Cement-based waterproof and crack-resistant material suitable for foundation bed of railroad bed in expansive rock area

A railway subgrade and cement-based technology, which is applied in the field of cement-based waterproof and anti-cracking materials, can solve the problems of increasing the depth of subgrade replacement, increasing construction costs, and rare reports, shortening the construction period, reducing the engineering cost, and reducing The effect of the amount of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

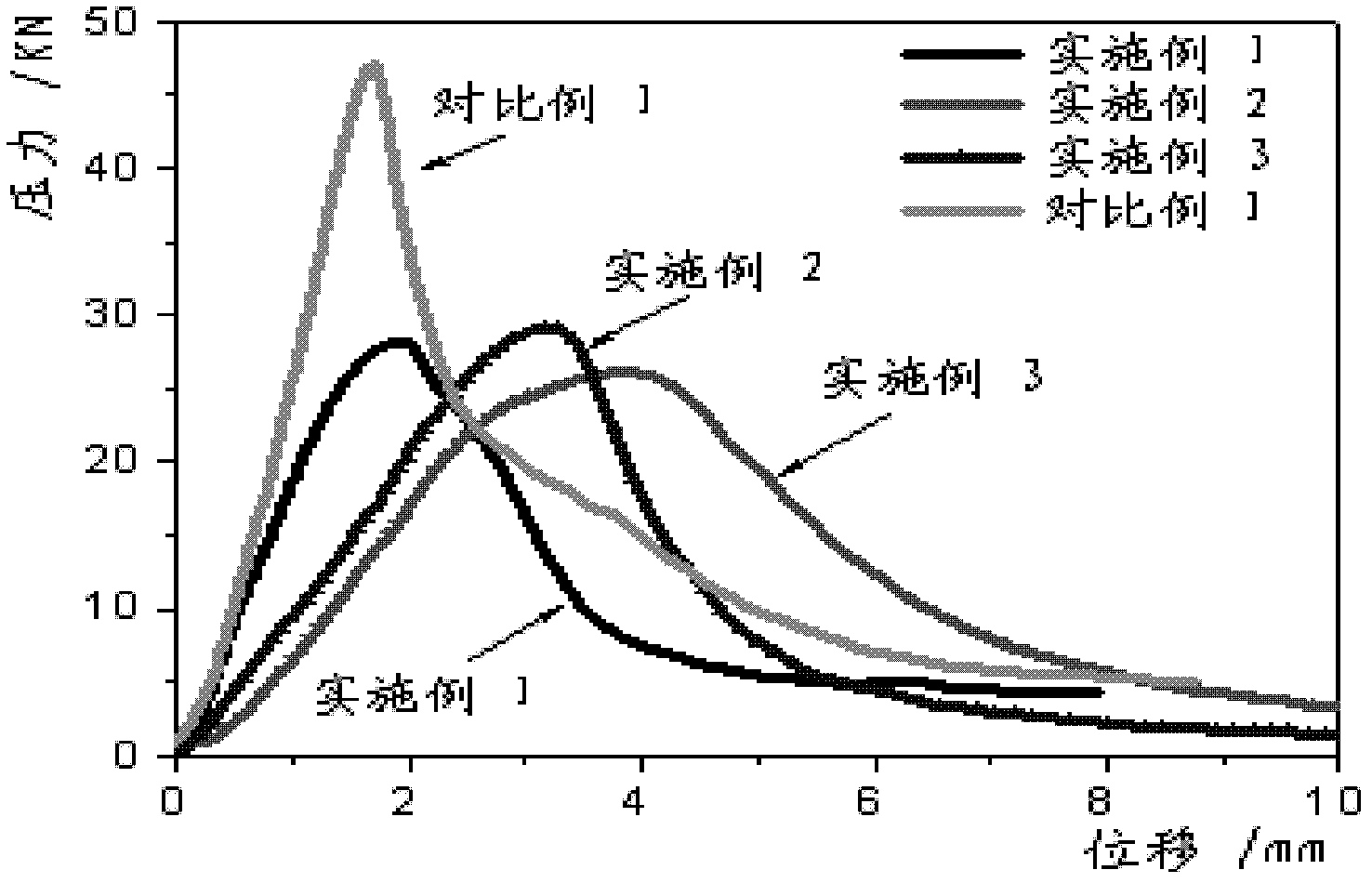

[0041] Wherein the mass ratio of rubber powder particles, polypropylene fiber, emulsified asphalt, latex powder and light calcium carbonate powder in the modified component of the invention example is 1:0.024:0.8:0.06:0.34.

