Rotor cage bar and end ring welding bench and welding method

A rotor cage and processing table technology, which is applied in metal processing, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency, and achieve the effects of high welding efficiency, uniform tightening force, and reduction of uneven force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

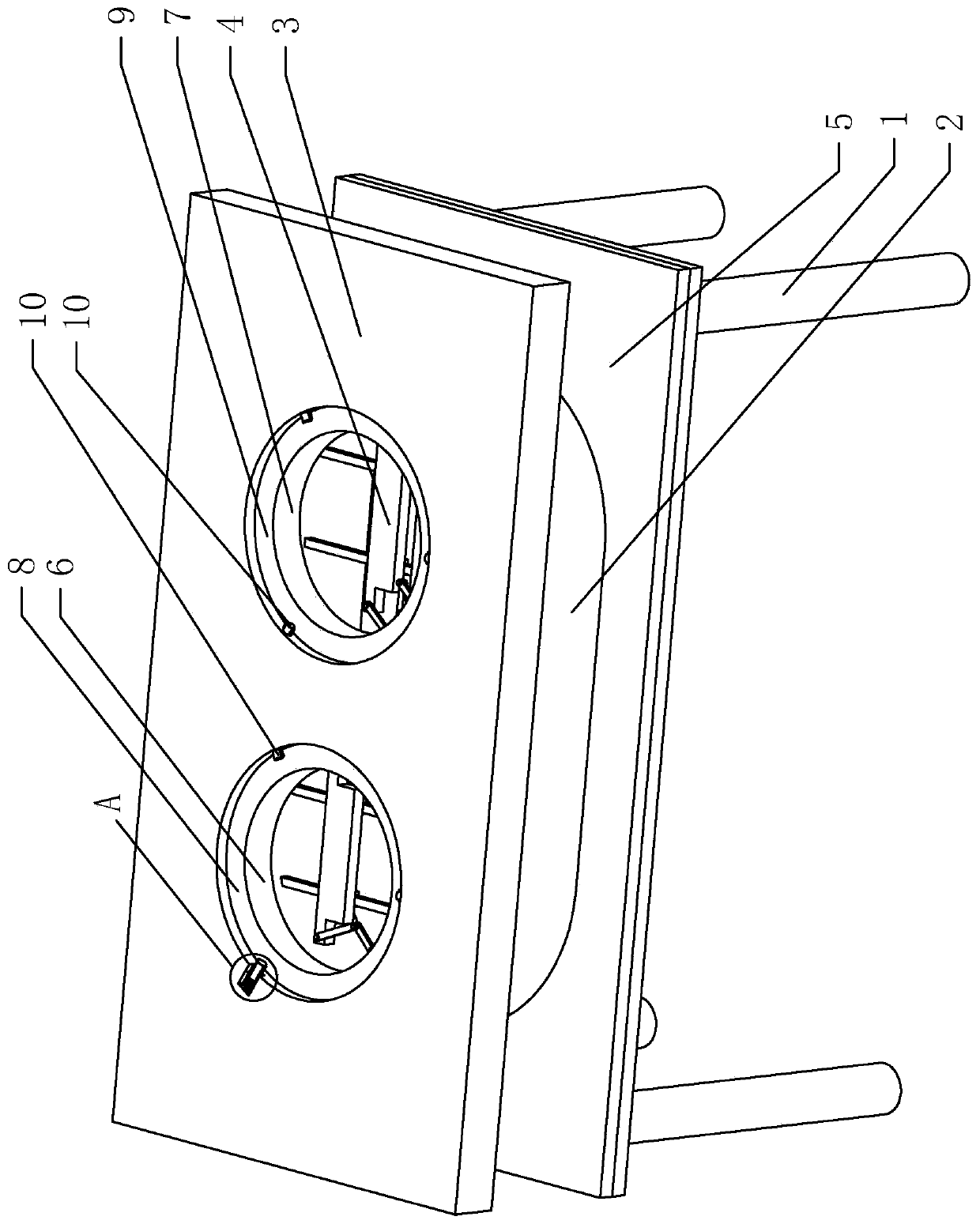

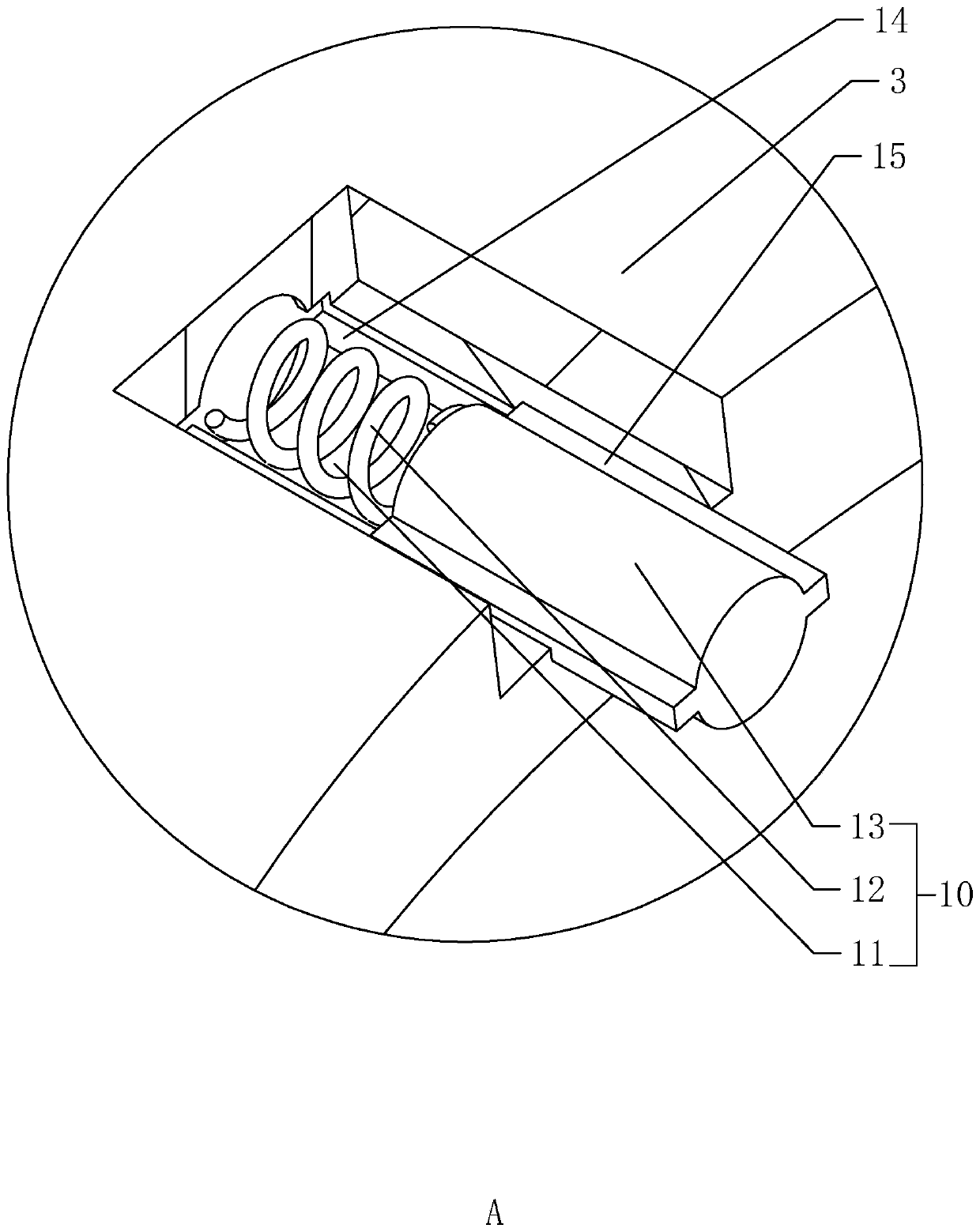

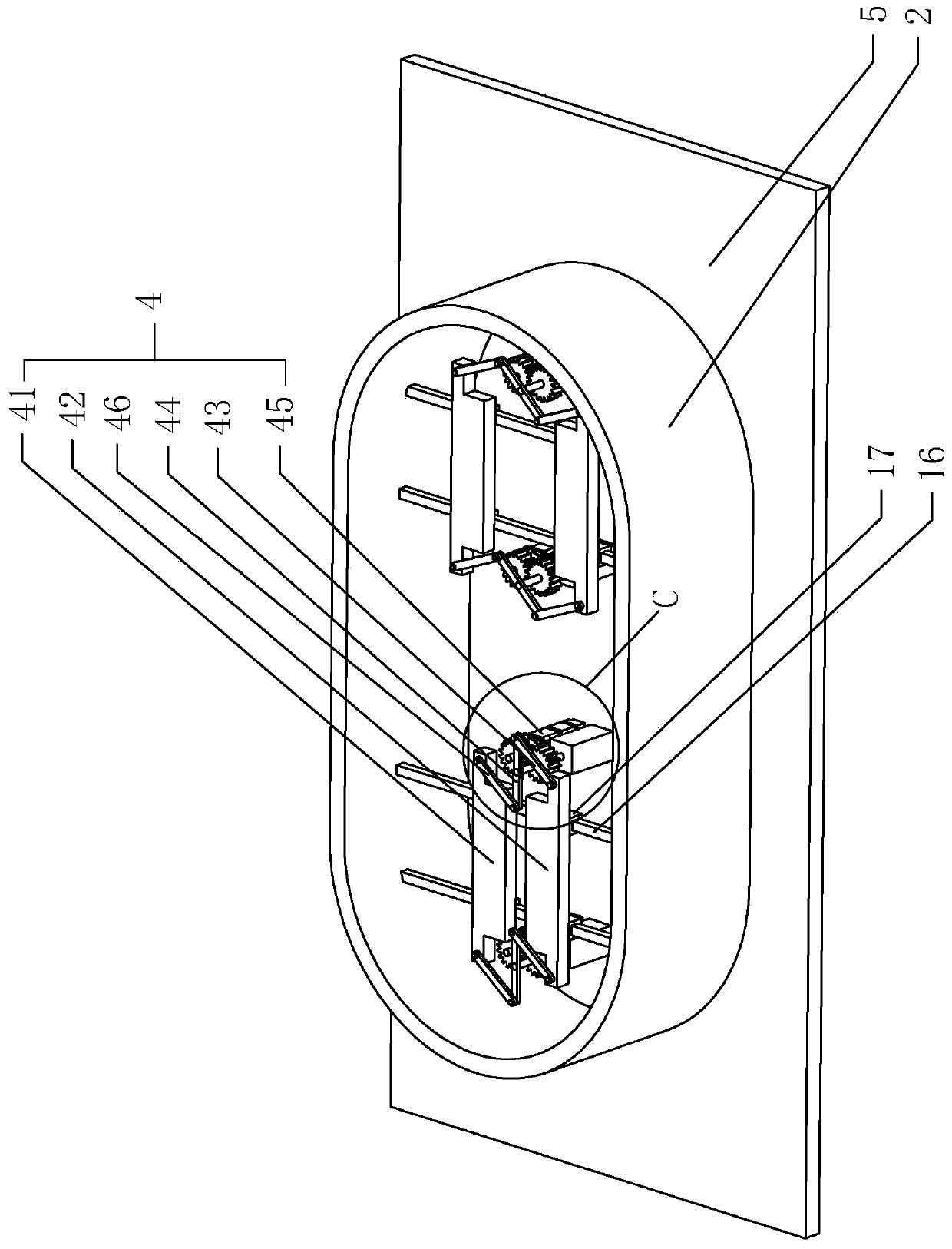

[0040] Embodiment 1: A rotor cage bar and end ring welding processing platform, such as figure 1 As shown, it includes a bracket 1 , a welding cylinder 2 , a workbench 3 and a clamping device 4 .

[0041] Such as figure 1 with figure 2 As shown, one end of the welding cylinder 2 is connected to the support 1, and the other end is connected to the