A bolt fastening machine

A fastening machine and bolt technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low labor efficiency, increased equipment cost, and inaccurate manual methods, so as to reduce the number of wrenches and equipment costs , the effect of high fixed precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

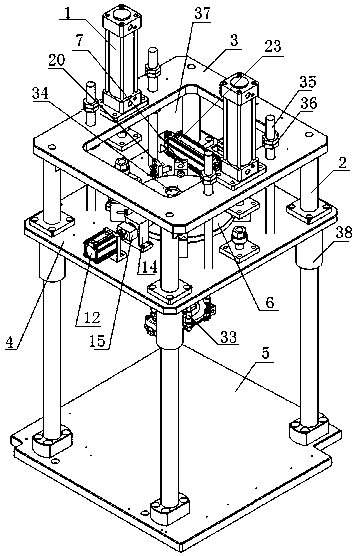

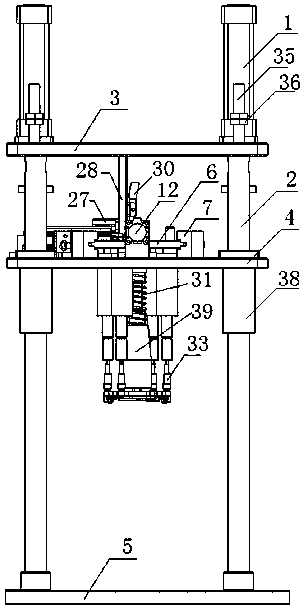

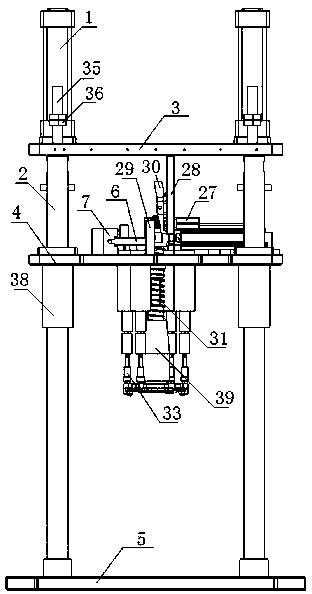

[0034] In this embodiment, the application of the bolt tightening machine is explained by taking the bolts on the front cover of the automobile compressor as an example. In this embodiment, the number of bolts is set to an even number, and the number of corresponding electric wrenches is the number of bolts. The distance between adjacent electric wrenches is an integer multiple of the adjacent bolts.

[0035] The bolt tightening machine of this embodiment includes a power system, a guide column 2, a fixed platform 3, a lifting plate 4, a bearing platform 5, and a fastening device; wherein, the lifting plate 4 is located between the fixed platform 3 and the bearing platform 5. The fixed platform 3, the lifting plate 4, and the bearing platform 5 are in the same vertical space. The middle of the fixed platform 3 and the lifting plate 4 is provided with an opening 37 for the fastening device to move up and down. The position of the opening 37 is for the fastening device to move up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com