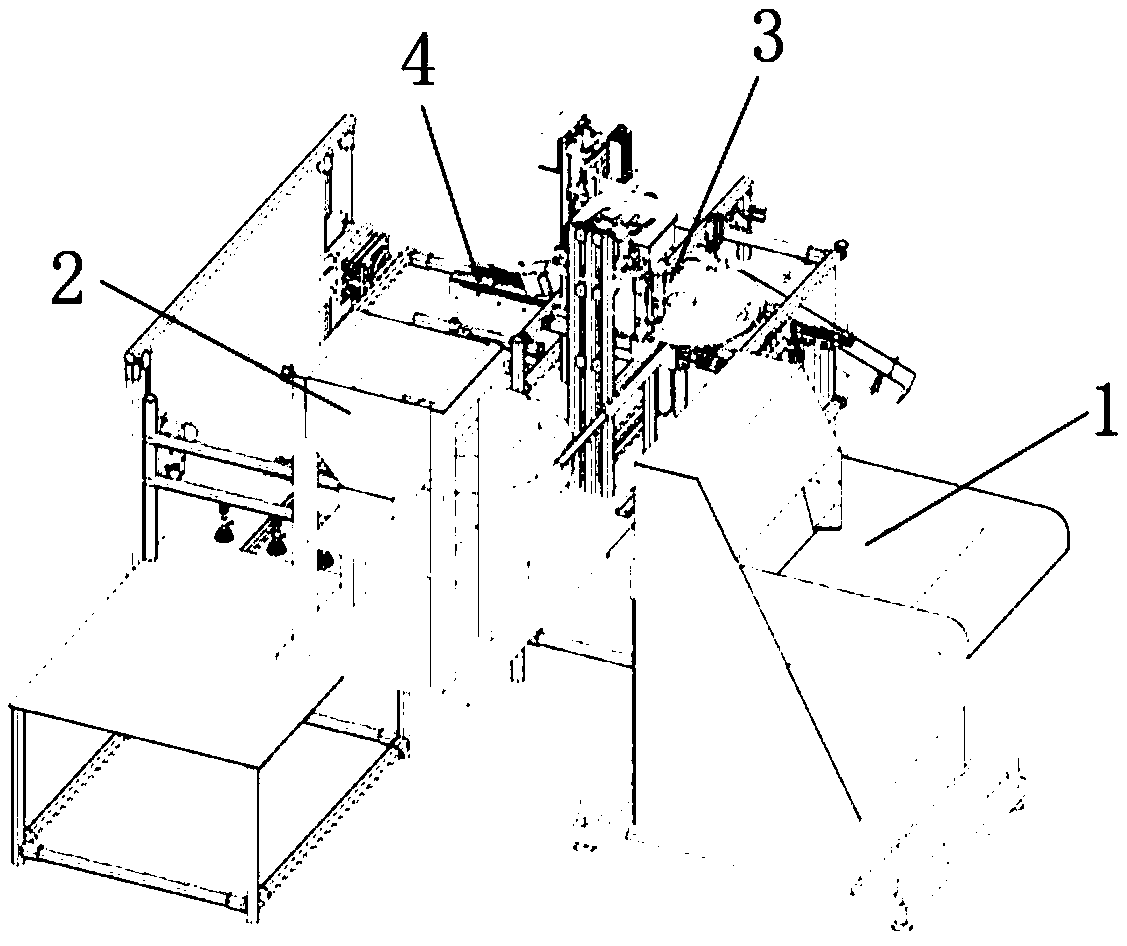

[0039] Such as figure 1 , an automatic production line for automatically assembling nuts and packing mats, the mat conveying system 1 and the nut conveying system 2 are connected with the nut tightening system 3, the nut tightening system 3 is connected with the bagging system 4, and the mat conveying system 1. The nut conveying system 2, the nut tightening system 3 and the bagging system 4 are all connected with the PLC control system 5.