[0042] Taking implementation 3 as an example, the ratio of materials per cubic meter is as follows: (unit: kg / m 3 )

[0043]

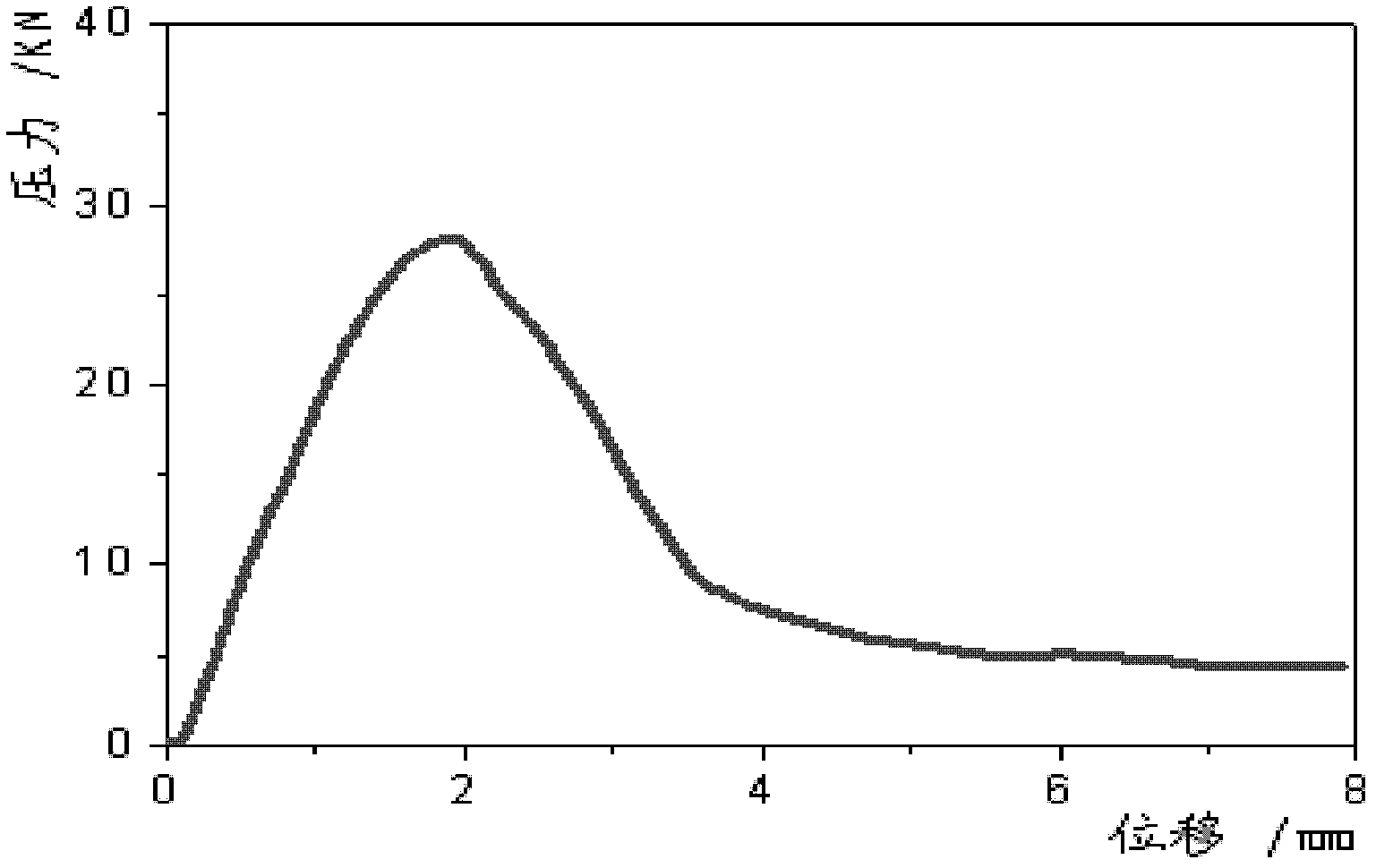

[0044] The cement-based waterproof and anti-cracking material of the present invention has undergone standard maintenance for 28 days, and its main properties are: compressive strength (2.0-5.0) MPa, elastic modulus ≤ 2GPa, 56d electric flux ≤ 6000C, typical stress-strain curve figure 2 shown.

