Patents

Literature

54results about How to "Shorten regeneration time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

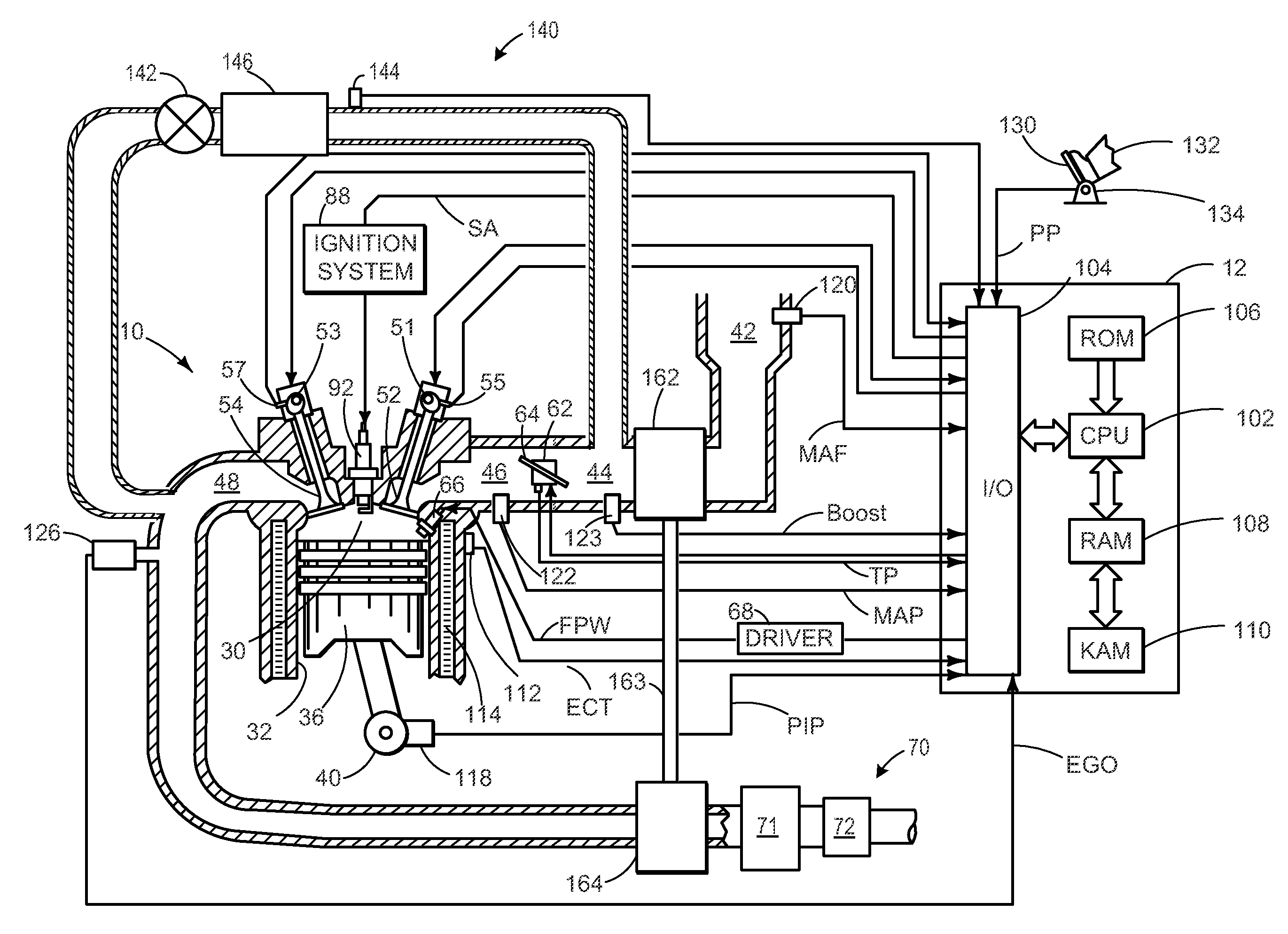

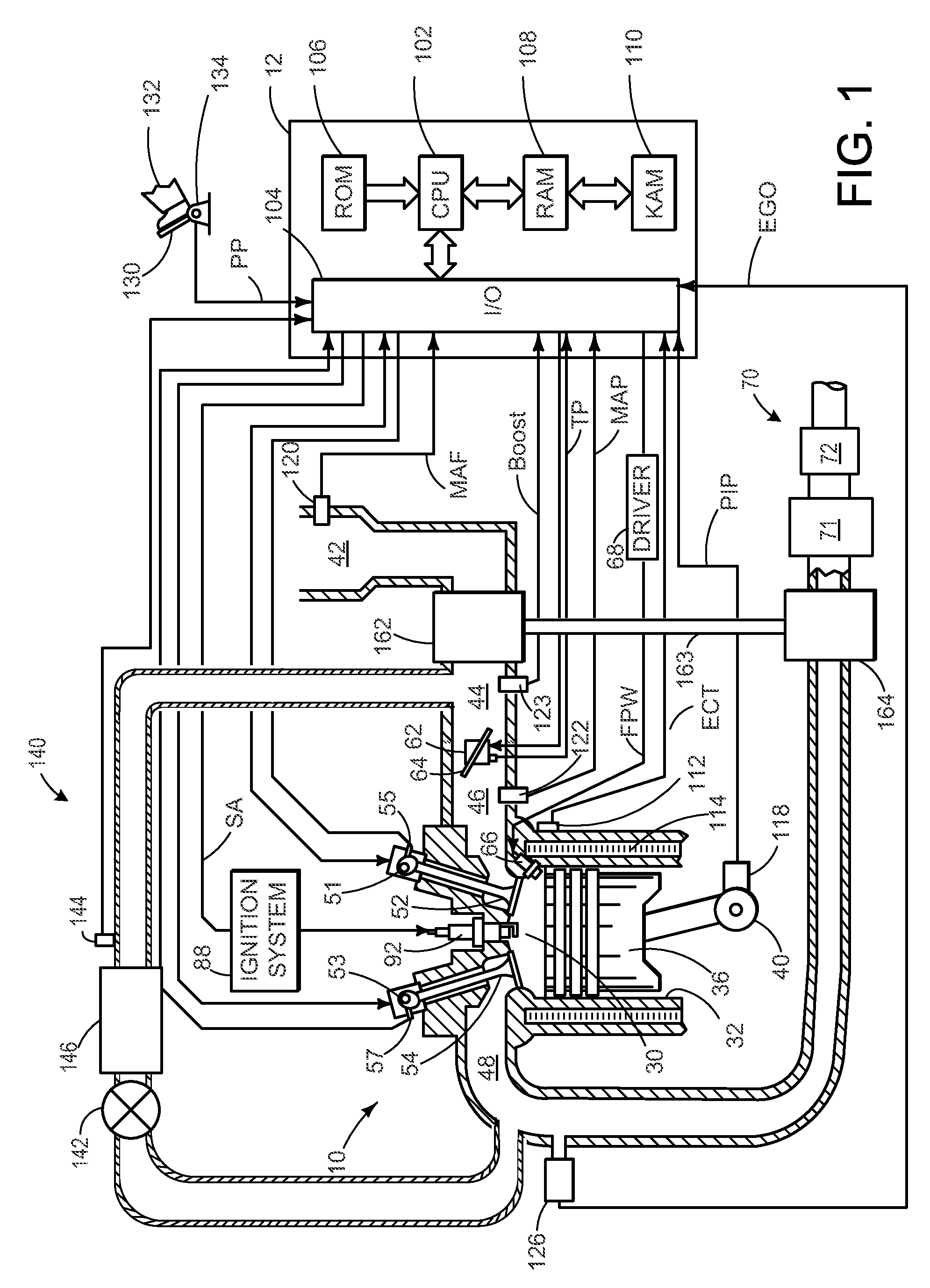

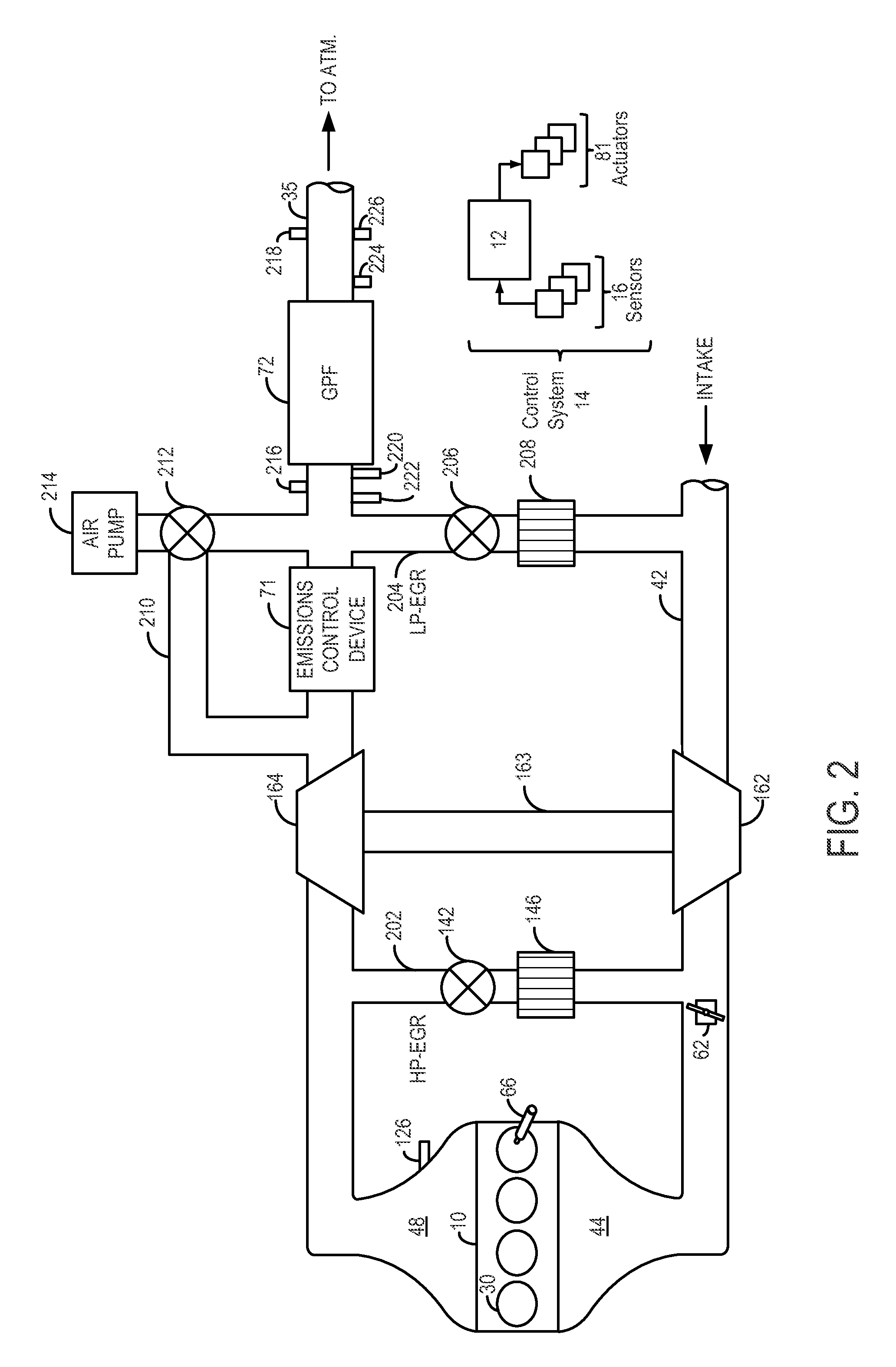

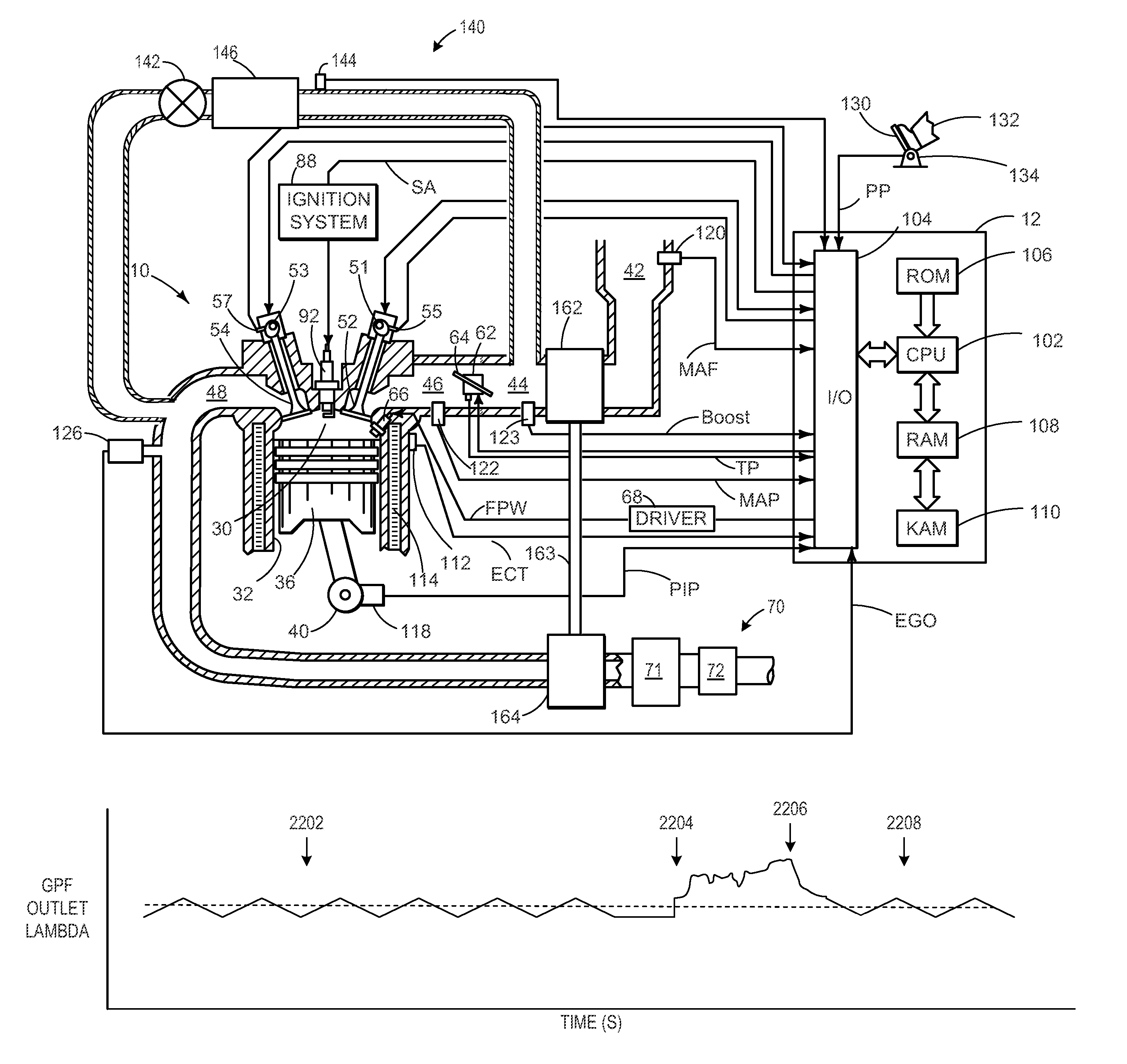

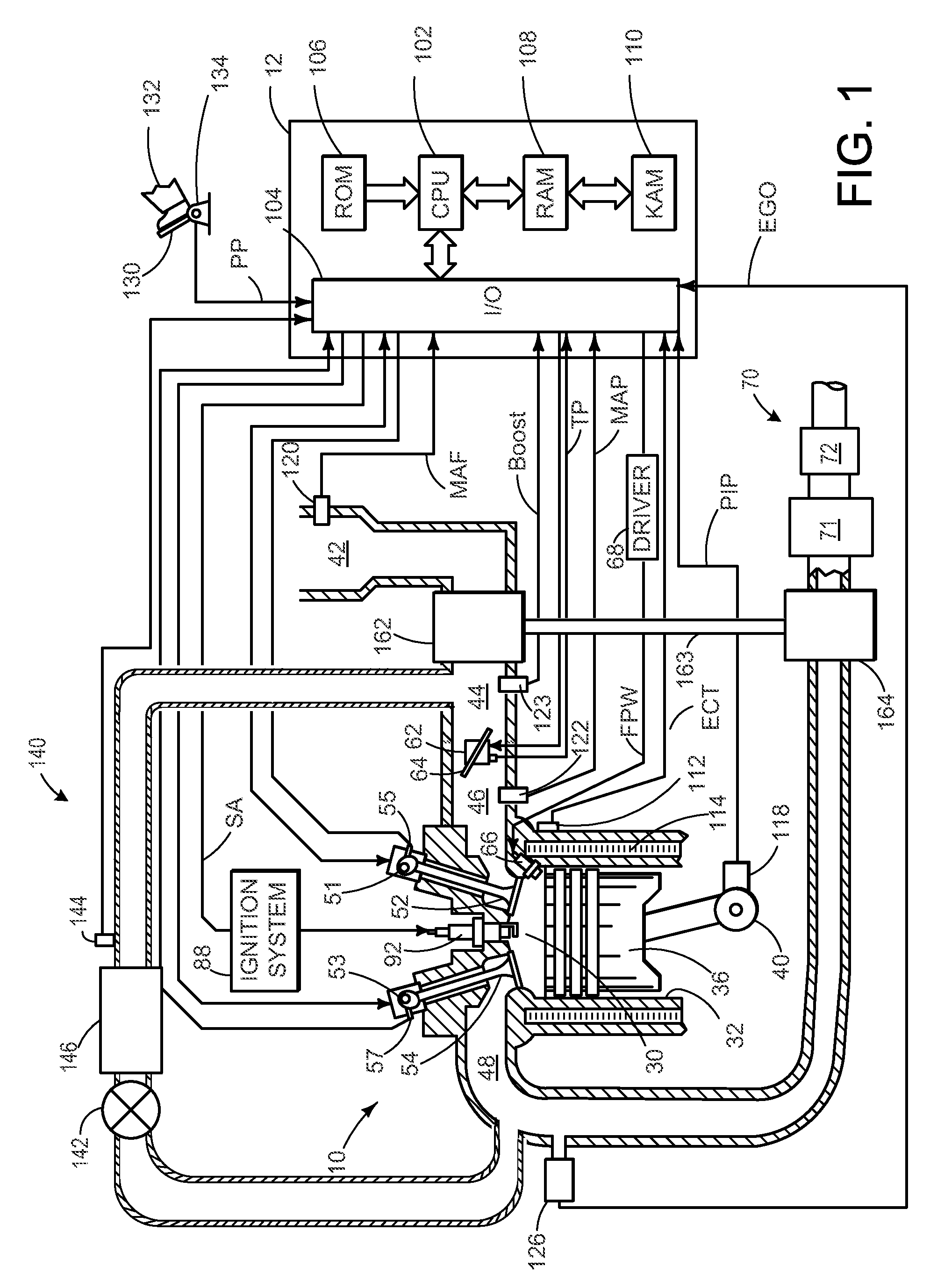

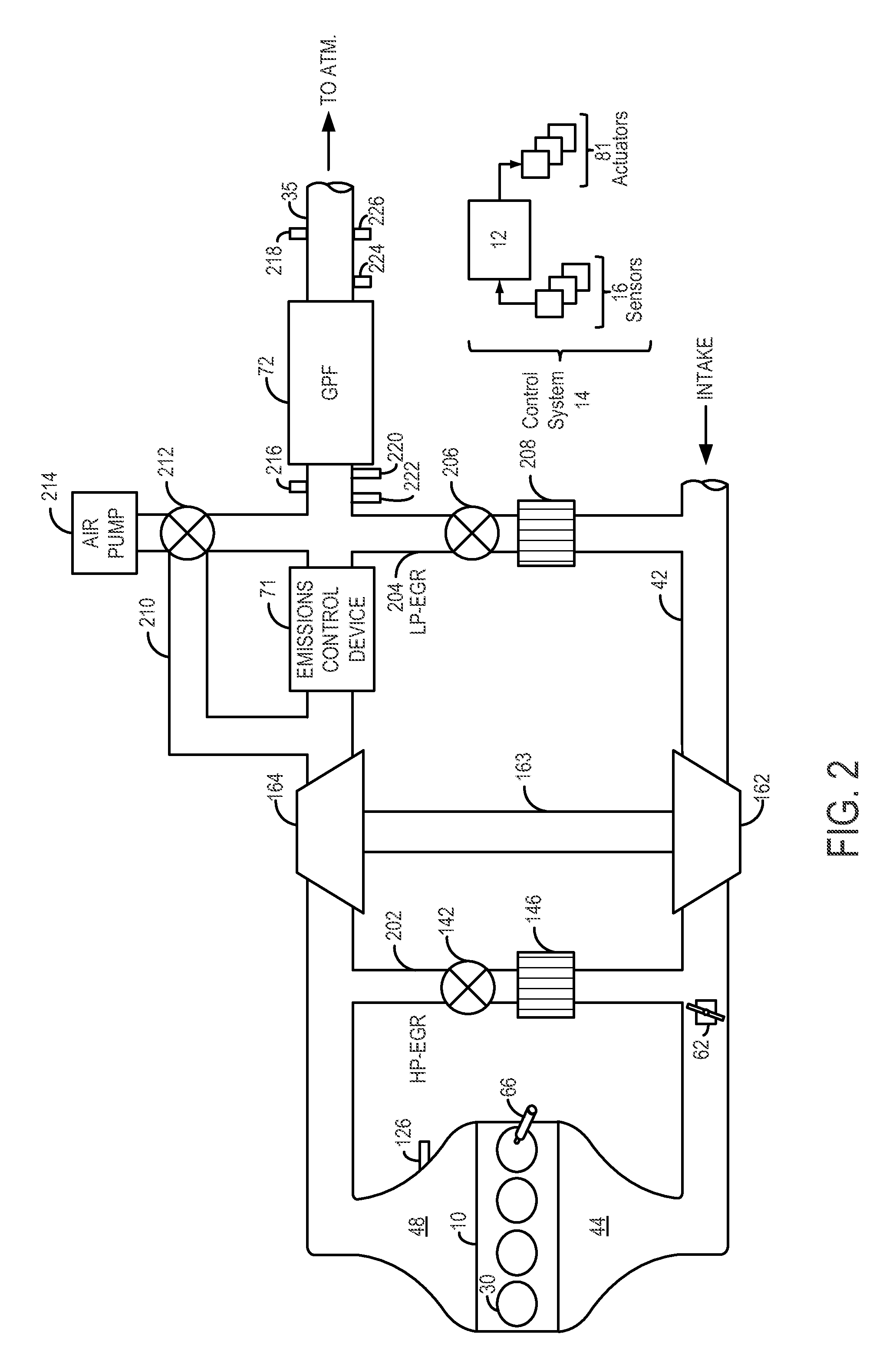

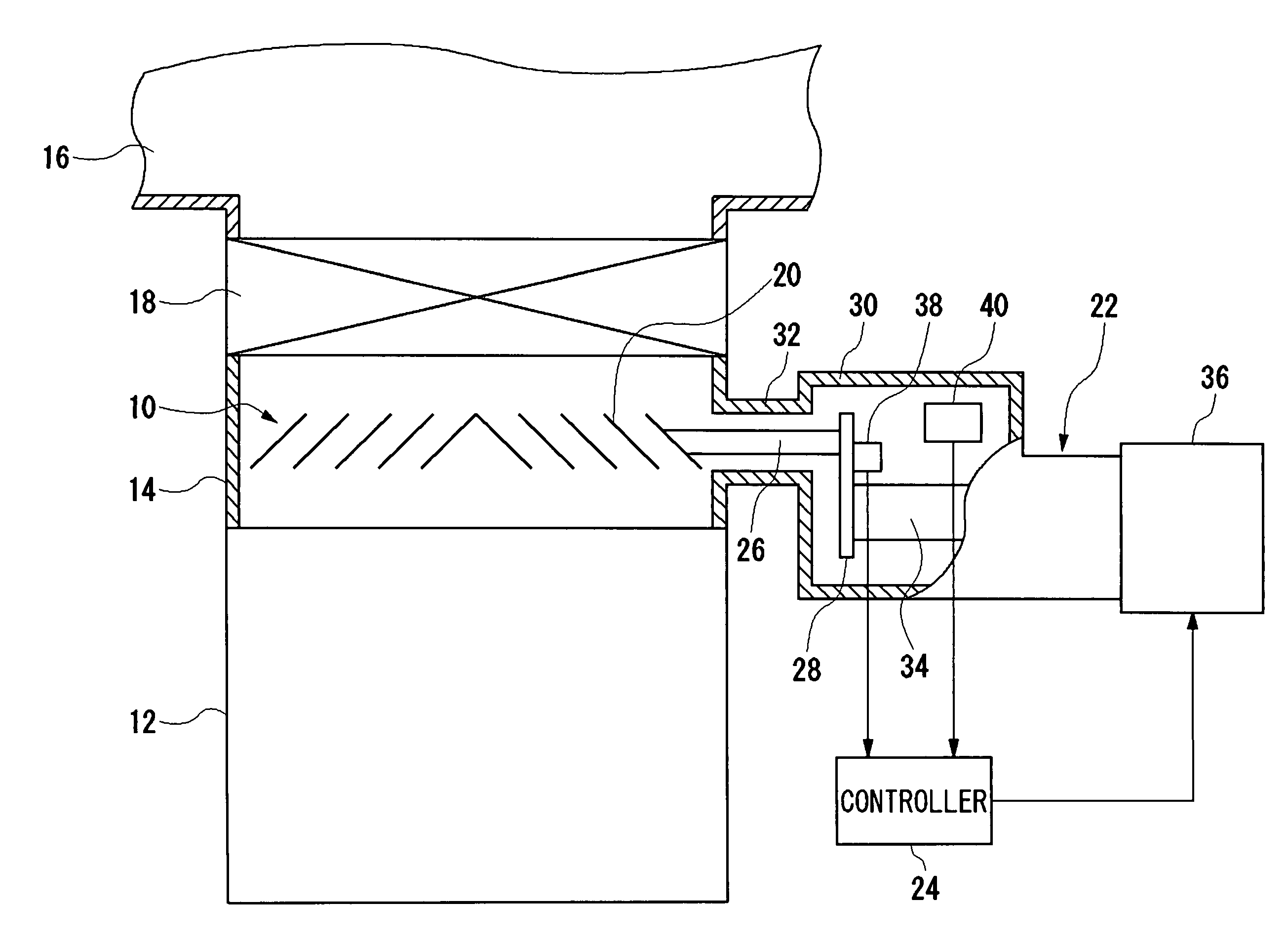

Gasoline particulate filter regeneration and diagnostics

ActiveUS20110072788A1Improve engine performanceReduce transient air-fuel disturbanceElectrical controlNon-fuel substance addition to fuelParticulatesGasoline

