Molecular sieve adsorption tower provided with heat transferring medium channels

A heat exchange medium and adsorption tower technology, which is applied in the field of adsorption purification equipment, can solve the problems such as the switching cycle of the adsorption device cannot be further shortened, the regeneration gas consumption is large, and the time required is long, so as to reduce the time required for regeneration and reduce The effect of waste and lower usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

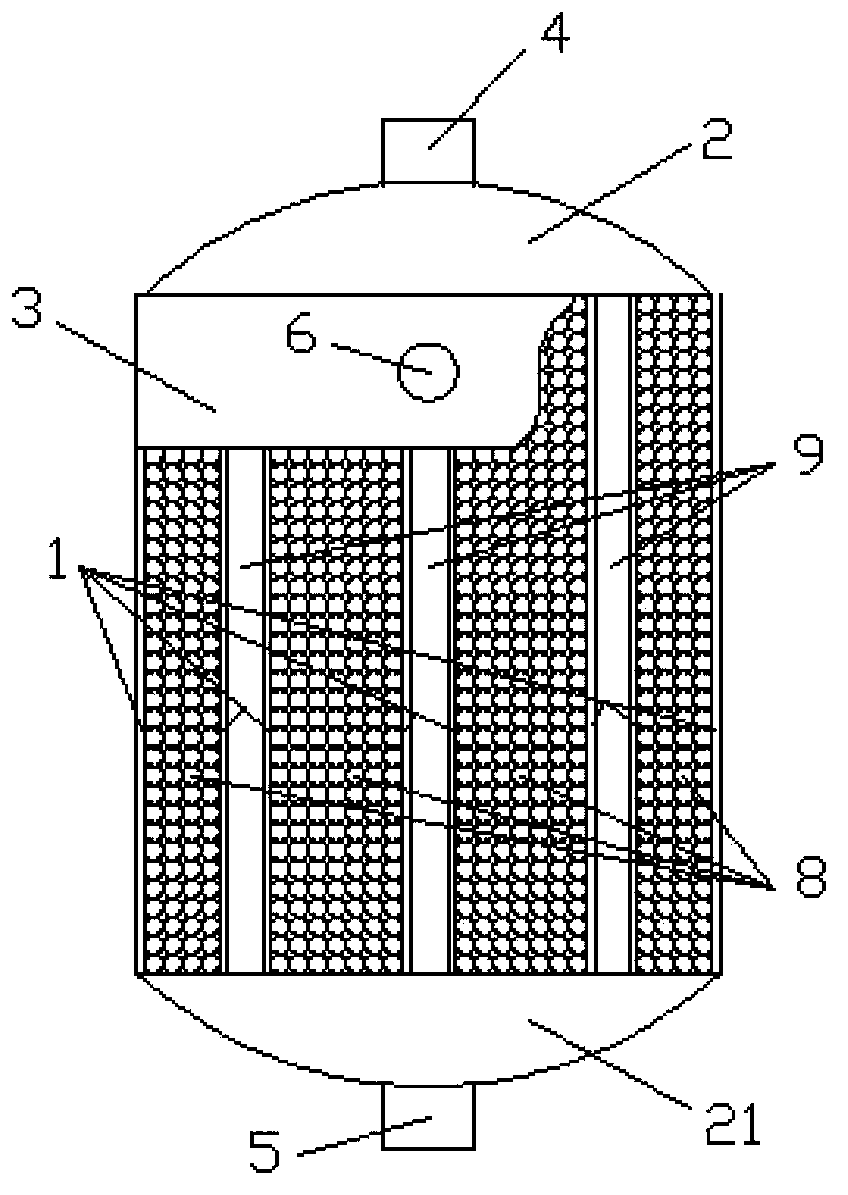

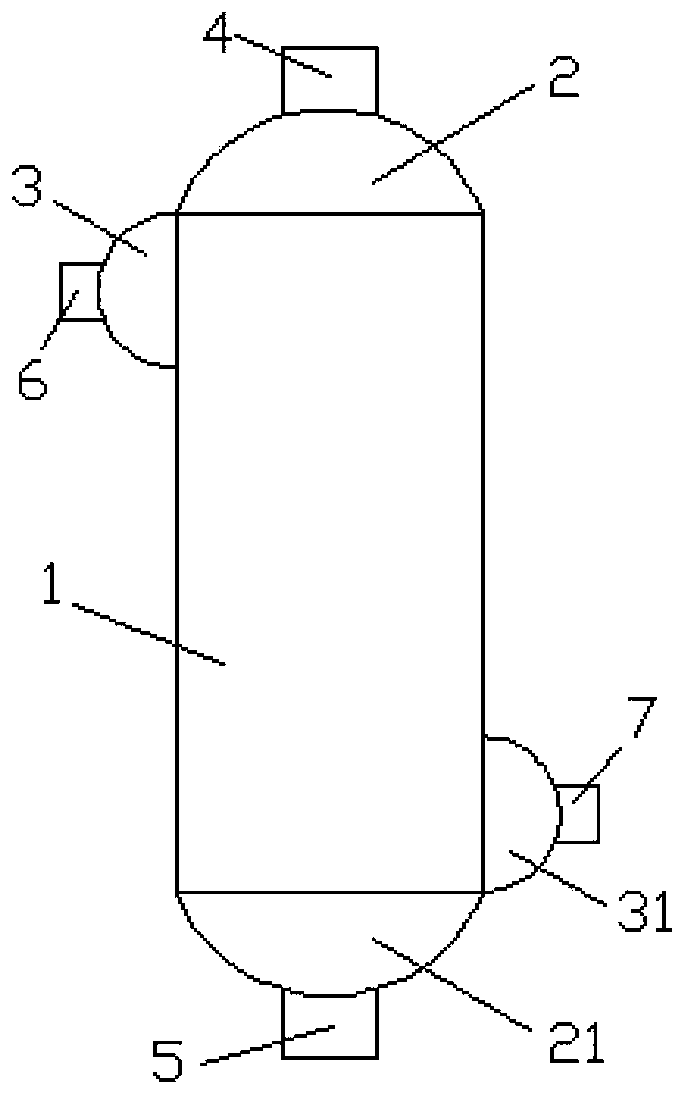

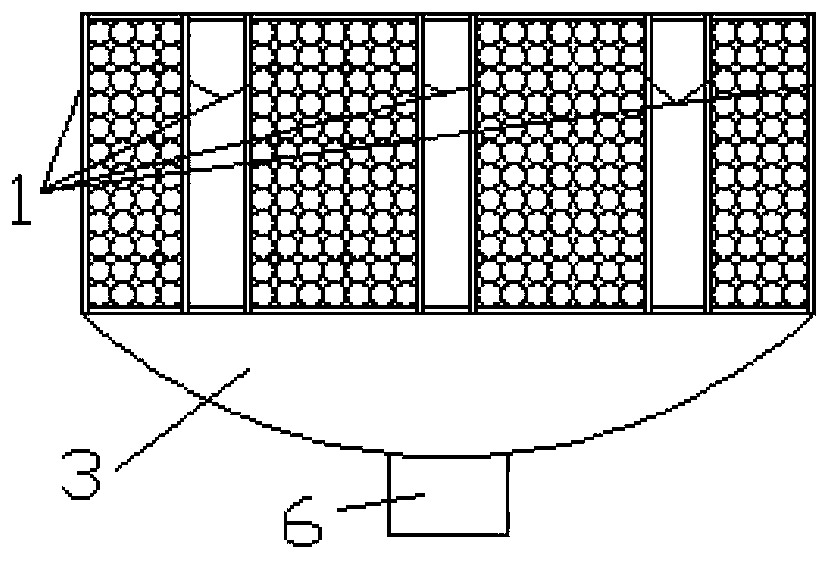

[0024] Such as figure 1 , figure 2 and image 3 As shown, the structural schematic diagram of the molecular sieve adsorption tower (embodiment) with heat exchange medium channels, it can be seen from the figure that the molecular sieve adsorption tower with heat exchange medium channels provided by the present invention is composed of the following components:

[0025] One adsorption tower container;

[0026] Vertical partitions 1 arranged at intervals in the container of the adsorption tower;

[0027] Adjacent vertical partitions 1 enclose a space flow channel, and the space flow channels distributed at intervals are filled with molecular sieve adsorbents; the space flow channels equipped with molecular sieve adsorbents are process gas channels 8; Heat medium channel 9;

[0028] The upper process gas seal head 2 and the lower process gas seal head 21 respectively mounted on the upper and lower ends of the adsorption tower container, the ends of the upper process gas seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com