Magnetic steel used for permanent-magnet direct drive wind power generator

A wind turbine, permanent magnet direct drive technology, applied in the field of magnetic steel, can solve the problems of large centrifugal force, large pulsation loss, complex claw pole structure, etc., to prevent falling off and oxidation, strong mechanical structure strength, and low precision requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

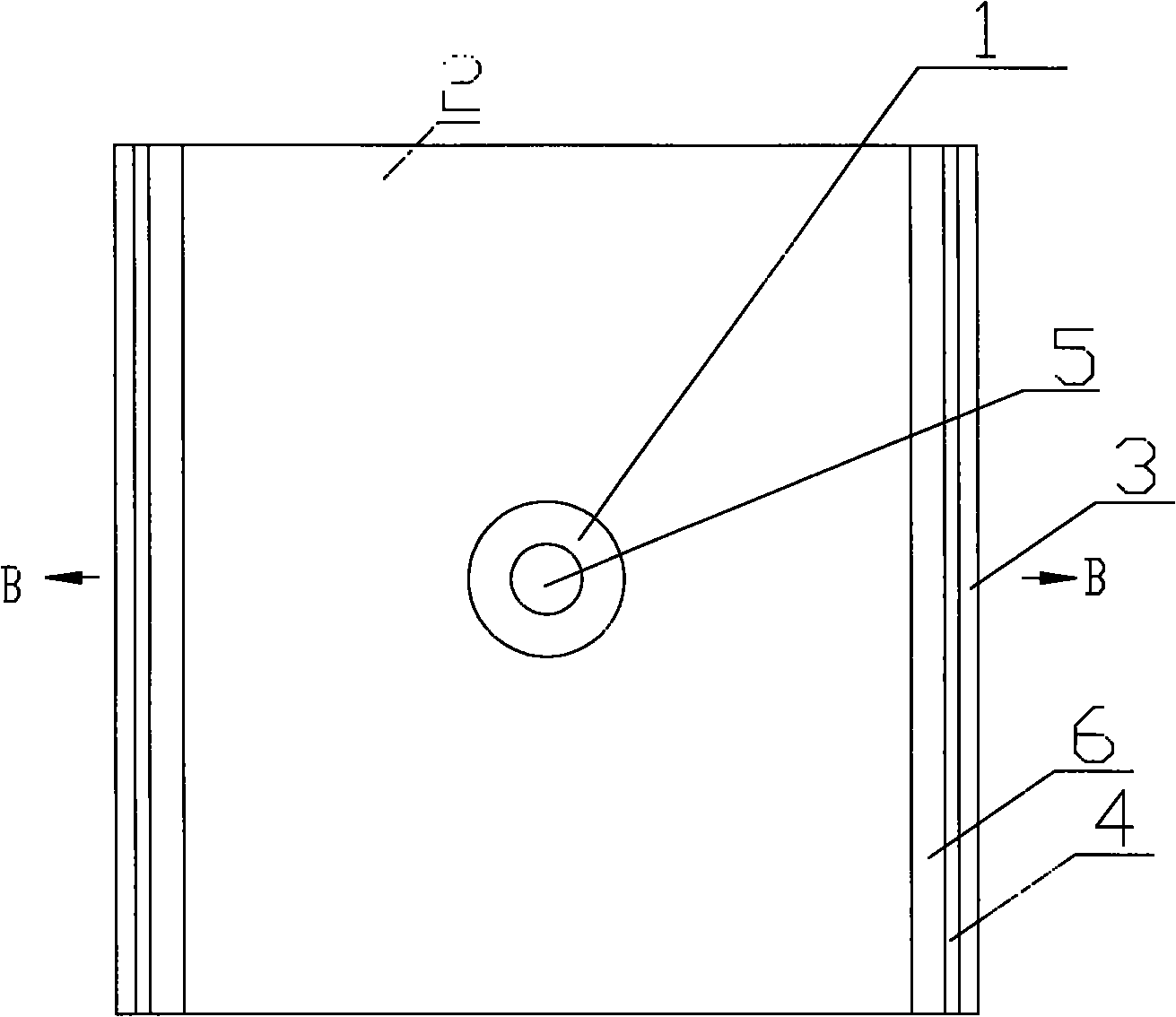

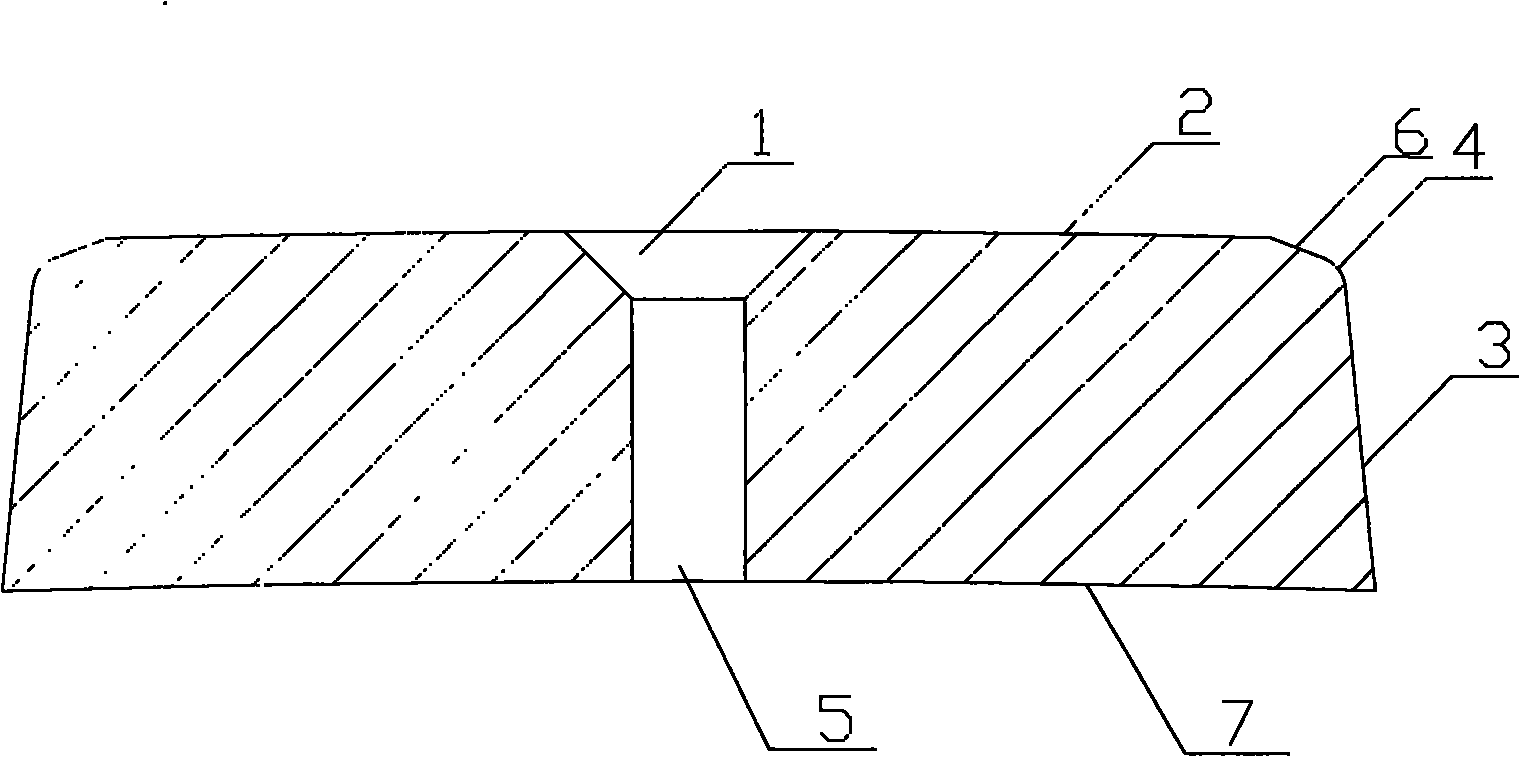

