Assembly machine provided with brush hose

An assembly machine and brush technology, which is used in the field of hose assembly machines, can solve the problems of the cap and the nozzle being screwed too tightly, too loosely, and cannot be brushed, so as to ensure assembly quality and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

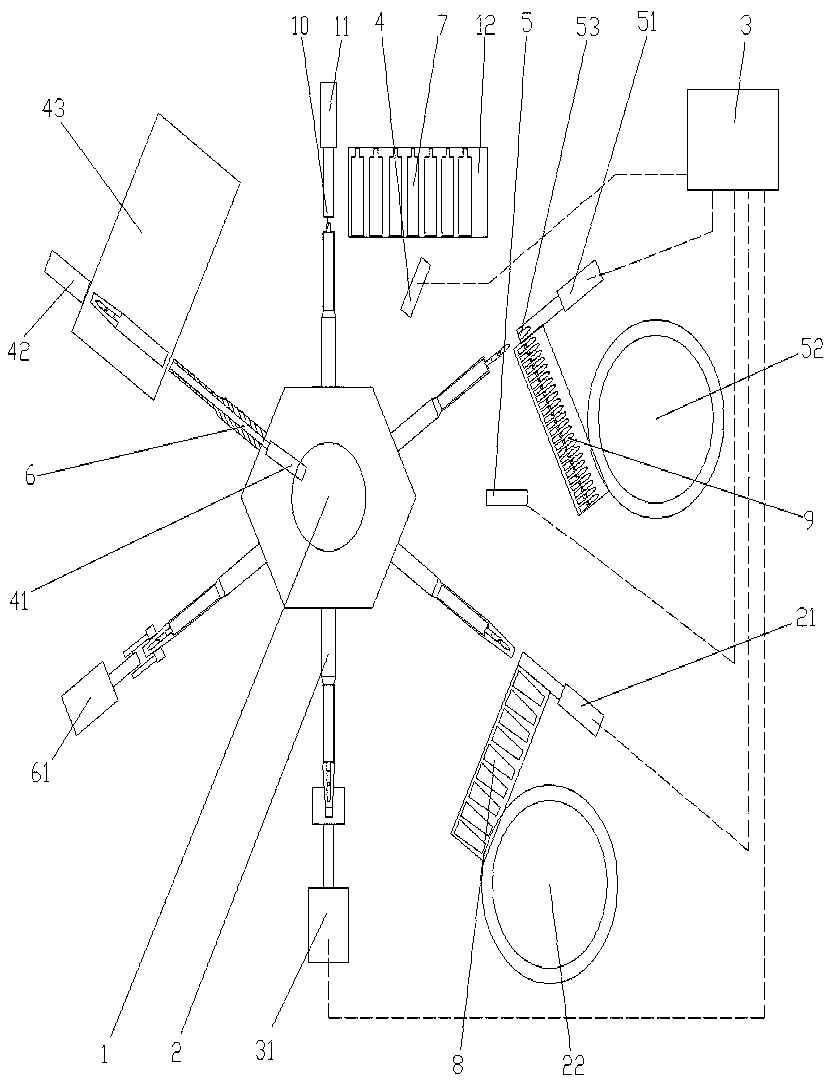

[0010] Such as figure 1 As shown, the present invention discloses an assembly machine with a brushed hose, comprising a turntable 1, a plurality of casing rods 2 are arranged on the periphery of the turntable 1, and the axis of the casing rod 2 It has a hollow air blowing cavity 6, and usually the casing rod 2 is evenly distributed along the periphery of the turntable 1 with the center of the turntable 1 as the center, and a tube sleeve is arranged on the periphery of the turntable 1 in turn. mechanism, a pipe cover insertion mechanism, a pipe cover screw-in mechanism and a pipe removal mechanism, the pipe body insertion mechanism is mainly used to insert the hose body 7 onto the sleeve rod 2, and the pipe cover The mechanism is mainly used to insert the cap 8 onto the nozzle 10 of the hose, the cap screwing mechanism is mainly used to tighten the cap 8 on the nozzle 10 of the hose, and the detachment mechanism is mainly used to screw the cap on The hose of 8 is disengaged fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com