Saddled vehicle

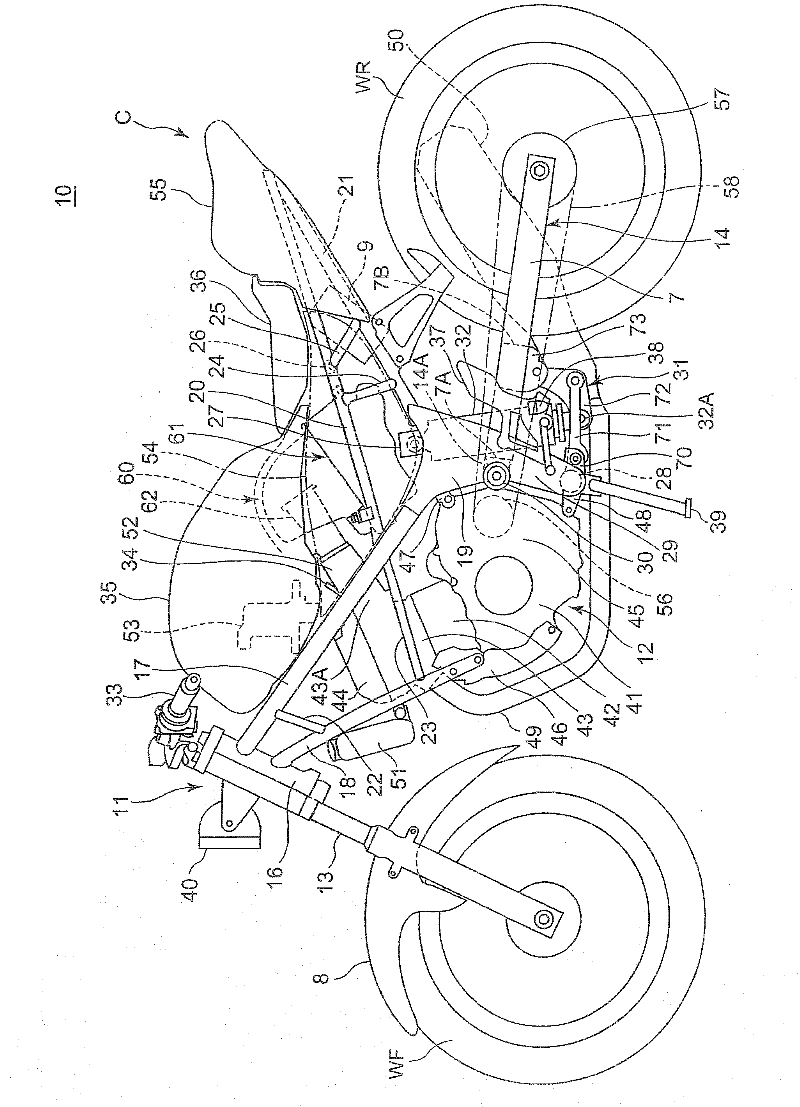

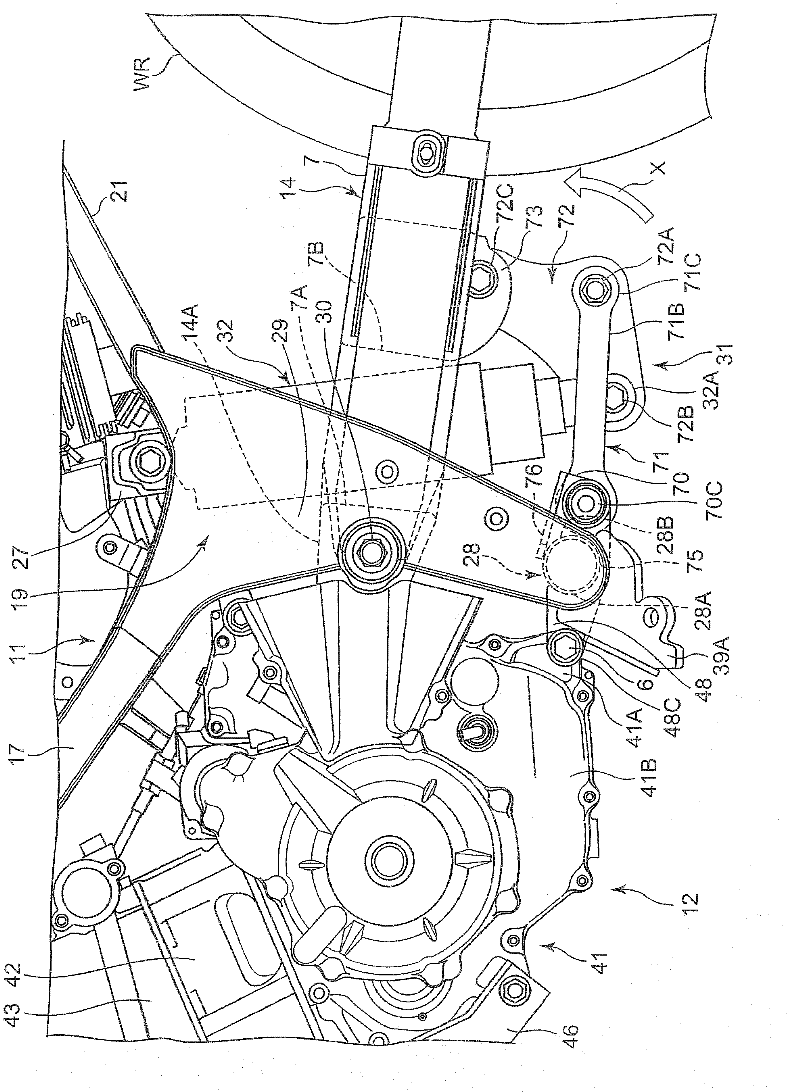

A straddle-type vehicle and frame technology, which is applied to motorcycles, motor vehicles, bicycles, etc., can solve problems such as beam deformation and difficulty in reducing weight, and achieve the effects of improved assembly, easy welding operations, and improved welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

[0102] Image 6 It is a side view showing the lower hook 148 and the link connecting bracket 170 in Modification 1 of the embodiment.

