Dried type clamp for quilting and grinding air cylinder sleeve

A cylinder liner, quilting grinding technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of low processing efficiency, difficult loading and unloading, inability to load and unload, etc., and achieve the effect of high processing precision and small processing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

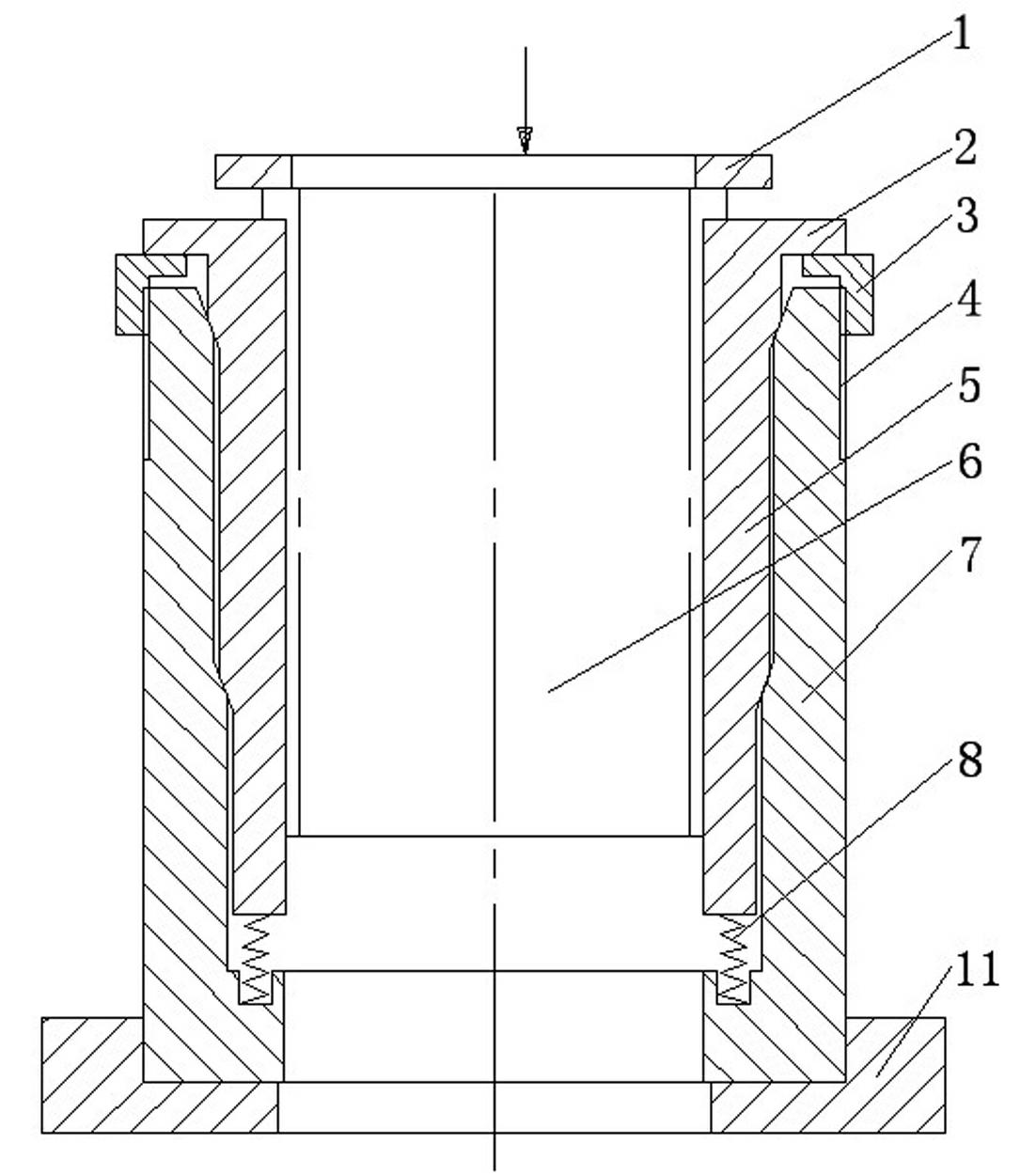

[0019] A dry cylinder liner honing fixture, such as figure 1 As shown, it includes a spring sleeve 5 , a fixed outer sleeve 7 , a positioning seat 11 and a spring 8 .

