Pipeline heat tracing device

A thermal device and pipeline technology, applied in pipeline protection, protection of pipelines through thermal insulation, heat exchange equipment, etc., can solve the problems of low installation accuracy, huge device volume, low installation efficiency, etc., and achieve weight reduction and cost reduction. , The effect of uniform tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following examples.

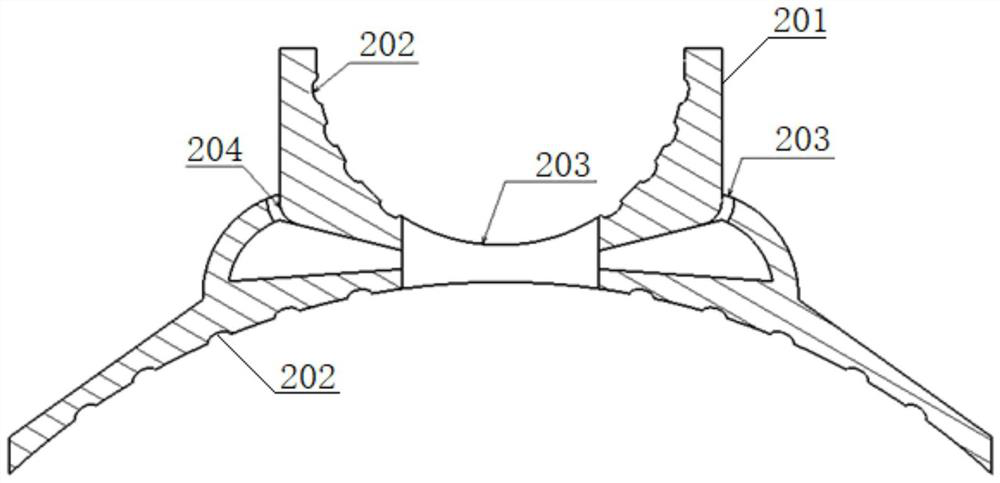

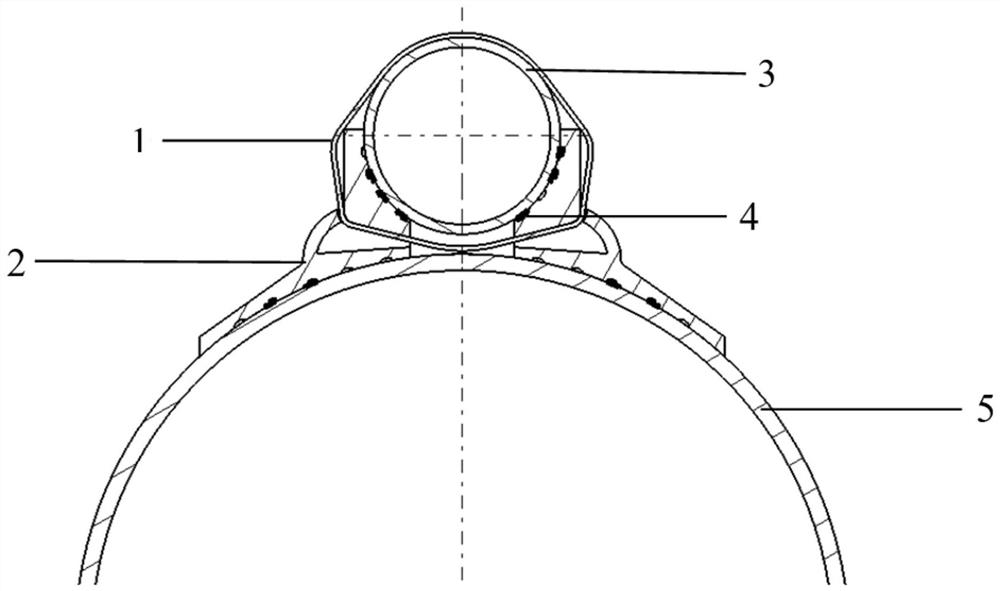

[0018] Such as figure 1 and 2 As shown, the pipe heating device 2 is arranged between the heating pipe 3 and the heated pipe 5, and is closely attached to the two; the outer surface of the pipe heating device 2 is provided with a convex structure 201, and There is a reserved hole 203 for the metal strap 1 to pass through; there is a stress point 204 between the convex structure 201 and the metal strap 1, and the convex structure 201 squeezed by force is between the metal strap 1 and the stressed Under the synergistic effect of the force points 204, local deformation occurs, so that the pipeline heating device 2 and the heating pipeline 3 are tightly connected and closel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com