Owner:FORD GLOBAL TECH LLC

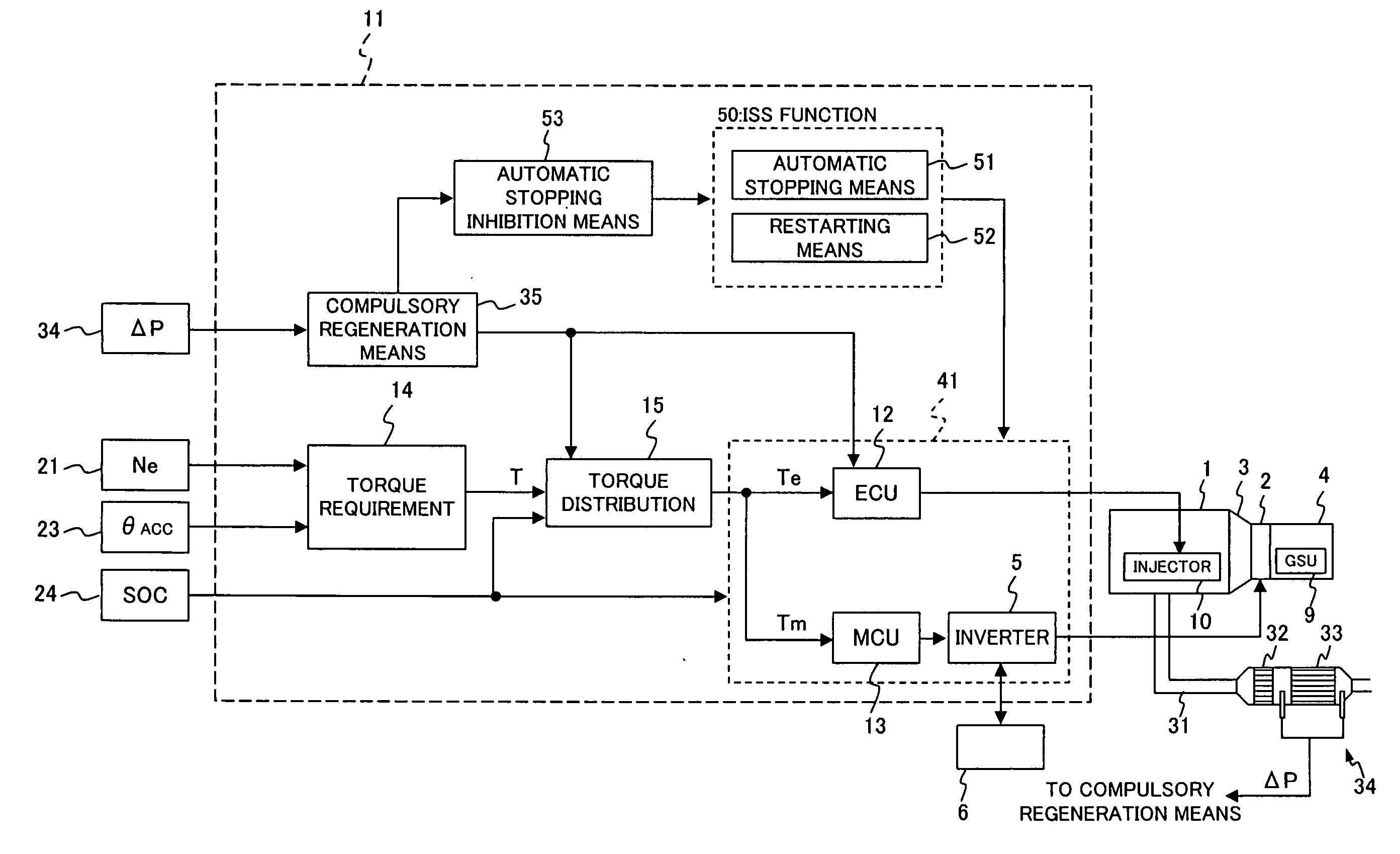

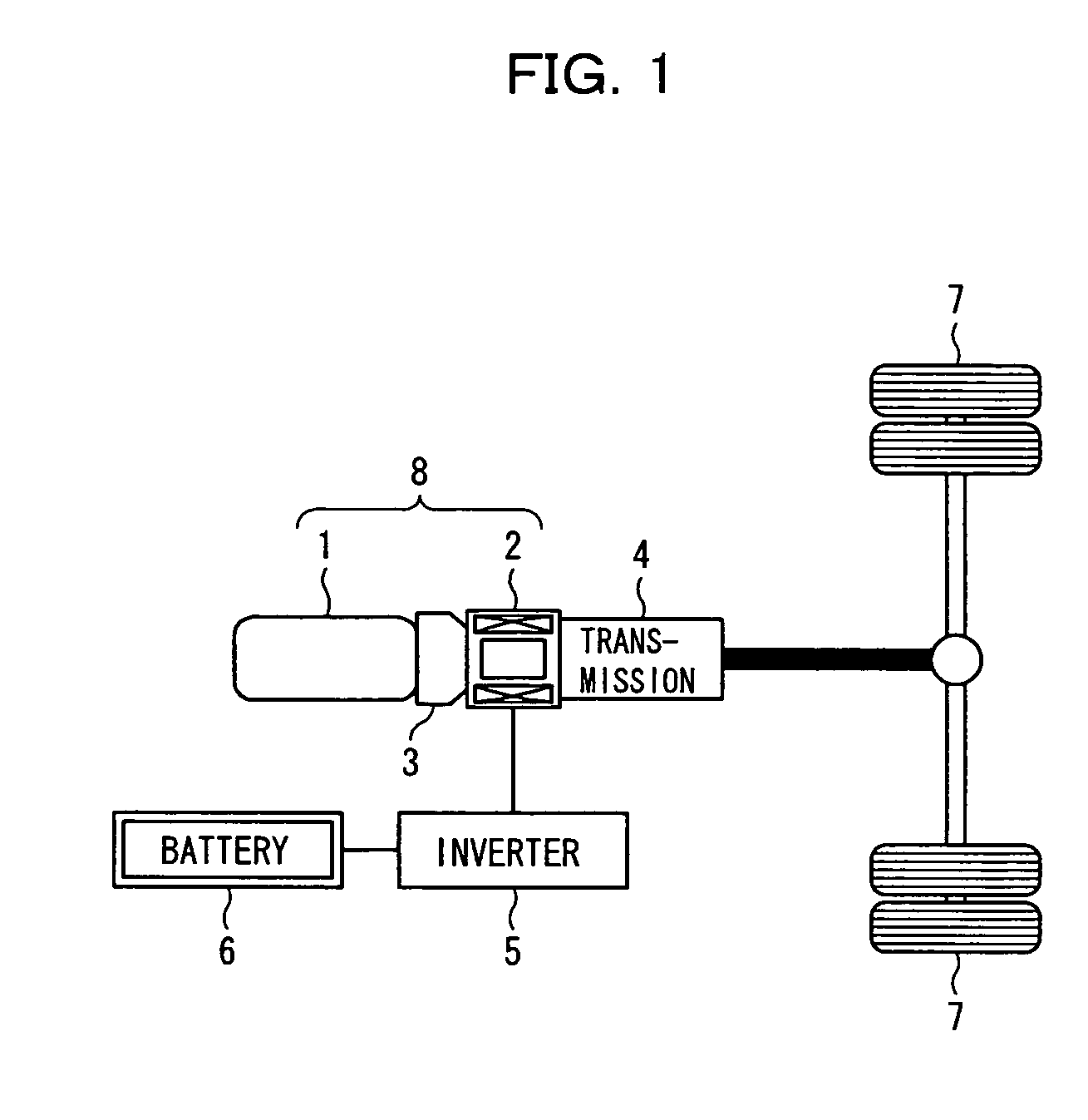

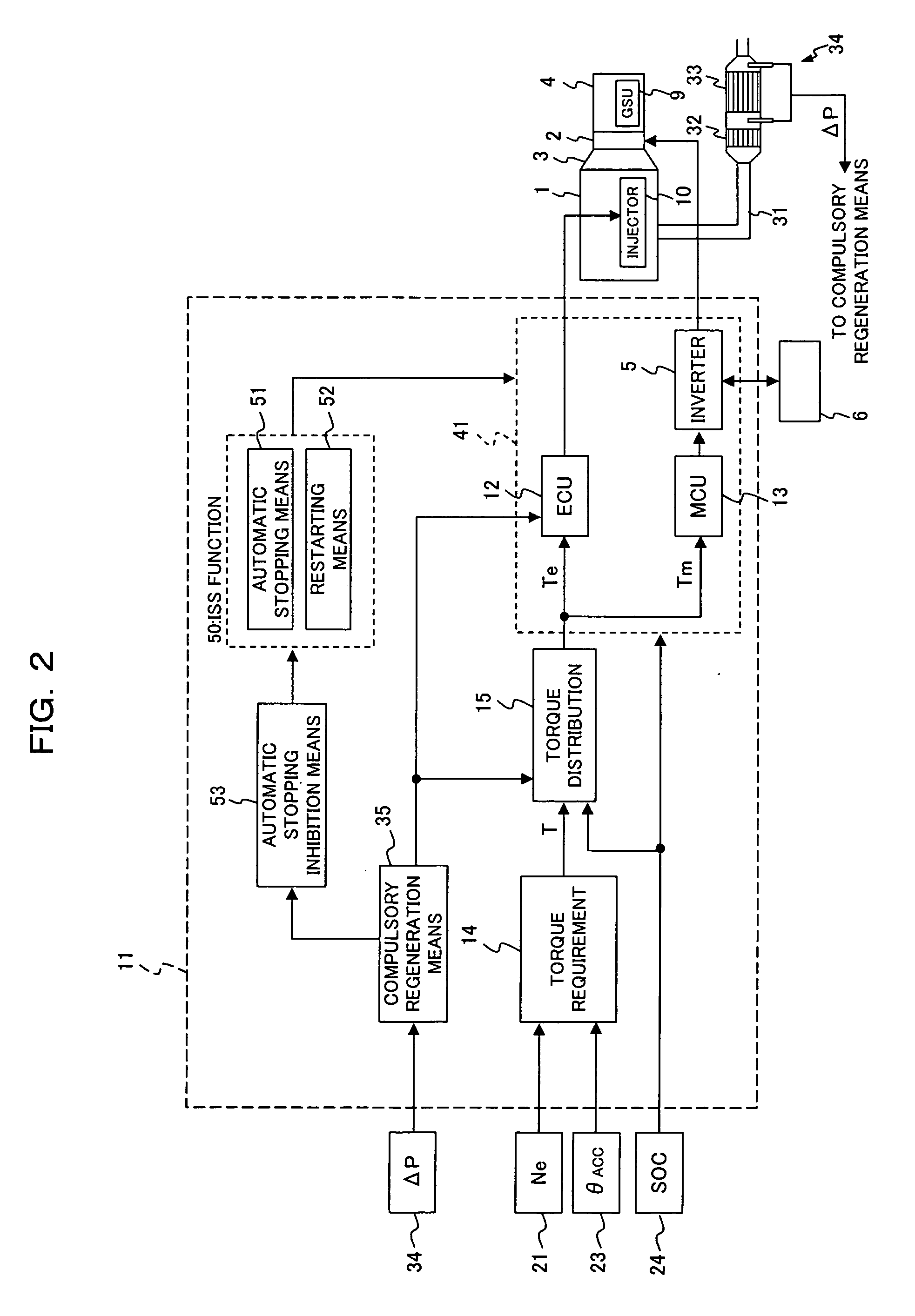

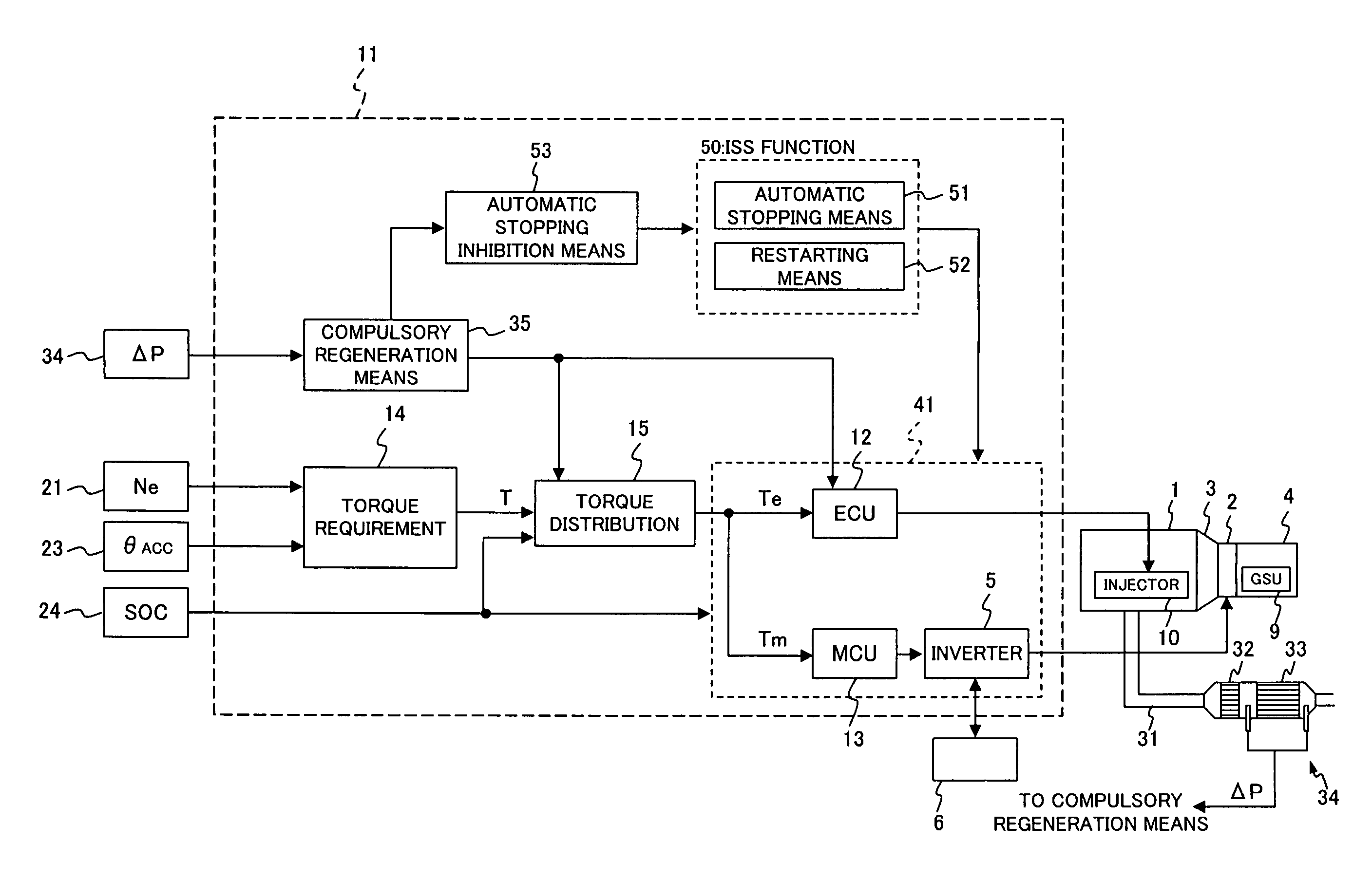

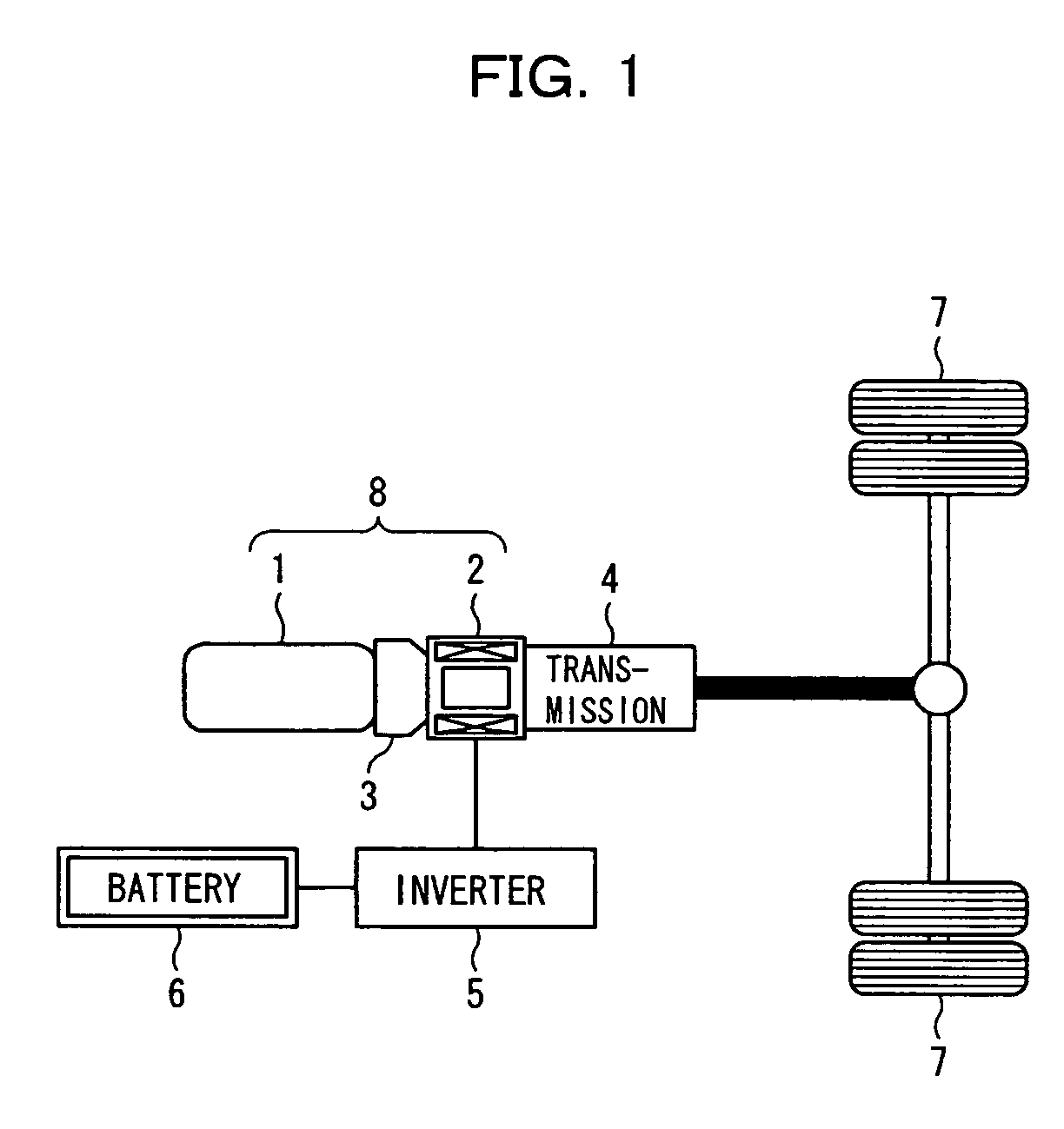

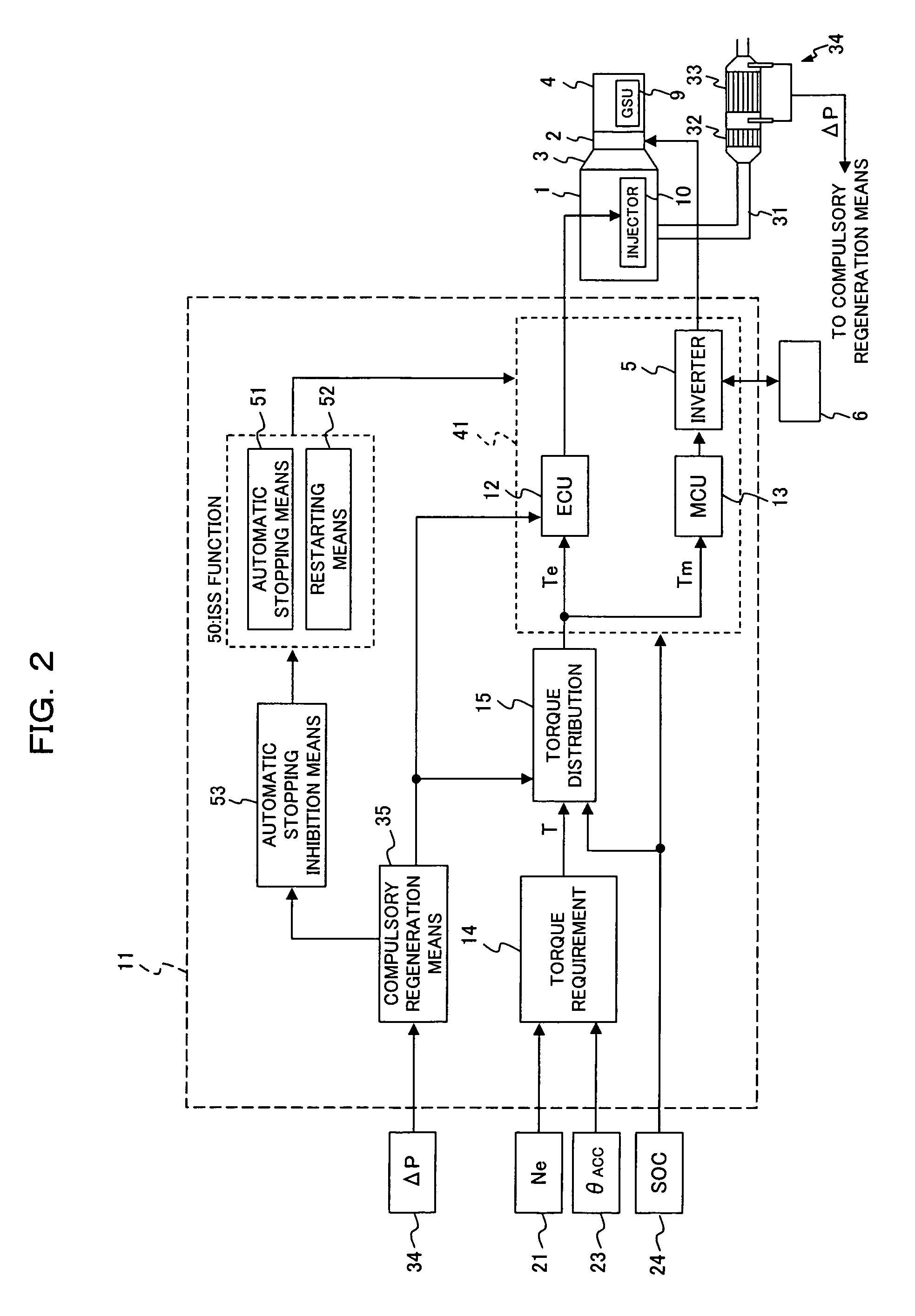

Motor control apparatus for a hybrid vehicle

InactiveUS20060218903A1Increased fuel costShorten the time periodElectrical controlInternal combustion piston enginesParticulatesElectrical battery

A motor control apparatus for a hybrid vehicle in which a diesel engine is used is disclosed by which the compulsory regeneration time period of the hybrid vehicle is reduced to achieve enhancement of the fuel cost. The motor control apparatus for a hybrid vehicle includes a filter for collecting particulate matter in exhaust gas of the diesel engine, compulsory regeneration means for compulsorily regenerating the filter, and battery charging means for converting the output power of the diesel engine into electric power based on a charged state of the battery and charging the battery with the electric power. When the compulsory regeneration is executed, the supply of electric power to the battery by the engine is inhibited.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

Olefin production process

InactiveUS8299313B2Improve thermal stabilityShorten regeneration timeHydrocarbon by isomerisationOrganic chemistry methodsRheniumIsomerization

A process is provided which is capable of producing olefins stably and efficiently by a metathesis reaction of identical or different olefins while preventing the lowering in metathesis catalyst activity due to trace impurities such as heteroatom-containing compounds that are contained in a starting olefin.The olefin production process includes supplying a starting olefin containing more than 0 ppm by weight to not more than 10 ppm by weight of one or more kinds of heteroatom-containing compounds to a reactor that contains a metathesis catalyst and an isomerization catalyst, the metathesis catalyst including at least one metal element selected from the group consisting of tungsten, molybdenum and rhenium, the isomerization catalyst including calcined hydrotalcite or yttrium oxide, and performing a metathesis reaction of identical or different olefins.

Owner:MITSUI CHEM INC

Olefin production process

InactiveUS20110152595A1Improve thermal stabilityShorten regeneration timeHydrocarbon by isomerisationOrganic chemistry methodsRheniumIsomerization

A process is provided which is capable of producing olefins stably and efficiently by a metathesis reaction of identical or different olefins while preventing the lowering in metathesis catalyst activity due to trace impurities such as heteroatom-containing compounds that are contained in a starting olefin.The olefin production process includes supplying a starting olefin containing more than 0 ppm by weight to not more than 10 ppm by weight of one or more kinds of heteroatom-containing compounds to a reactor that contains a metathesis catalyst and an isomerization catalyst, the metathesis catalyst including at least one metal element selected from the group consisting of tungsten, molybdenum and rhenium, the isomerization catalyst including calcined hydrotalcite or yttrium oxide, and performing a metathesis reaction of identical or different olefins.

