Spring contact for an electric connector and connection

A technology of elastic contacts and plug-in devices, which is applied to parts of connection devices, contact parts, coupling devices, etc., can solve the problems of contact burnout, insufficient contact area and contact force, and achieve compact structure and good The effect of contact pressure transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

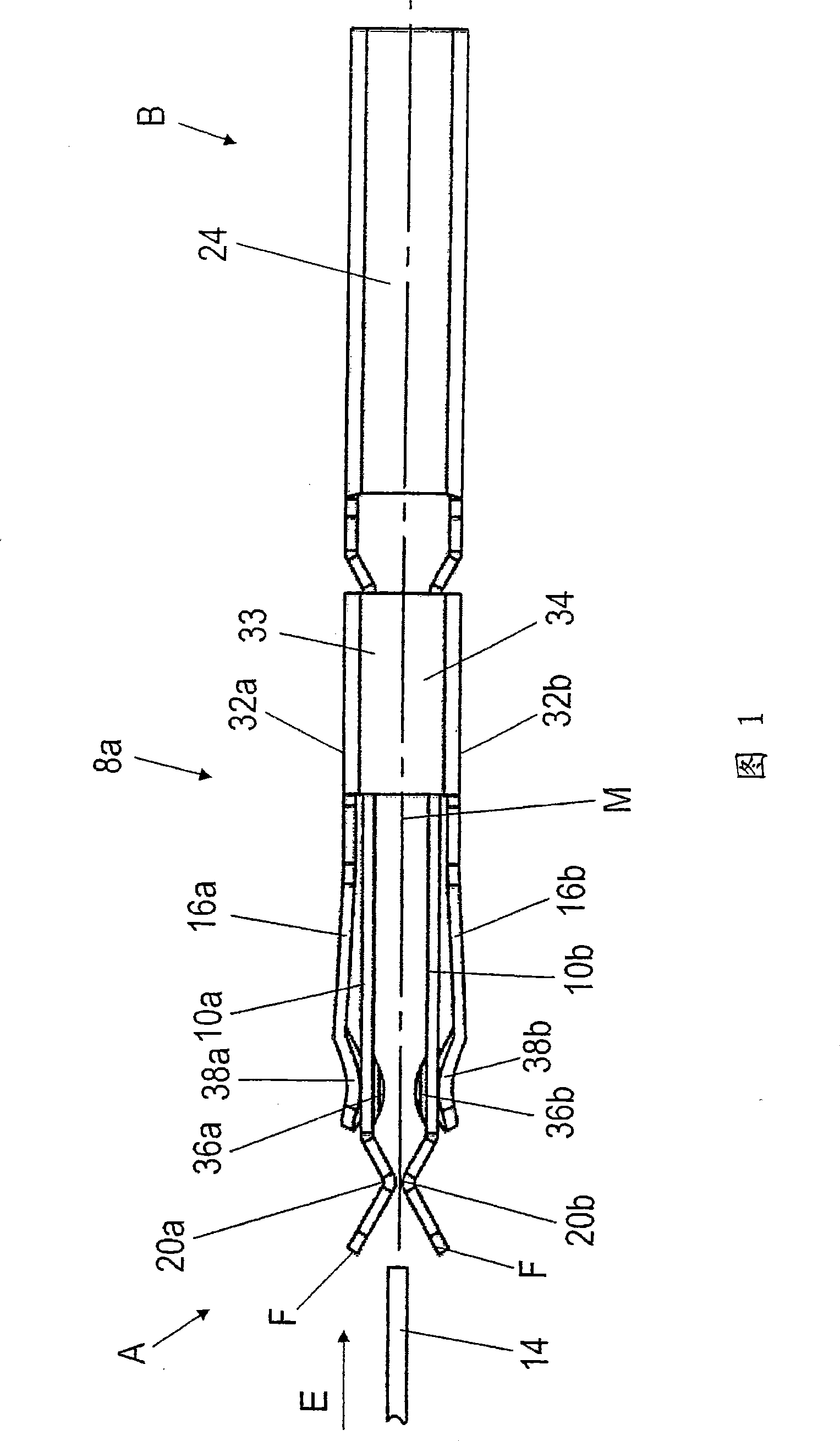

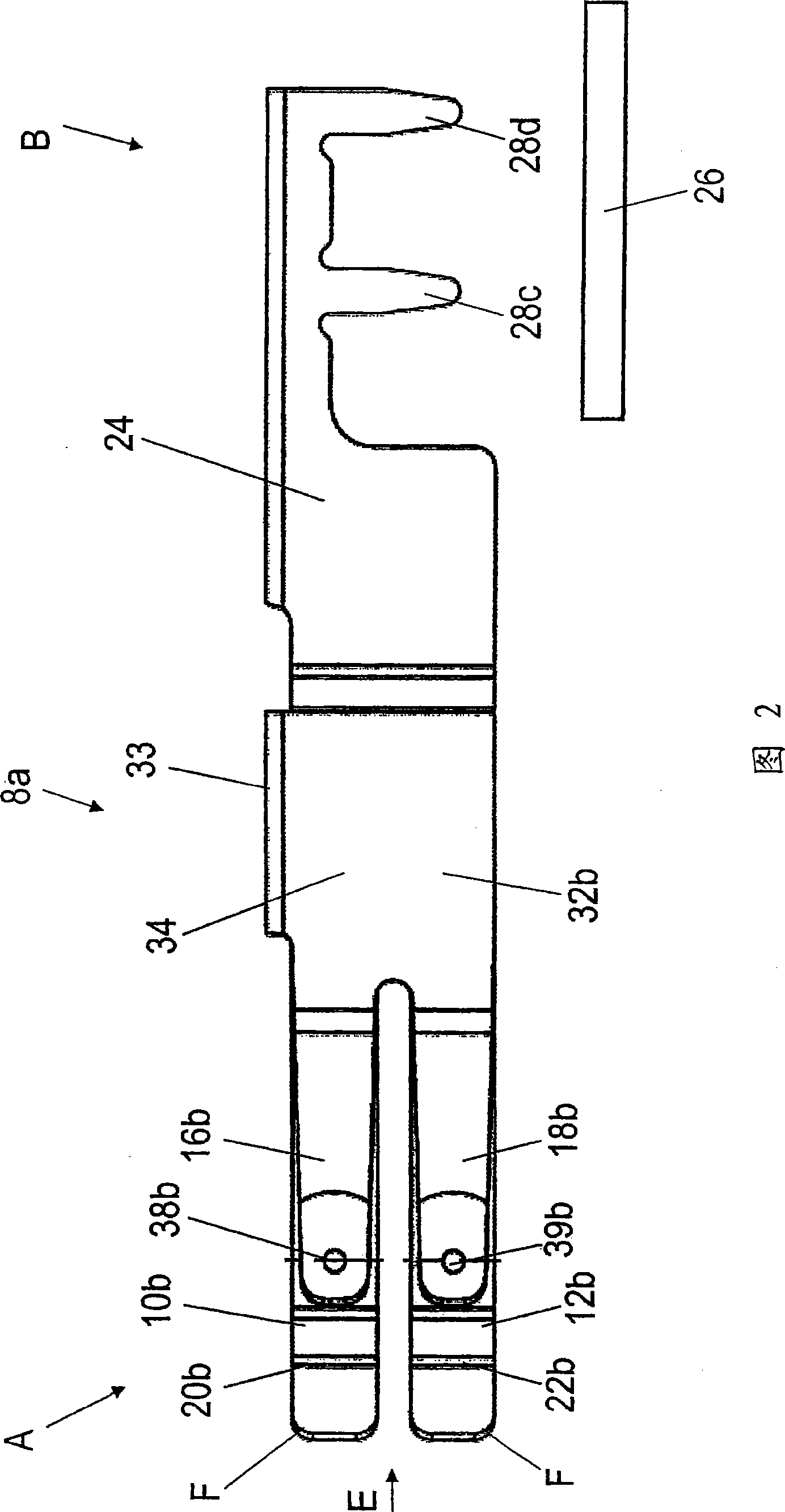

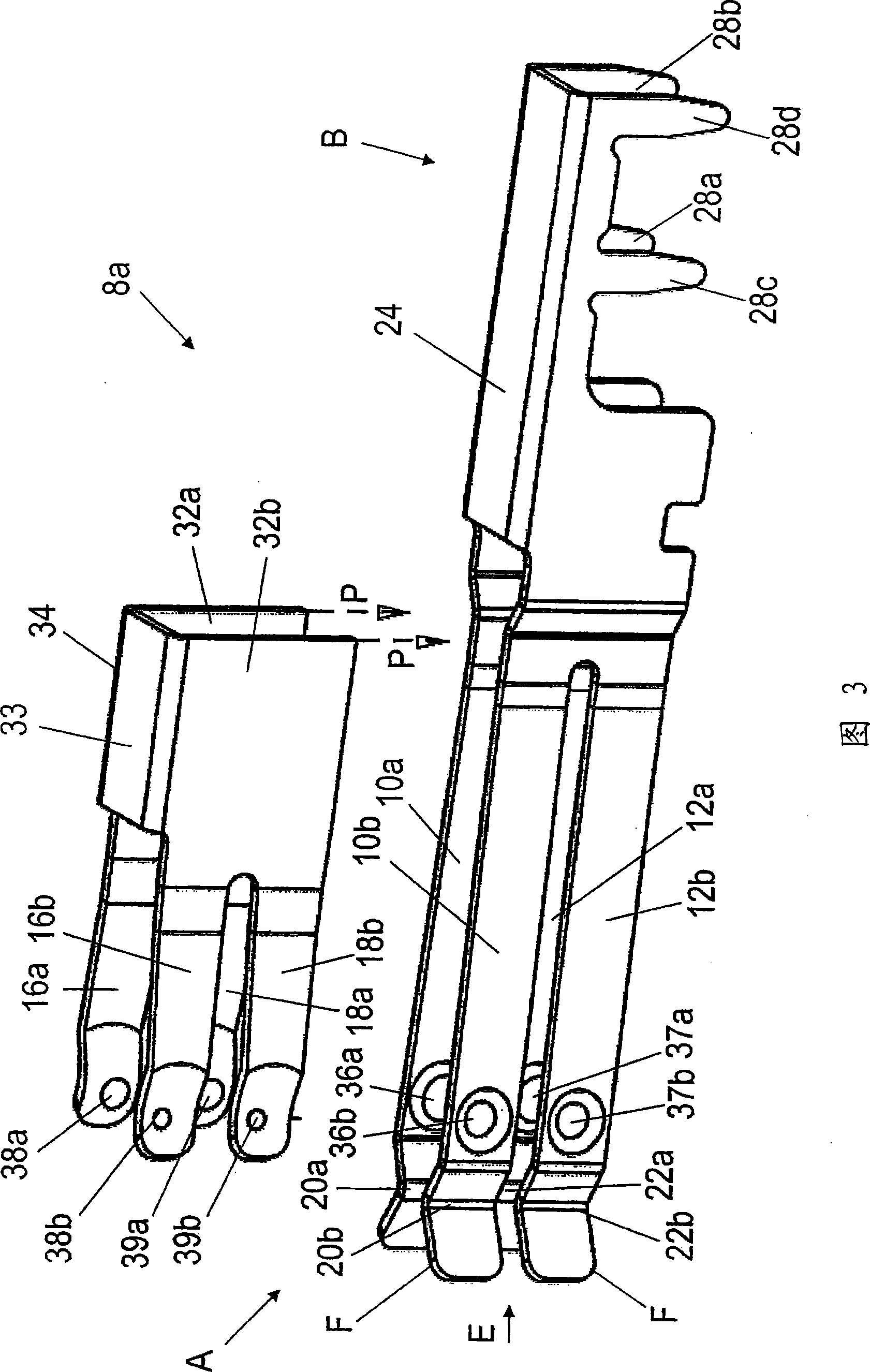

[0030] Figures 1 to 3 schematically show an elastic contact 8a of the electrical plug-in device in different views. Fig. 1 shows a plan view of the elastic contact 8a, Fig. 2 shows a side view, and Fig. 3 shows an exploded perspective view.

[0031] The elastic contact 8a has four elastic contact arms 10a and 10b or 12a and 12b opposite to each other in pairs at the left end A in FIGS. 1 to 3. The corresponding contact 14 shown only schematically in FIG. 1 can be inserted between the opposing contact arm pairs 10a and 10b or 12a and 12b along the insertion direction E of the elastic contact center line M. The corresponding contact 14 is designed as a measuring contact.

[0032] On the outside of the contact arms 10a, 10b, 12a, and 12b facing away from the center line M, a spring arm 16a, 16b, 18a, or 18b is applied, respectively. These spring arms 16a, 16b, 18a, or 18b extend parallel to the corresponding contact arms 10a, 10b, 12a, and 12b. Each of the spring arms 16a, 16b, 18a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com