[0103] In addition, in this modification 1, the same code|symbol is attached|subjected to the part comprised similarly to the said embodiment, and description is abbreviate|omitted.

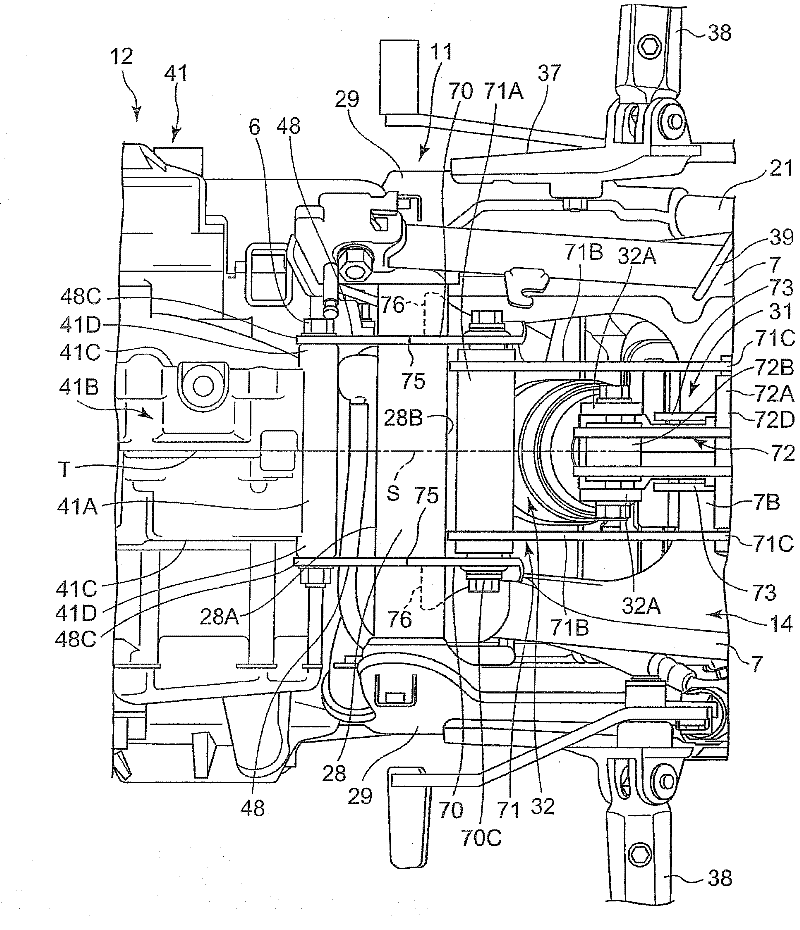

[0104] A lower hook 148 fixed to a front portion 28A of the lower beam 28 has a rear end 148B extending to an upper end 28D of the lower beam 28 . The link connecting bracket 170 fixed to the rear portion 28B of the link connecting bracket 170 has a front end 170B extending to the upper end 28D of the lower cross member 28 . The rear end 148B contacts the front end 170B at the upper end 28D to form a contact portion 175 .

[0105] In Modification 1, in addition to the contact portion 75 at the lower end 28C, the lower hook 148 and the contact portion 175 at the upper end 28D of the link connecting bracket 170 are also welded in contact with each other, so that ...

Deformed example 2

[0108] Figure 7 It is a side view showing the bracket member 200 in Modification 2 of the embodiment.

[0109] In addition, in this modification 2, the same code|symbol is attached|subjected to the part comprised similarly to the said embodiment, and description is abbreviate|omitted.

[0110] Bracket member 200 is formed in a flat plate shape extending in the vehicle front-rear direction. The bracket member 200 has an arc-shaped joining portion 200A formed in an arc shape along the circular outer peripheral shape of the cross-section of the lower beam 28 at the upper edge of the front-to-back intermediate portion, and the arc-shaped joint portion 200A is fixed to the lower beam by welding. 28 on the lower surface side. The bracket member 200 is provided in a state where the upper edge 200B is substantially horizontal. The arc-shaped engaging portion 200A is a recess formed in a semicircular shape, and is fixed in a state of being engaged with the lower half of the outer p...

Deformed example 3

[0115] Figure 8 It is a side view showing the bracket member 300 in Modification 3 of the embodiment.

[0116] In addition, in this modification 3, the same code|symbol is attached|subjected to the part comprised similarly to the said modification 2, and description is abbreviate|omitted.

[0117] In Modification 3, the tubular beam connecting the lower portions of the left and right center frames 19 is constituted by the lower beam 328 having a rectangular square cross section.

[0118] The bracket member 300 is formed in a flat plate shape extending in the vehicle front-rear direction. The link connection bracket portion 270 and the lower hook portion 248 are integrally provided on the bracket member 300 .

[0119] The bracket member 300 has a concave joint portion 300A formed along the front surface 328A, the lower surface 328B, and the rear surface 328C of the lower beam 328 at the upper edge portion of the front and rear middle portion, and the concave joint portion 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com