Resin-sand combined mold protection device and method

A protection device and resin sand technology, which is applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve problems such as fire escape, and achieve the effects of uniform force, simple operation, and easy sand cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

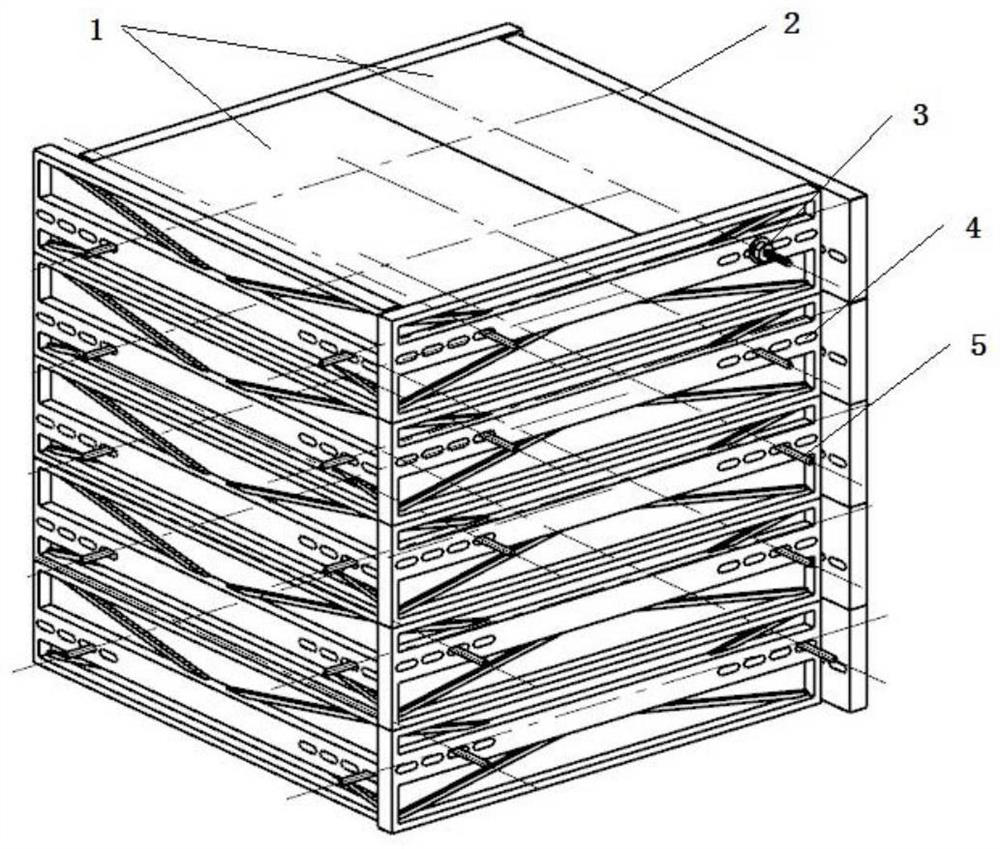

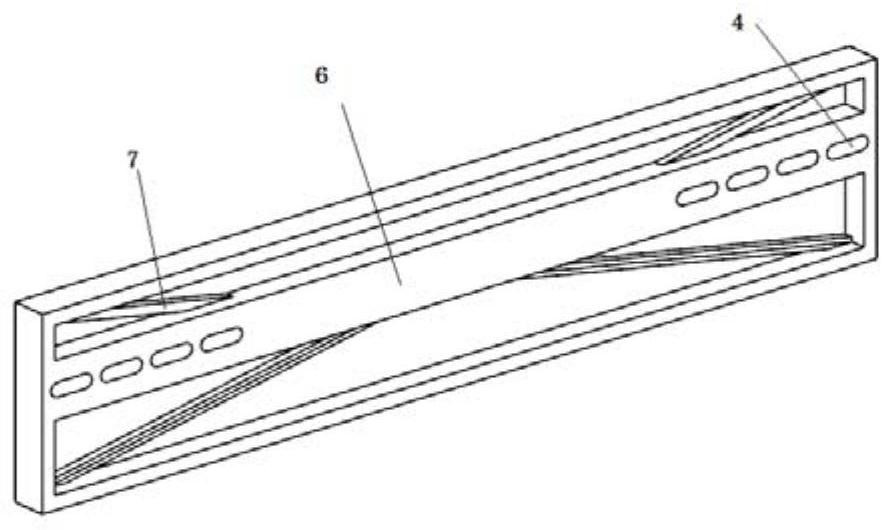

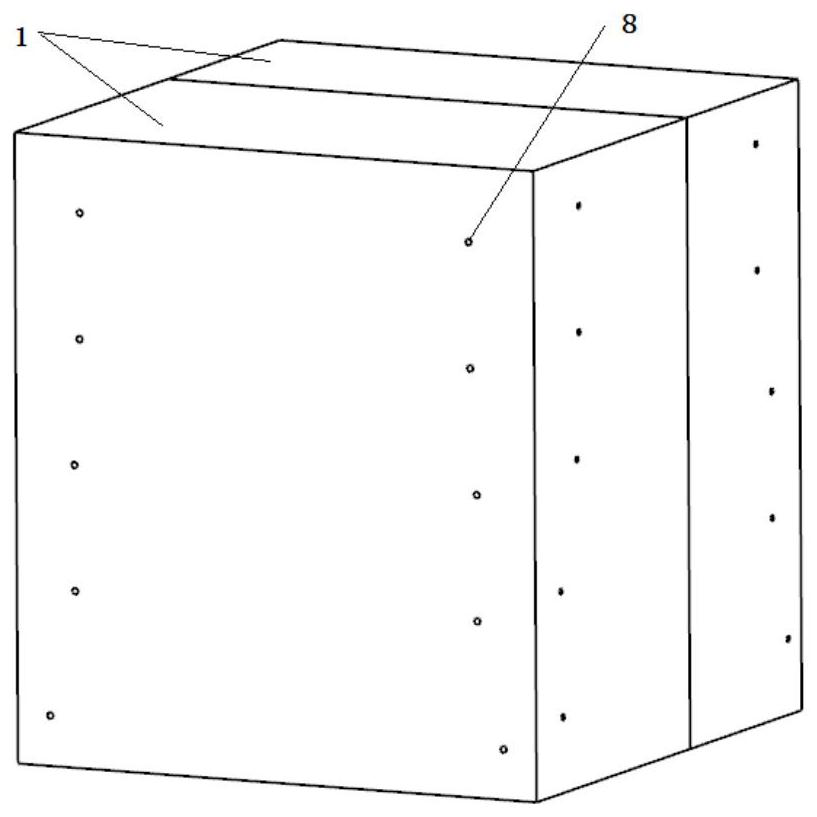

[0037] 1. According to the combined casting (such as figure 1 Shown) size to select the appropriate guard plate (such as figure 2 Shown) size, for example, in the embodiment, it is 1000 long, 200 high, and 15 thick. Reinforced flanging can be set around the guard plate, and reinforcing ribs can be set inside the guard plate. guard plate ( figure 2 ) The top, bottom and back are machined surfaces. Set a reinforced thick platform on the guard plate, the reinforced thick platform is 20mm away from the horizontal center line of the guard plate, and 4 oblong holes are arranged at both ends of the reinforced thick platform. The length and spacing of the oblong holes should ensure that the combined size of the left and right oblong holes is continuous. For example, in the embodiment, the distance between the centers of the oblong holes is 35mm, the distance between the connected oblong holes is 10mm, and the distance between the most two oblong holes and the side of the guard pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com