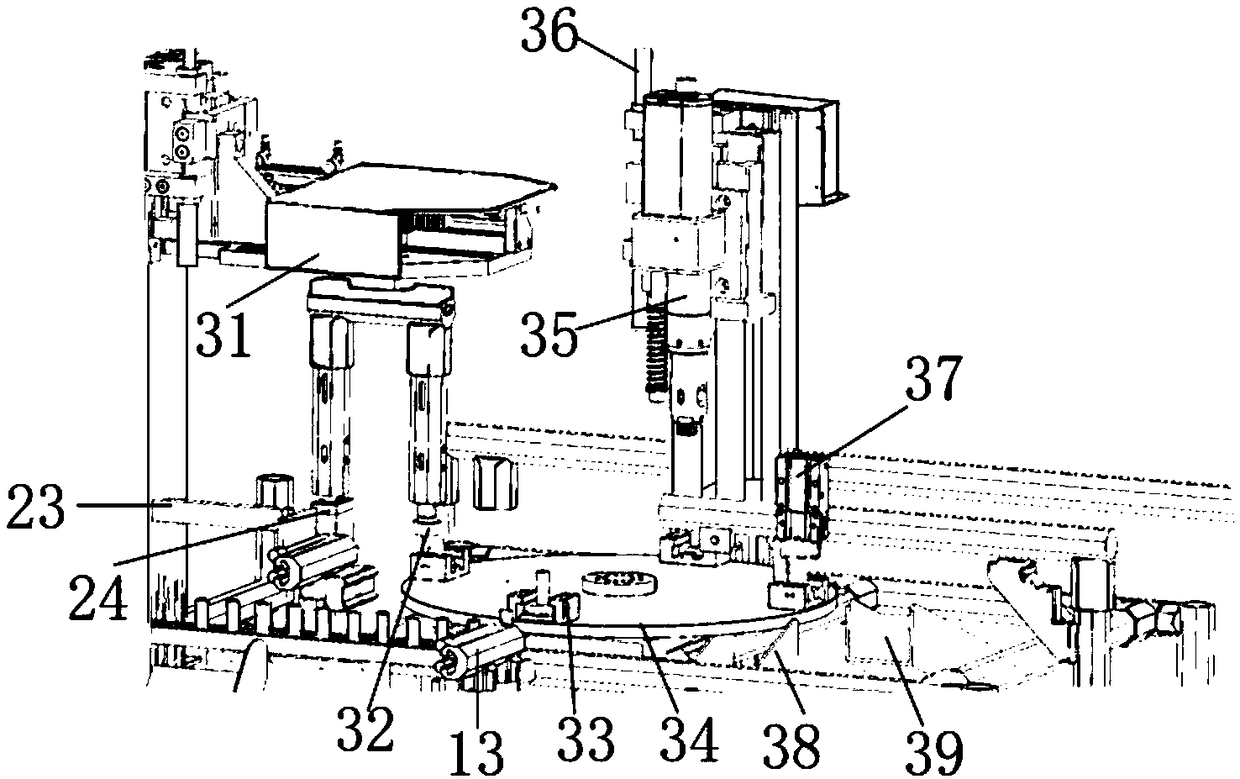

[0040] Such as image 3 , the above-mentioned nut tightening system 3 includes a nut pre-tightening assembly and a nut tightening assembly, and the nut pre-tightening assembly and the nut tightening assembly are fixedly arranged on adjacent positions on the frame of the automatic production line for automatically assembling nuts and packaging of the foot pads respectively; An assembly plate 34 is arranged under the nut pre-tightening assembly and the nut tightening assembly, and foot pad grooves 33 are arranged on the assembly plate 34. Th...

