Bus-bar middle joint for rigid suspension catenary

A technology of intermediate joints and busbars, applied in the field of intermediate joints of busbars for rigid suspension catenary, can solve the problems of different thermal expansion and contraction, safety threats of traction power supply system, loose parts of suspension system, etc., and achieves high connection strength. , The connection is reliable, and the effect of improving the tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail now in conjunction with accompanying drawing.

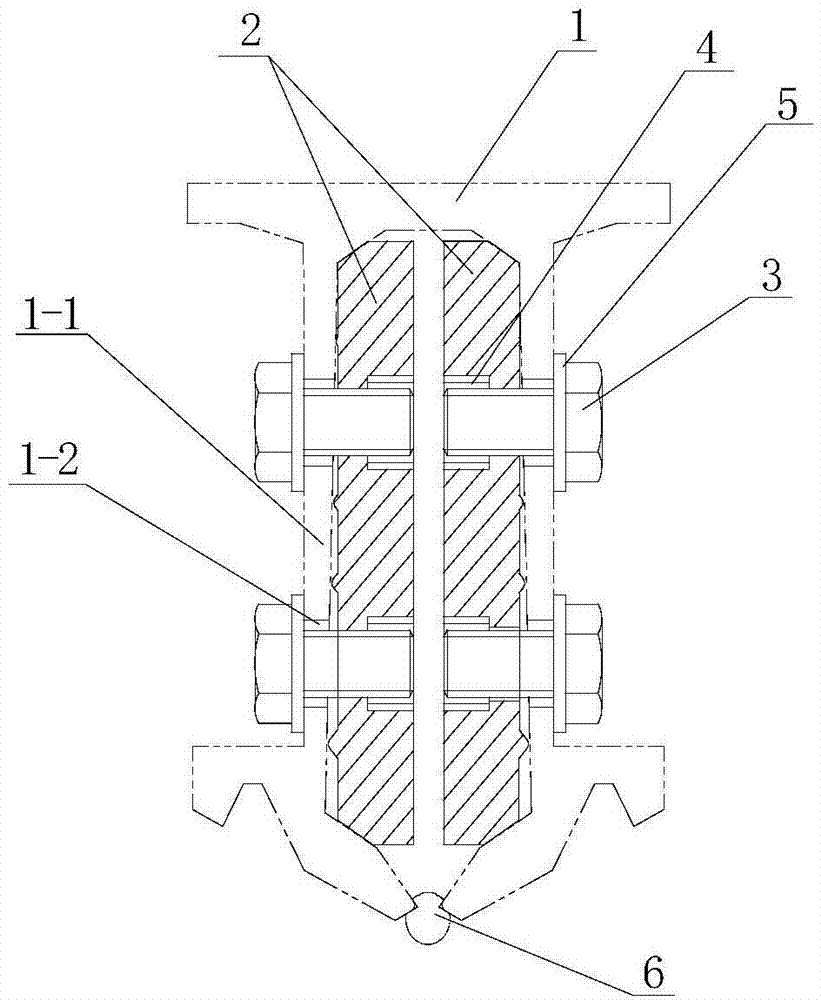

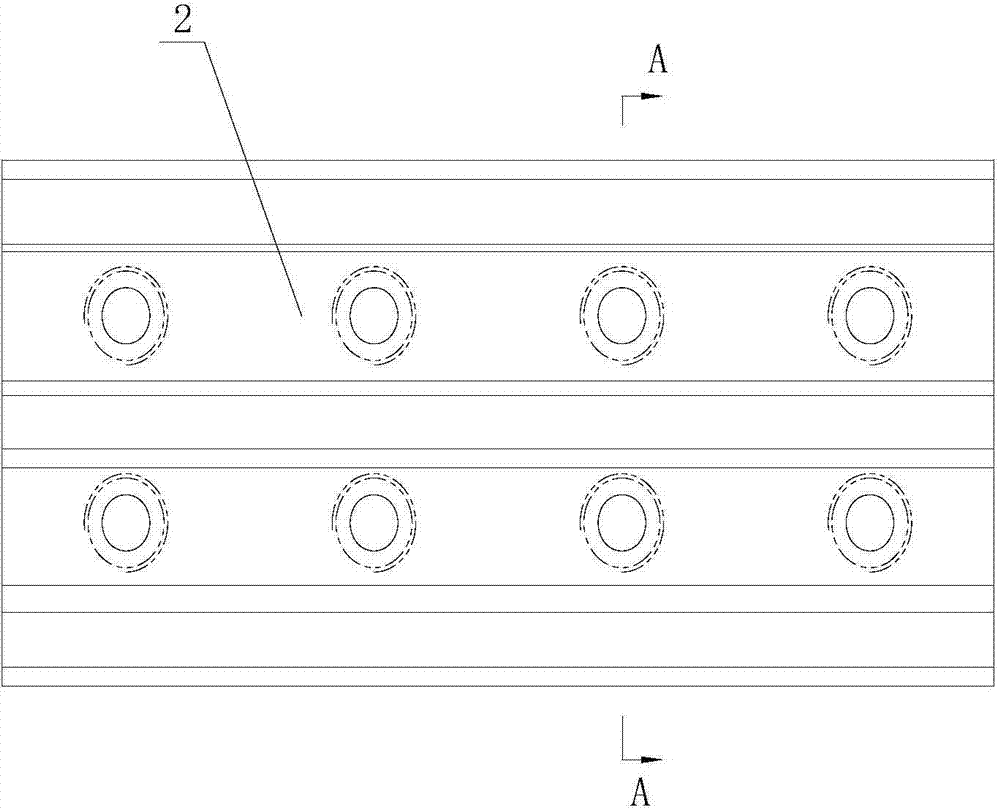

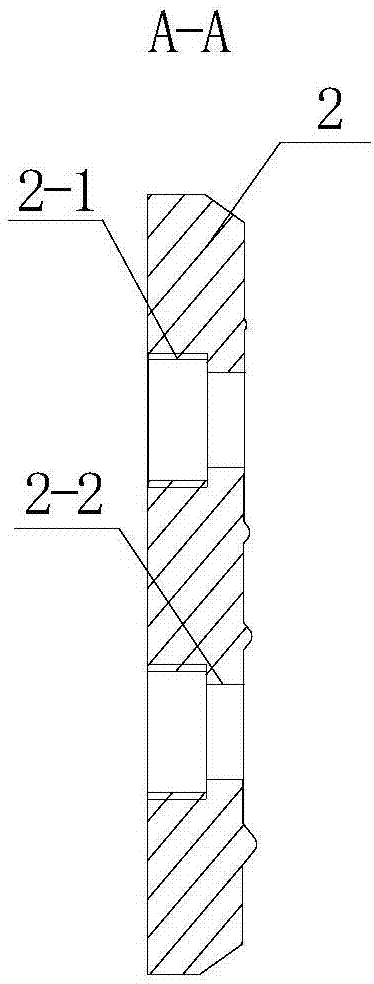

[0020] A kind of busbar intermediate joint for rigid suspension catenary, as attached figure 1 , has a pair of threaded splints 2 that are arranged on both sides of the busbar 1 in the clamping walls 1-1 to connect two busbars 1, and pass through the holes 1-2 on the busbar 1 to connect the two ends of the threaded splint 2 to the two busbars respectively. row 1 fixed bolt 3, as attached figure 2 , 3 , the mounting hole on the threaded splint 2 has a constricted light hole section 2-2 at the mouth and a threaded section 2-1 at the bottom, attached figure 2 The specific method is that there are 8 mounting holes, and then there are 4 holes 1-2 at the end of the connected bus bar 1.

[0021] The intermediate joint also has a steel threaded sleeve 4 that is threaded both inside and outside the ring, as attached Figure 4 , 5 , the external thread of the threaded sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com