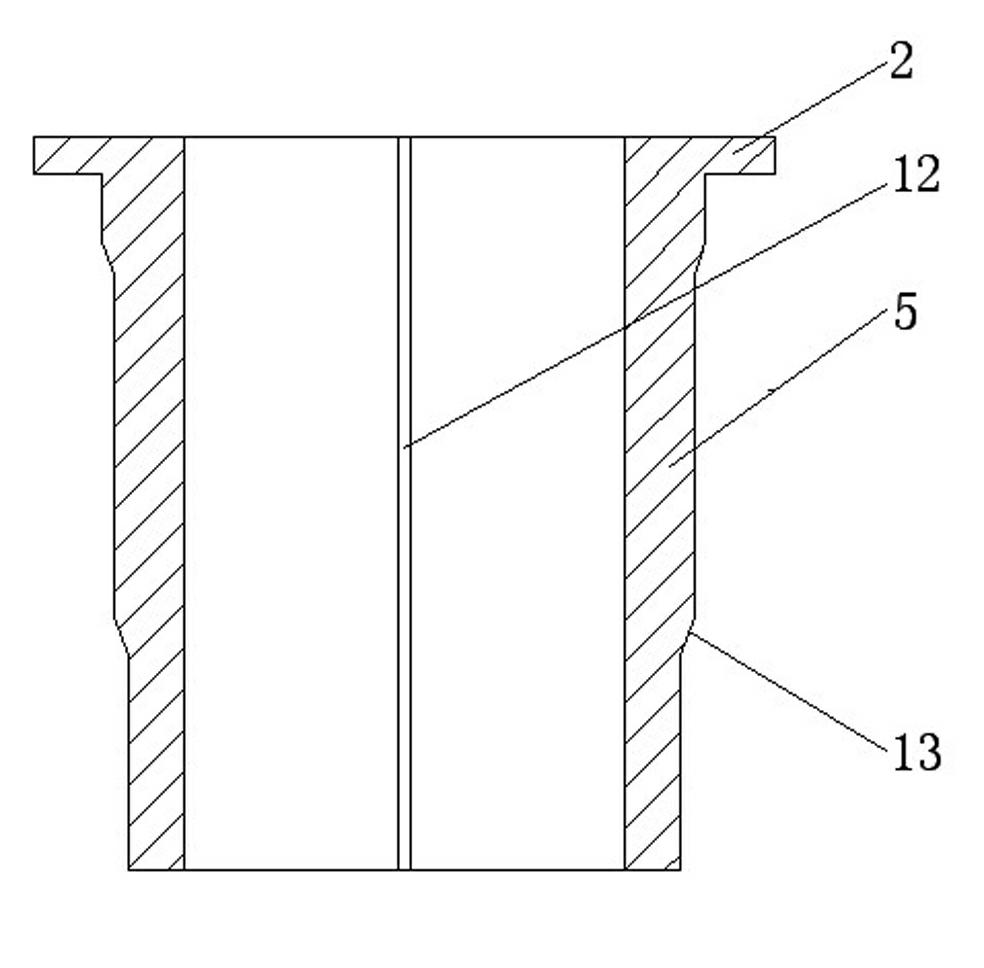

[0020] The structure of spring cover 5 is as figure 2 , the top of the spring sleeve 5 is provided with the spring sleeve boss 2, the outer circular surface of the spring sleeve 5 is provided with two outer conical surfaces 13, and the spring sleeve 5 is provided with an opening 12 with a width of 3mm along a busbar.

