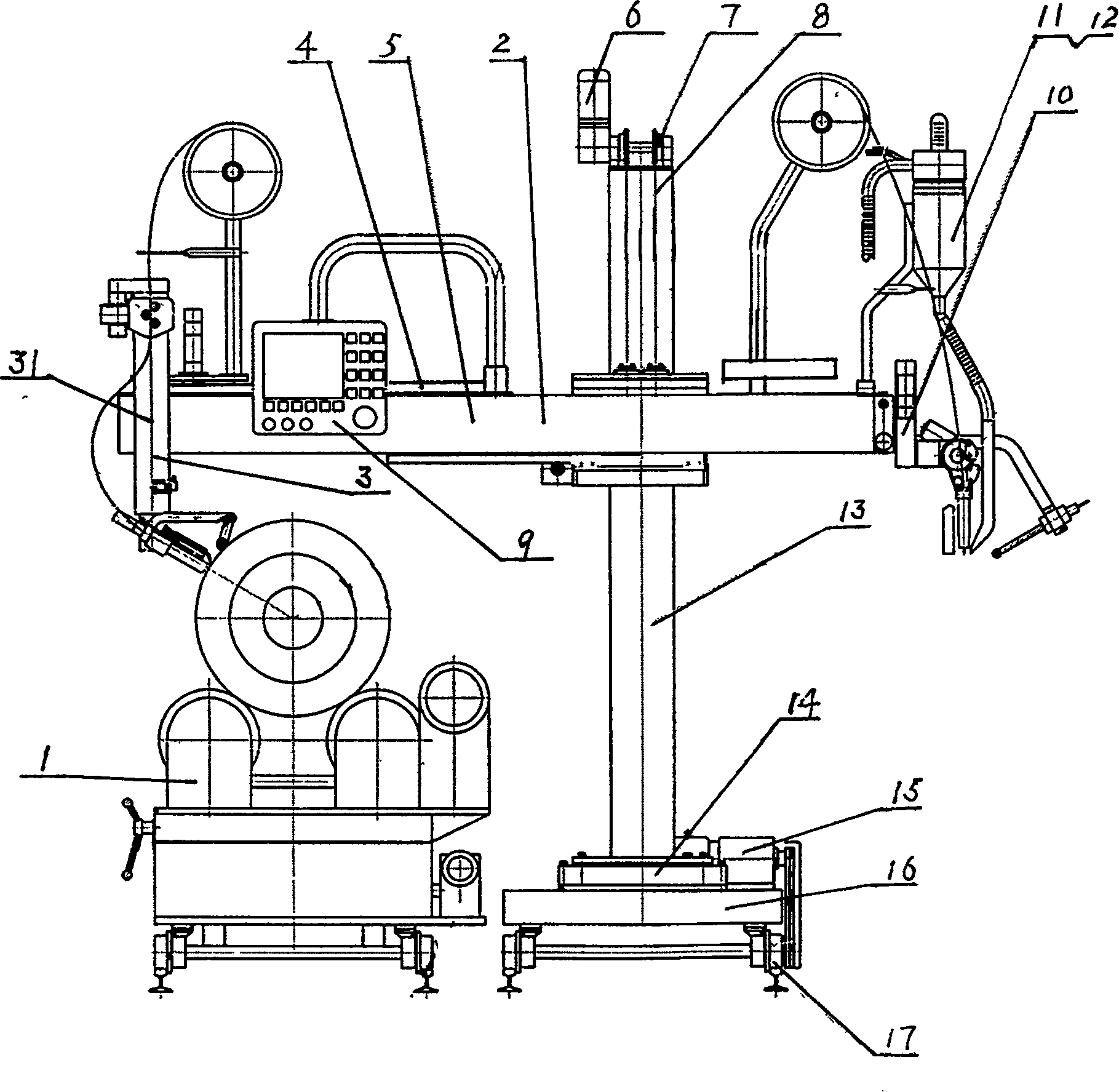

Process and device for automatic argon arc welding and narrow gap burial arc welding for circular pipe header seam