Owner:MITSUI CHEM INC

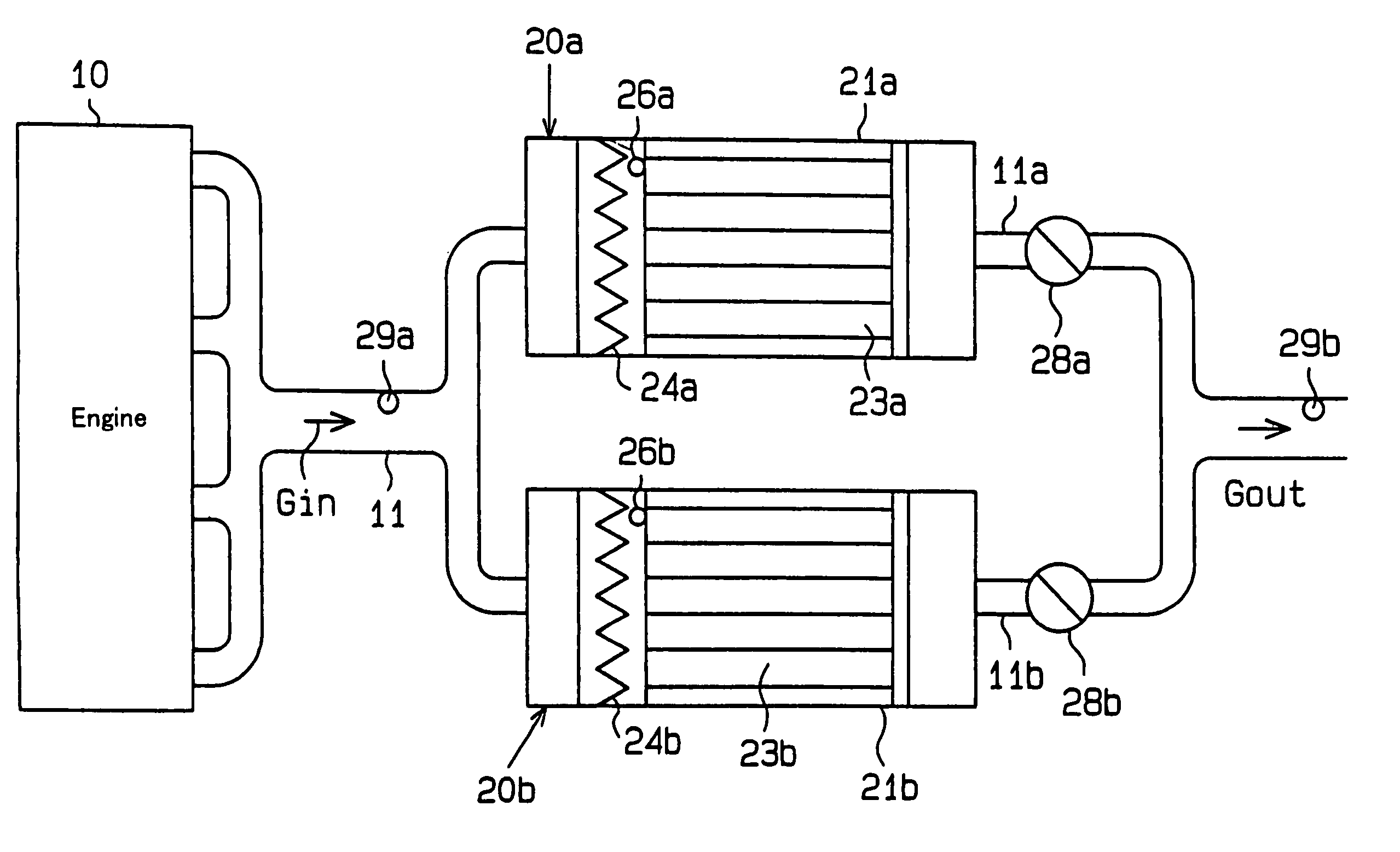

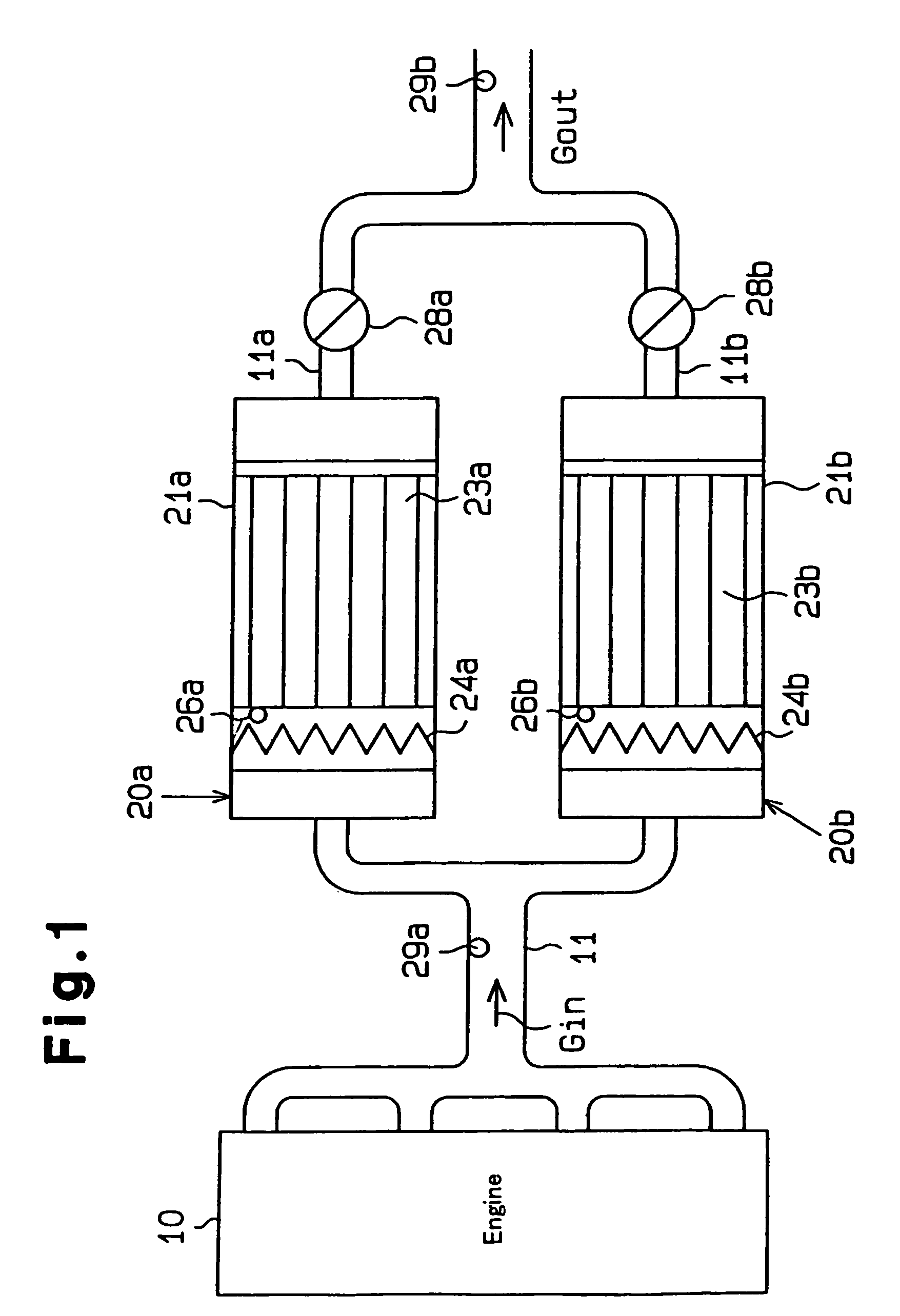

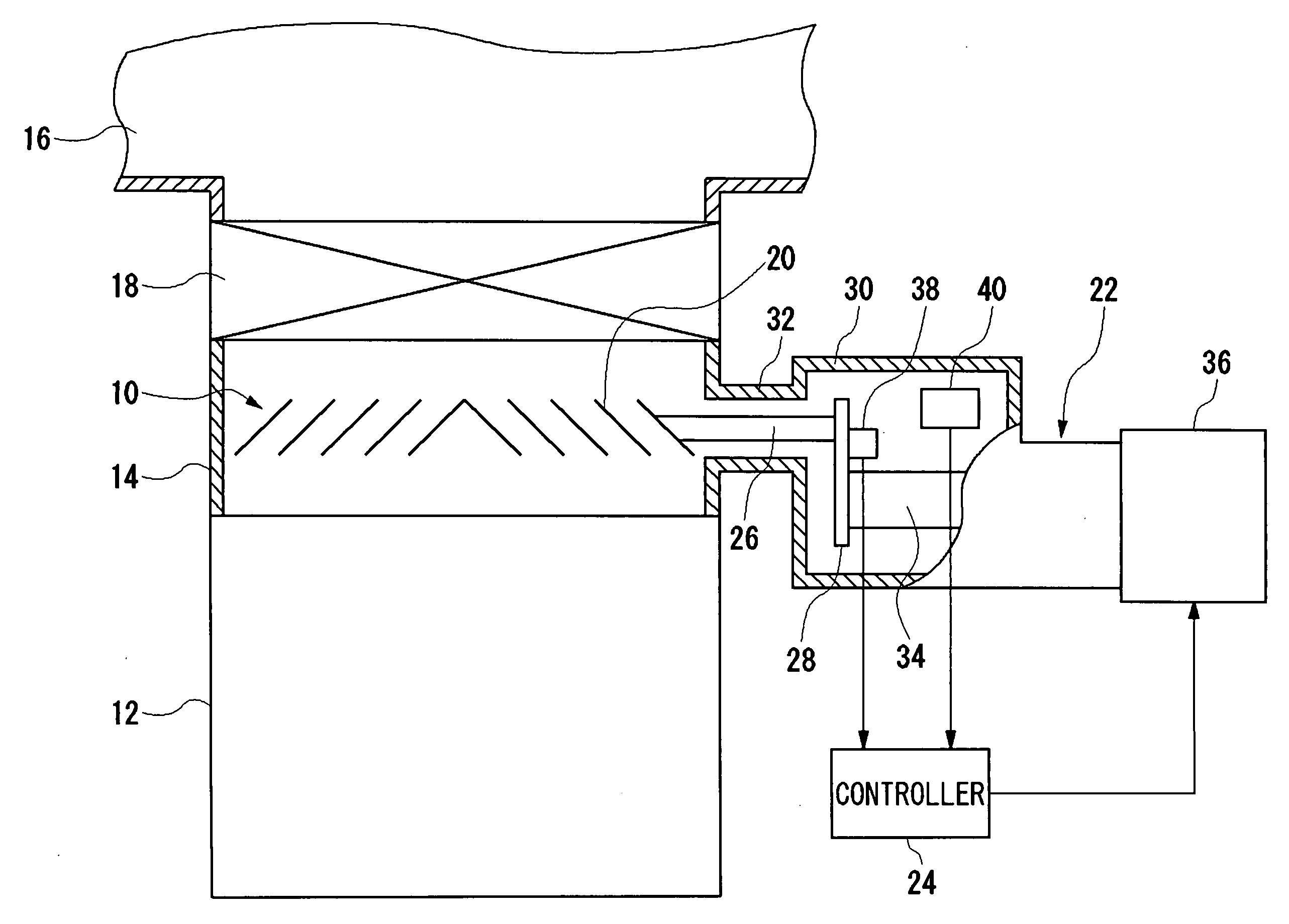

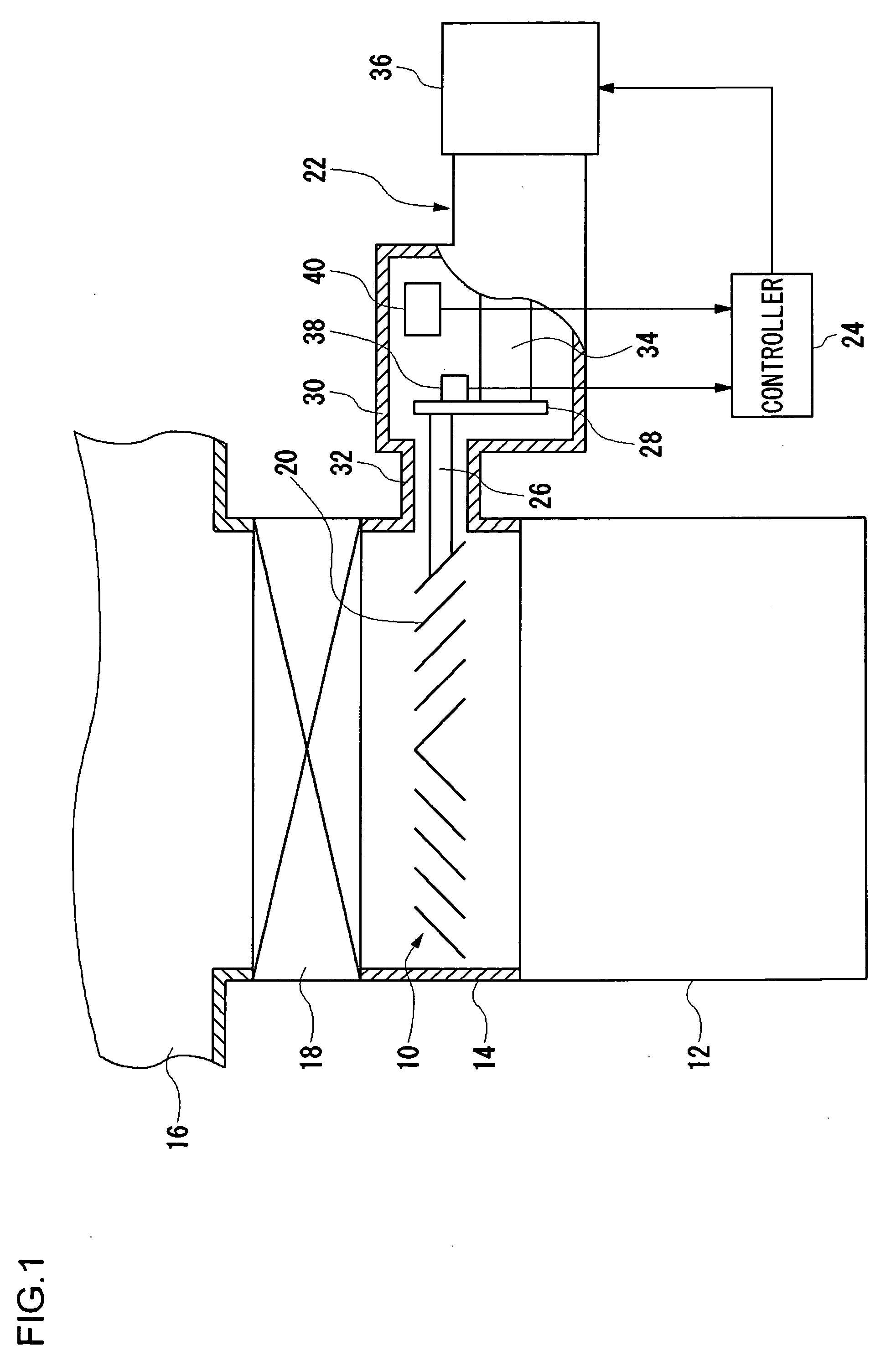

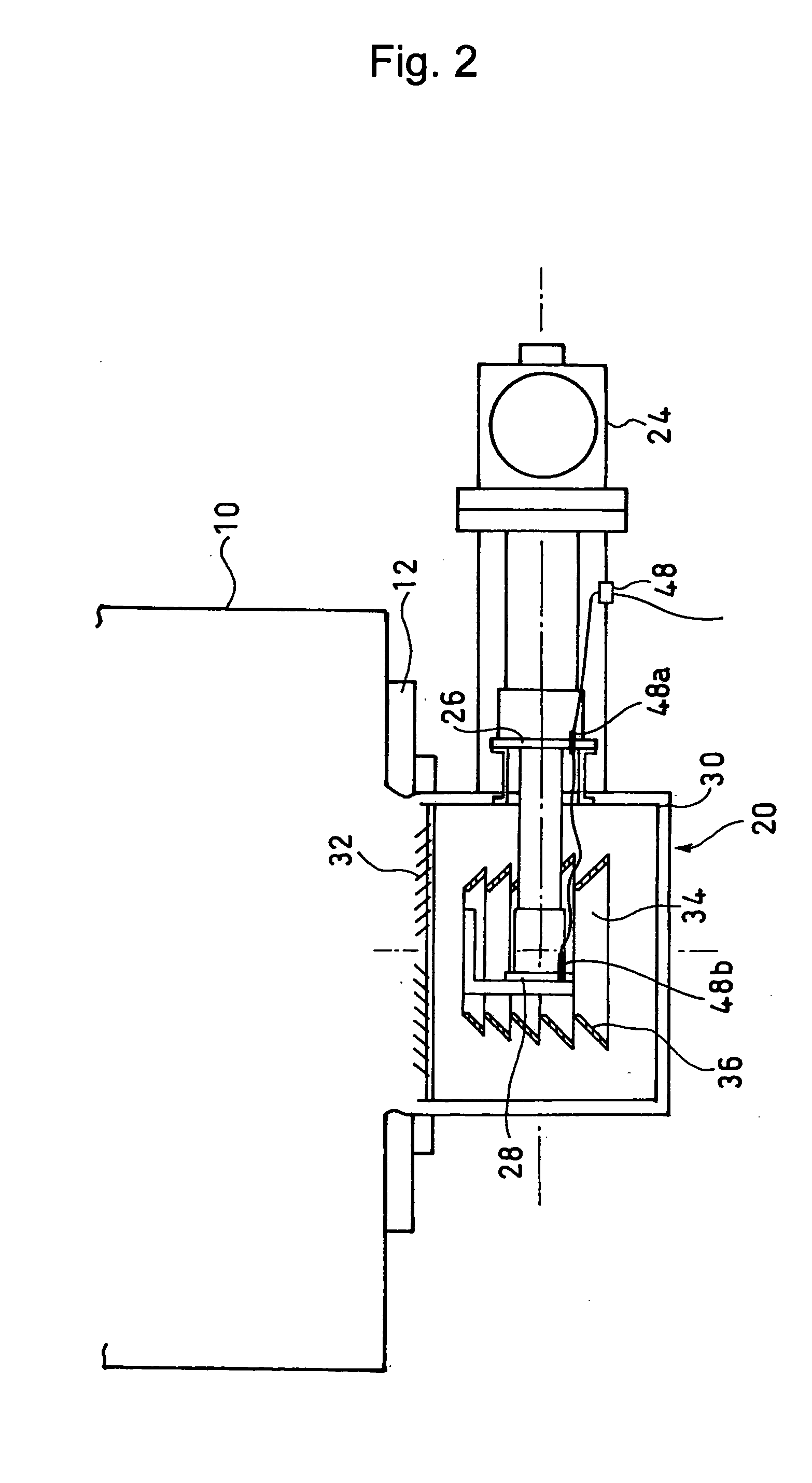

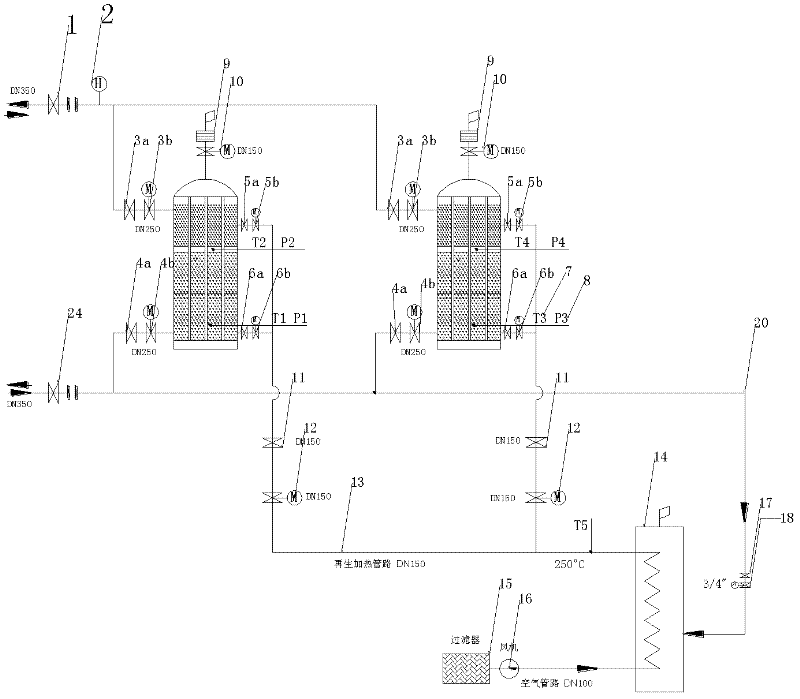

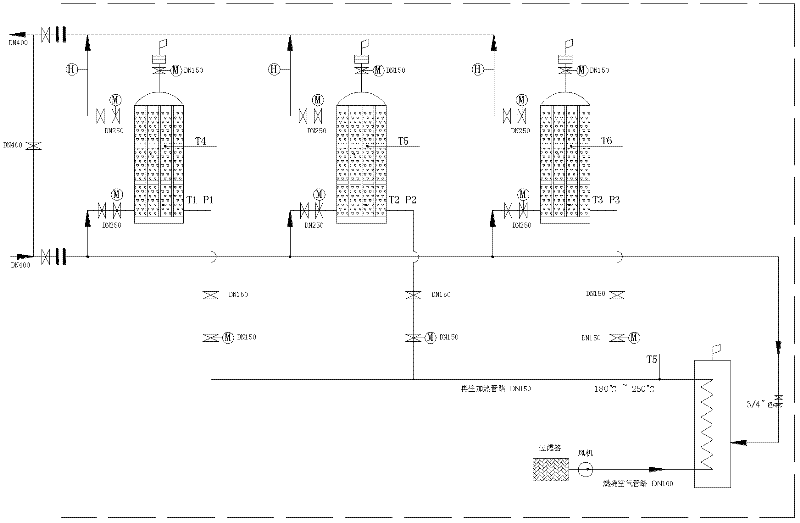

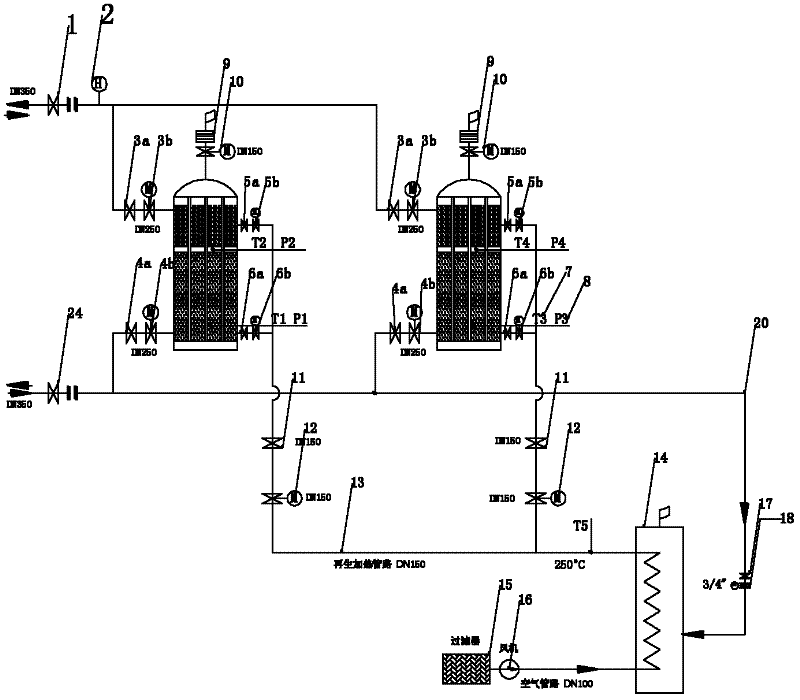

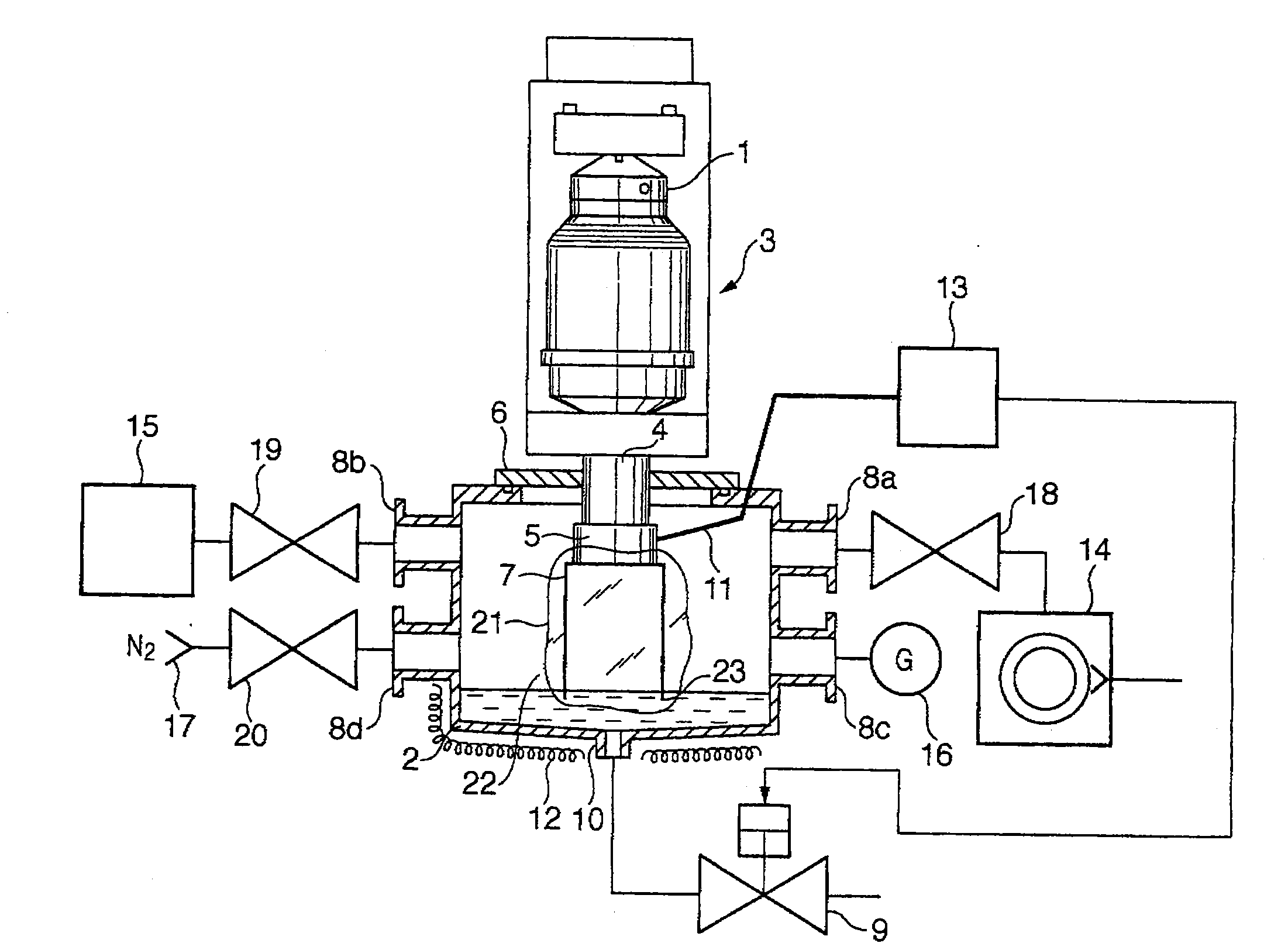

Regeneration device of exhaust gas purification filter and filter regeneration method

