A tungsten inert gas welding protection device for turbine blades

A tungsten inert gas and protection device technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of easy occurrence of welding cracks and affect the processing quality of parts, and achieve the effect of improving welding quality and reducing manufacturing costs.

Active Publication Date: 2019-10-01

AECC AVIATION POWER CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a tungsten inert gas welding protection device for turbine blades, which solves the problem that only the inert gas flowing out of the welding torch is used to protect the parts when the welding part of the existing low-pressure turbine blade crown is welded, resulting in easy welding after welding. Cracks, defects that affect the processing quality of parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

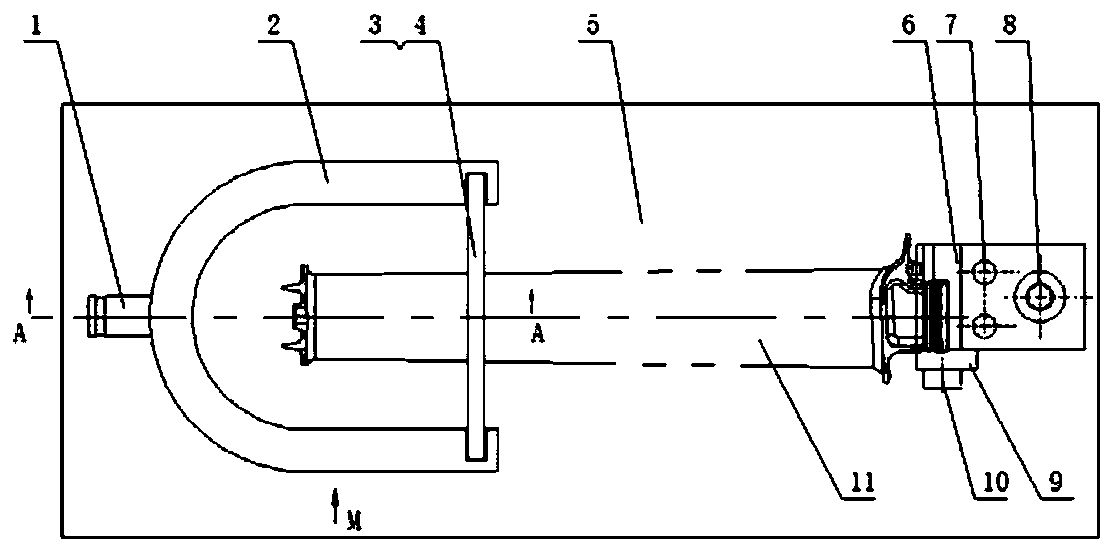

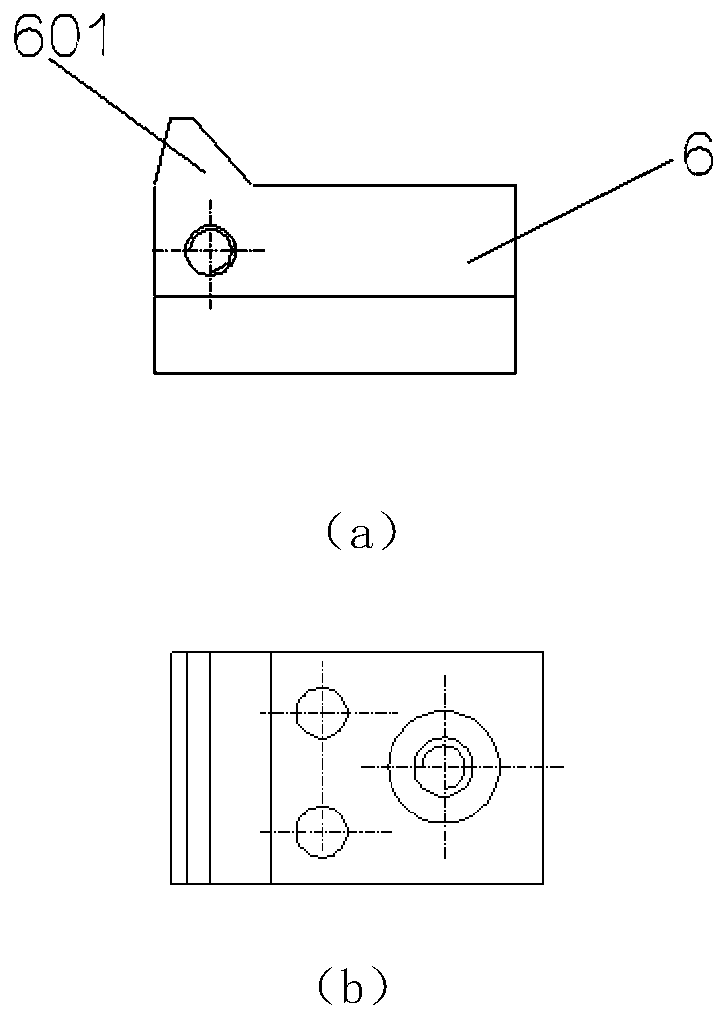

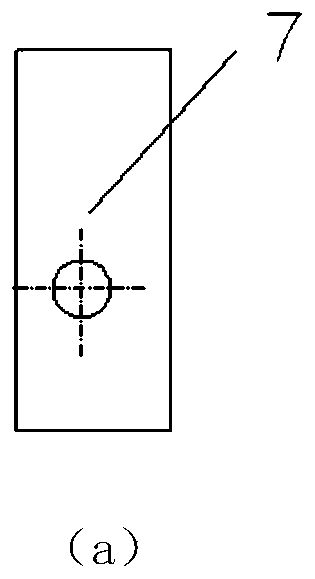

The invention provides a turbine blade tungsten electrode inert gas welding protective device. Firstly, a low-pressure turbine blade is placed on a bottom plate, the blade root part of the low-pressure turbine blade is fixed through a fixing device simultaneously, the condition that welding quality is influenced due to back-and-forth movement of a welded part during welding is prevented, finally the low-pressure turbine blade is placed in a protective shell with an annular space, and meanwhile, the annular space of the protective shell is filled with inert gas during welding. Therefore, when the part is welded, the front welded face of the welded part is protected through the inert gas flowing out of a welding gun, the side face of the welded part is protected through the inert gas in theannular space of the protective shell, all-round protection of the welded part during welding is achieved, and welding quality of the part is improved.

Description

technical field The invention belongs to the manufacturing field of turbine blades, in particular to a tungsten inert gas welding protection device for turbine blades. Background technique At this stage, almost all low-pressure turbine blades will add anti-vibration shoulders formed by hard alloy surfacing welding on the blade crown. At present, tungsten inert gas shielded welding is used for surfacing of hard alloys. Due to the special structure of the crown of the low-vortex blade, the thickness of the welded part is only 2 to 3mm. Only the inert gas flowing out of the welding torch is used to protect the parts. Cracks affect the processing quality of parts. Contents of the invention The purpose of the present invention is to provide a tungsten inert gas welding protection device for turbine blades, which solves the problem that only the inert gas flowing out of the welding torch is used to protect the parts when the welding part of the existing low-pressure turbine bl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23P15/04B23K37/00

Inventor 崔保卫钱勇徐文博温学兵白变琴杨嘉杨壮高敏雀

Owner AECC AVIATION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com