A technology of submerged arc welding and argon arc welding, which is applied in the field of automatic welding process of header box of power station boiler, can solve the problems of high labor intensity of welders, influence of welding quality, low production efficiency, etc., save auxiliary time and improve welding quality , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

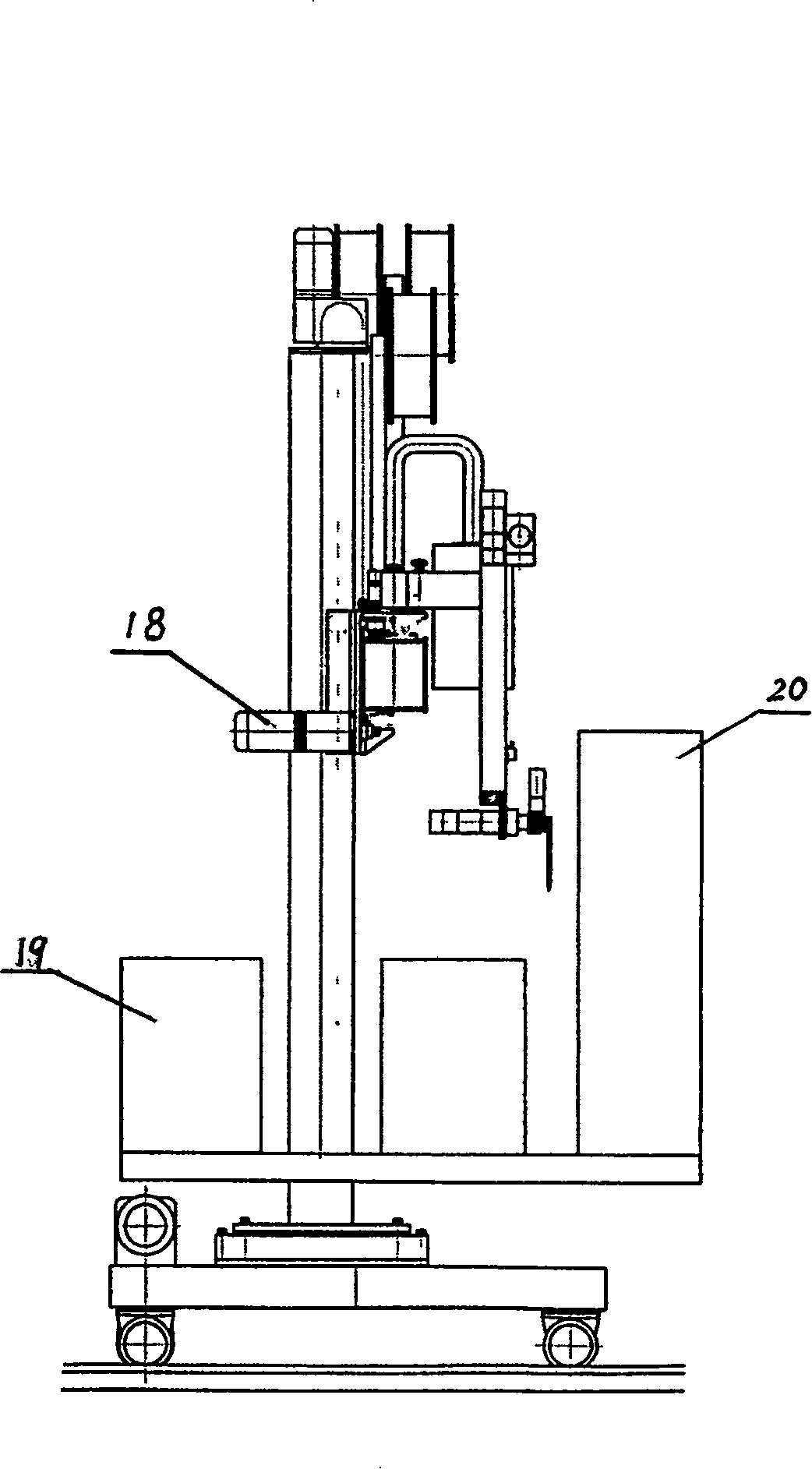

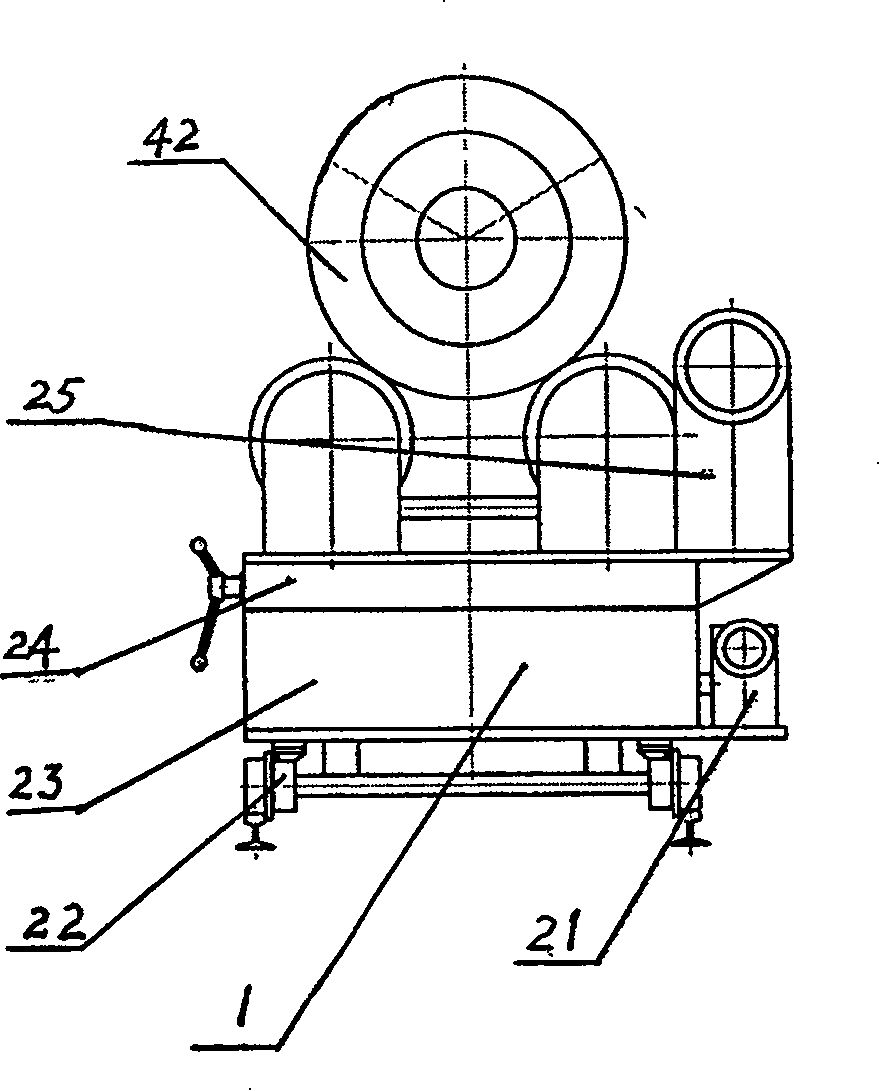

Method used

Image

Examples

Embodiment

[0030] The main technical parameters of the header during welding

[0031] Applicable range of header diameter: Φ219-838mm

[0032] Scope of header wall thickness: 16-120mm Header length: scope of application: single tube:

[0033] 1-12m; total length after welding: max.25m

[0034] Header material: carbon steel, alloy steel and stainless steel

[0035] Preheating temperature before welding: ≤300℃

[0036] Groove type of header ring seam:

[0037] U-shaped bevel with narrow gap, bevel angle range: 2~5°, root R 6, blunt edge 2mm, no gap; it can also adapt to ordinary double V-shaped bevel.

[0038] Wire Diameter:

[0039] Automatic argon arc welding TIG welding wire: Φ1.0~1.2mm

[0040] Fine wire narrow gap submerged arc welding NG-SAW wire: Φ1.6~2.0mm

[0041] Ordinary submerged arc welding SAW wire: Φ3.0~4.0mm

[0042] The automatic argon arc welding + narrow gap submerged arc welding process of the header ring seam is:

[0043] 1. The preheating temperature of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com