Device and method for reducing machining deformation of heat exchange fin

A technology for processing deformation and heat exchange fins, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of easy deformation of heat transfer fins, achieve the effects of reducing processing deformation, improving work efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

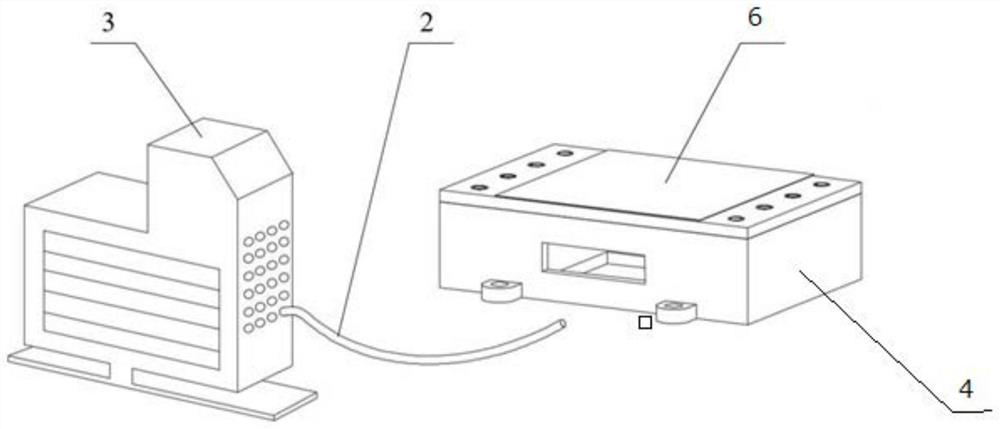

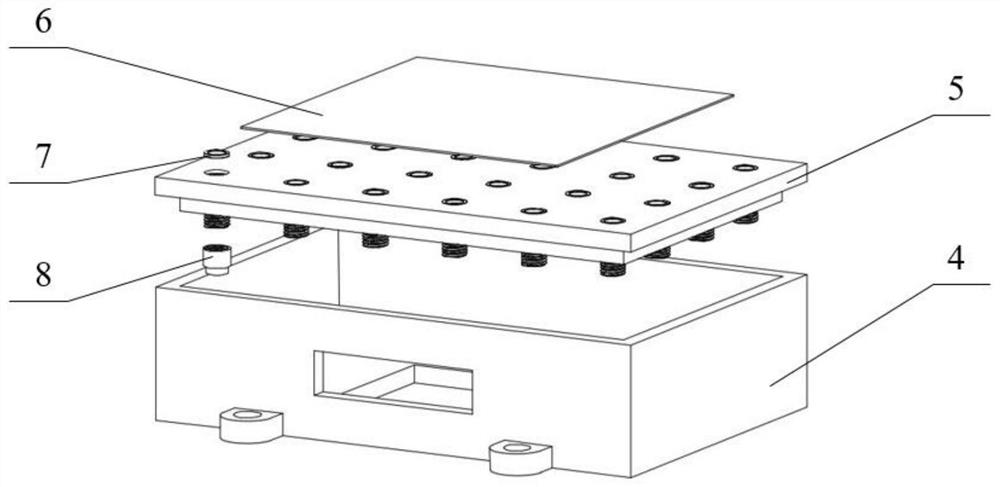

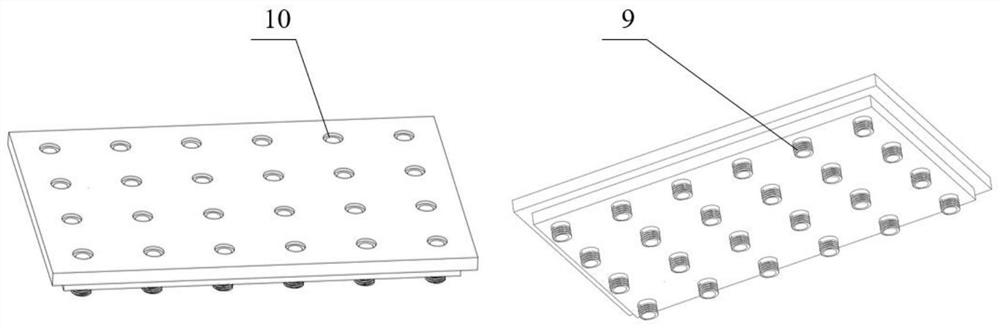

[0046] A device for reducing processing deformation of heat exchange fins, the device includes a base 4, a support plate 5, and a vacuum pump, the base is rectangular, the support plate 5 is arranged above the base 4, and 60 pipes are arranged on the support plate 5 10. The pipeline 10 is a circular pipeline, one end of the pipeline 10 is flush with the surface of the support plate 5 , and the other end is sealed and connected with the vacuum device 3 . The material of the base 4 is No. 45 steel with good comprehensive mechanical properties, and the material of the support plate 5 is aluminum alloy. The heat exchange fin blanks 6 are placed above the pipes 10 on the support plate 5 and cover the upper openings of 20 pipes 10 , that is, the pipes 10 covered by the heat exchange fin blanks 6 are connected to the vacuum pump 3 .

Embodiment 2

[0048]On the basis of Embodiment 1, the pipeline 10 is airtightly connected with the vacuum pump 3 through the vacuum hose 2 . The pipeline 10 is connected to the vacuum hose 2 through a hose connection sleeve 8, the hose connection sleeve 8 is a stepped sleeve, the large-diameter end of the hose connection sleeve is connected to the pipeline thread, and the small-diameter end is connected to the pumping hose 2. Vacuum hose socket. The side wall of the base 4 is provided with a hose outlet, and the vacuum hose 2 passes through the hose outlet 15 and is connected to the pipeline 10 .

[0049] The support plate 5 is adapted to the size of the base 4 and is inlaid and sealed. A sealing ring 7 matching the caliber of the pipeline 10 is provided at the opening above the pipeline 10. A cooling liquid storage tank 13 is provided at the bottom of the base 4. The cooling liquid containing groove 13 is arranged below the heat exchange fin blank.

[0050] In another aspect, the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com