Onsite test device for testing concentration distribution of corrosion inhibitor, and method thereof

A technology of concentration distribution and on-site testing, which is applied in the direction of measuring devices, particle size analysis, and analytical materials, etc., can solve the problems of not being able to give full play to the anticorrosion effect of corrosion inhibitors, staying in numerical simulation, waste of corrosion inhibitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

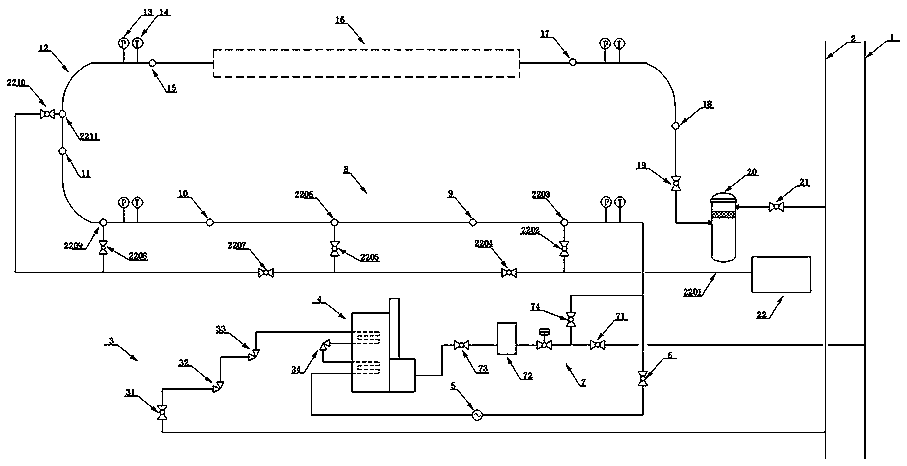

[0078] In this embodiment, the test loop is installed on the bypass pipeline of a section of the pipeline on site.

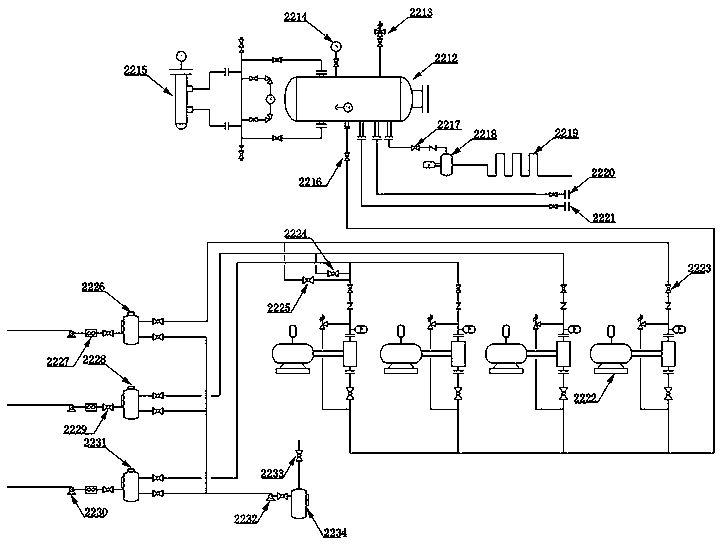

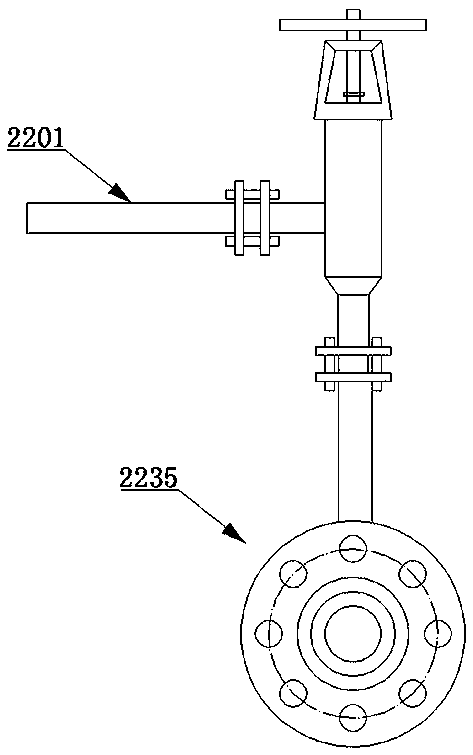

[0079] Such as figure 1As shown, a field test device for corrosion inhibitor concentration distribution test is characterized in that it includes fuel gas pipeline 1, acid gas pipeline 2, pressure regulating module 3, heating furnace 4, flow meter 5, acid gas valve 6, fuel gas Processing module 7, horizontal test module 8, first detection area 9, second detection area 10, third detection area 11, elbow test module 12, pressure sensor 13, temperature sensor 14, fourth detection area 15, vertical test module 16. Fifth detection area 17, sixth detection area 18, inlet separator valve 19, separator 20, air outlet valve 21, continuous injection of corrosion inhibitor module 22, corrosion inhibitor droplet size test module 23, test ring Road 24;

[0080] The pressure regulation module 3, the heating furnace 4, the horizontal test module 8, the elbow test module 12, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com