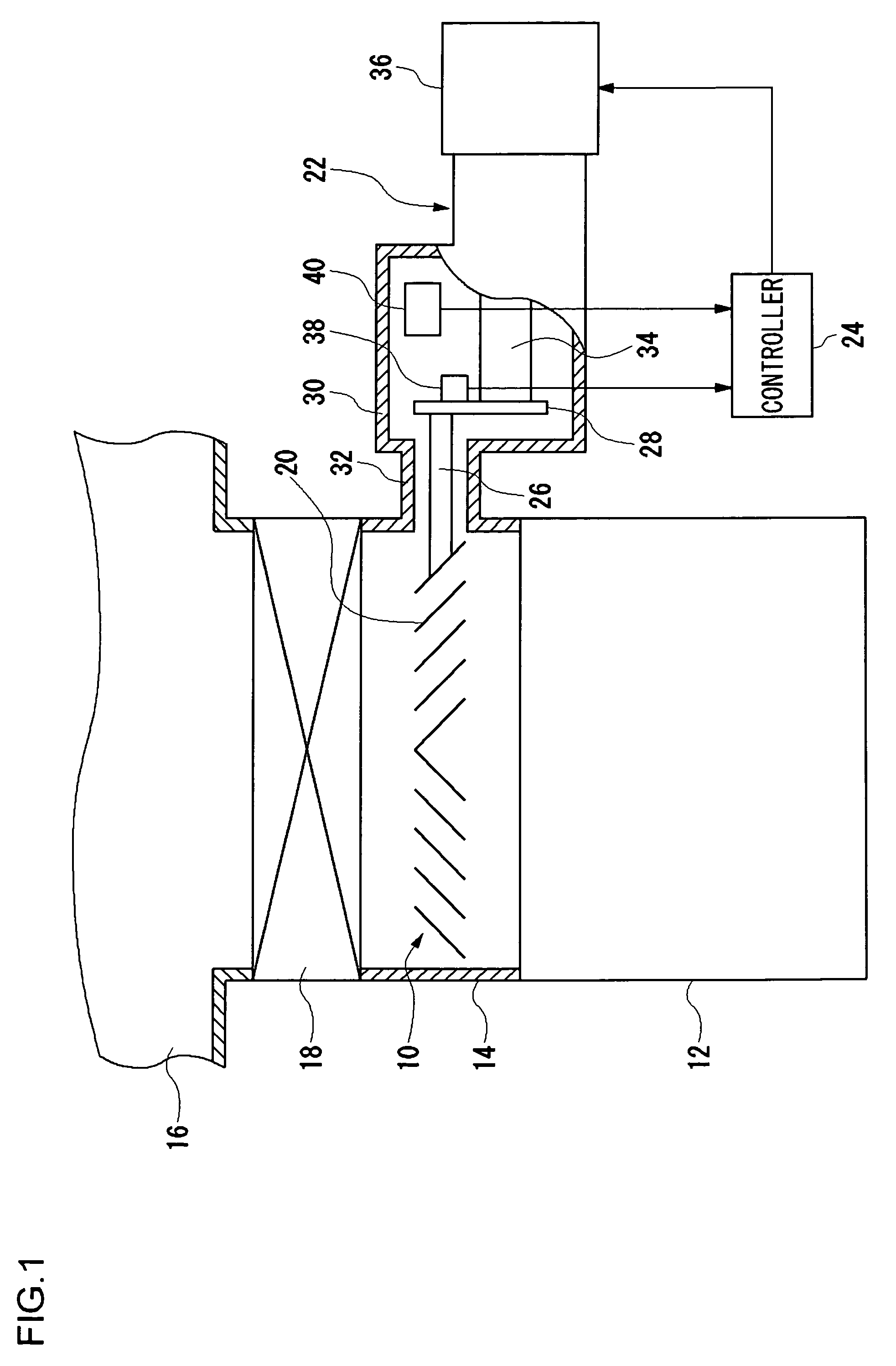

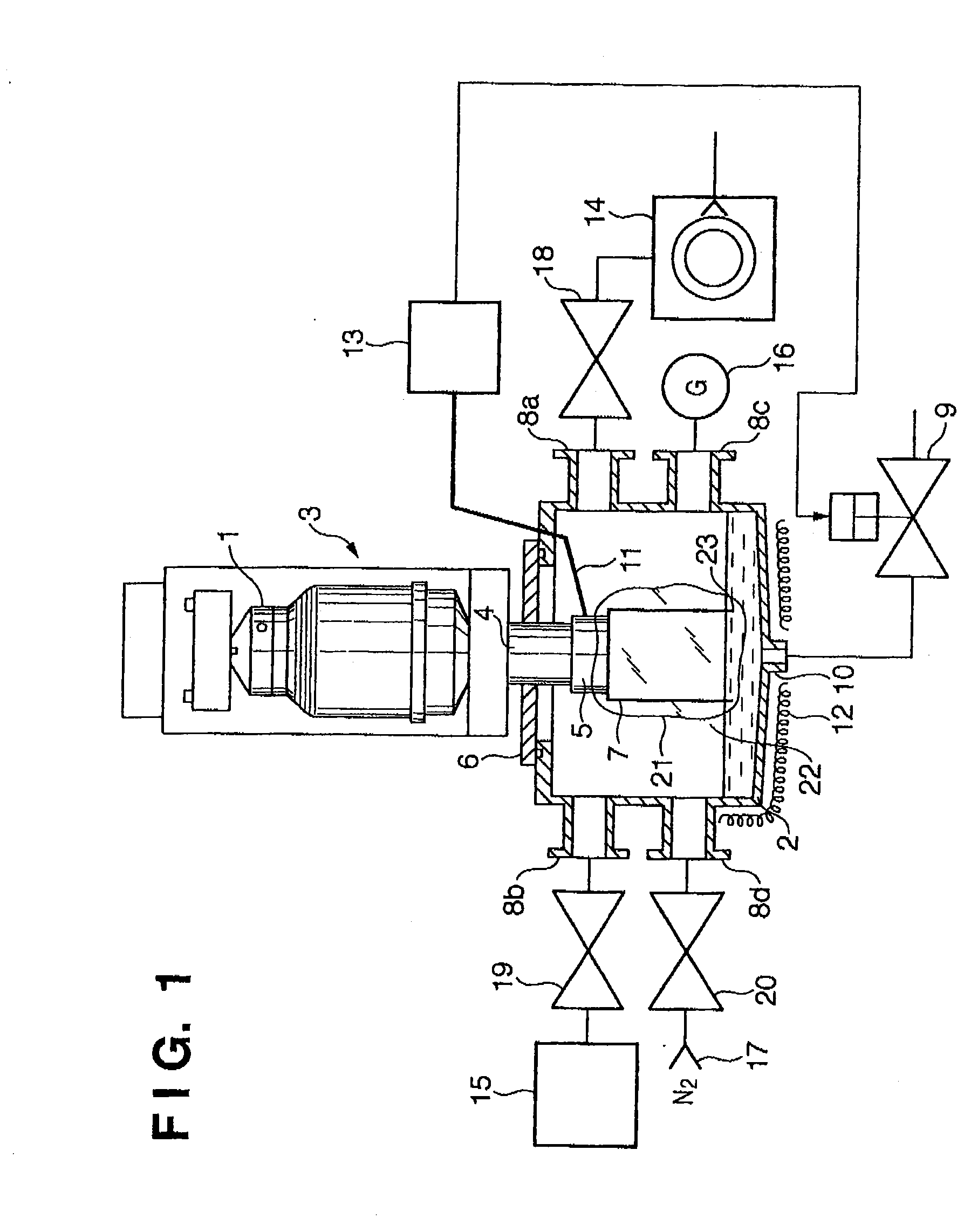

InactiveUS7550119B2Reduce filter timeShorten regeneration timeCombination devicesInternal combustion piston enginesExhaust fumesEngineering

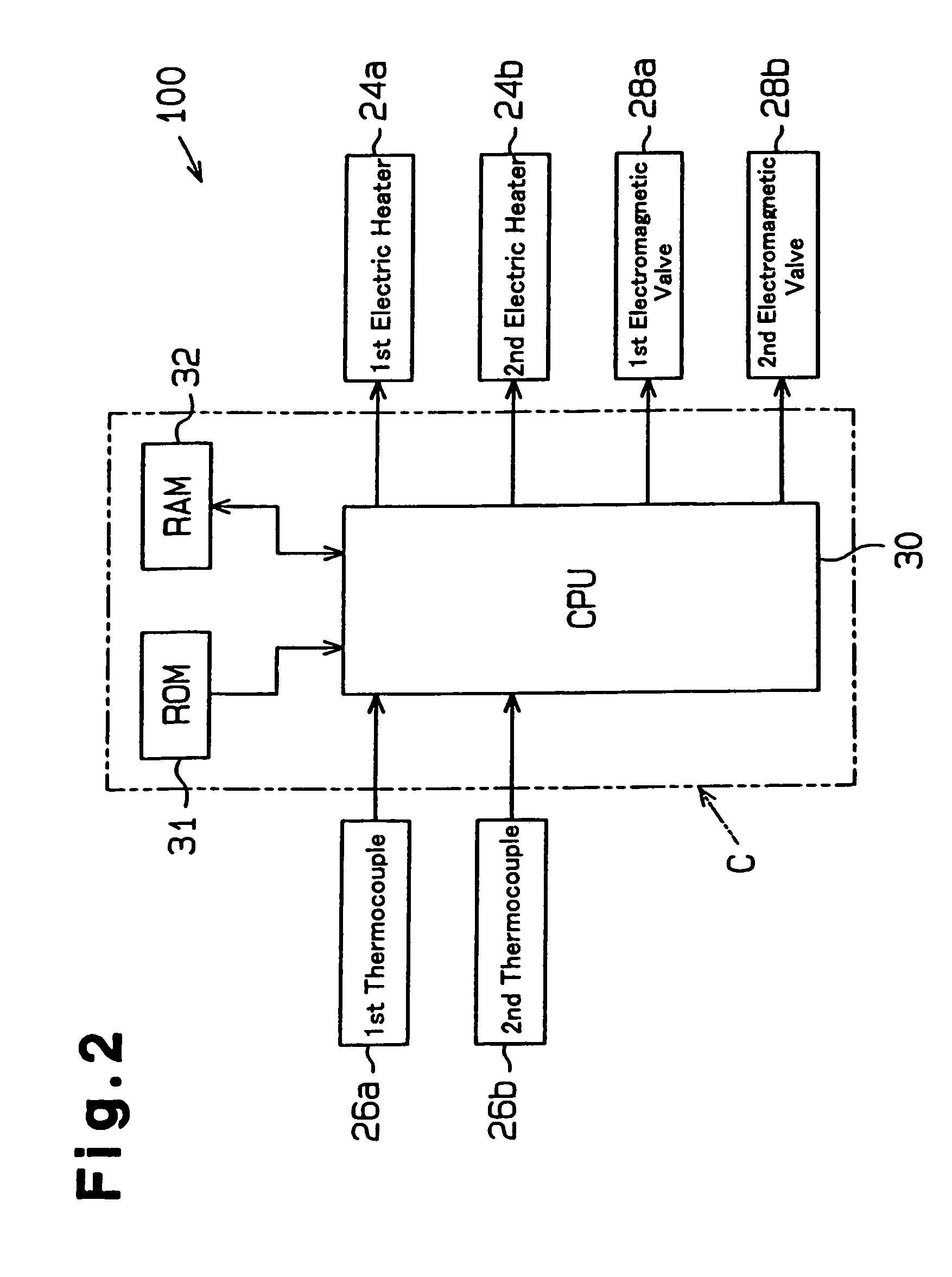

A regeneration device of an exhaust gas purification filter that reduces the regeneration time of the filter. The regeneration device includes a plurality of first temperature detectors (26a, 26b) arranged in casings to detect the temperature in each casing and a second temperature detector (26a, 26b) for detecting the temperature of the exhaust gas. A processor (30) is connected to the first temperature detectors and the second temperature detector. The processor compares the temperature of the exhaust gas and the temperature of at least one of the casings, opens the associated switch valve based on the comparison result, and preheats at least one of the filters with the exhaust gas. The heat of the exhaust gas suddenly increases the temperature of the filter from the initial temperature and reduces the filter regeneration time.

Owner:IBIDEN CO LTD

Method for regenerating filter and apparatus thereof

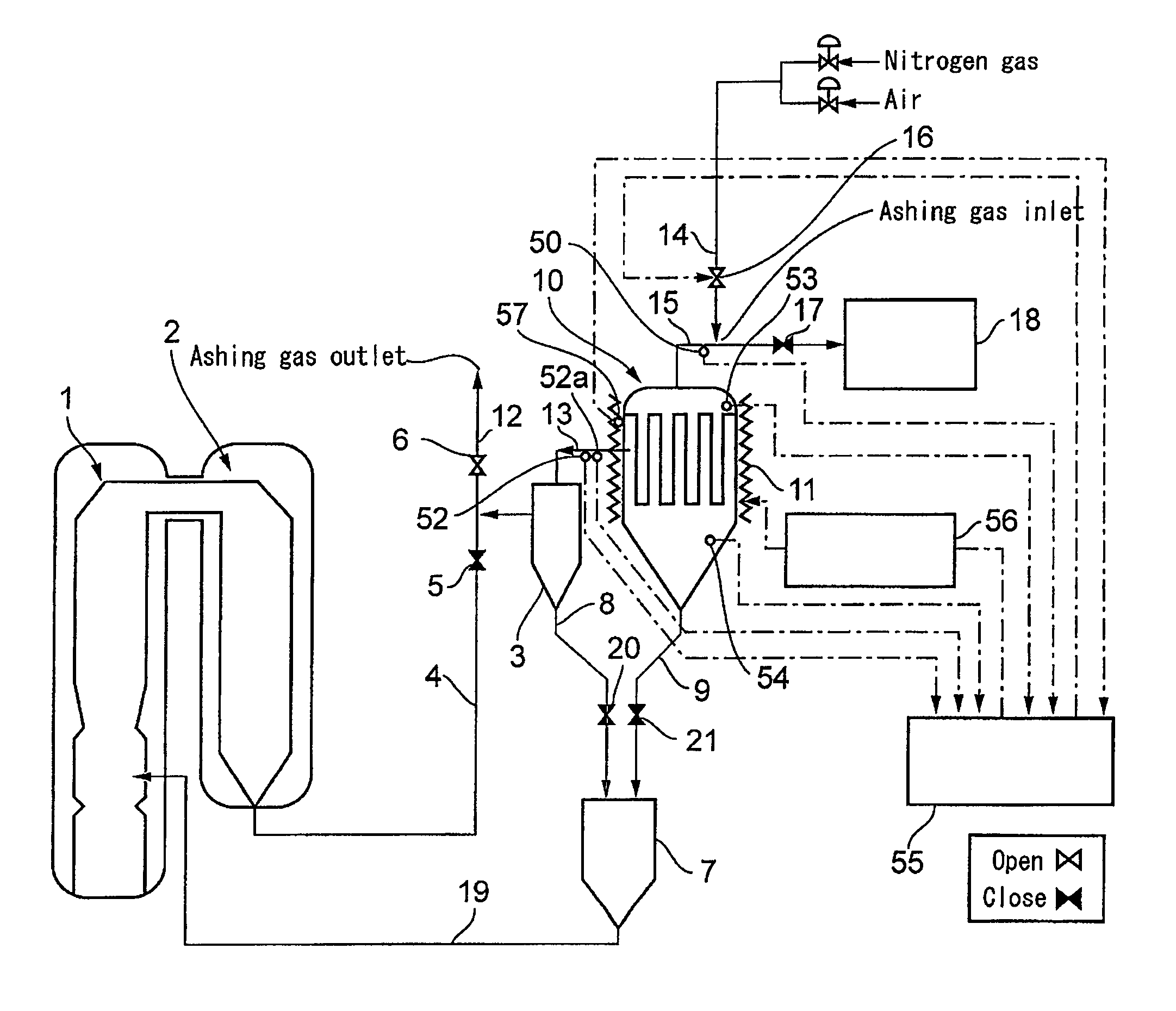

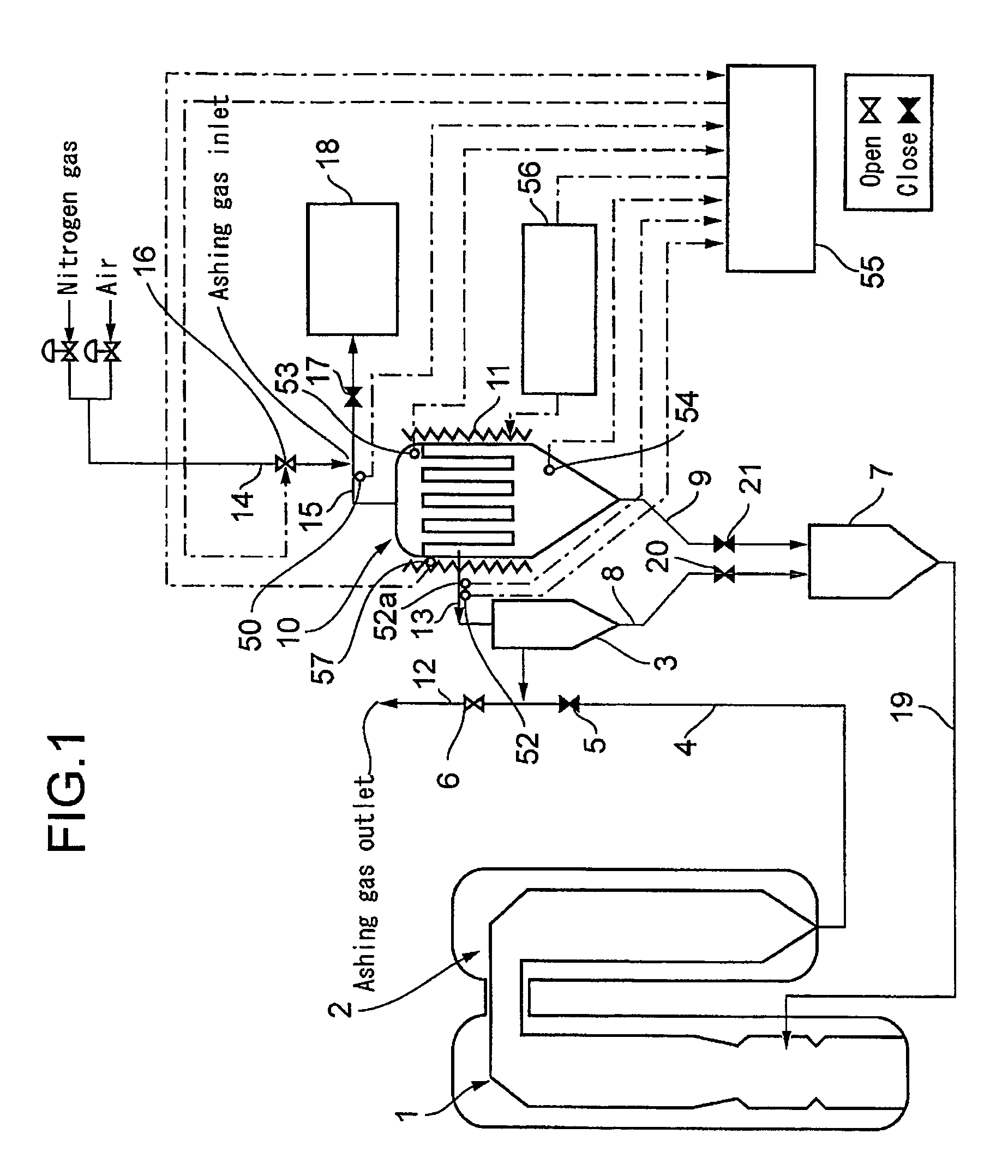

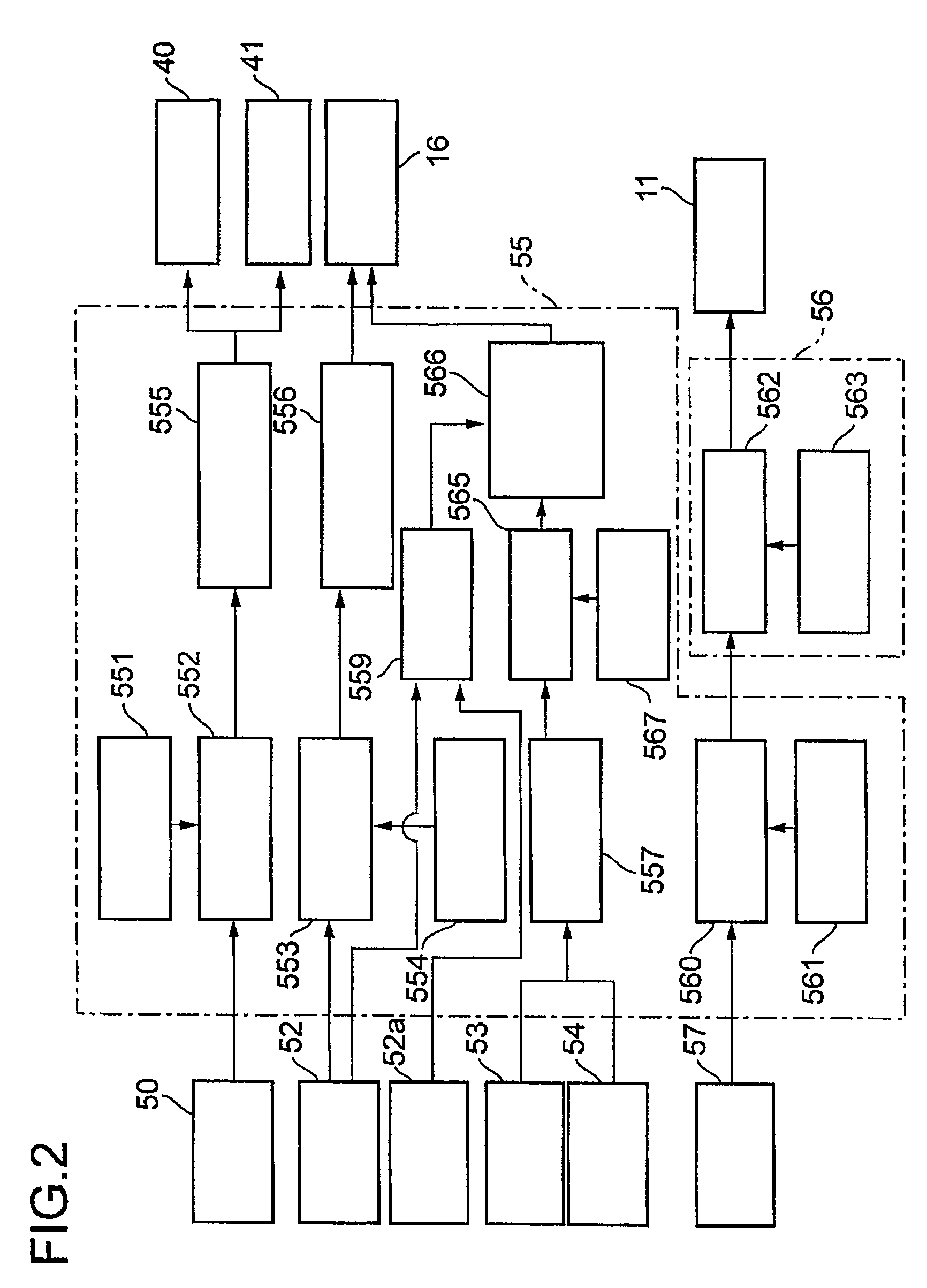

ActiveUS7896956B2Shorten regeneration timeShorten the timeCombination devicesAuxillary pretreatmentProcess engineeringCoal gasifier

A filter regeneration apparatus of a coal gasification system having a filter for capturing char (unburned matter) present in exhaust gas at an exhaust gas passage communicating with exhaust gas source including a coal gasification furnace, fills the filter container with inactive gas having oxygen concentration of less than 5 vol. % and heat the filter to a target temperature of 400 to 450° C. and feed ashing gas having oxygen concentration of 5 to 15 vol. %, thereby ashing char in the filter. This method and apparatus achieve ashing of char in a safe manner and shortens the time of regenerating the filter by controlling the oxygen concentration in the ashing gas and the filter temperature constantly to reach preset target values.