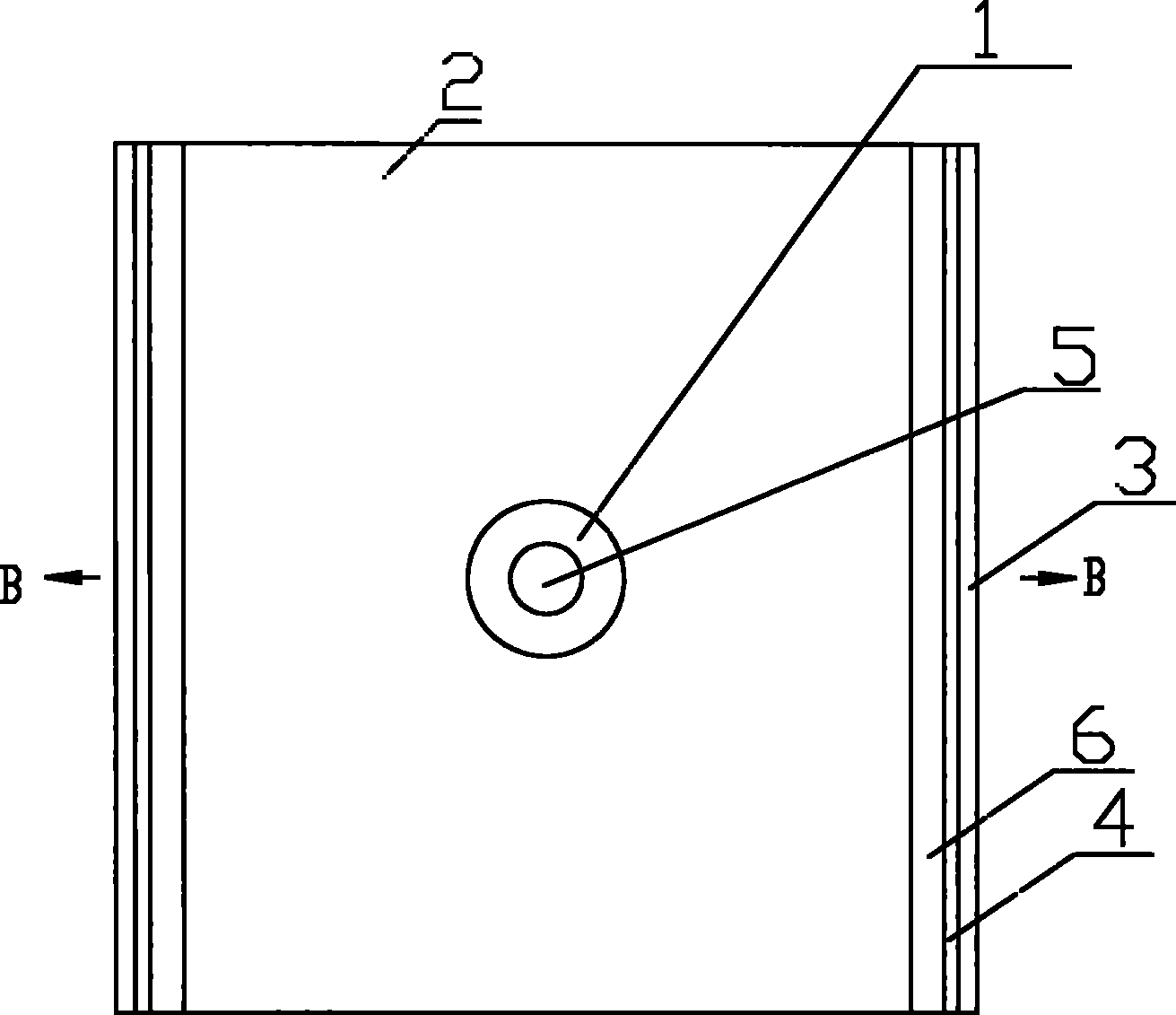

[0033] Such as figure 1 , figure 2 As shown, a magnet for permanent magnet direct-drive wind power generators, the magnet has a rectangular cross section with a through hole in the center, its upper surface 2 is arched, the lower surface 7 is arched, and the sides include 6 on the upper side, 4 on the middle side and 3 on the lower side. The through hole includes an upper part 1 and a lower part 5, wherein the upper part 1 is a rounded frustum, and the lower part 5 is a cylinder. The arched arcs of the upper surface 2 and the lower surface 7 have the same diameter. The upper side 6 is rectangular. The middle side 4 is arched. The lower side 3 is rectangular.

[0034] There is a through hole at the center of the magnetic steel that can be fixed with a countersunk screw, and it is viewed as a rectangle from above and below. The bottom surface has the same arc as the rotor outer circle radius, and the side is arc-shaped. The surface of the magnetic steel is galvanized.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com