Full-automatic nut pre-loading machine

A pre-installed machine and nut technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor cost, danger, and different tightening strength, so as to save labor cost, ensure quality, and balance the strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

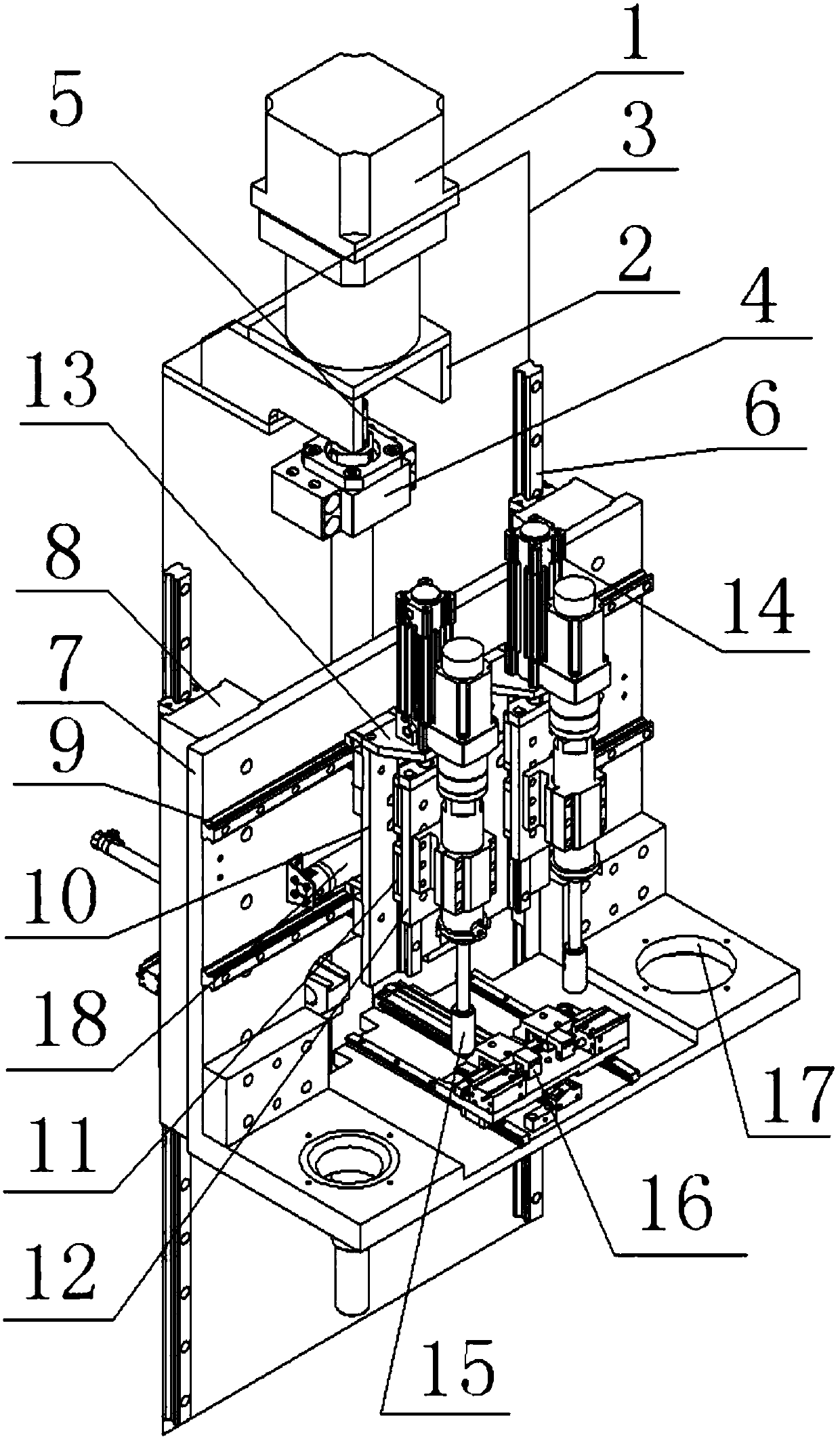

[0016] Attached below figure 1 The specific embodiment of the present invention will be further described.

[0017] Fully automatic nut pre-installation machine, including servo motor 1, installation back plate 3, screw assembly 4, cylinder one 14, tightening shaft 15, nut material channel 16 and cylinder two 18; servo motor 1 is installed on the On the installation backplane 3, the servo motor 1 is connected to the lead screw assembly 4 through the coupling 5; the two sides of the installation backplane 3 are longitudinally and parallelly installed with the Z-axis guide rail slider-6, and the Z-axis guide rail slider-6 and the Z-axis guide rail slider-6 are installed in parallel. The shaft lift plate 7 is slidingly connected, and a backing plate 8 is arranged between the Z-axis guide rail slider 1 and the Z-axis lift plate 7; the Z-axis lift plate 7 has an L-shaped structure, and the screw nut of the screw assembly 4 and the Z-axis lift plate 7 vertical plates are connected;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com