Owner:MITSUBISHI POWER LTD

Gasoline particulate filter regeneration and diagnostics

ActiveUS8327628B2Reduce smoke and dust emissionsImprove engine performanceElectrical controlInternal combustion piston enginesParticulatesGasoline

Owner:FORD GLOBAL TECH LLC

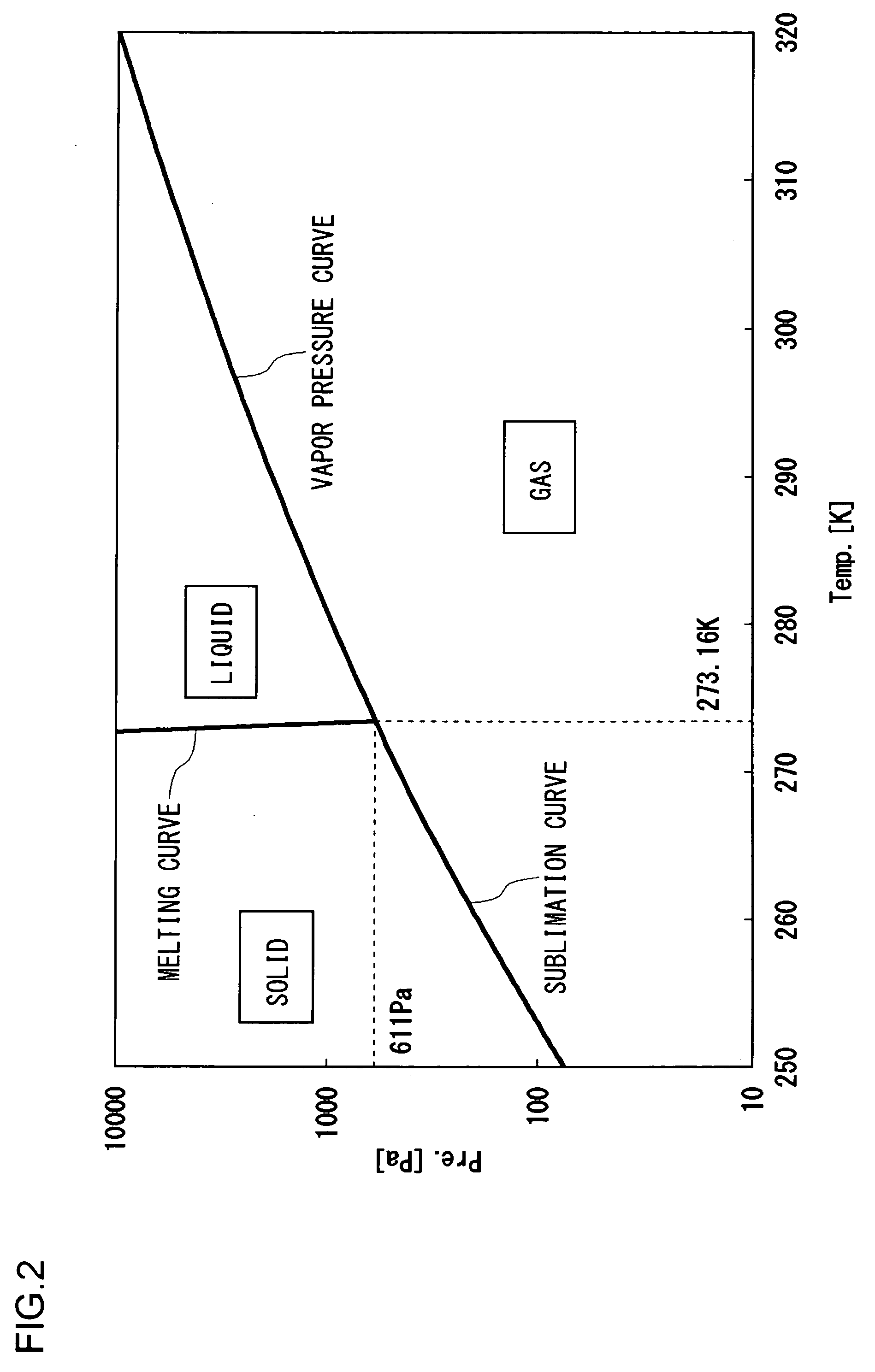

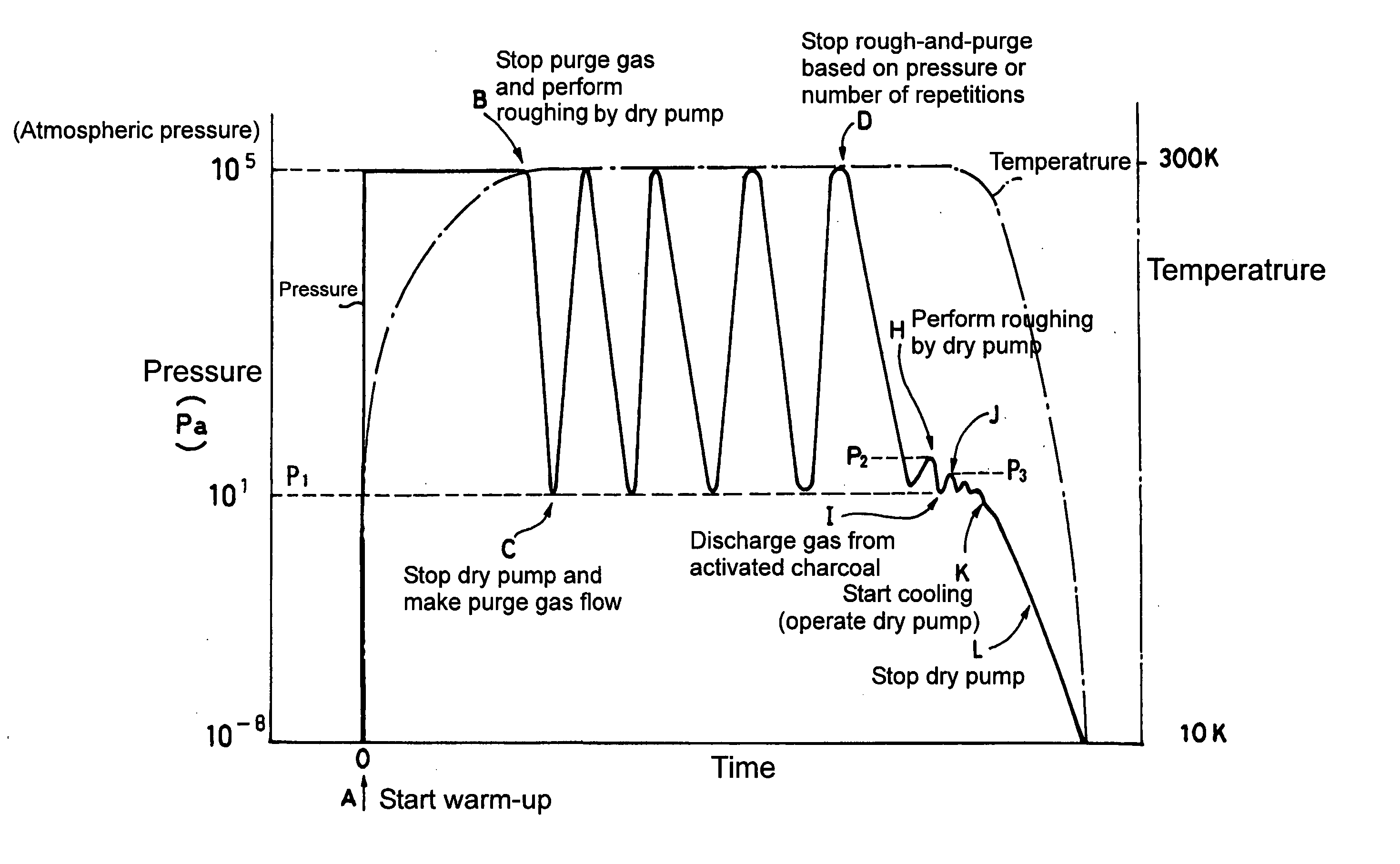

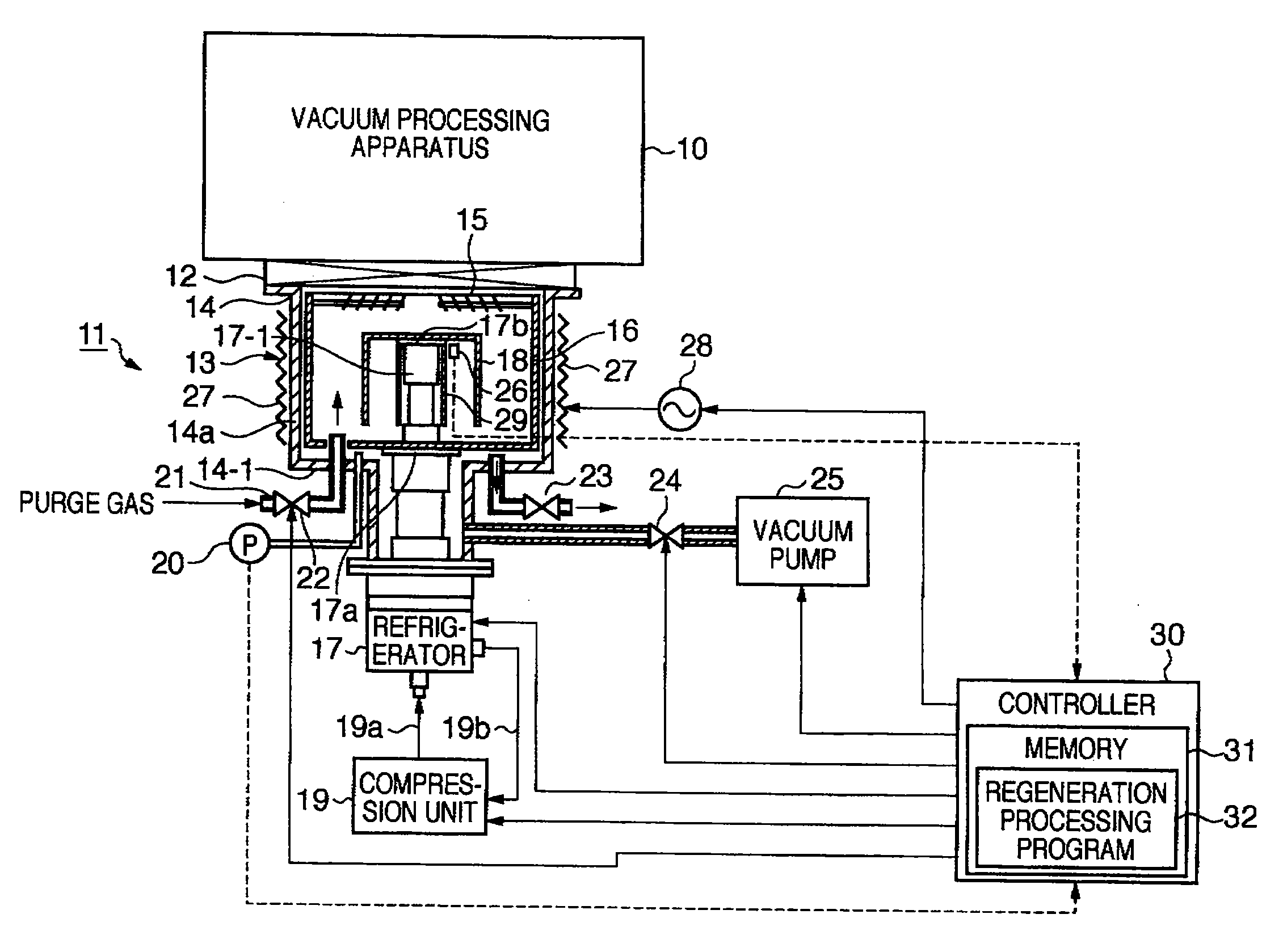

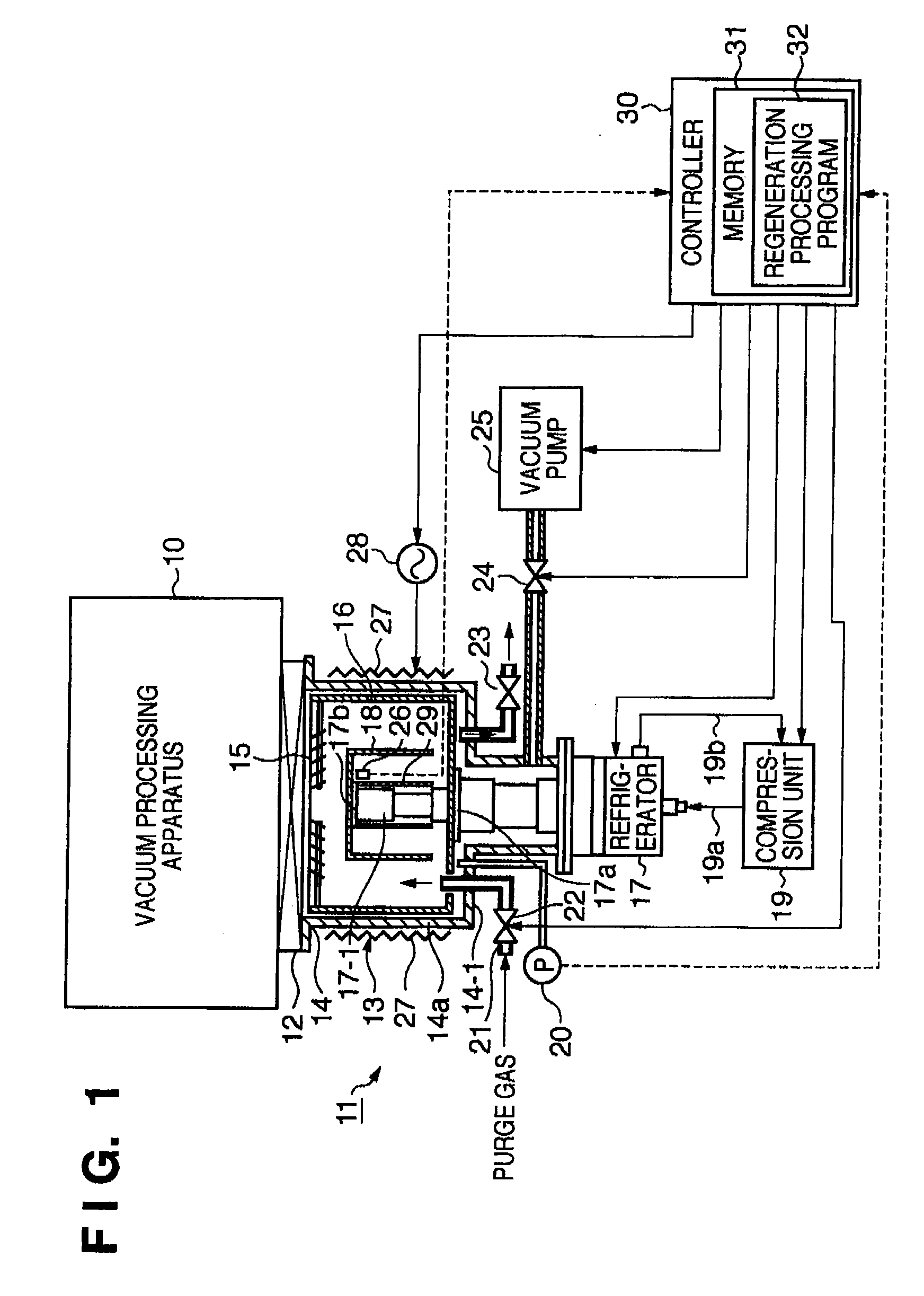

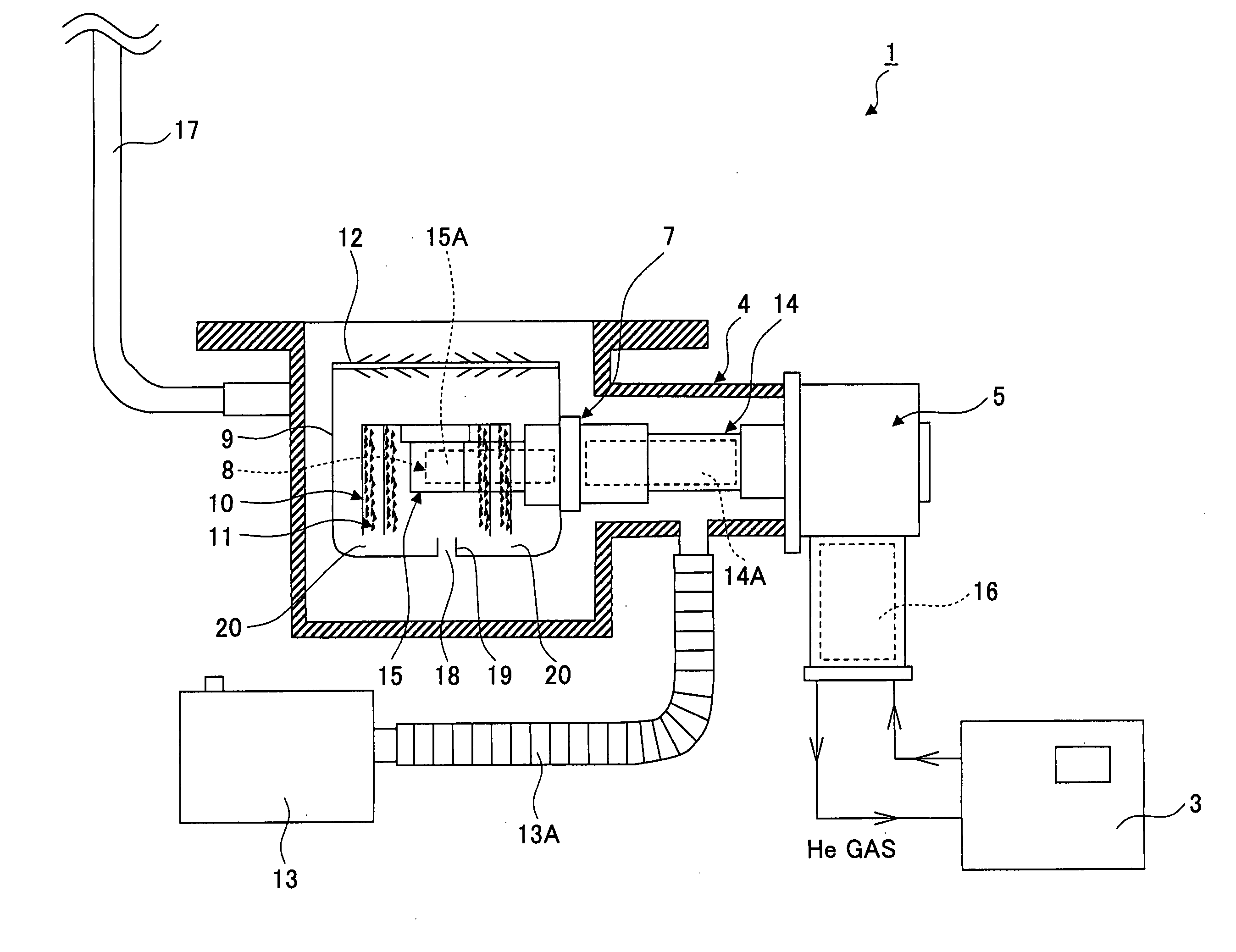

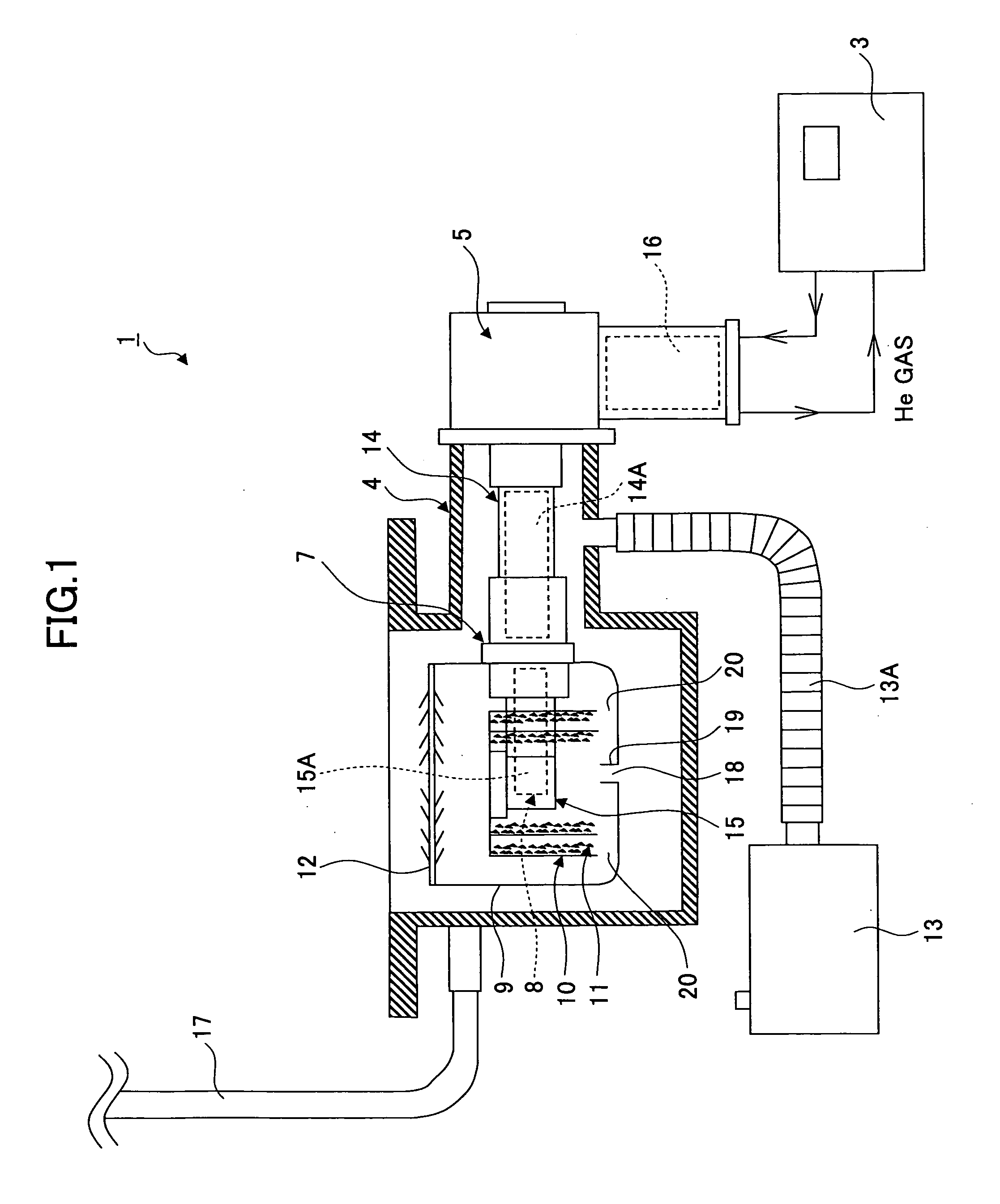

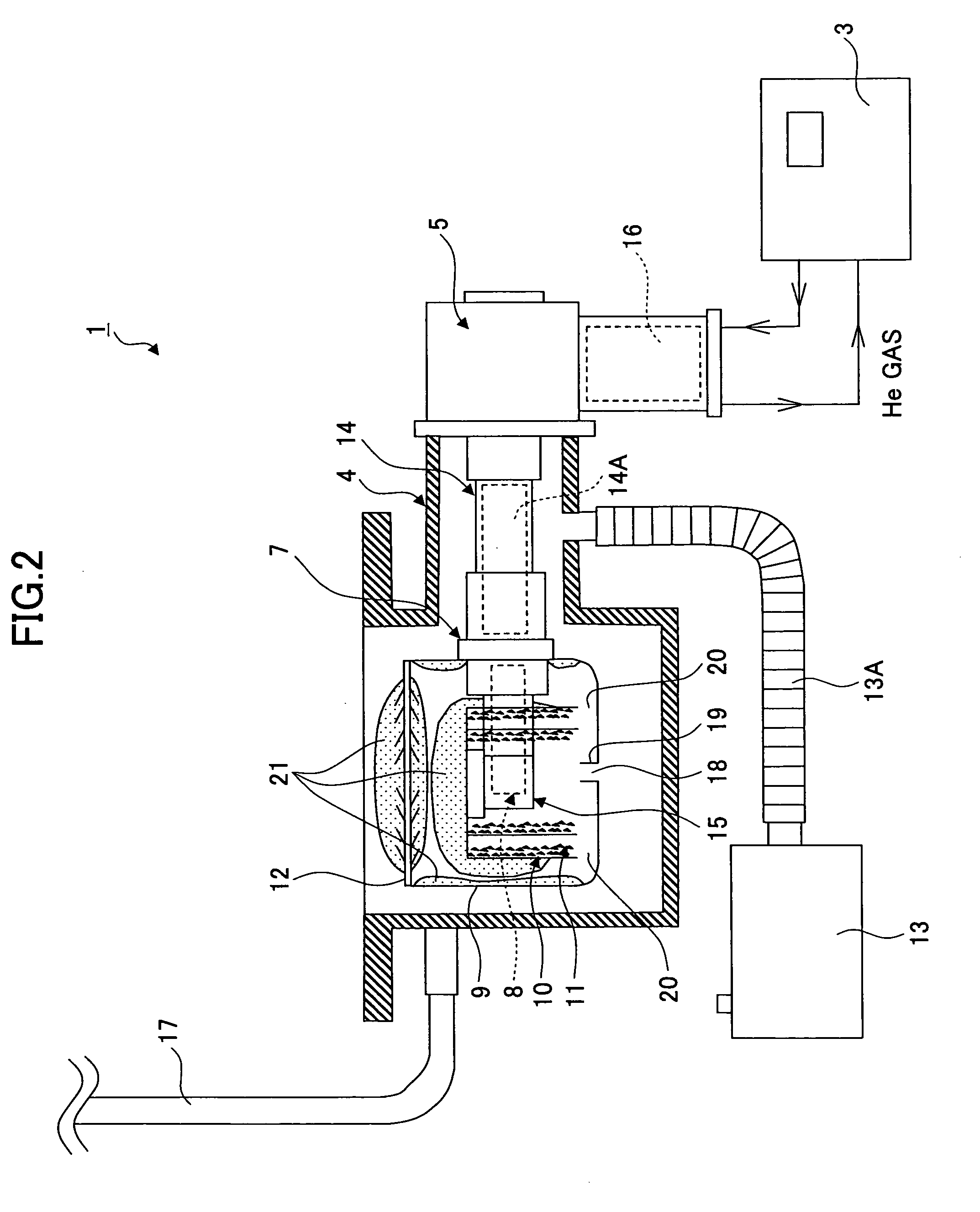

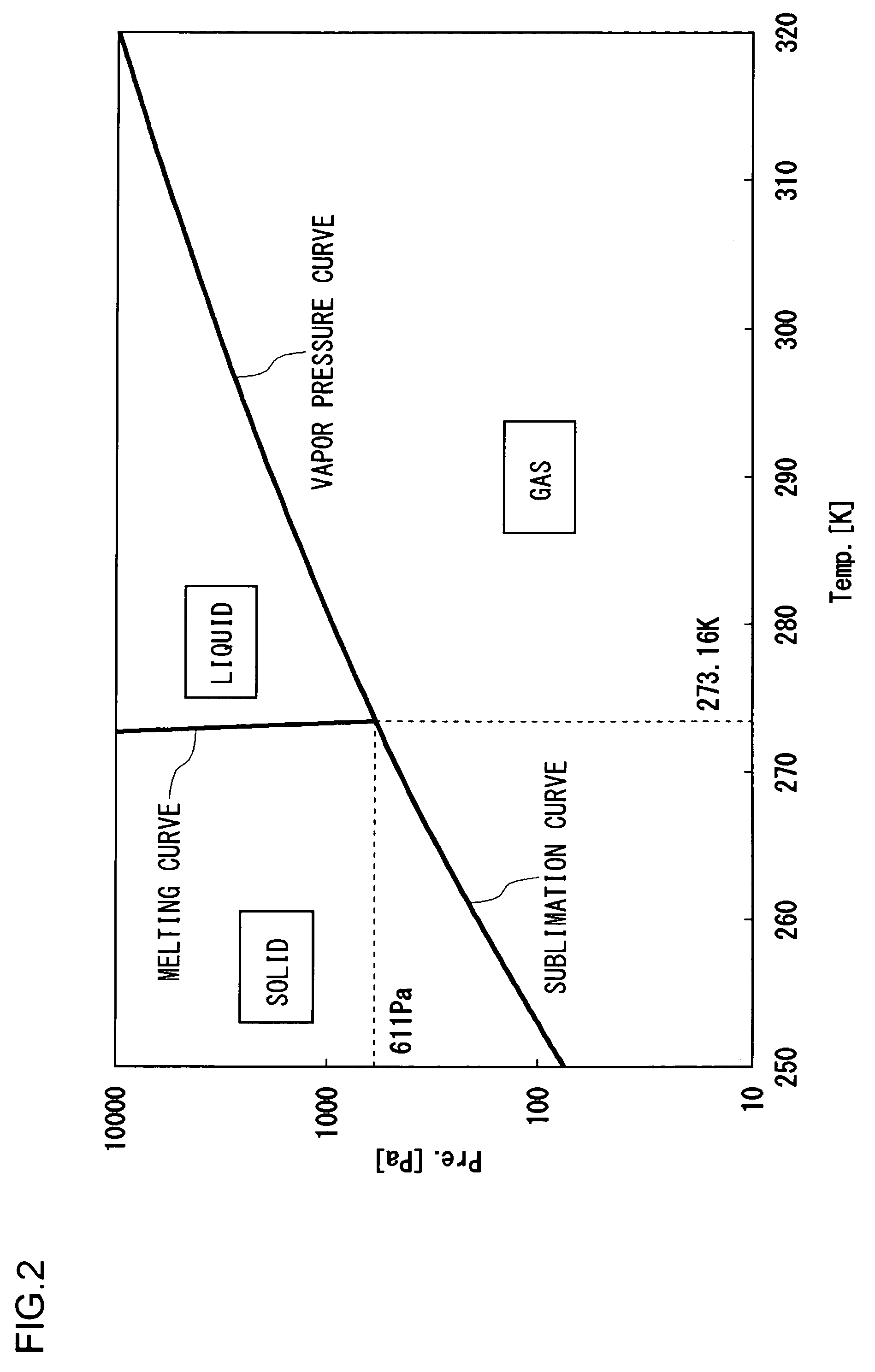

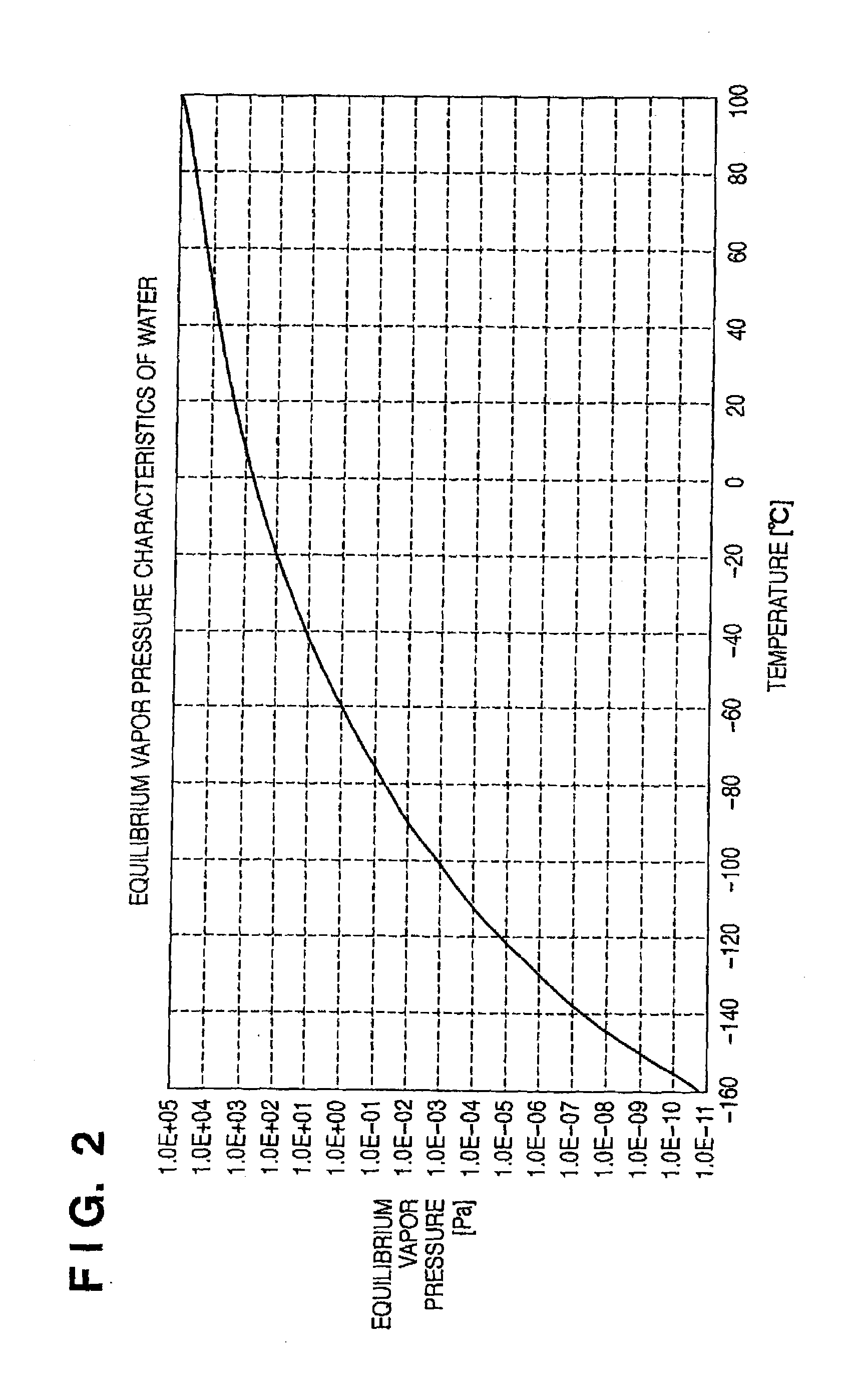

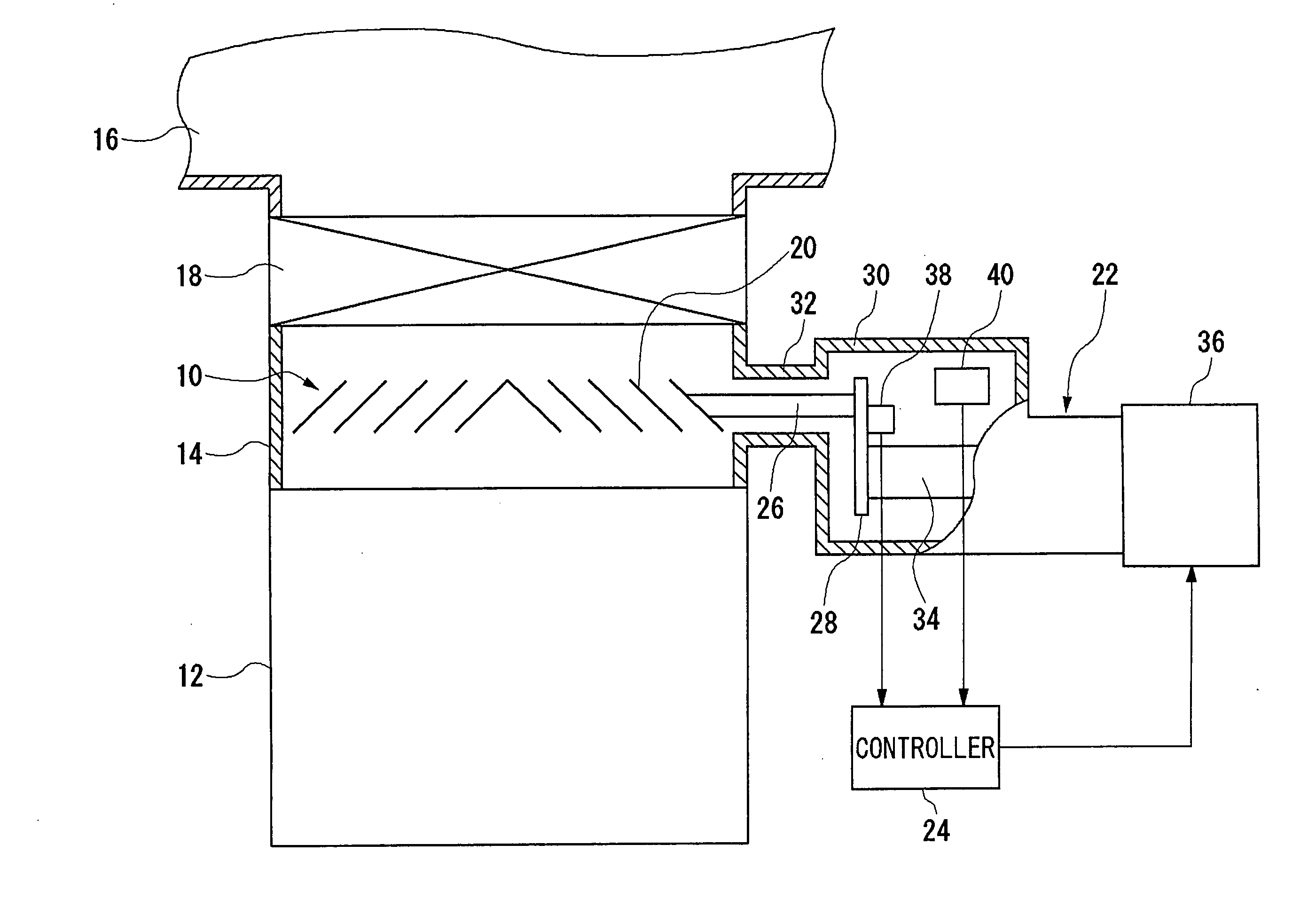

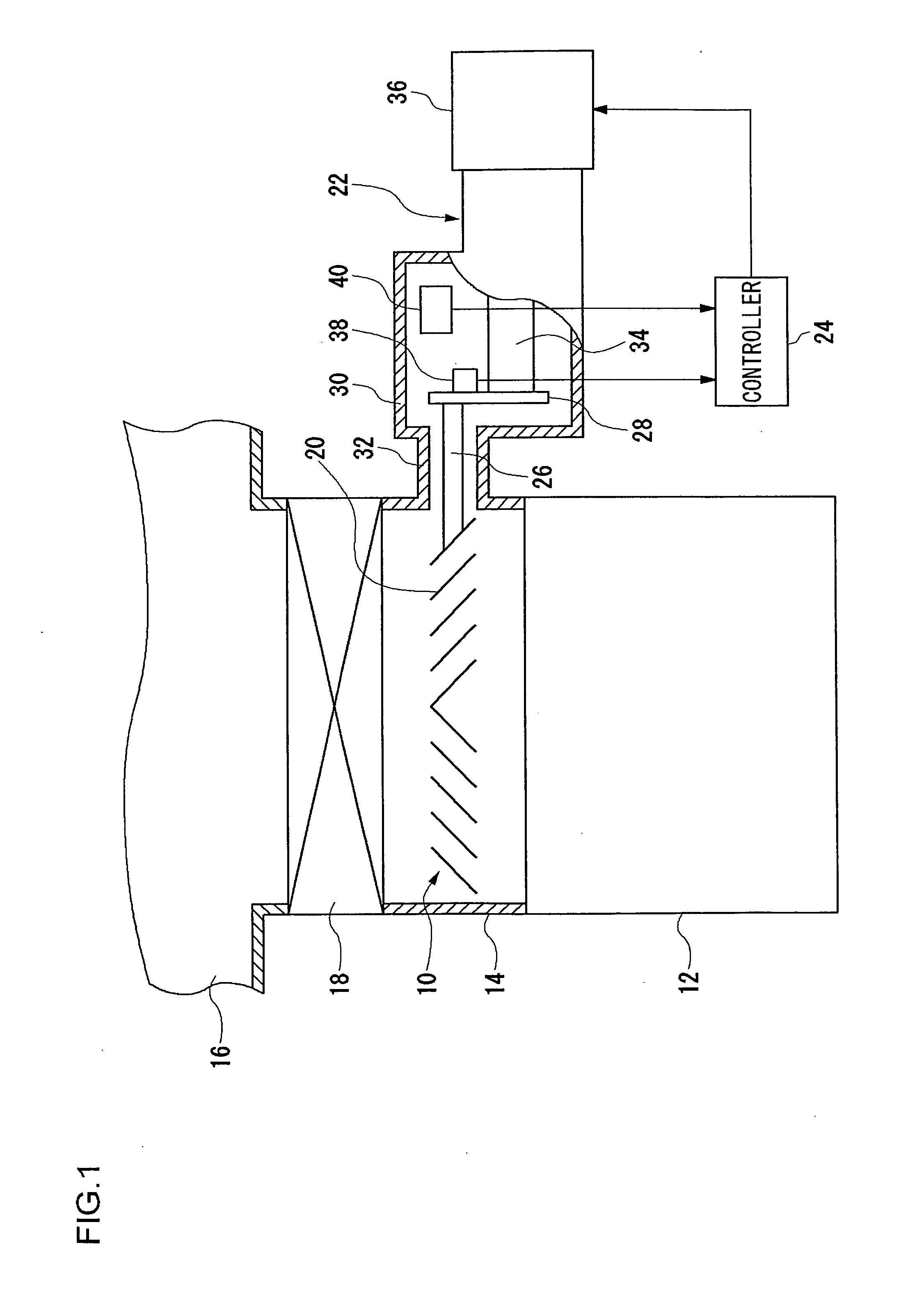

Cold trap and cold trap regeneration method

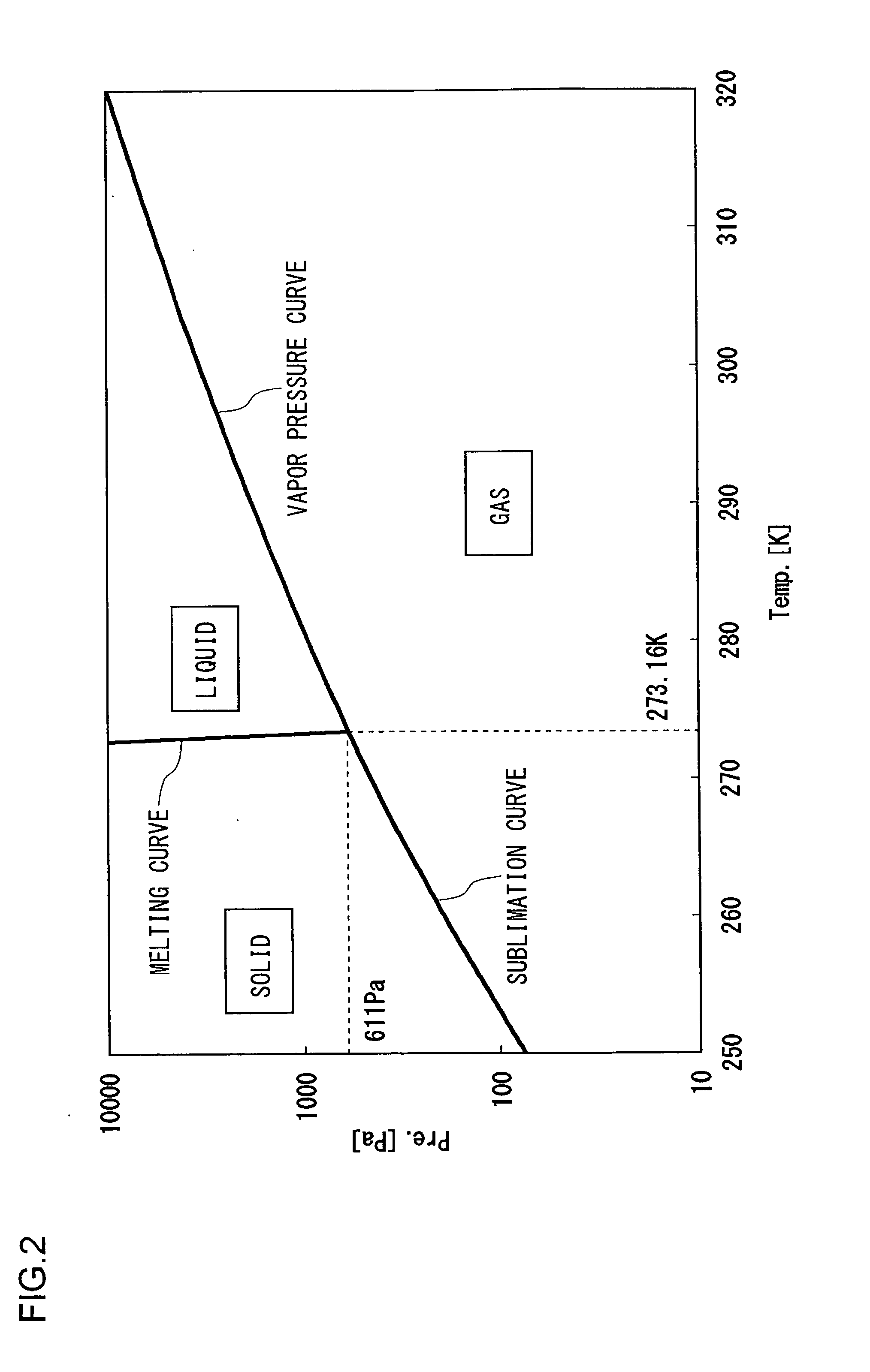

ActiveUS20090266088A1Reduce regeneration timeLess affectedPressurized chemical processSolidificationProduct gasRefrigerated temperature

A cold trap is provided with a cold panel provided in a pumping path such that the panel is exposed, a refrigerator thermally coupled to the cold panel and operative to cool the cold panel; and a controller configured, in a regeneration process for evaporating a gas frozen on the surface of the cold panel and discharging the gas outside using the vacuum pump, to control the refrigerator so as to raise the temperature of the cold panel to a temperature exceeding a non-liquefaction temperature range and to adjust a pressure in the pumping path at the temperature so that the gas frozen on the surface of the cold panel is evaporated without being melted, the non-liquefaction temperature range being a range in which it is guaranteed that a gas frozen on the surface of the cold trap is evaporated without being melted.

Owner:SUMITOMO HEAVY IND LTD

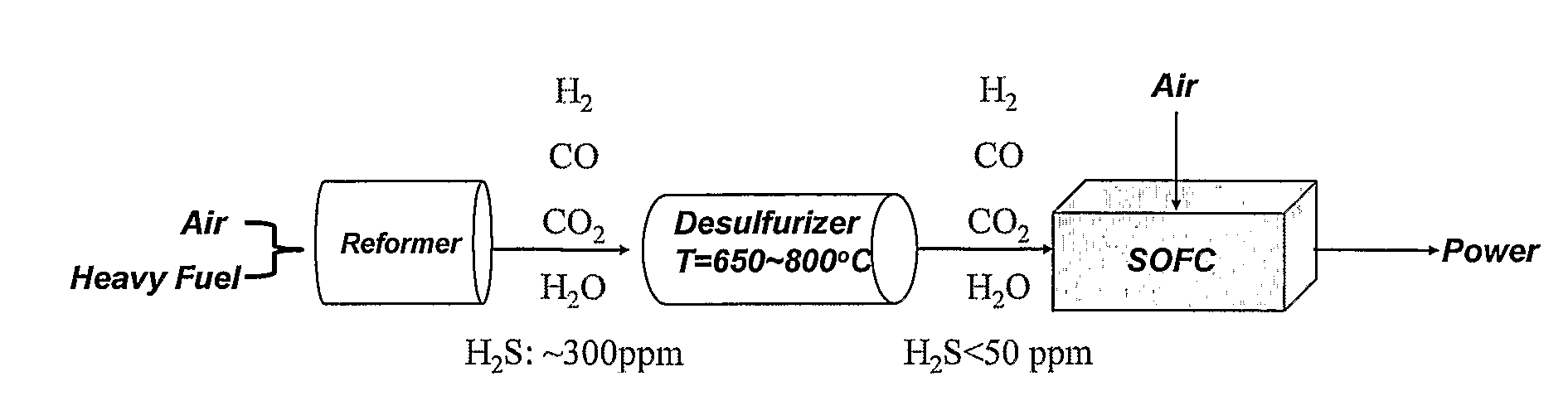

Method and apparatus for regeneration water

