Improved split wheel

A split type, wheel technology, applied in the direction of rims, vehicle parts, transportation and packaging, etc., can solve the problems of low mechanical properties of rivet or bolt connection, etc., to solve the problem of fastening torque drop, disperse fastening force, and increase preload The effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

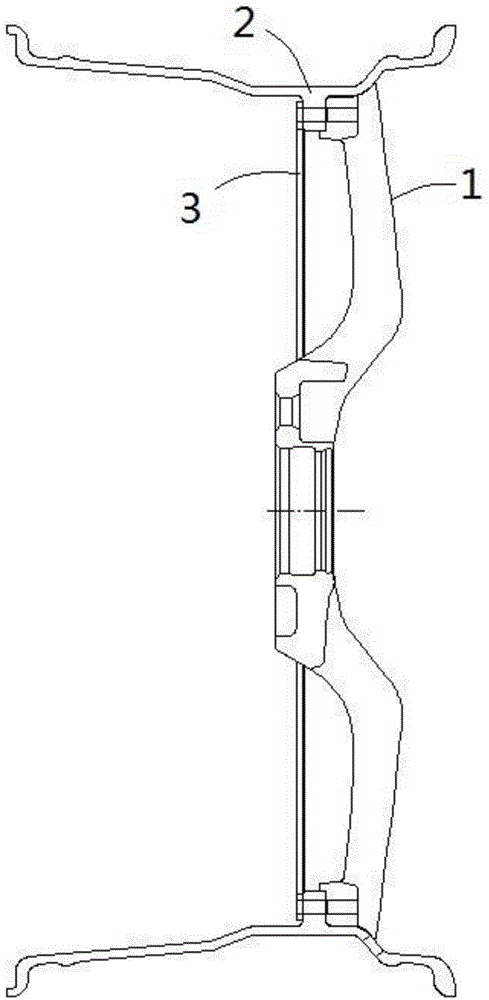

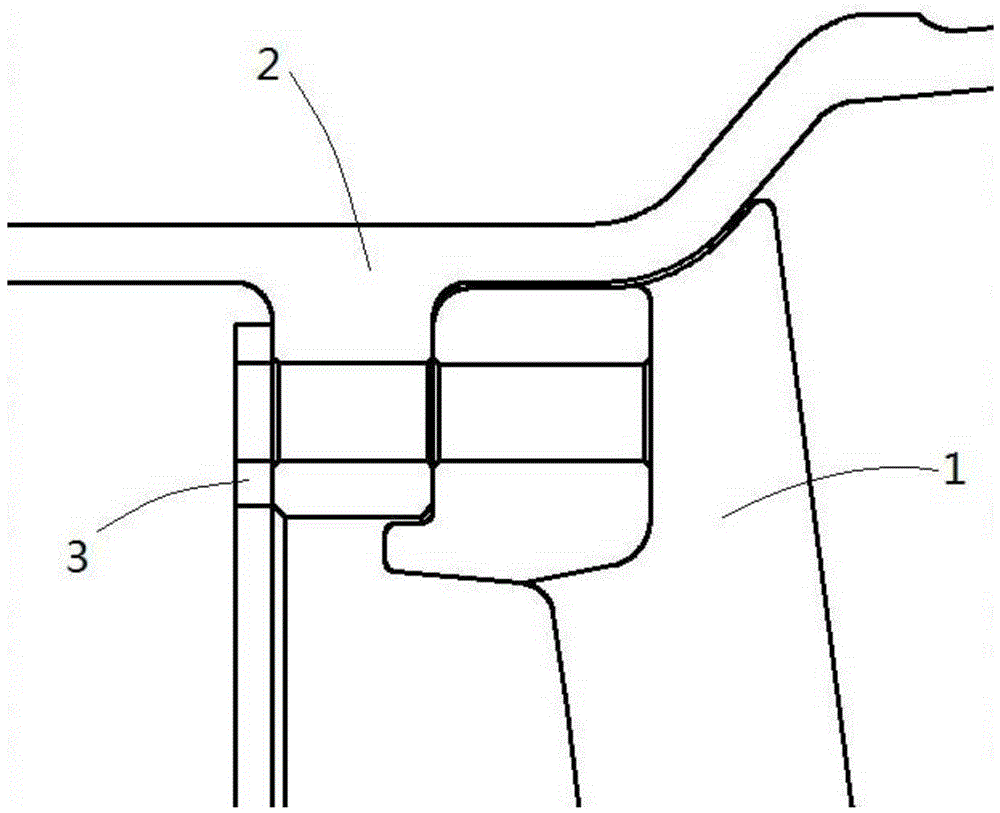

[0021] Such as Figure 1-2 As shown, the present invention is an improved split wheel, including an aluminum alloy wheel disc 1, a composite material rim 2, and a metal fastening ring 3.

[0022] In order to increase the contact area and improve the fastening reliability, a metal fastening ring 3 is installed at the connection part of the composite material rim 2, and the aluminum alloy wheel disc 1, the composite material rim 2 and the metal fastening ring 3 are connected together by bolts or rivets. The metal fastening ring 3 is reinforced in the form of right-angle wrapping.

[0023] In order to limit the weight gain, the through-holes of the metal fastening ring 3 are evenly arranged.

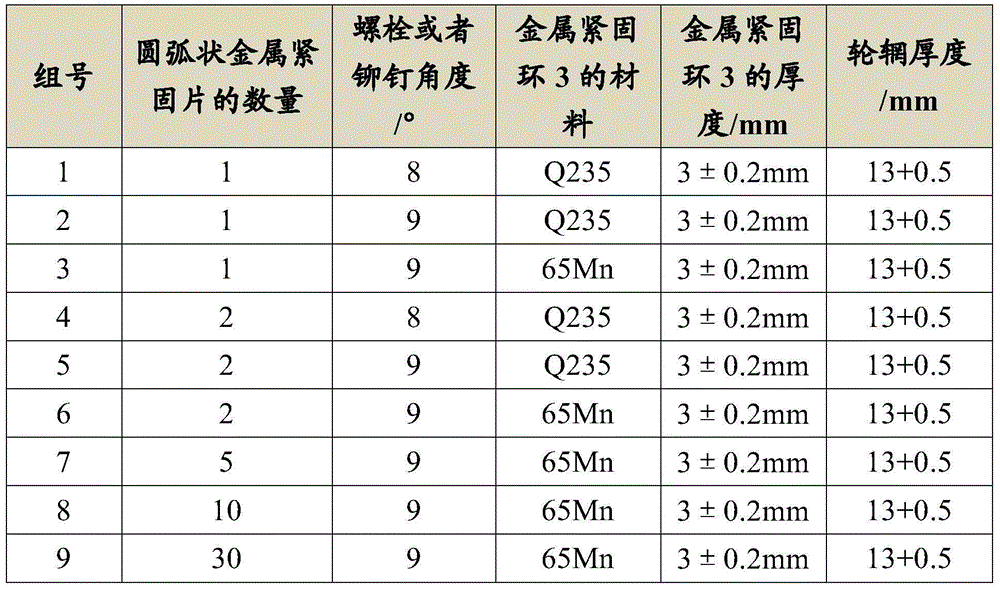

[0024] Meanwhile, other experimental parameters were as follows:

[0025] Table 1: Structural parameters of split wheels

[0026]

[0027] The materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com