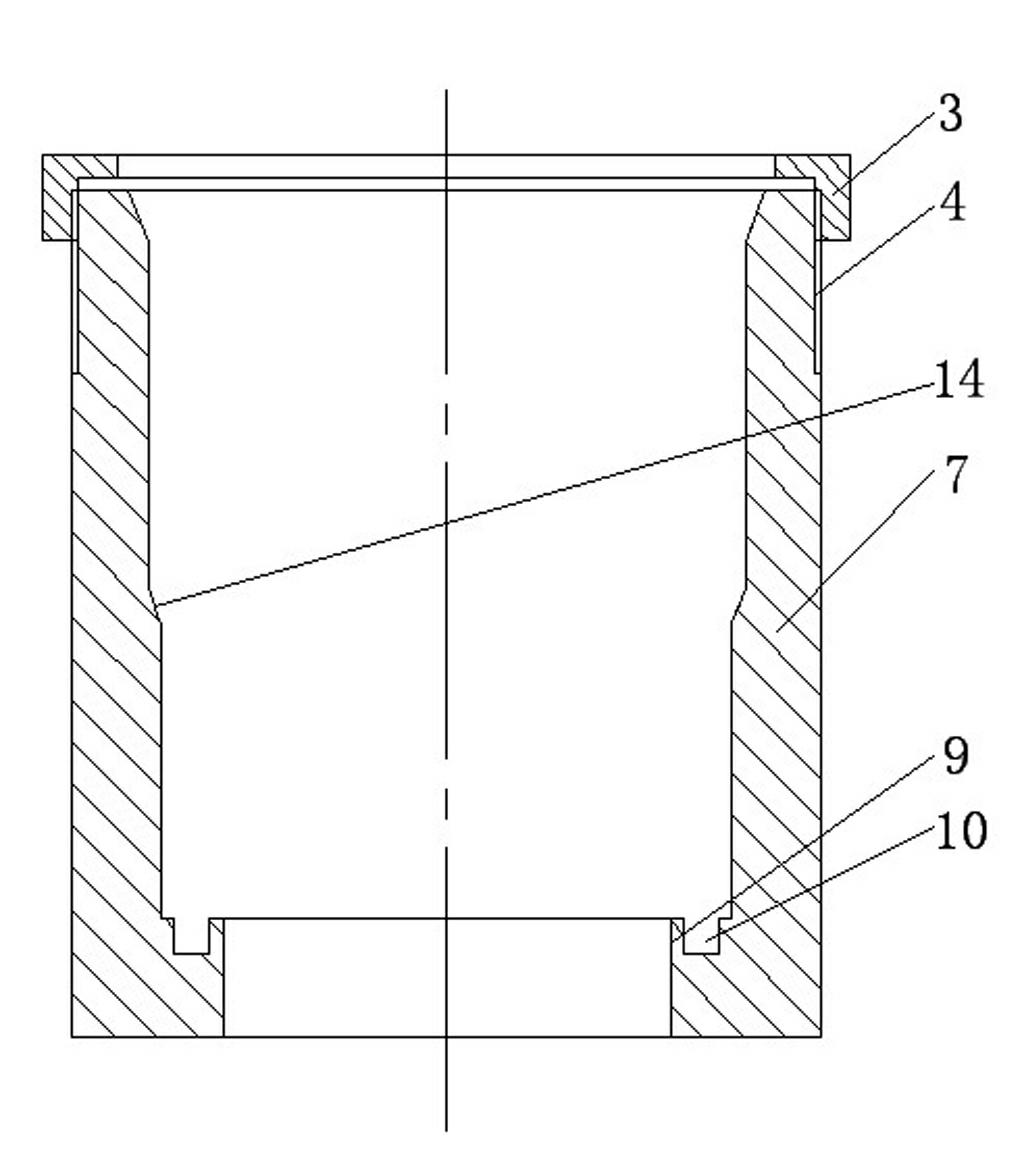

[0021] The structure of the fixed coat 7 is as image 3 , on the inner circular surface of fixed overcoat 7, be provided with two inner conical surfaces 14 matched with the outer conical surface 13 of the outer circular surface of spring sleeve 5, the outer circular surface above fixed overcoat 7 is provided with screw thread 4, thread 4 Adjustment nut 3 is arranged out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com