ActiveUS20070125112A1Efficient dischargeShorten regeneration timeSolidificationLiquefactionWater vaporLiquid state

Ice condensed in a portion in a case in which a cryogenic refrigerator is installed, which is cooled by the cryogenic refrigerator, is melted by increasing a temperature of the ice to a melting point of the ice or higher. Then, while the temperature of the melted ice and a pressure thereof are kept to be equal to or higher than a freezing point of water, the pressure is reduced by rough evacuation so as to vaporize water. At a time at which the water is discharged, the pressure is further reduced so as to discharge water vapor. In this manner, regeneration of water is performed in accordance with a state of the water (i.e., a solid state, a liquid state, and a gas state), thereby shortening a regeneration time.

Owner:SUMITOMO HEAVY IND LTD

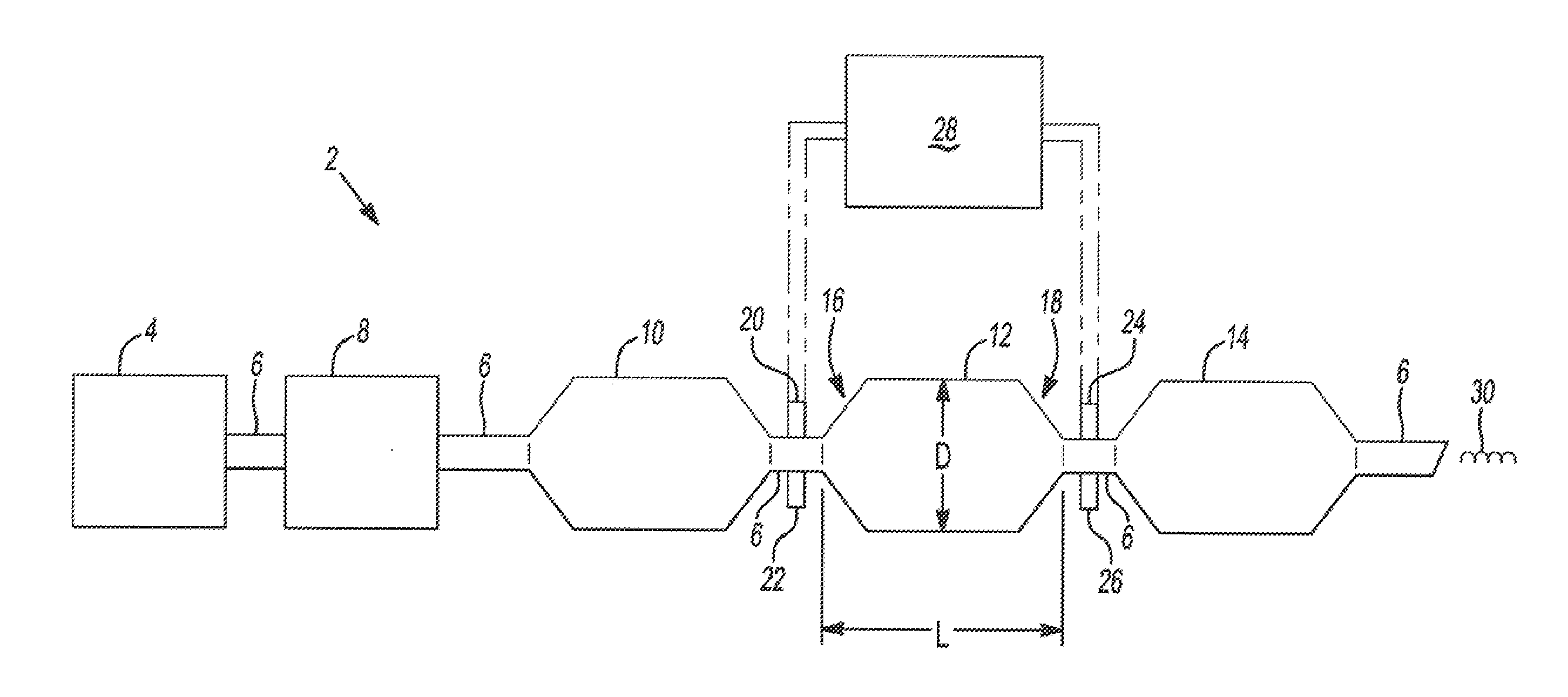

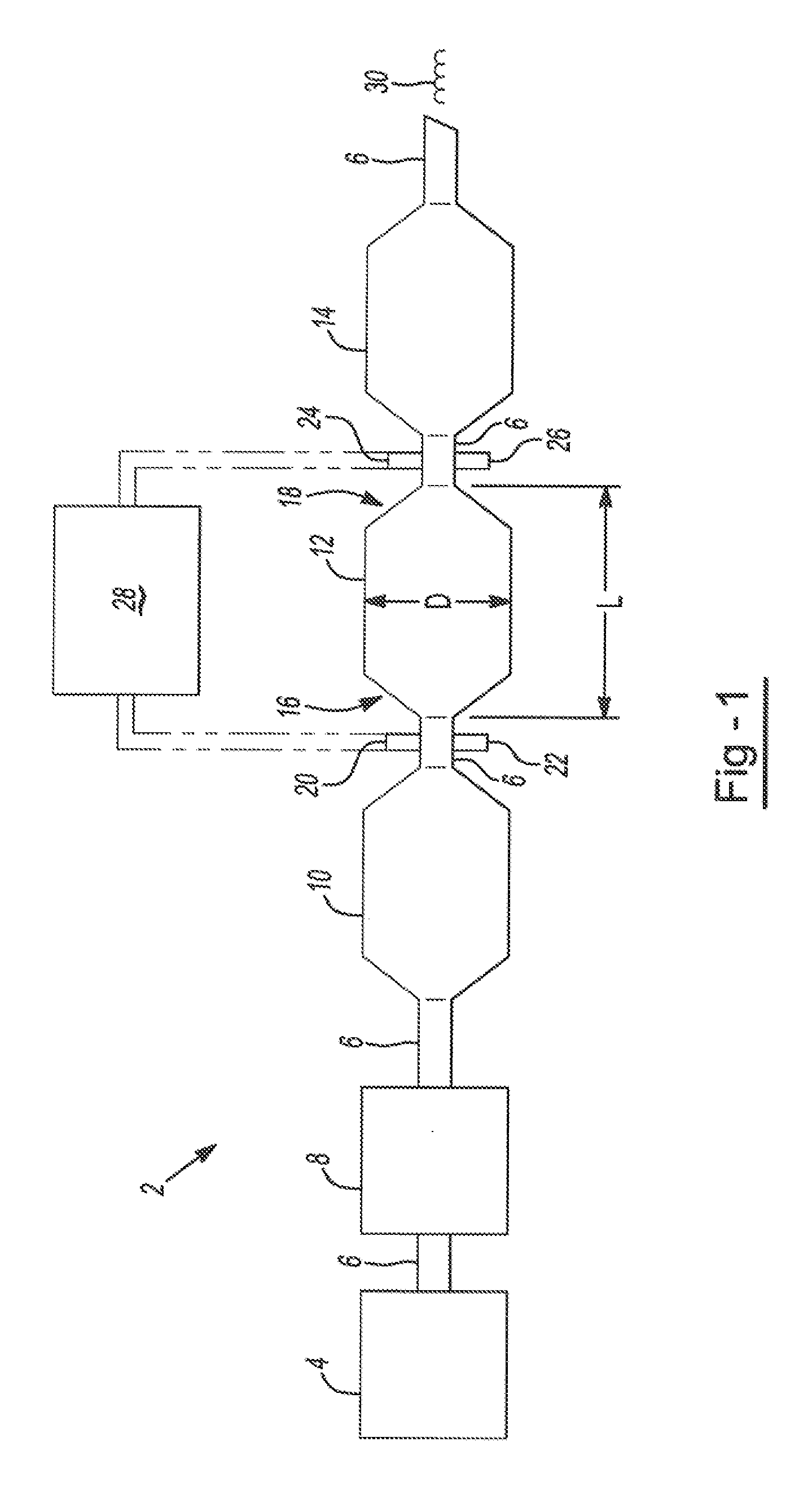

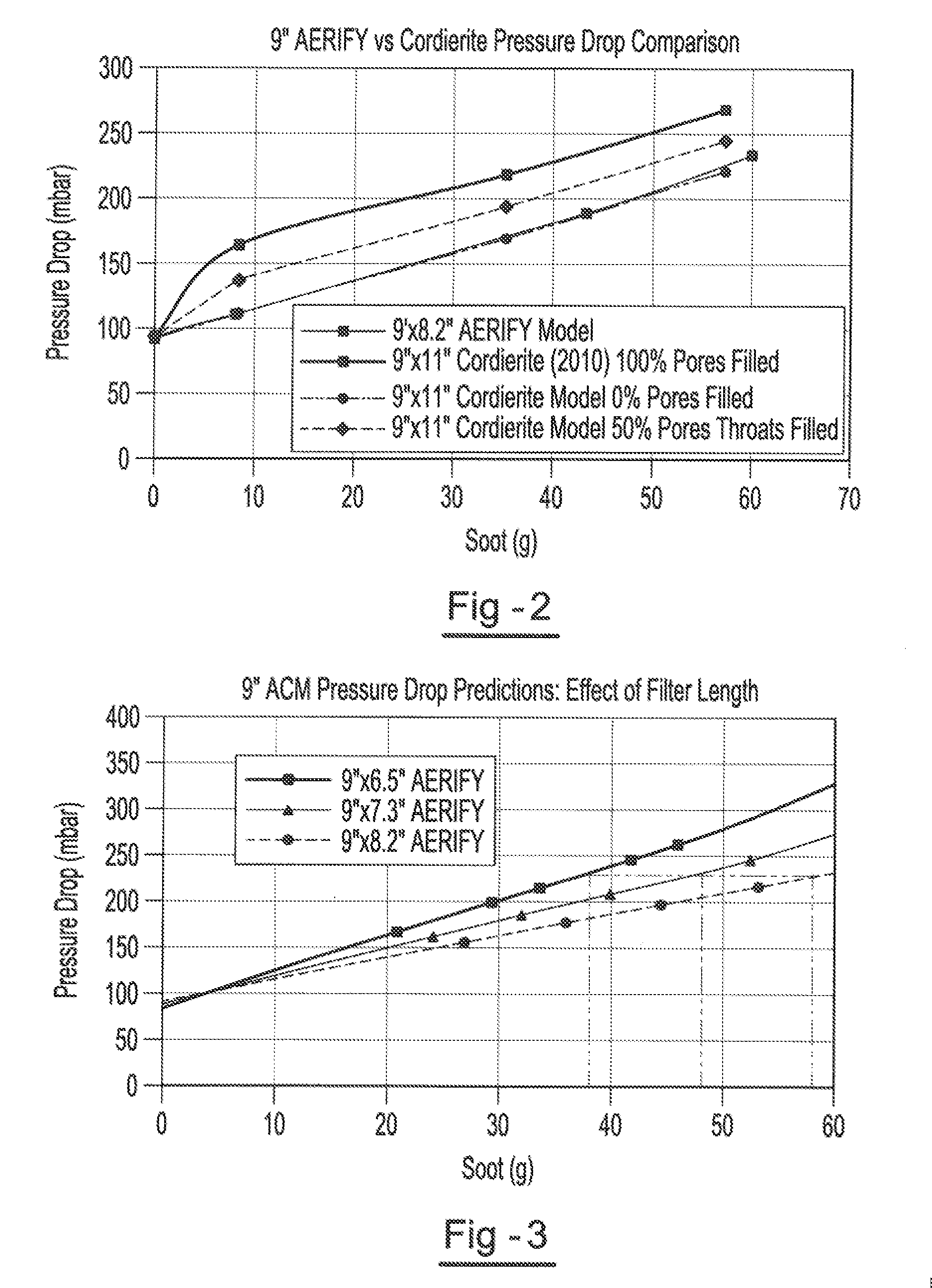

Method and apparatus for decreasing fuel comsumption during particulate filter generation

InactiveUS20130152551A1Small sizeThe right amountCombination devicesAuxillary pretreatmentDiesel particulate filterSoot

A diesel particulate filter system comprising: a temperature sensor on the inlet side of the diesel particulate filter; a temperature sensor on the outlet side of the diesel particulate filter; a pressure sensor on the inlet side of the diesel particulate filter; and a control module in communication with the temperature sensors and the pressure sensor, and the control module is loaded with a look-up table that correlates the amount of soot loaded in the diesel particulate filter to a change in pressure measured by the pressure sensor; wherein the control module Initiates a regeneration cycle when soot loading of the diesel particulate filter achieves a predetermined soot load.