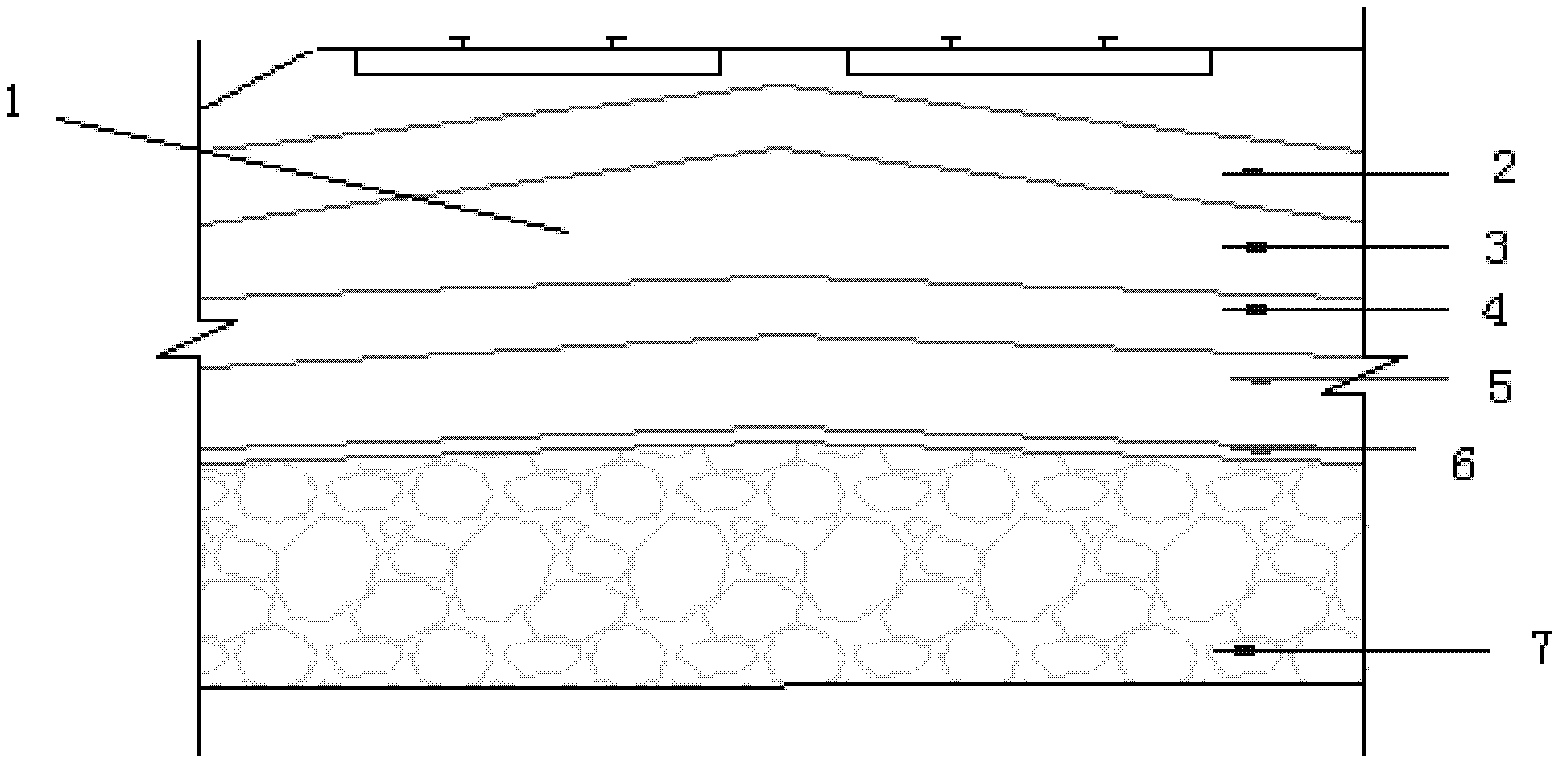

[0045] figure 1 The material of the present invention is used in the expansive rock subgrade bed, in the figure: 1-bed surface layer, 2-0.7 (0.6) m thick graded gravel, 3-2.15 (1.75) m thick A, B group filler, 4 -0.10m thick medium-coarse sand (buffer layer), 5-cement-based waterproof and anti-cracking material, 6-surface tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com