Power battery pack thermal management system air tightness detection tool and detection system

A technology for air tightness detection and power battery, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems such as threatening the personal safety of drivers and passengers, potential safety hazards, losses, etc., and achieves convenient operation, convenient maintenance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

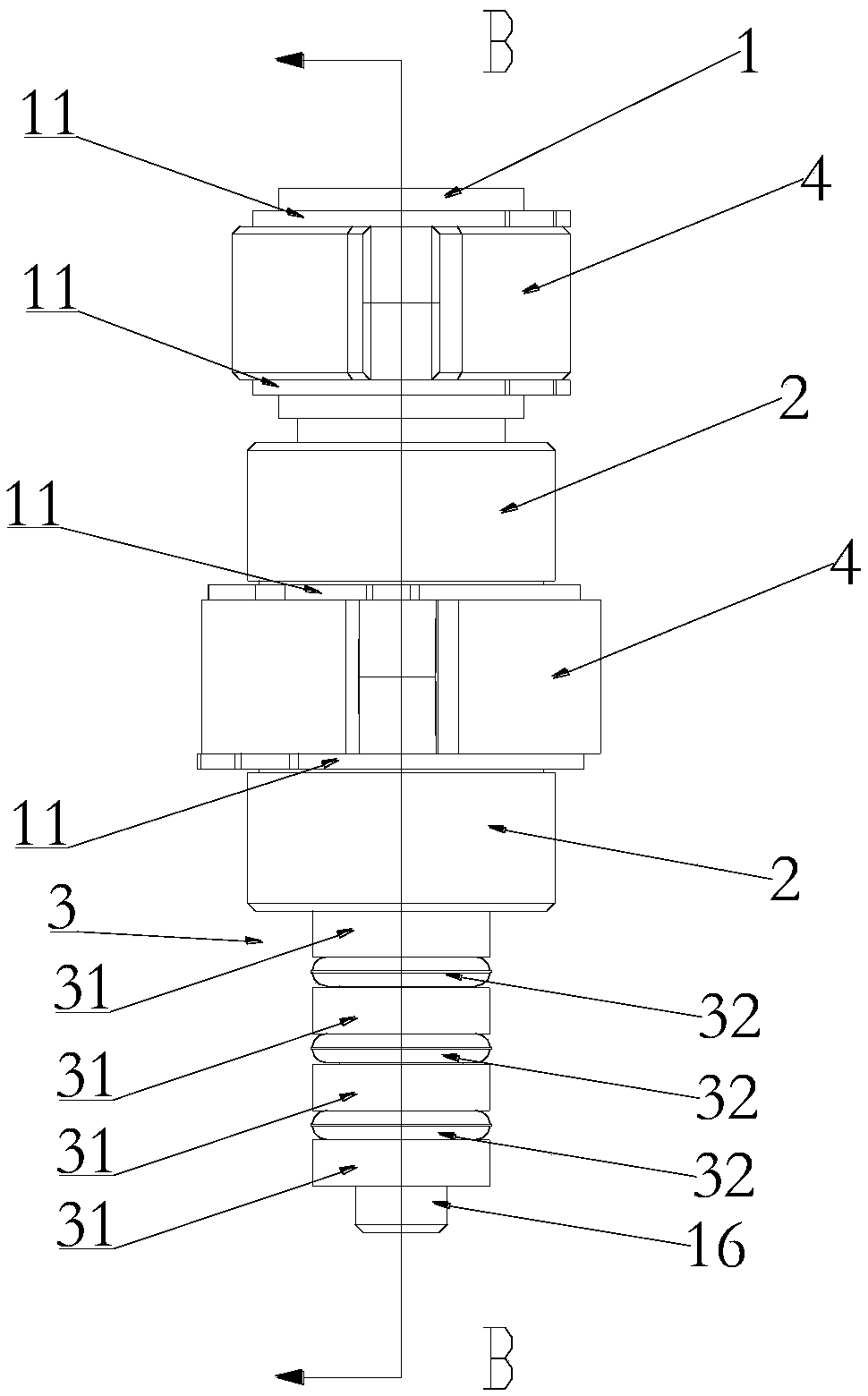

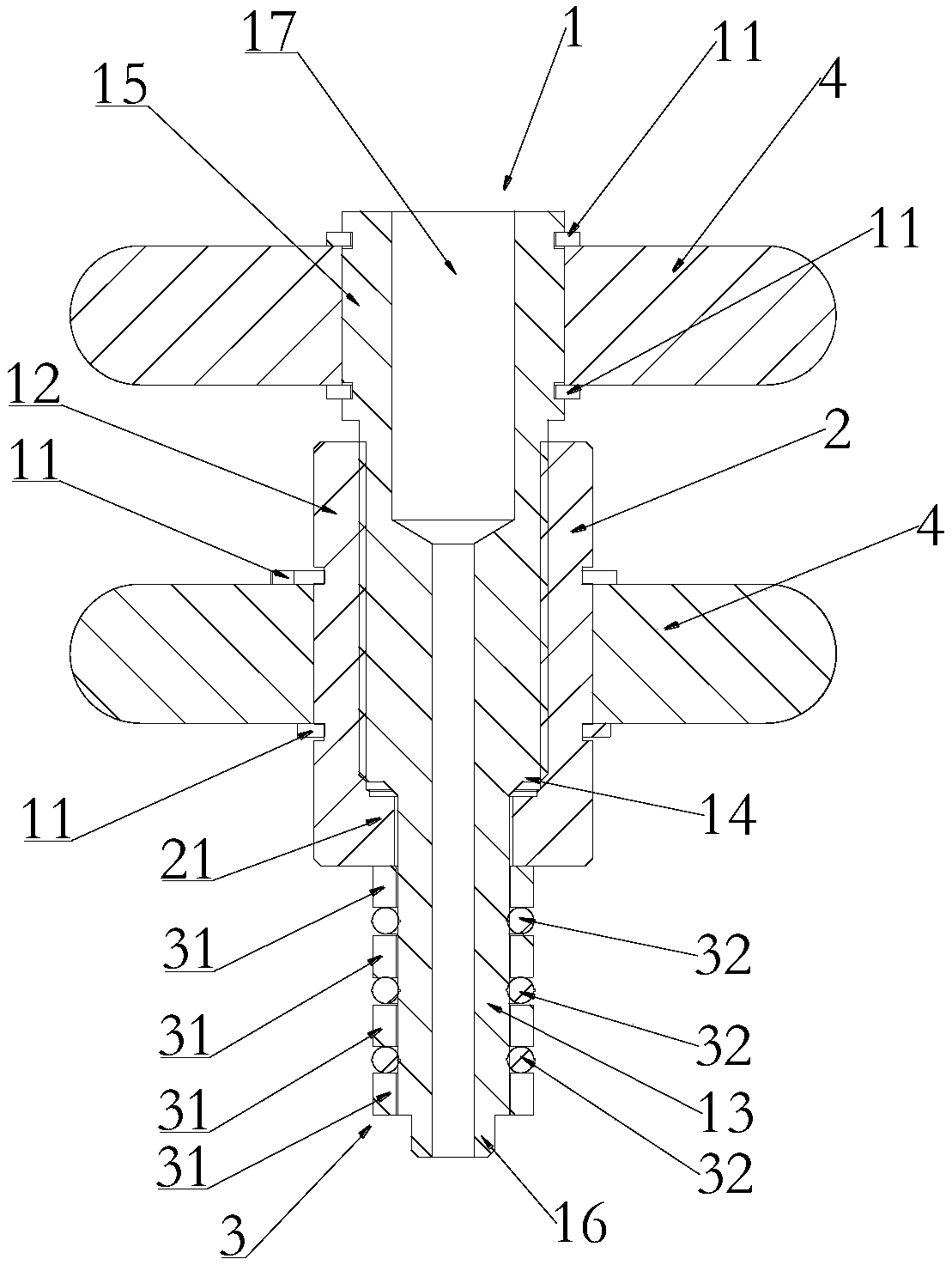

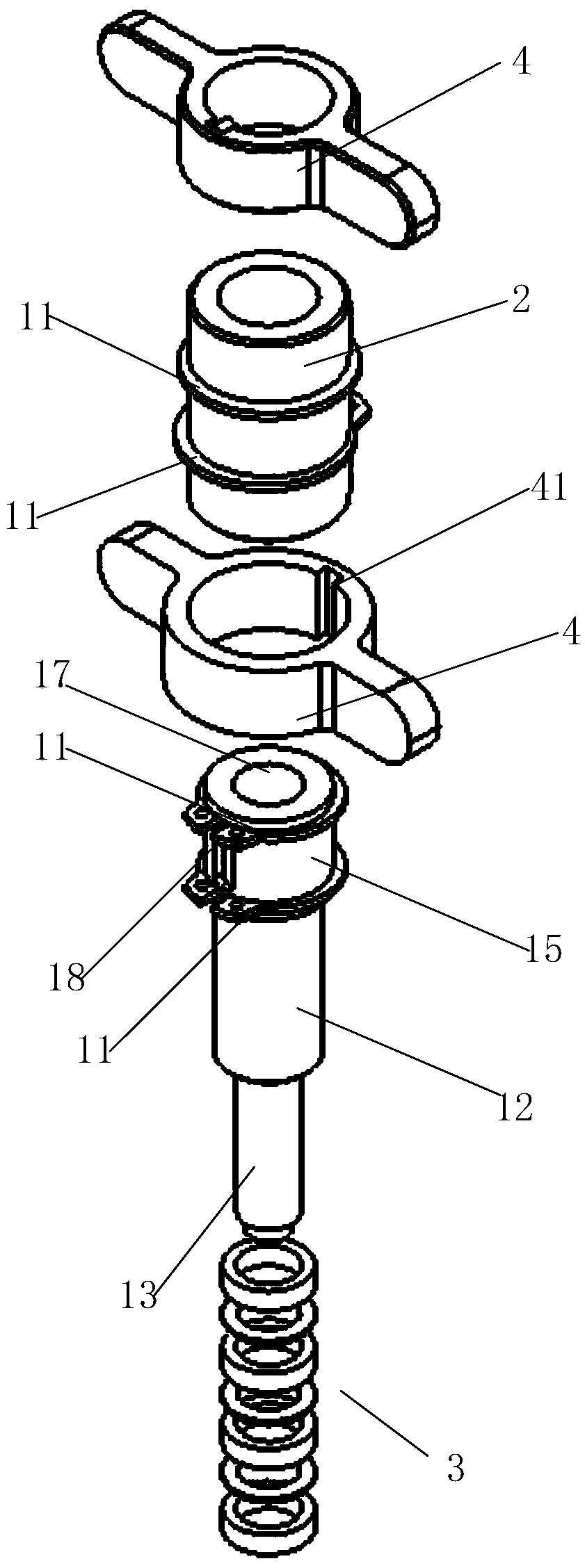

[0037] Such as Figure 1-Figure 3 As shown, an airtightness detection tool for a thermal management system of a power battery pack in this embodiment includes a ventilation rod 1, an expansion rod 2 and an elastic expansion part 3, and the elastic expansion part 3 is sleeved on the ventilation On the outer