Owner:DOW GLOBAL TECH LLC

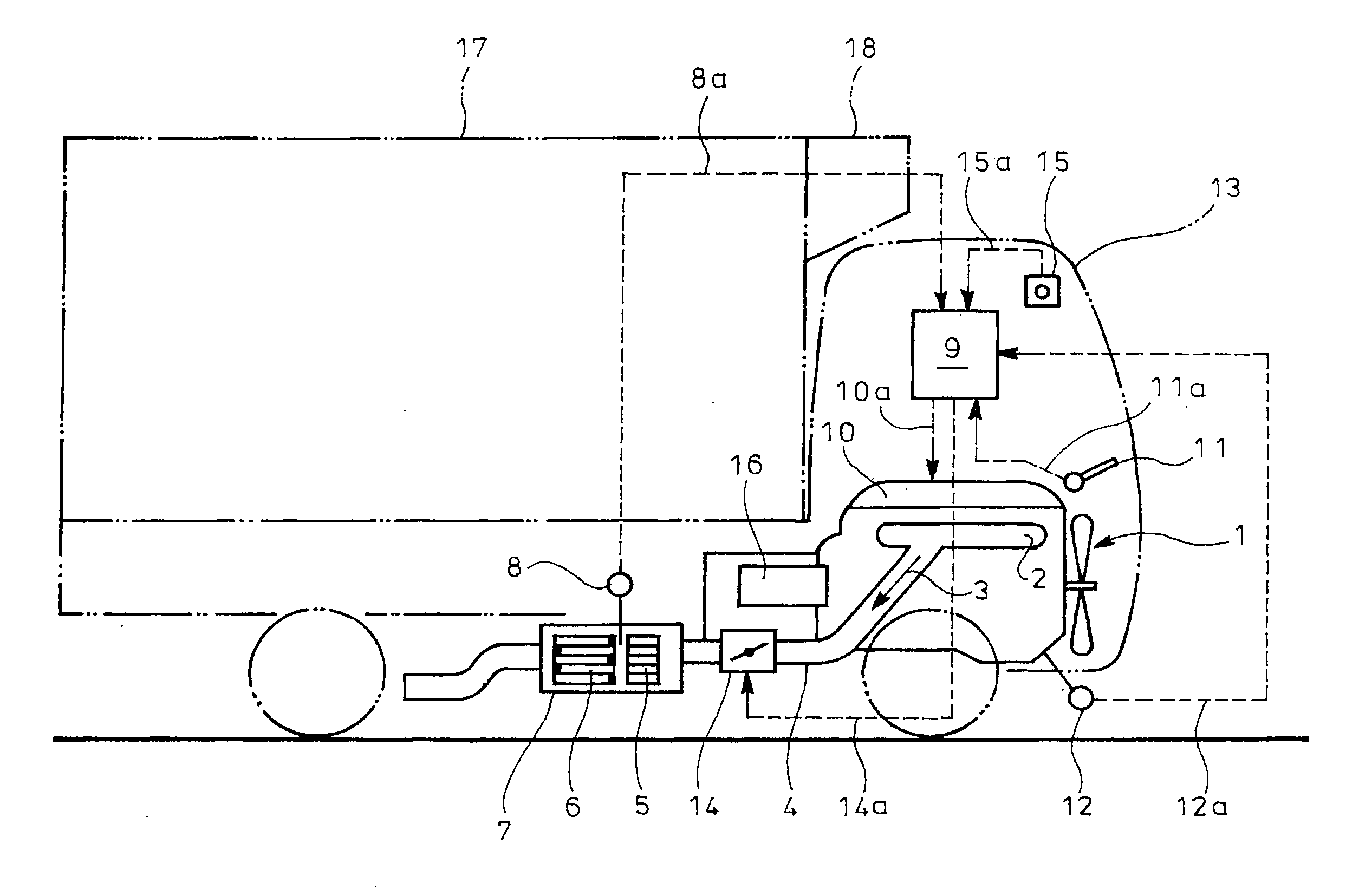

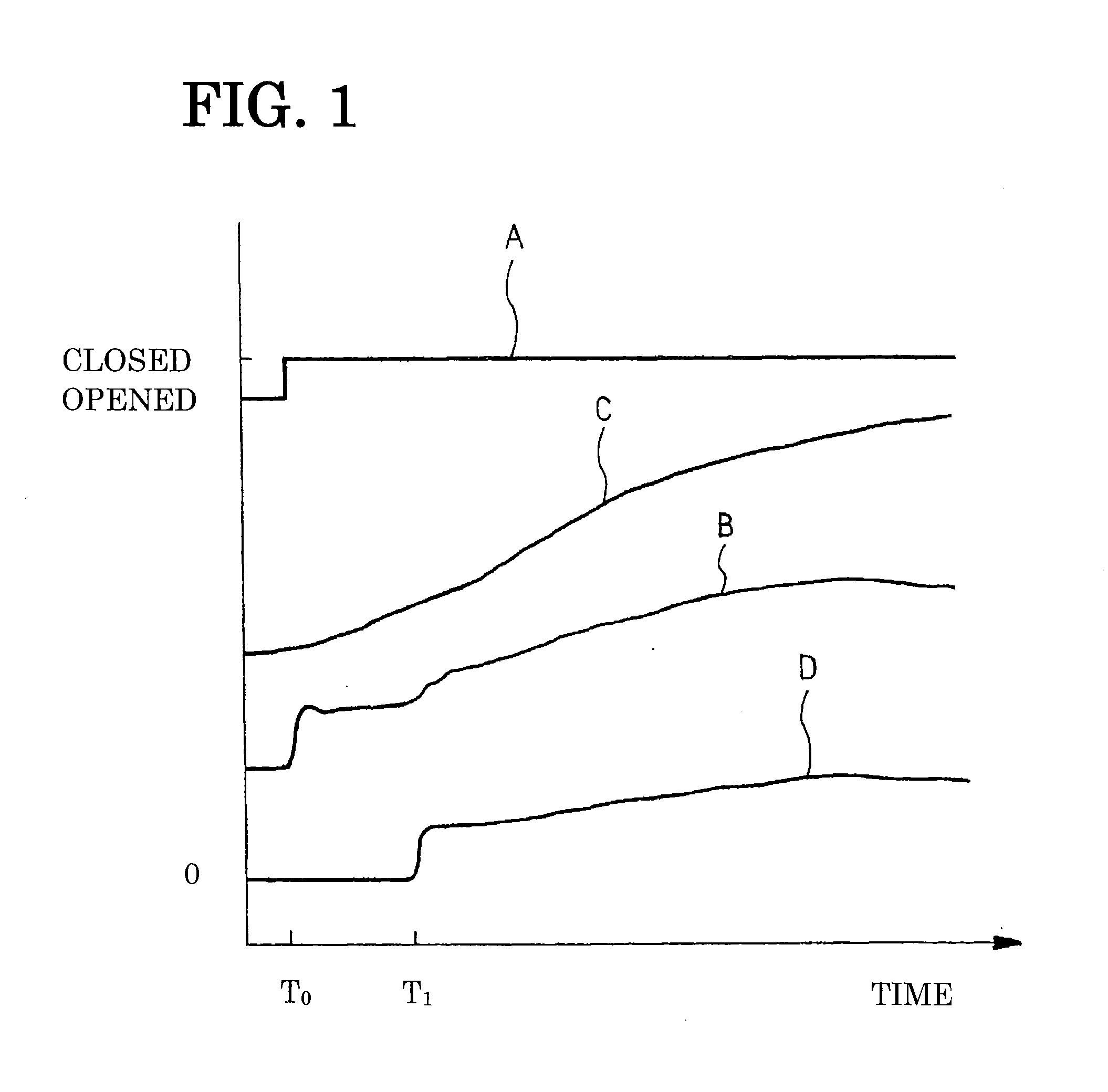

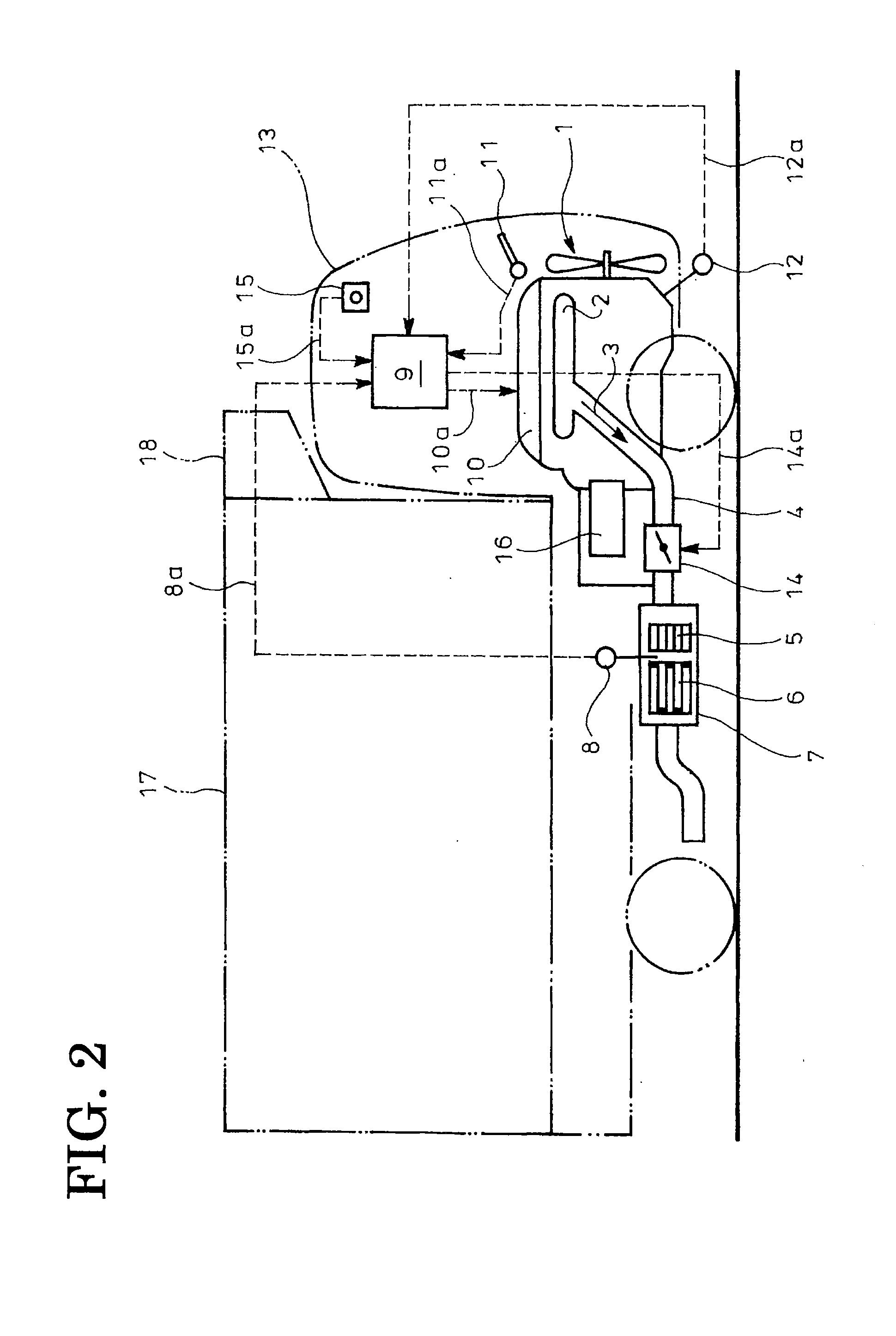

Method for manually regenerating particulate filter

InactiveUS20140033923A1Shorten regeneration timeFacilitated releaseGas treatmentElectrical controlExhaust gasPost injection

Related is a method for regeneration of a particulate filter 6 wherein manual regeneration of the particulate filter 6 started with a vehicle being stopped causes an exhaust brake 14 to throttle an exhaust passage. This increases an engine load and a fuel injection amount to elevate in temperature an exhaust gas 3; then, fuel addition is started by post injection with a fuel injection device 10, and the particulate filter 6 is regenerated by heat of an oxidation reaction of the added fuel on an oxidation catalyst 5 . After the starting of the manual regeneration, whether a fuel injection amount exceeds a reference value or not is judged. Only if the judgment is affirmative, throttling of the exhaust passage by the exhaust brake 14 is released provided exhaust temperature exceeds a reference temperature on an entry side of the particulate filter 6.

Owner:HINO MOTORS LTD

Adsorptive permeation hollow fiber membrane, method of manufacturing the same, and gas adsorptive/desorptive separation system utilizing the same

ActiveUS20150273390A1Increase the adsorption areaDecreasing amount of usedMembranesSemi-permeable membranesFiberHollow fibre membrane

Disclosed are an adsorptive permeation hollow fiber membrane formed by uniformly dispersing an adsorbent capable of selectively adsorbing only a specific gas in mixed gas components inside a porous hollow fiber membrane having a sponge structure capable of non-selectively permeating a mixed gas in a powder or crystalline powder form, a method of manufacturing the same, and a gas adsorptive / desorptive separation system utilizing the same.

Owner:SEPRATEK

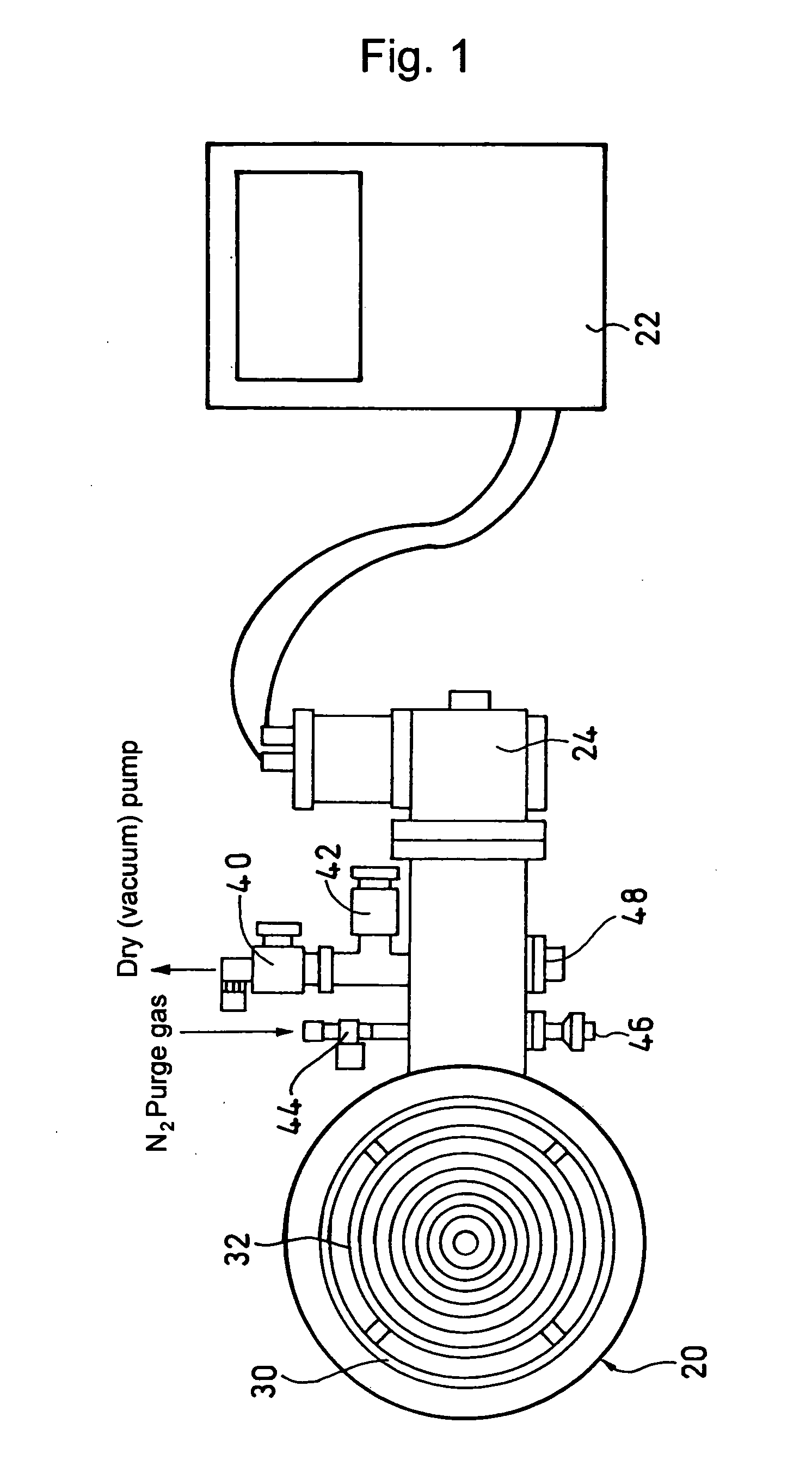

Cryopump, cryopump unit, vacuum processing apparatus including cryopump unit, and cryopump regeneration method

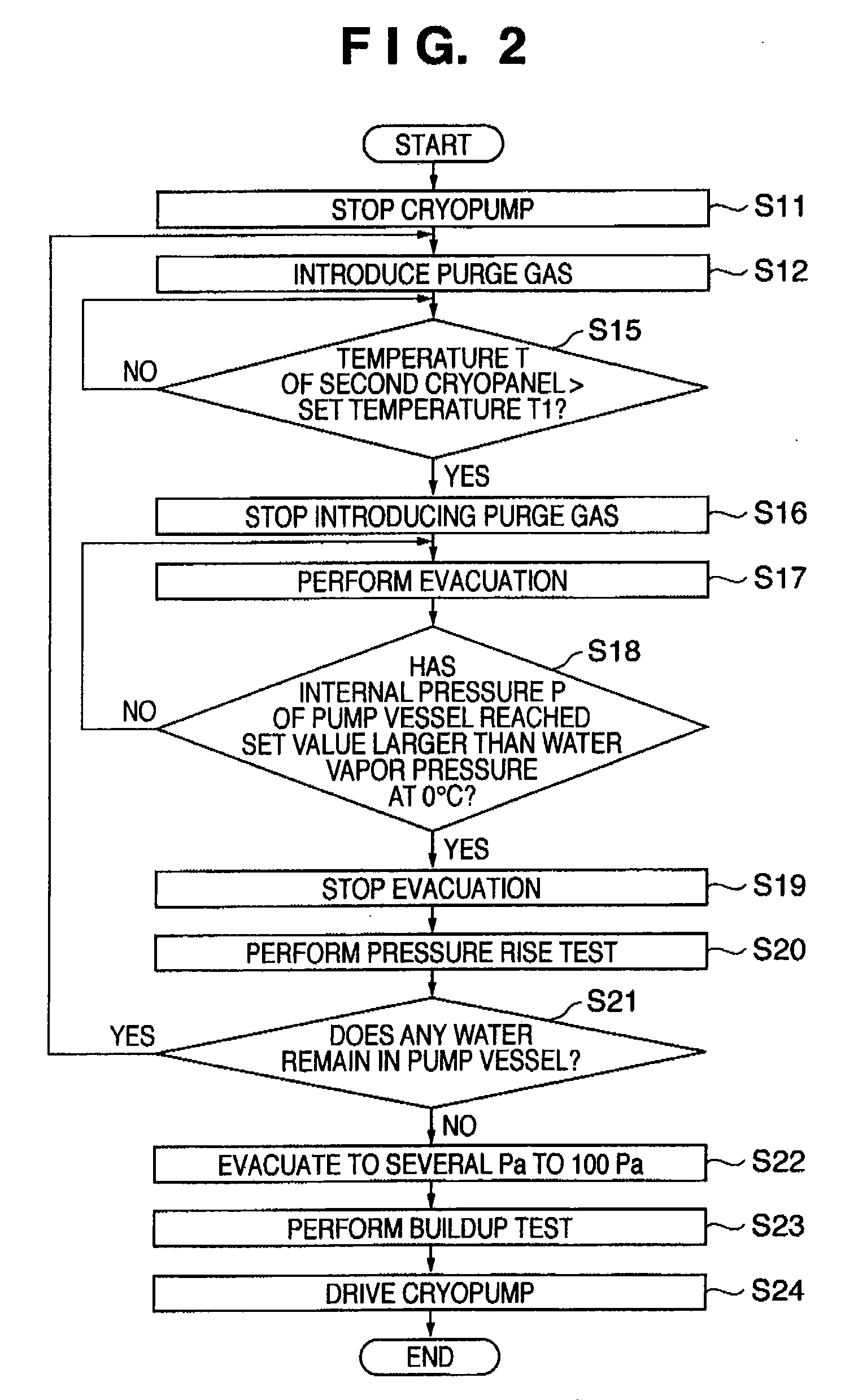

InactiveUS20090165470A1Shorten regeneration timeAccurately and rapidly knowSolidificationLiquefactionPressure riseInternal pressure

A cryopump regeneration method includes a temperature raising step of raising the temperature of a cryopanel so as to vaporize gas molecules condensed on the exhaust surface of the cryopanel, an evacuation step of evacuating a pump vessel, a determination step of determining whether the internal pressure of the pump vessel has reached a set pressure higher than the water vapor pressure at 0° C., a pressure rise test step of stopping the evacuation and performing a pressure rise test, and an observation step of observing residual water based on the internal pressure of the pump vessel.

Owner:CANON ANELVA CORP

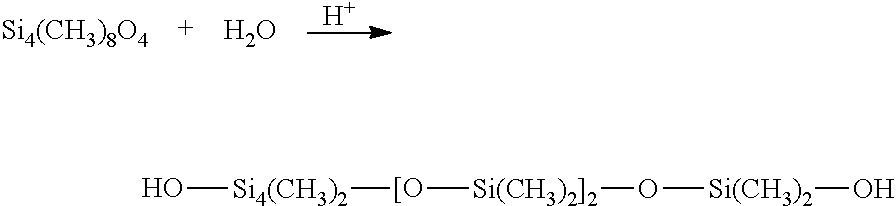

Regenerative adsorption process for removal of silicon-containing contaminants from process gas using a neutral adsorbent media

A natural gas-containing stream such as biogas from landfills and sewage treatment plants is freed of siloxane contaminants by passing the biogas through a bed containing an adsorbent having a neutral surface, which adsorbs the siloxanes. When the bed of neutral adsorbent is filled to capacity, the adsorbent bed is heated to remove the siloxanes and regenerate the bed. The neutral adsorbent reduces disadvantageous reactions between the adsorbent and siloxane and other impurities in the natural gas-containing stream.

