Energy-saving lamp automatic assembly line

A technology of automatic assembly and energy-saving lamps, applied in the field of machinery, can solve the problems that the cam rotation is not easy to control the up and down movement of the transmission rod, curb the large-scale automatic production of energy-saving lamps, and replace parts for defective products. Good welding effect and uniform tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

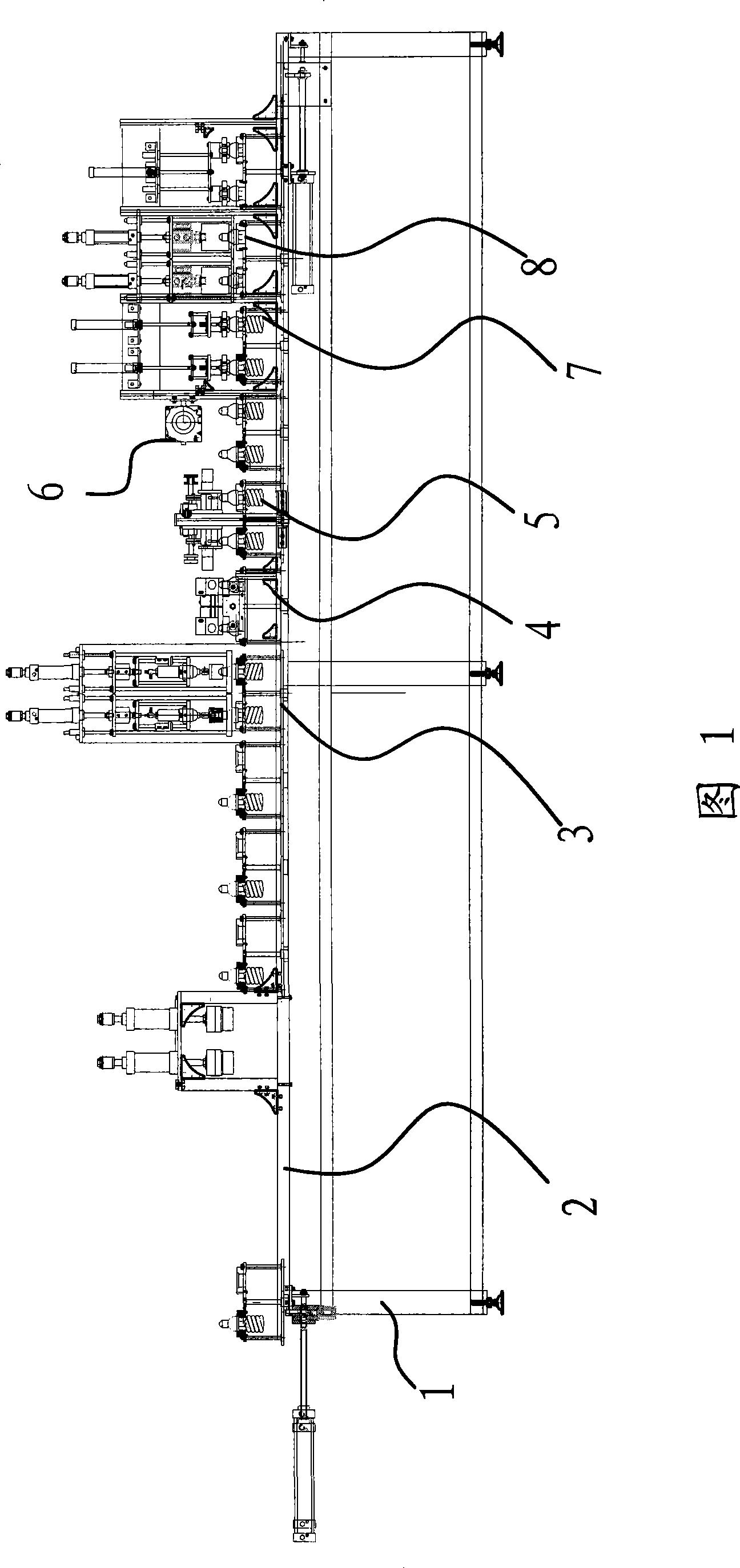

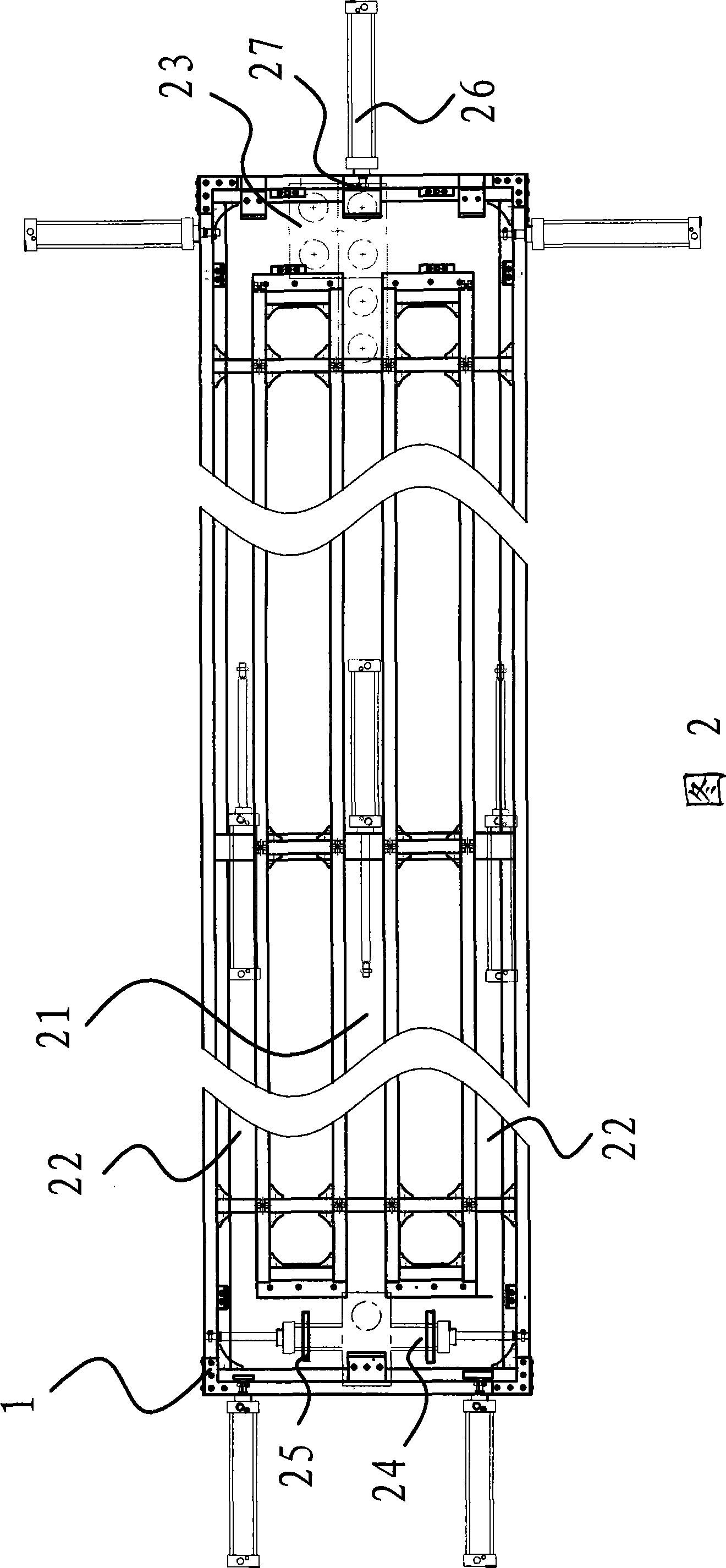

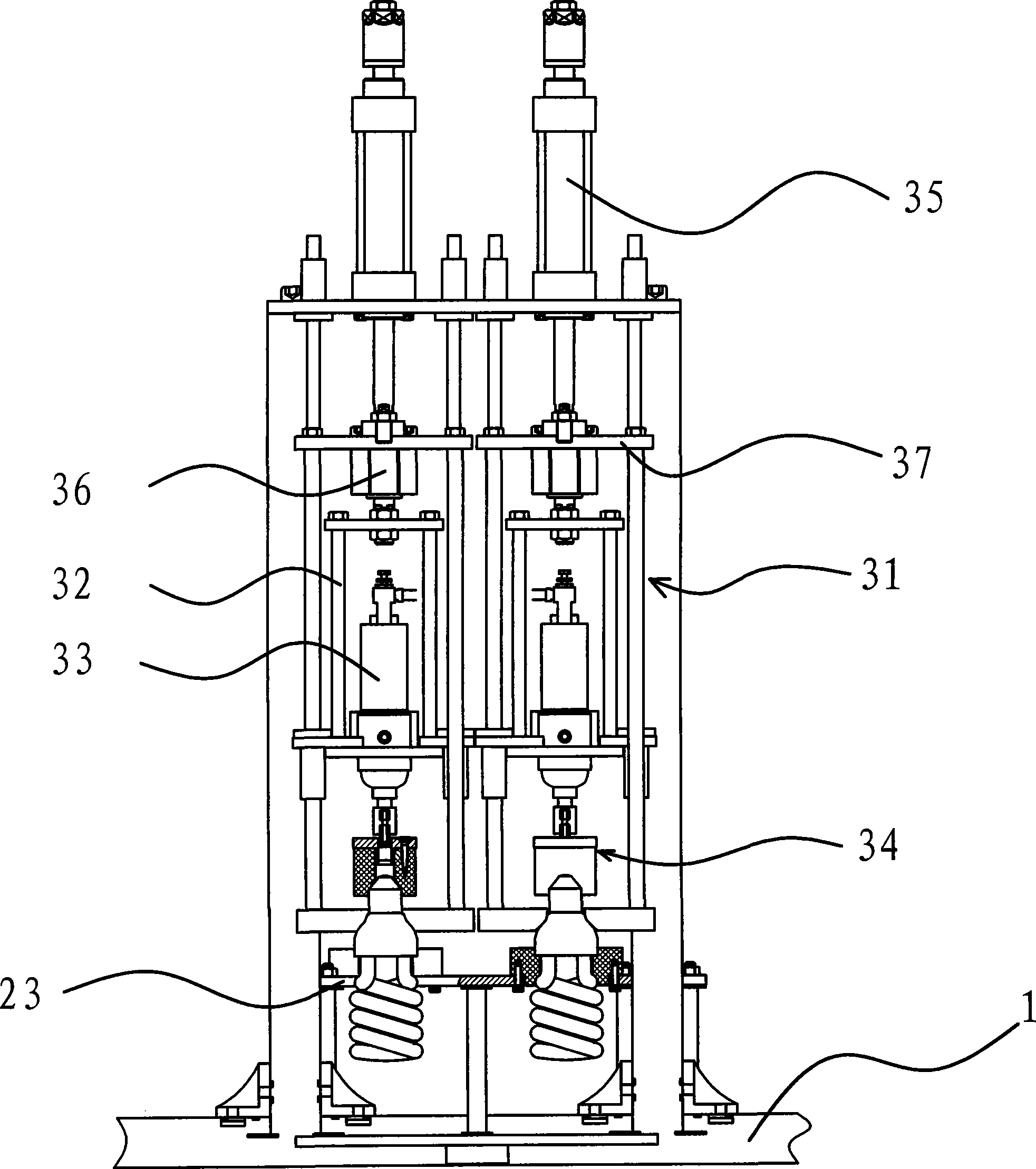

[0040] As shown in Figure 1, the energy-saving lamp automatic assembly line includes a frame 1, an energy-saving lamp assembly transmission system 2 arranged on the frame 1 for transporting energy-saving lamps, and an automatic rotating energy-saving lamp cap device 3 that connects the lamp cap and the lamp body. . Automatic cutting device for energy-saving lamps that automatically cuts excess filament from the lamp cap of energy-saving lamps. 4. Automatic soldering device for energy-saving lamps that automatically welds filaments to the lamp cap. 5. Cooling mechanism 6. Will detect whether the lamp cap and the lamp body are connected A solid energy-saving lamp automatic detection control system 7, an energy-saving lamp aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com