wall of one end of the rod 1 , the expansion rod 2 is screwed on the outer wall of the middle part of the ventilation rod 1 and its one end is arranged close to the elastic expansion part 3 . When in use, first tighten the expansion rod 2 on the ventilation rod 1, and then screw the ventilation rod 1. When the ventilation rod 1 moves downward, it also drives the expansion rod 2 to move downward. The expansion rod 2 can push the elastic The expansion part 3 moves downward and realizes the expansion fit with the air inlet.

[0038] Wherein, an air tightness detection channel 17 is opened in the middle of the ventilation rod 1 along its axial direction.

[0039] In the airtig...

Embodiment 2

[0053] Such as Figure 4 As shown, an air tightness detection system for a thermal management system of a power battery pack in this embodiment includes the detection tool 100, a high-pressure gas source 200, a detector 300, a water cooling plate 400 for a thermal management system of a power battery, and the ventilation One end of the rod 1 is plugged into the water inlet 401 of the water-cooled plate 400 of the power battery thermal management system and sealed with the inner wall of the water inlet 401 through the elastic expansion part 3 , and the other end of the ventilation rod 1 is connected to the water inlet 401. The detector 300 is connected through a pipeline 500 , and the detector 300 is connected with a high-pressure gas source 200 through the pipeline 500 .

[0054] When the detection system of this embodiment is in use, the detection tooling is installed in the air inlet of the water-cooled plate of the thermal management system of the power battery, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com