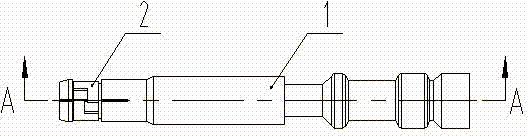

Female pin for cable connector

A technology of cable connectors and female plugs, which is applied in the field of connector pins, can solve problems such as poor contact, reduced clamping force, and short service life of cable connectors, and achieves the effects of easy processing and avoiding poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

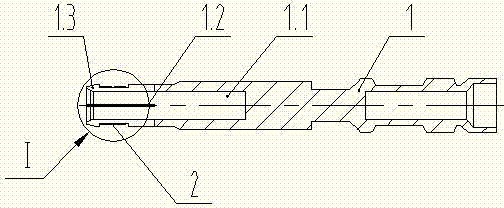

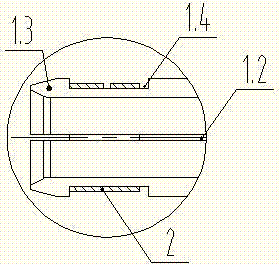

[0024] The female pin used for the cable connector shown in the accompanying drawings includes a cylindrical terminal body 1 and an elastic tightening device 2. The end of the terminal body 1 is provided with an inner hole 1.1, and the wall of the inner hole 1.1 is provided with a number of The axial straight groove 1.2 starting from the end forms the clamping jaw 1.3 arranged along the circumferential direction; the outer wall of the clamping jaw 1.3 is provided with a ring groove 1.4; the elastic tightening device 2 is set on the outer wall of the ring groove 1.4 to tighten the clamping jaw 1.3.

[0025] The elastic tightening device 2 is an open elastic metal sleeve with an opening on the side wall, and the opening on the side wall is stepped (in other embodiments, the opening on the side wall can be staggered in other forms along the axial direction).

[0026] In this embodiment, the elastic tightening device 2 is made of beryllium copper (in other embodiments, the elastic ...

Embodiment 2

[0028] This embodiment is the same as Embodiment 1 except the elastic tightening device 2 .

[0029] In this embodiment, the elastic tightening device 2 is a non-metallic elastic ring.

Embodiment 3

[0031] This embodiment is the same as Embodiment 1 except the elastic tightening device 2 .

[0032] In this embodiment, the elastic tightening device 2 is a non-metallic elastic sleeve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com