Dish-washing machine

A technology for dishwashers and sinks, which is applied to tableware washing machines/rinsing machines, tableware washing machines/rinsing and rinsing machine parts, cleaning equipment, etc., and can solve the requirements of large waterway space, waste of bottom space, and material tensile properties Advanced problems, to achieve the effect of reducing the space occupied by waterways, reducing manufacturing costs, and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

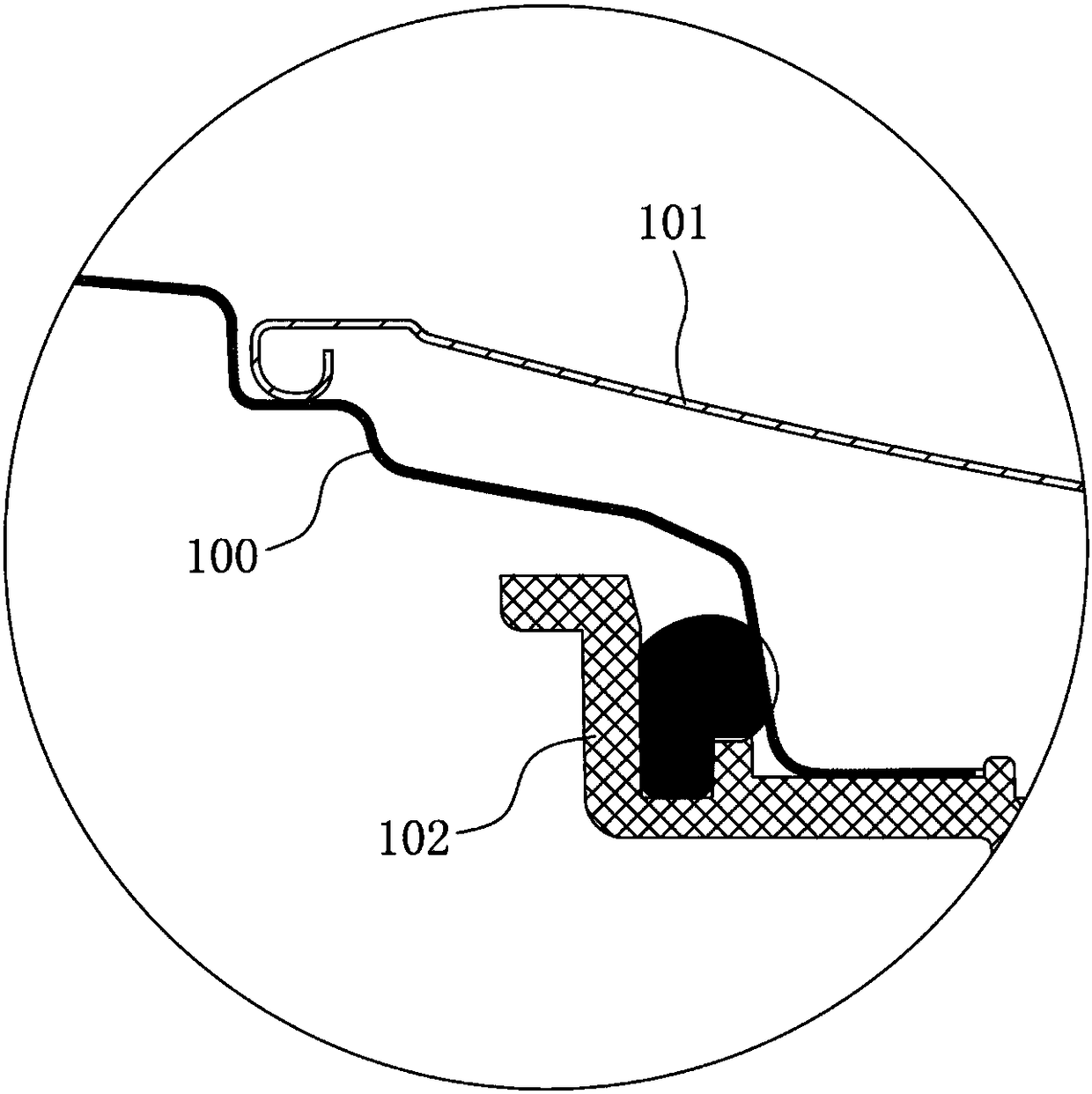

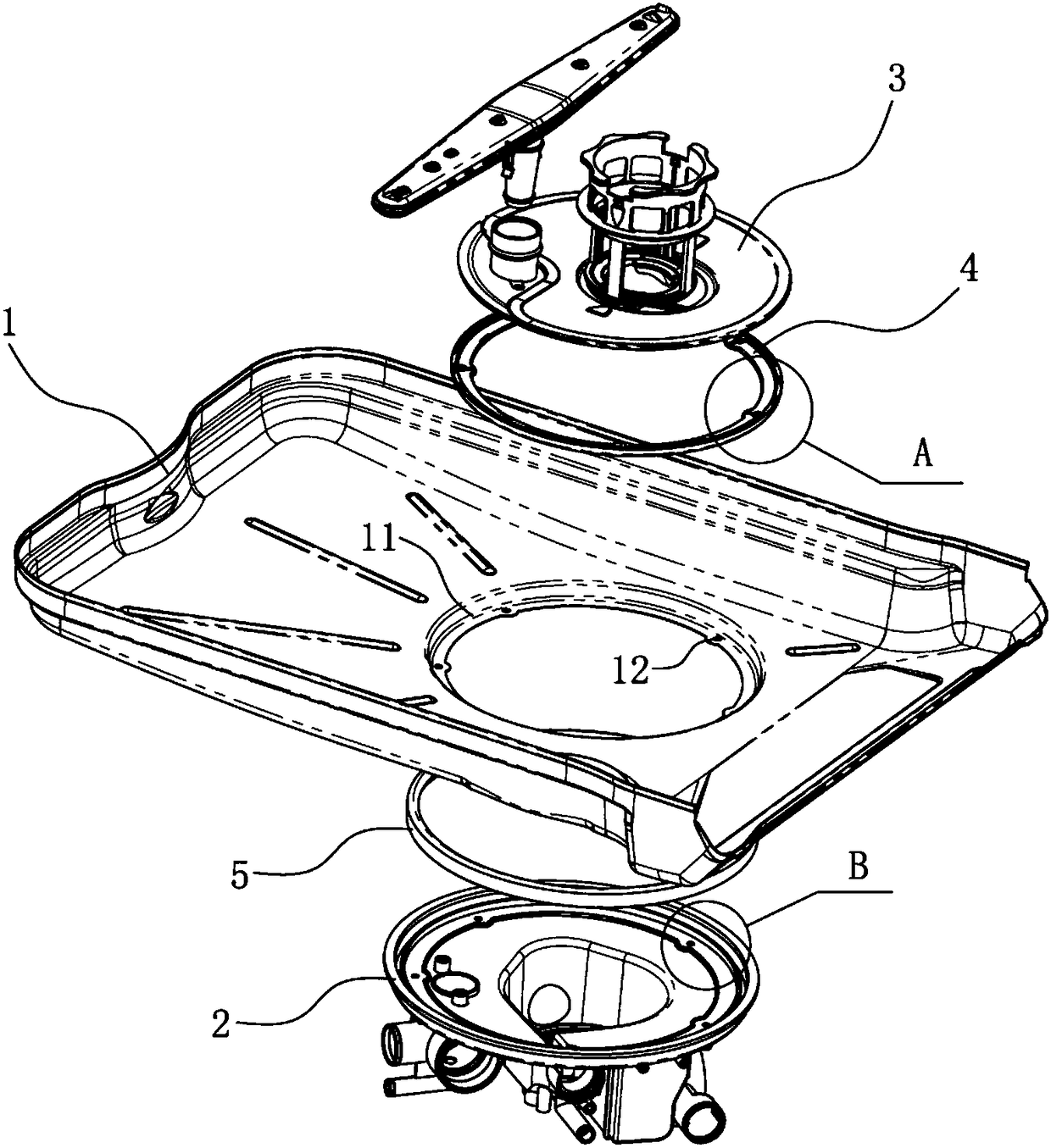

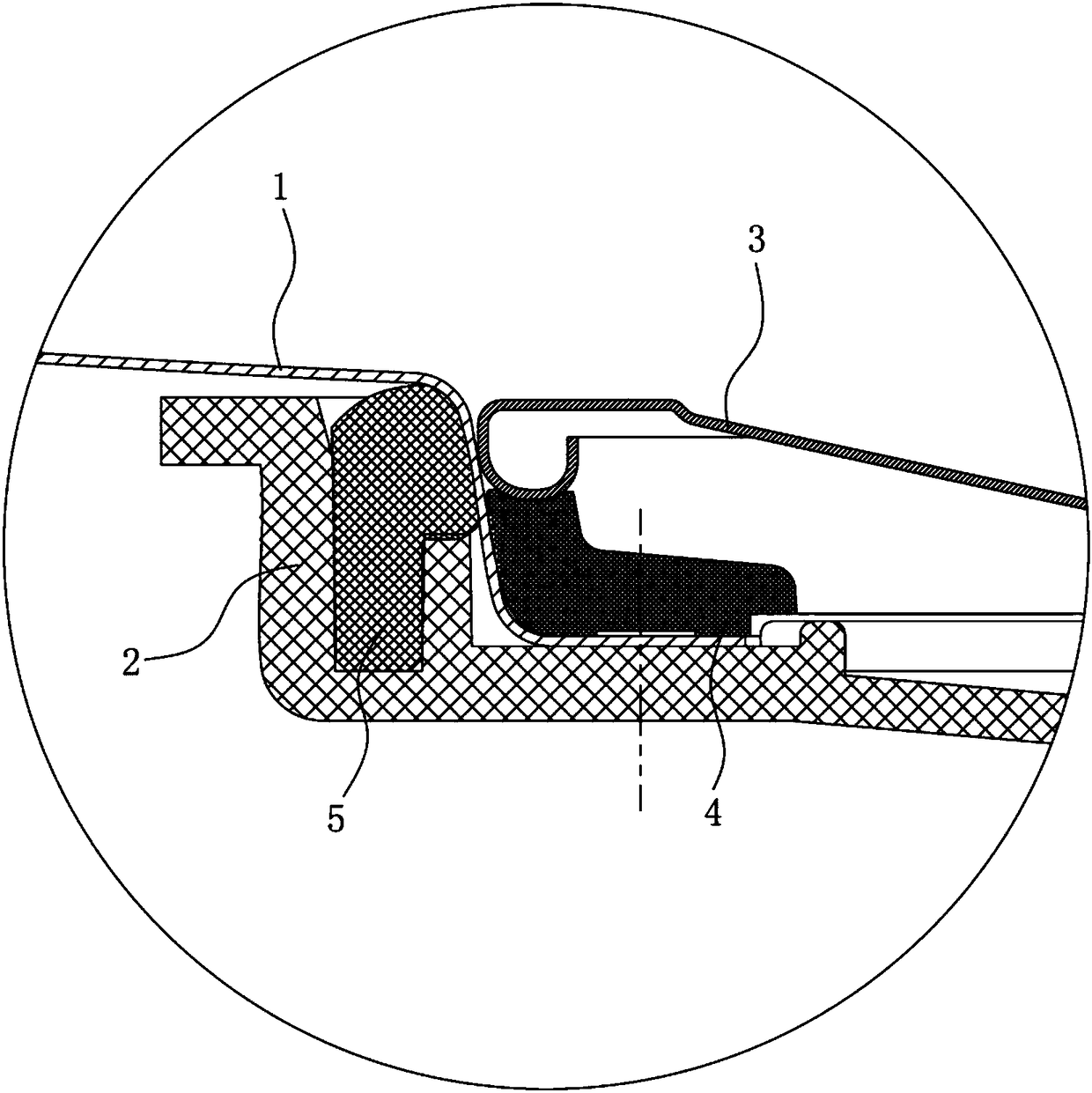

[0024] The invention provides a dishwasher, such as Figure 2-5 As shown, the dishwasher includes an inner container 1 and a water tank 2, and the part where the inner container 1 is connected to the water tank 2 is downwardly cylindrically recessed to form a concave part 11, and the bottom surface of the concave part 11 of the inner container 1 A nozzle (not shown in the figure) is provided on the top, and the liner 1 communicates with the water tank 2 through the nozzle.

[0025] A plane filter 3 is installed in the recessed part 11 of the liner 1 , and a support member 4 is arranged around the bottom surface of the planar filter 3 and the recessed part 11 for supporting the plane filter 3 .

[0026] In this embodiment, the part where the liner 1 and the water tank 2 are connected is downwardly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com