Glass plate stack, and method of extracting glass plate

A technology of glass plates and laminates, applied to impact-sensitive items, internal frames, rigid containers, etc., can solve problems such as broken wires and poor pattern formation, and achieve the effect of smooth removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, preferred embodiments of the glass plate laminate and the glass plate taking-out method of the present invention will be described in detail with reference to the drawings. It should be noted that, in this specification, "above" means vertically above, and "below" means vertically below.

[0037] In the following embodiments, the paper 14 is illustrated as a sheet.

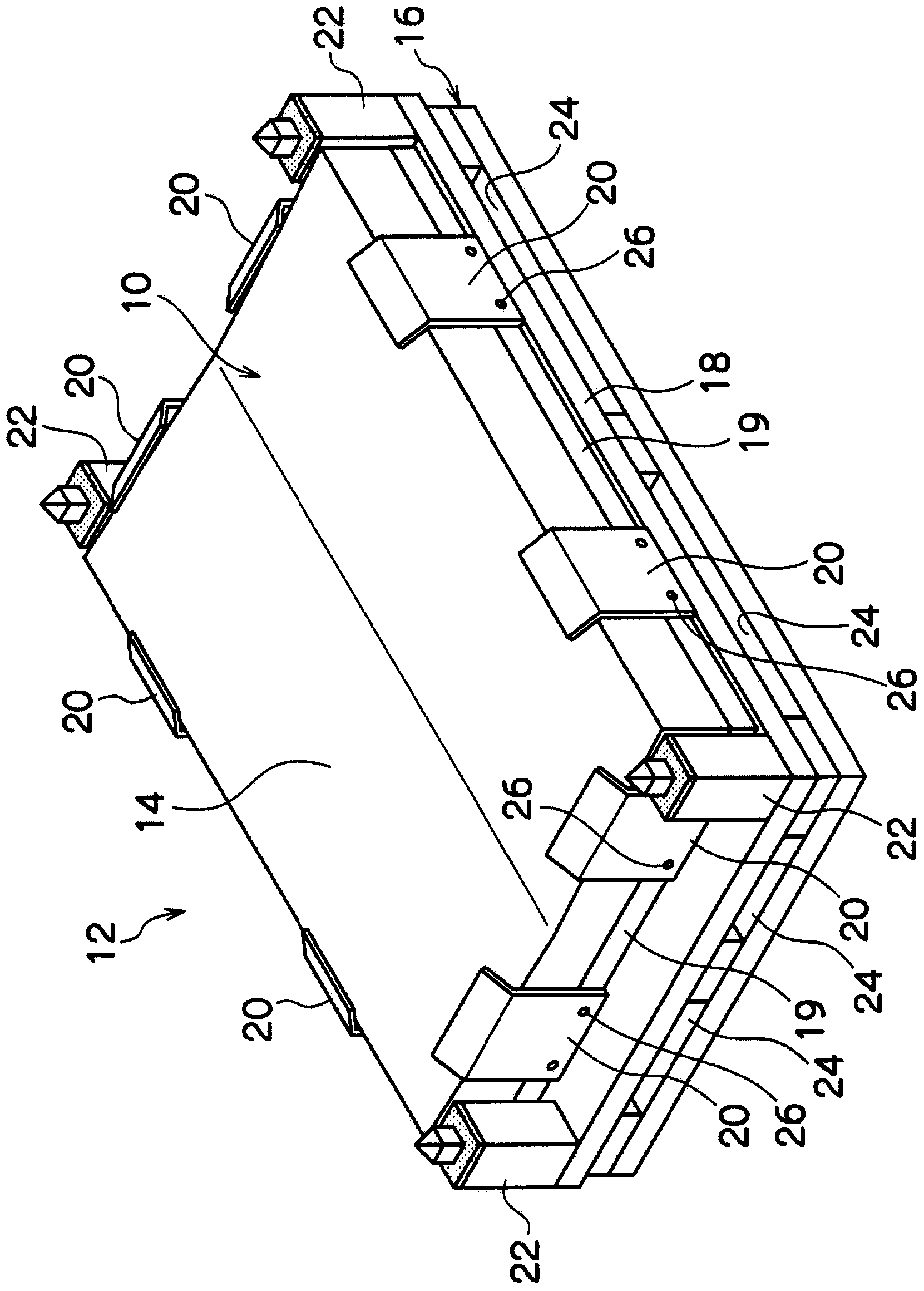

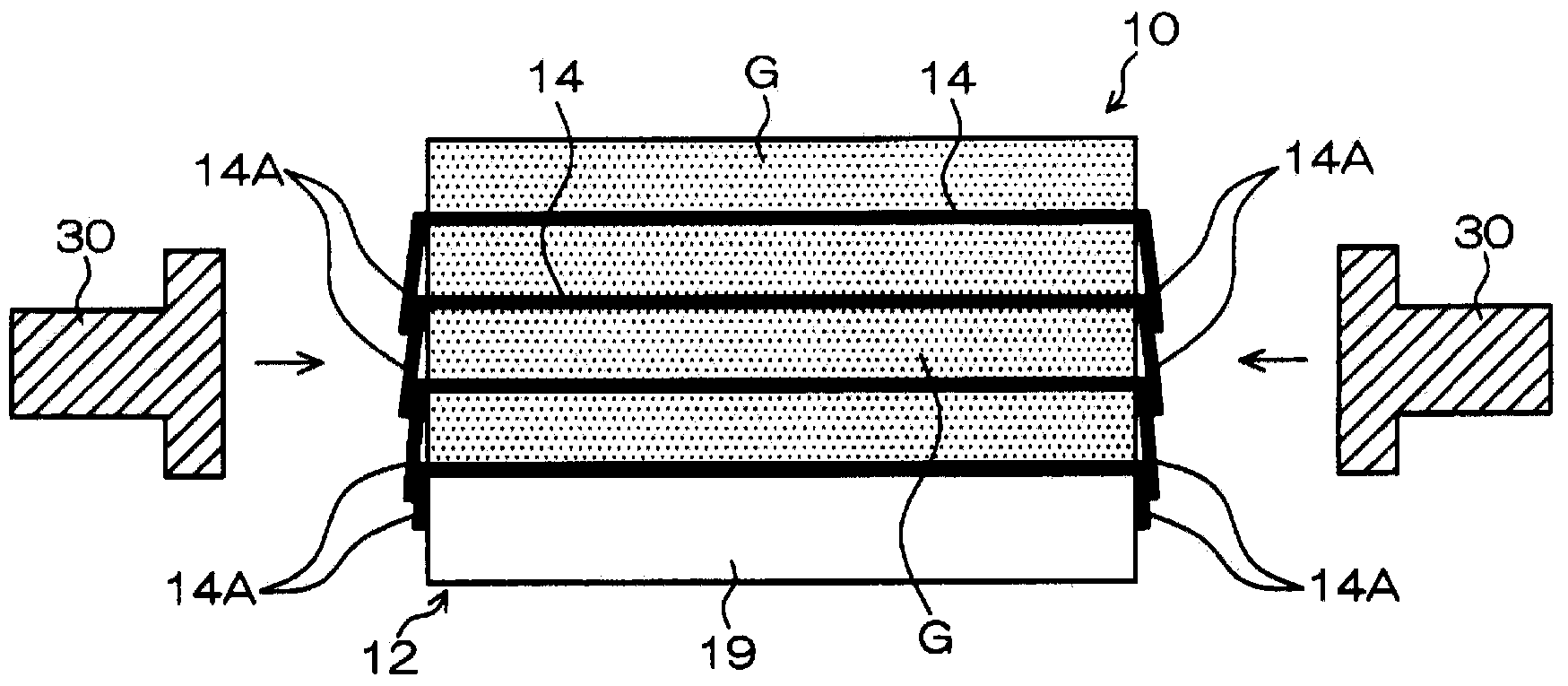

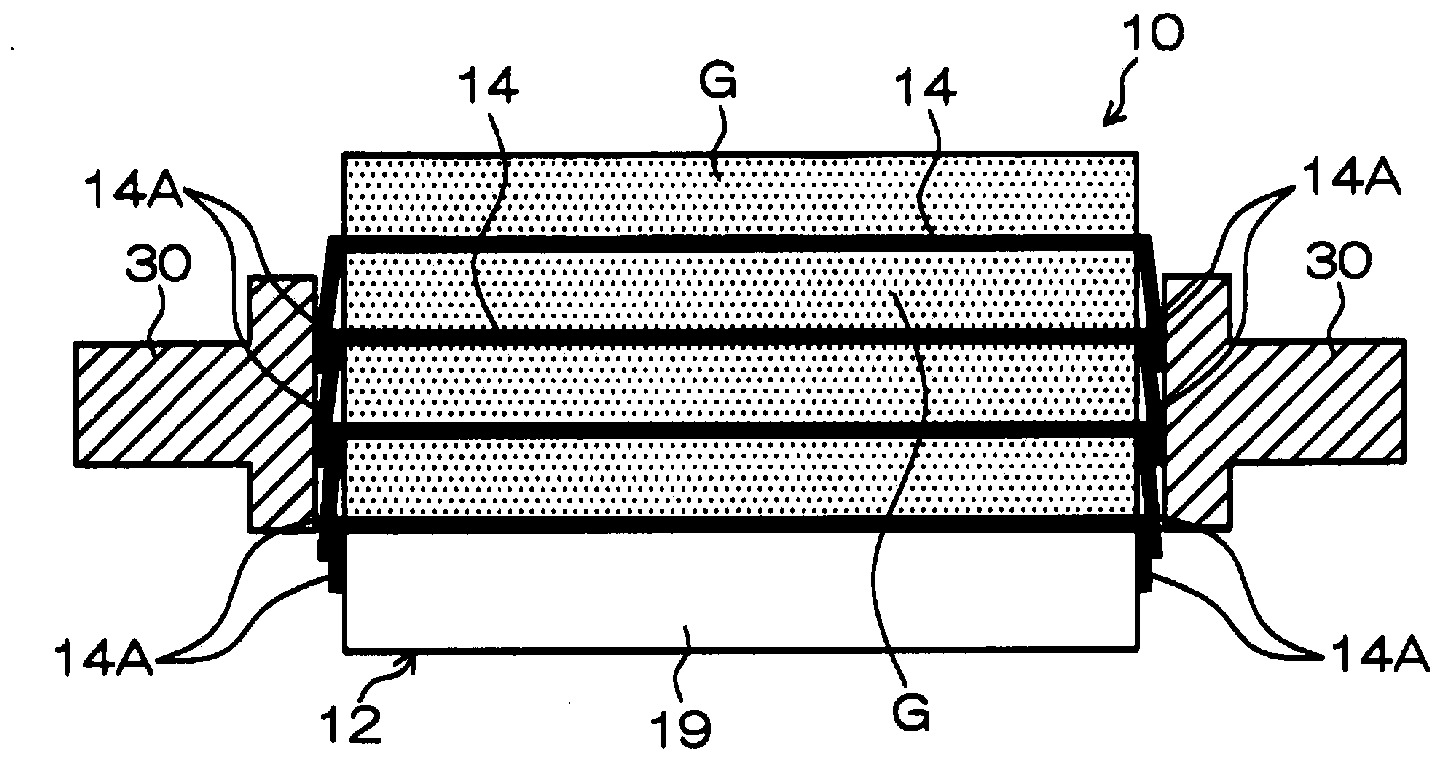

[0038] figure 1 It is an external view of the packaging pallet 12 which packs the glass plate laminated body 10 which concerns on embodiment horizontally. and, Figure 2-8 It is a schematic diagram explaining the take-out procedure of the glass plate G of the glass plate laminated body 10 packaged in the packaging pallet 12, and the paper 14 in chronological order.

[0039] exist figure 1 In the shown packaging pallet 12, a plurality of (for example, 80 to 150) rectangular shaped glass plates G, G... (refer to figure 2 ) is substantially horizontal, and sandwiches rectangular papers 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com