worktable 3. The welding cylinder 2 is provided with a welding plate 5, which is welded with the support 1. The workbench 3 is provided with a first welding hole 6, a second Two welding holes 7, the first limiting groove 8 and the second limiting groove 9, the first welding hole 6 and the second welding hole 7 are all communicated with the welding cylinder 2, and the center line of the first limiting groove 8 is connected with the first limiting groove The centerlines of the positioning holes 11 are collinear, the centerlines of the second limiting groove 9 are collinear with the centerlines of the second limiting holes 11, the sid...

Embodiment 2

[0048] Embodiment 2: A method for welding rotor cage bars and end rings, which includes the following steps:

[0049] S1: brush flux, brush the flux on the surface of the rotor cage:

[0050] S2: Assemble, place the end ring in the first limit groove 8 and the second limit groove 9 of the workbench 3, and make the limit rod 13 touch the side wall of the end ring, and place the rotor cage on the workbench 3 , so that the end of the rotating cage is in the annular groove of the end ring;

[0051] S3: Clamping, start the motor 451 to move the first clamping arm 41 and the second clamping arm 42 toward each other, the first clamping arm 41 and the second clamping arm 42 clamp the rotating shaft 22 of the motor 451, Fixed motor 451 rotating shaft 22;

[0052] S4: Welding, using a high-frequency induction welding machine to weld the rotor cage bar and the end ring together, the solder is silver-based brazing solder, and the flux is silver-based brazing flux.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com