Amorphous metal extrusion die capable of rapidly replacing die core, and extrusion process thereof

A technology of amorphous metals and extrusion dies, applied in the direction of metal extrusion dies, etc., can solve problems affecting the forming accuracy of parts, failure of forming process, oxidation of amorphous alloy parts, etc., to improve cooling speed and ensure surface dimensional accuracy and surface quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

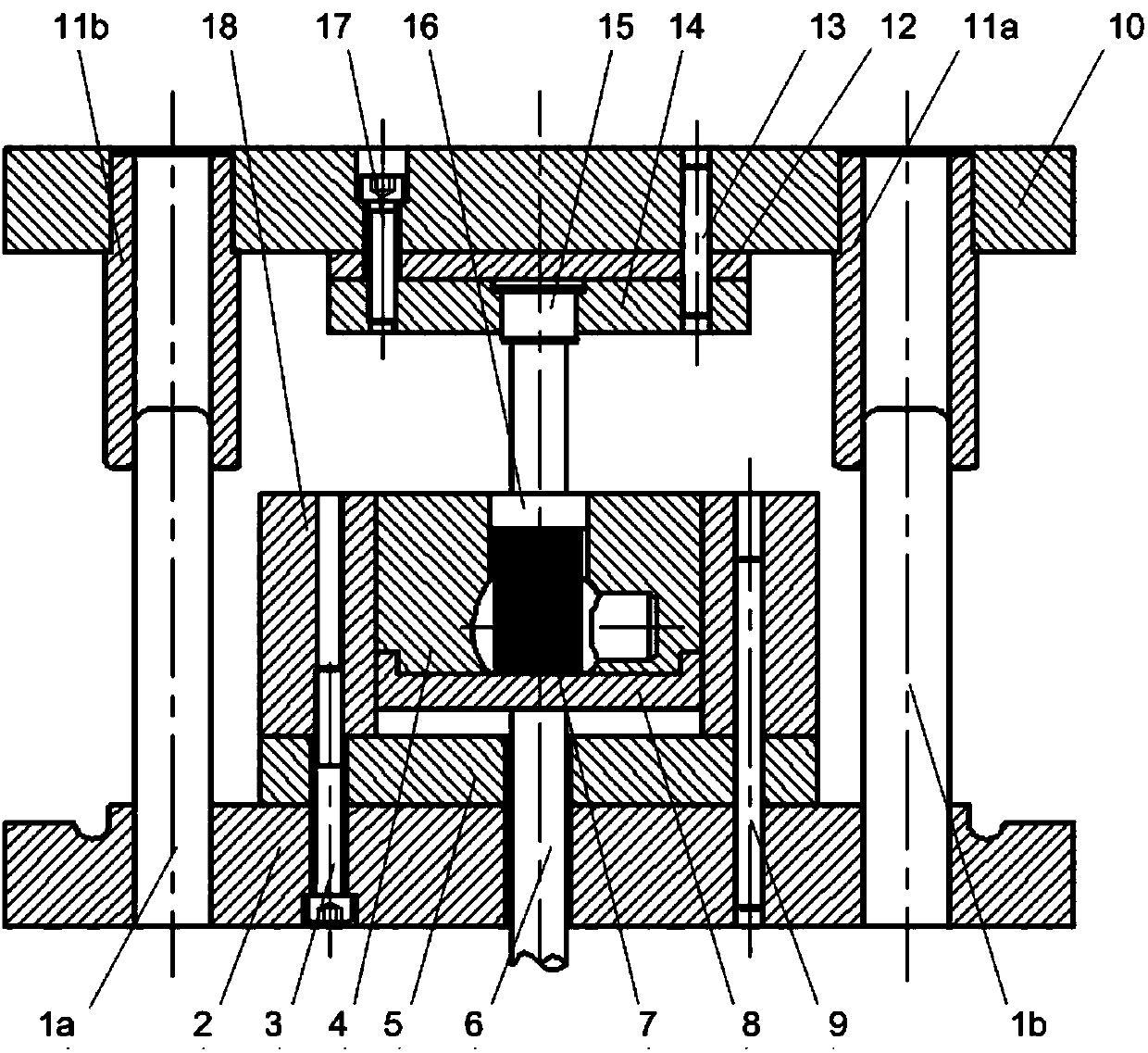

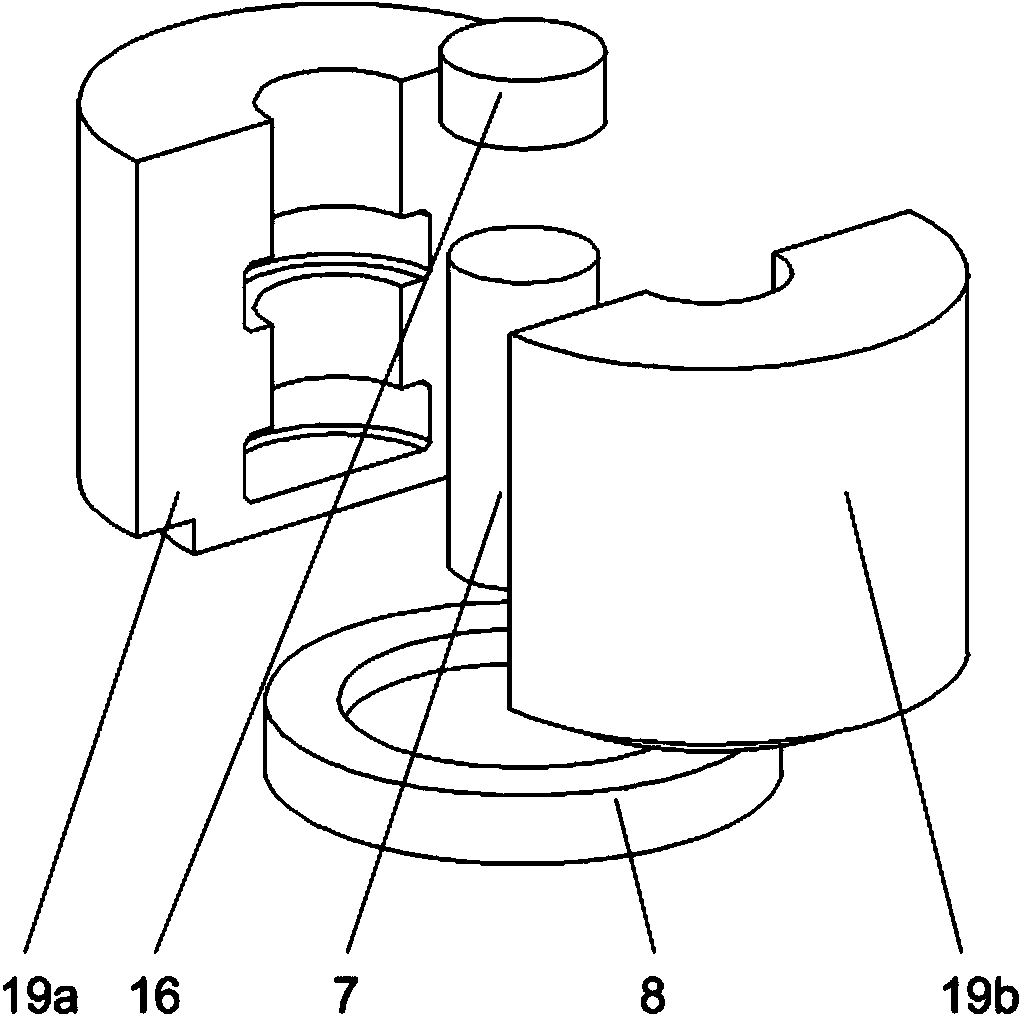

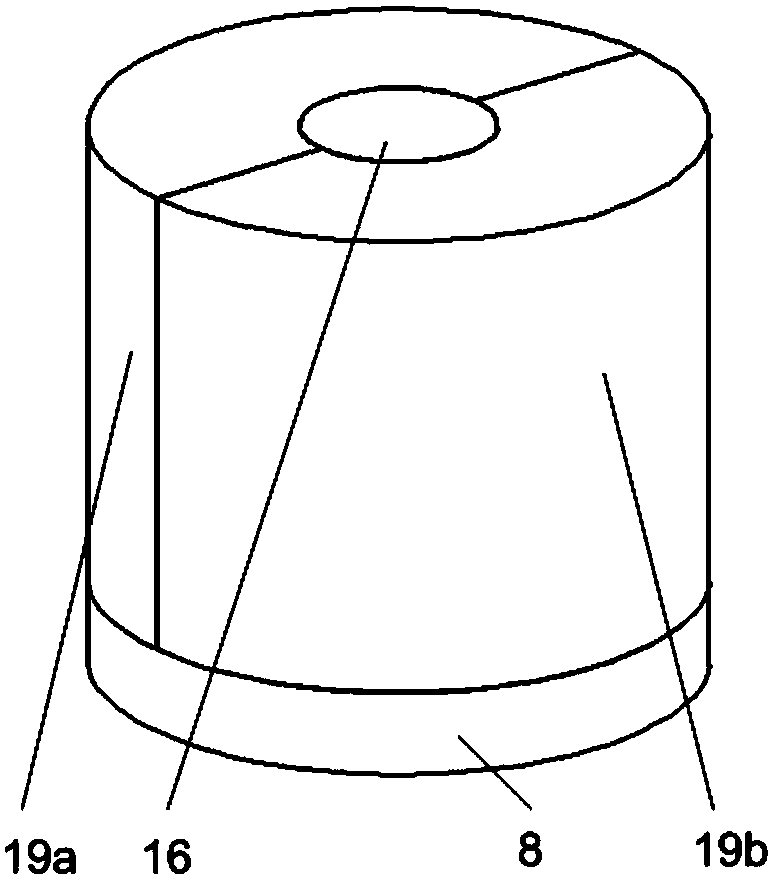

[0056] Example 1: Split-type composite mold core with stepped shaft, such as Figure 2-6 , the core cavity is a stepped shaft.

[0057] The amorphous alloy is Zr58.5Cu15.6Ni12.8Al10.3Nb2.8, and the glass transition temperature and crystallization temperature are 385℃ and 470℃, respectively. When the heating temperature of the amorphous alloy is 405° C., the temperature can be kept for 30 minutes without crystallization, which can meet the requirements of the process. During the heating process, the heating temperature of the box-type resistance furnace was set at 403° C. to 407° C., and the heating time was 20 minutes. The protective atmosphere is argon. The material of the combined core is H13 hot work die steel. The cooling medium is quenching oil.

Embodiment 2

[0058] Example 2: The split-type composite mold core of the three-pin shaft, such as Figure 7-11 , the core cavity is three-pin shaft.

[0059] The amorphous alloy is Zr58.5Cu15.6Ni12.8Al10.3Nb2.8, and the glass transition temperature and crystallization temperature are 385℃ and 470℃, respectively. When the heating temperature of the amorphous alloy is 405° C., the temperature can be kept for 30 minutes without crystallization, which can meet the requirements of the process. During the heating process, the heating temperature of the box-type resistance furnace was set at 403° C. to 407° C., and the heating time was 20 minutes. The protective atmosphere is argon. The material of the combined core is H13 hot work die steel. The cooling medium is quenching oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com