Embodiment 2

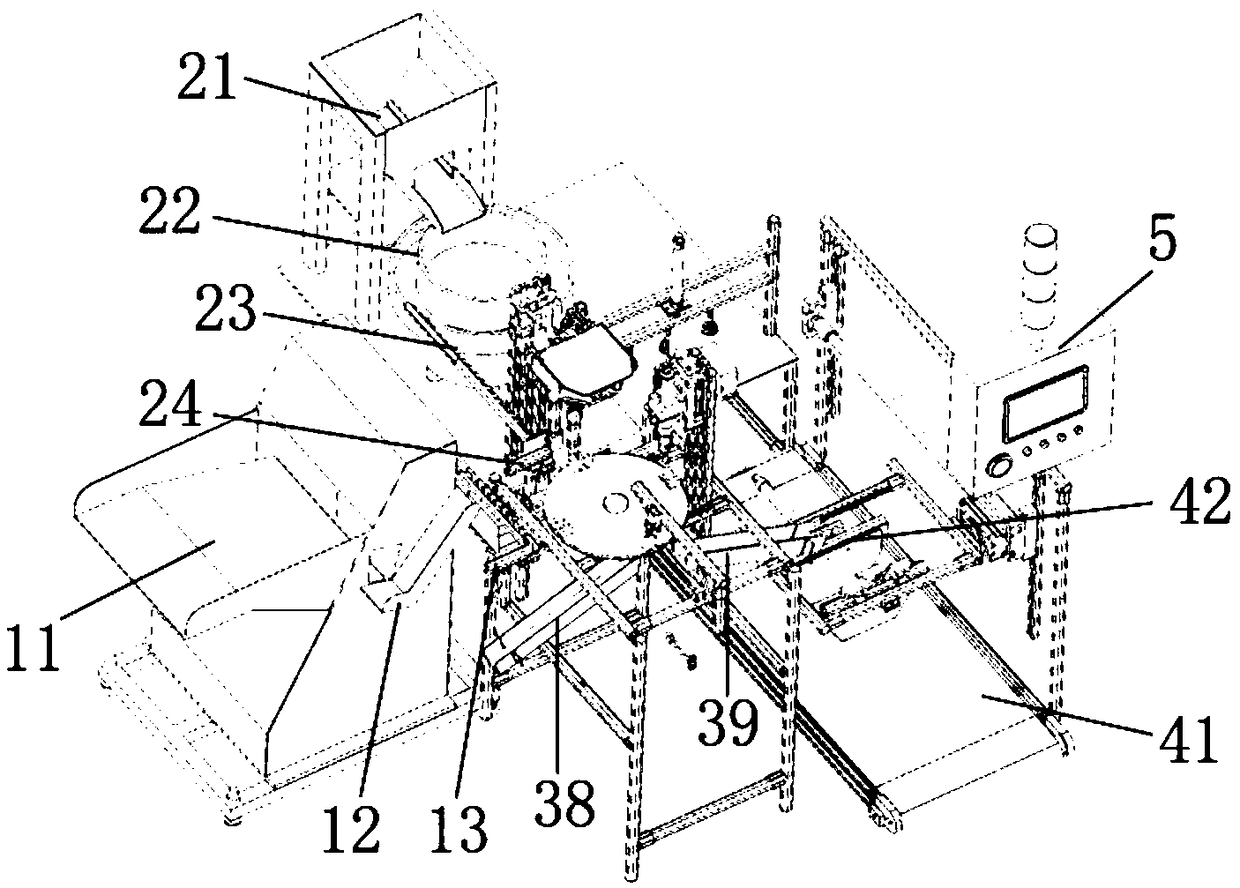

[0050] On the basis of Example 1, such as figure 2 , in the nut tightening system, the non-conforming product guide rail 38 and the qualified product guide rail 39 symmetrically distributed below the manipulator device 37 have been added. In addition, a sensor is set on the manipulator device 37, which can Detect whether the product is qualified, sense that the high-speed screw gun 35 reaches or fails to reach the torque and transmit it to the next process; if the sensor senses that the torque has reached, the manipulator device 37 will pick up the foot pad after receiving the signal and put it into the qualified product guide rail 39, Otherwise, it is put into the unqualified guide rail 38, and the qualified product guide rail 39 is provided with an infrared induction counter, which can accurately count the products, thereby ensuring the quality and quantity of each bag of products during bagging, and further improving The production efficiency of the automatic production li...

Embodiment 3

[0052] On the basis of Example 1, such as image 3 , the number of pre-twist suction nozzles 32 can be adjusted flexibly. If the production efficiency is not high, setting one pre-twist suction nozzle 32 can successfully complete the automatic production work of automatic assembly nuts and packaging of foot pads; if the production efficiency When the requirements are relatively high, the number of pre-twisting nozzles 32 can be increased according to the conditions. The following takes two pre-twisting nozzles as an example to introduce its setting method and working process:

[0053] Below the rotating device 31, two pre-twist suction nozzles 32 are symmetrically arranged. After the nut enters the nut slot 24, it is sucked by one of the pre-twist suction nozzles 32, and rotates to the foot pad slot 33 to pre-twist with the foot pad to prevent The nut is crooked, and another pre-twist suction nozzle 32 sucks the nut at the same time, and both sides move at the same time, reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com