Owner:GUILD ASSOCS

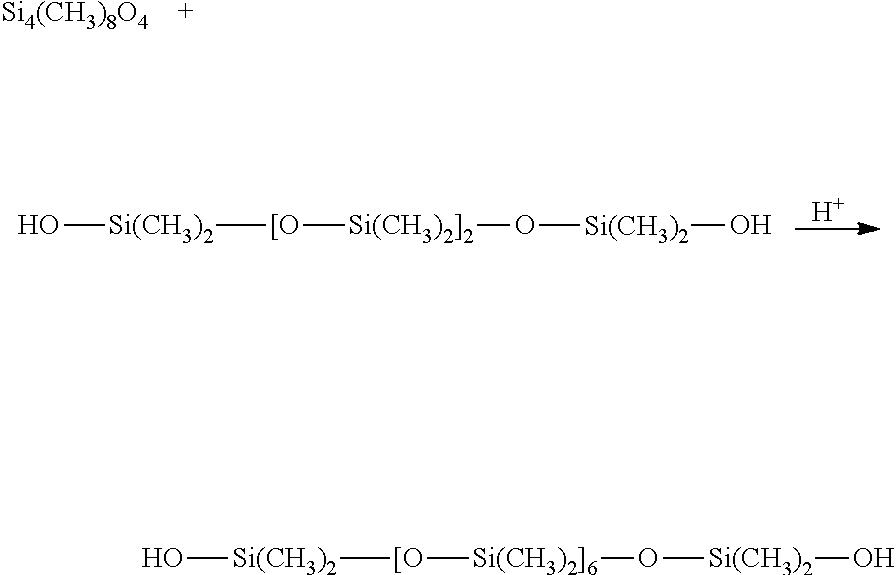

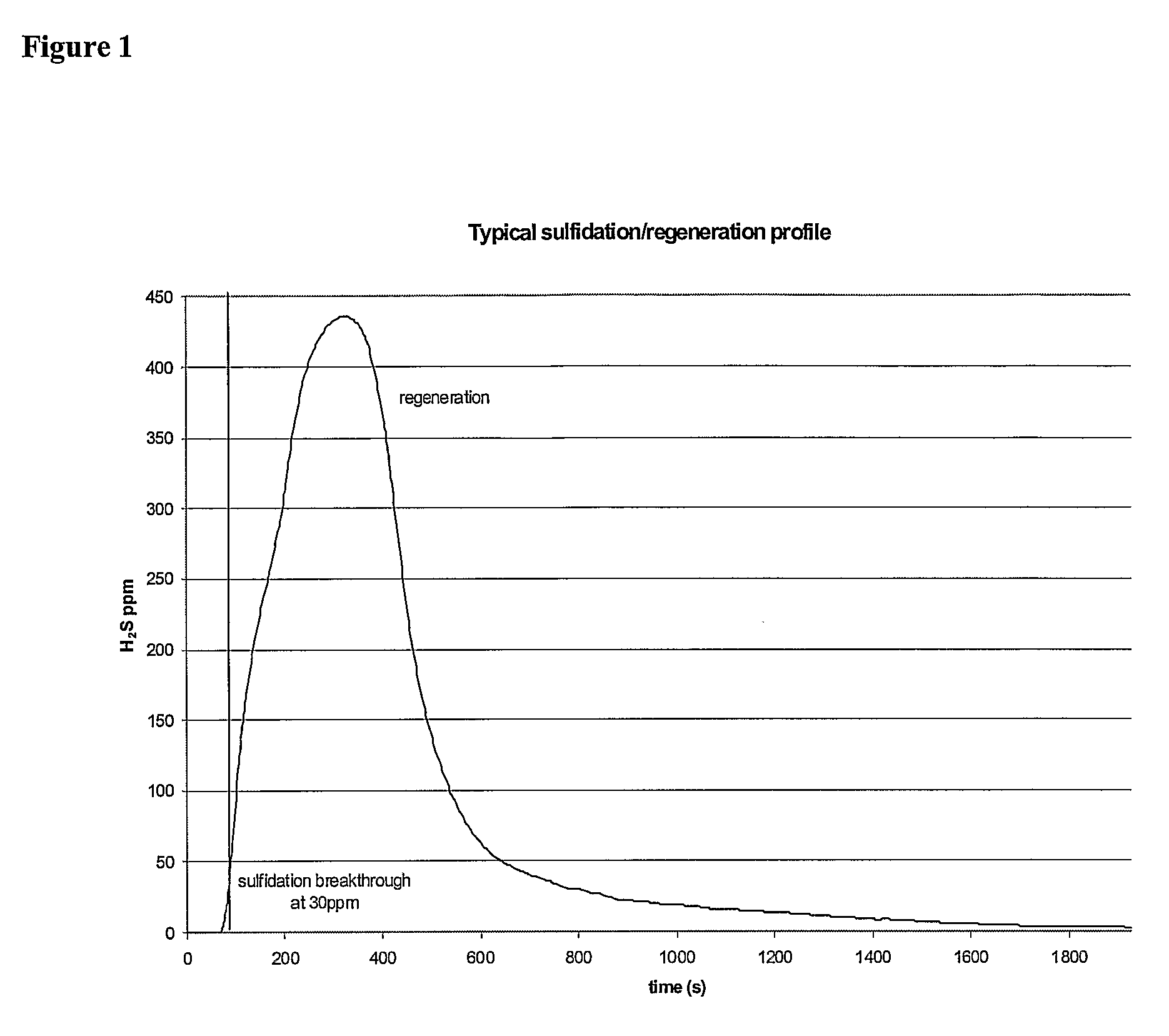

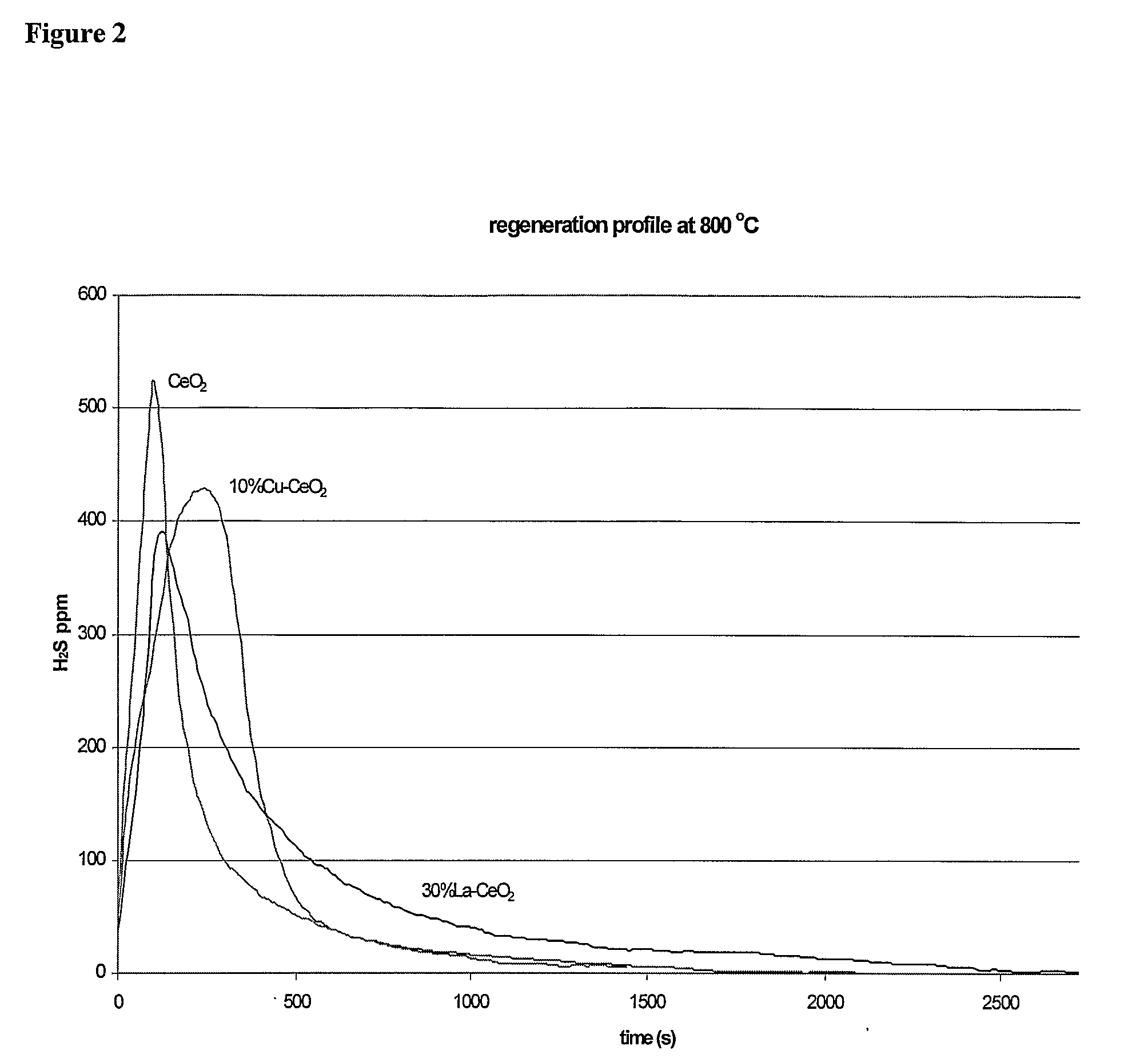

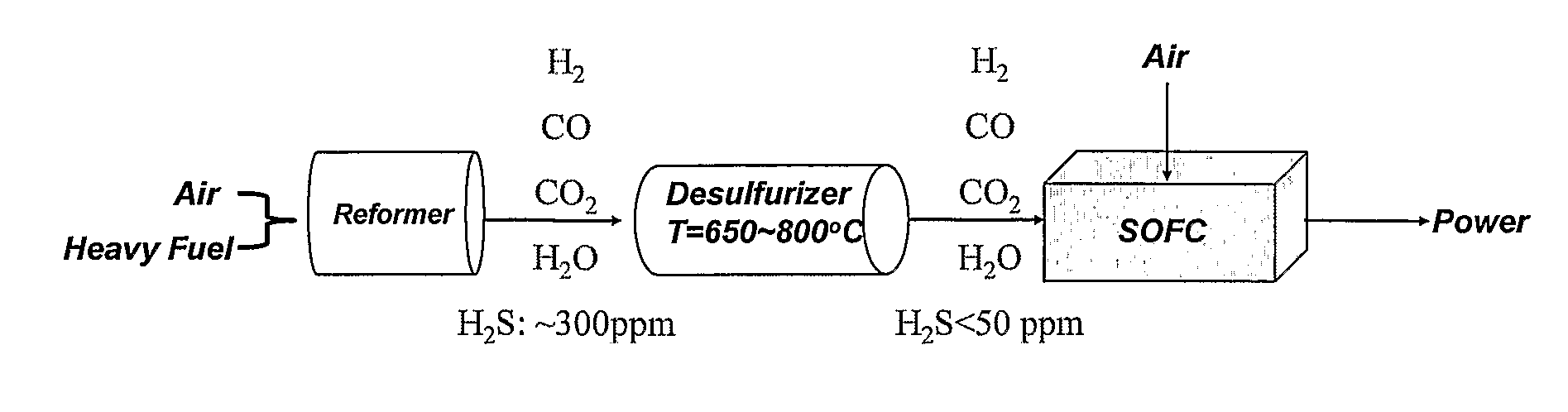

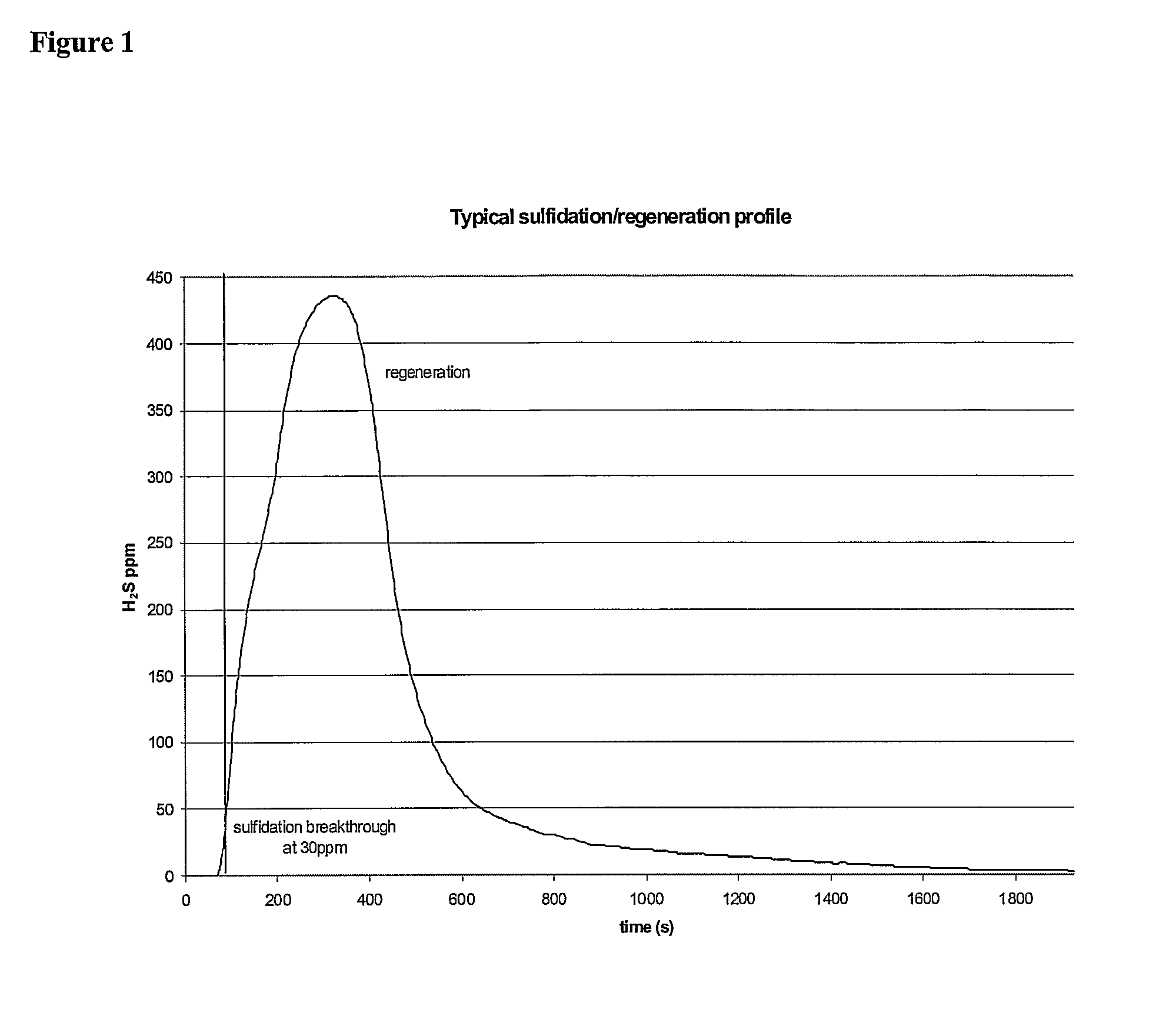

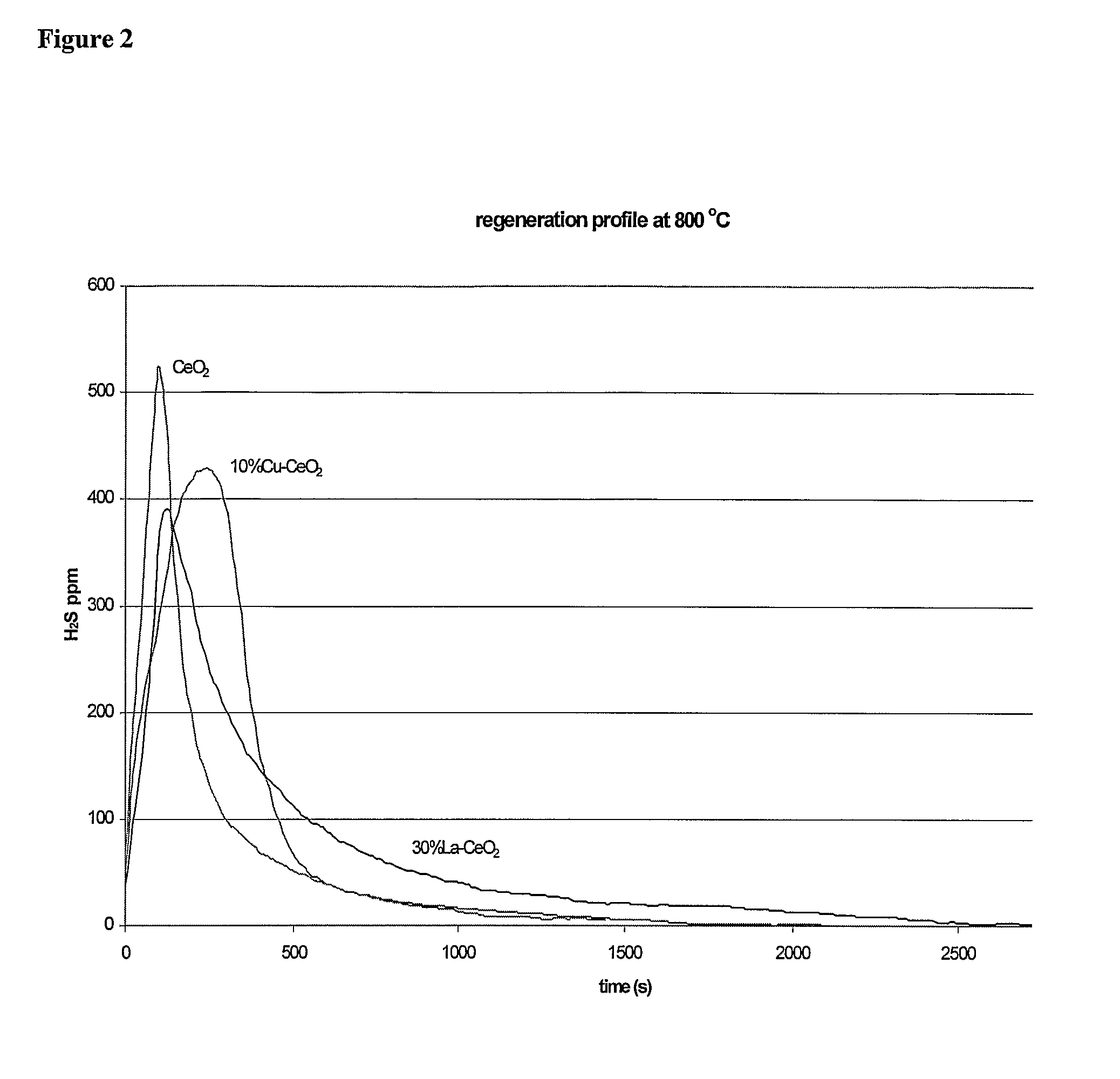

Apparatus and Methods for Non-Regenerative and Regenerative Hot Gas Sulfurization

ActiveUS20080267848A1Effectively and regenerably removeReducing sorbentGas treatmentGaseous fuelsSorbentSulfur

Disclosed is a doped cerium oxide sorbent that can effectively and regenerably remove H2S in the temperature range of about 500° C. to about 1000° C. Regenerable sorbents (e.g., ZnO, La2O3, CeO2) and methods of using them are disclosed that allow cyclic desulfurization from about 300-500° C., 350-450° C., and at about 400° C. In one embodiment, the present invention relates to a method of desulfurizing fuel gas comprising passing the fuel gas through the sorbent at a space velocity wherein the sulfur compounds are adsorbed substantially on the surface of the sorbent; and regenerating the sorbent by passing a regenerating gas through the sorbent, wherein substantially all of the sulfur compounds are desorbed from the sorbent surface. In a further embodiment, the method of desulfurizing fuel gas further comprises repeating the aforementioned steps while the fuel processor is in operation. In another embodiment, the step of passing the fuel gas may be preceded by reducing the sorbent by passing a reducing gas through the sorbent. In another embodiment, the sorbent may be fully sulfided, i.e., sulfided on its surface and bulk (internally).

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

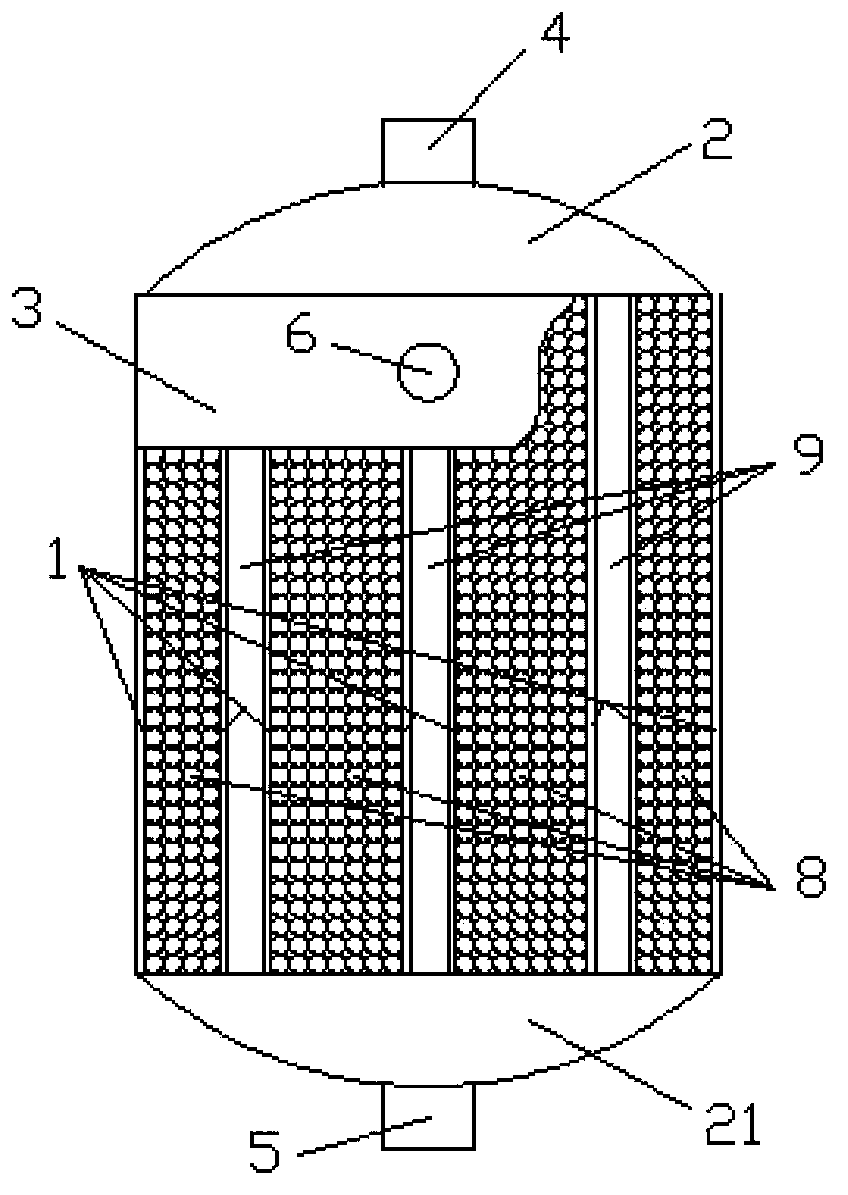

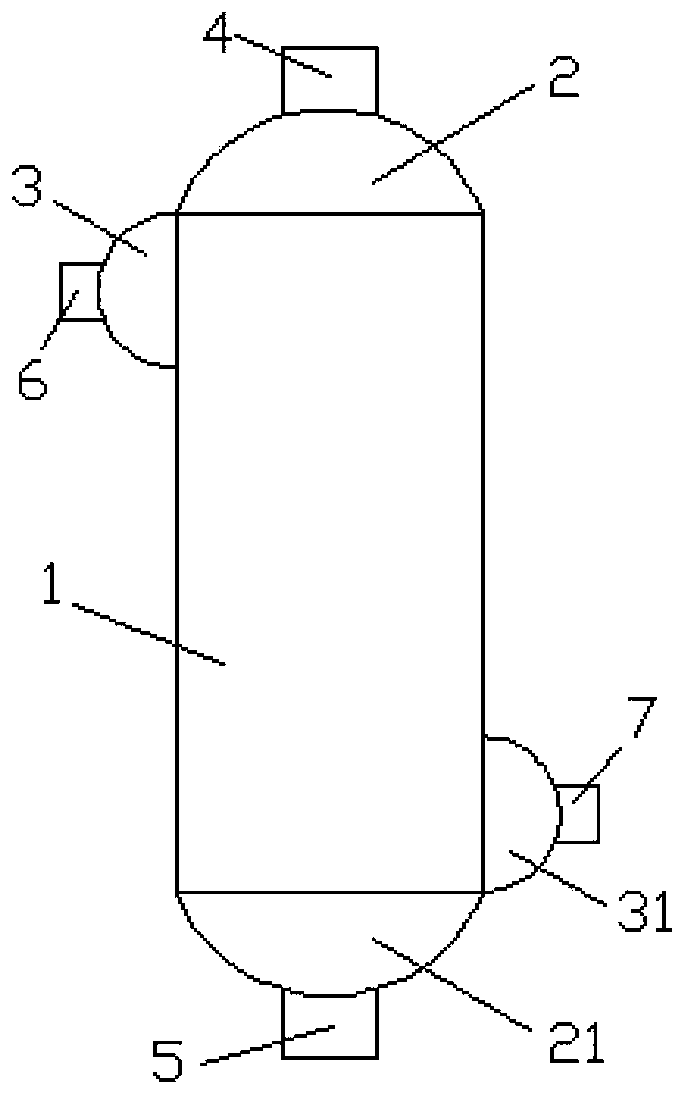

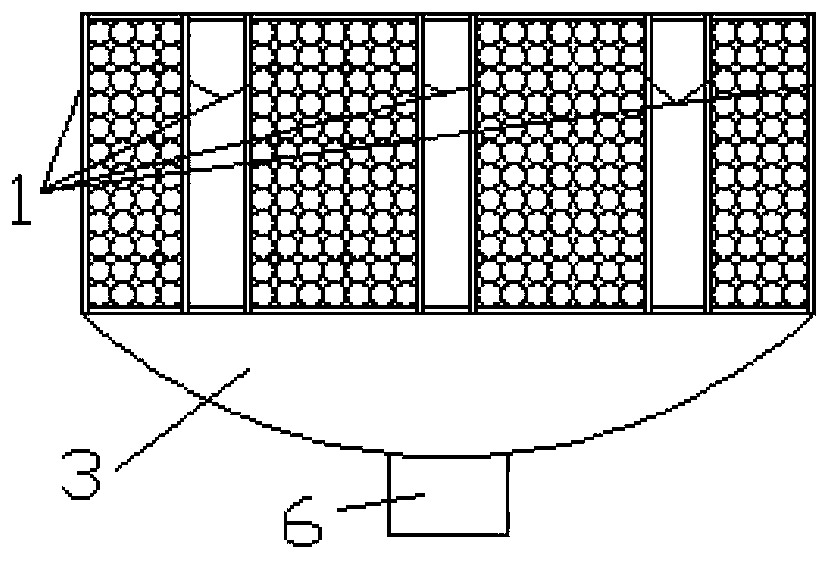

Molecular sieve adsorption tower provided with heat transferring medium channels

InactiveCN103463926AReduce fill volumeReduce wasteDispersed particle separationMolecular sieveSorbent

The invention discloses a molecular sieve adsorption tower provided with heat transferring medium channels. The molecular sieve adsorption tower comprises vertical separator plates arranged in a adsorption tower container; space flow channels are formed by adjacent vertical separator plates, and a plurality of the space flow channels distributed at intervals are filled with a molecular absorbent, and are called as process gas channels; the rest space flow channels are taken as the heat transferring medium channels; the upper end and the lower end of the adsorption tower are provided with an upper process gas shell cover and a lower process gas shell cover respectively; the ends of the upper process gas shell cover and the lower process gas shell cover are provided with a process gas inlet and a process gas outlet respectively; two opposite side walls of the container are provided with an upper heat transferring medium shell cover and a lower heat transferring medium shell cover respectively; the ends of the upper heat transferring medium shell cover and the lower heat transferring medium shell cover are provided with a heat transferring medium inlet and a heat transferring medium outlet respectively; the process gas inlet and the process gas outlet are communicated with the process gas channels via the process gas shell covers respectively; and the heat transferring medium inlet and the heat transferring medium outlet are communicated with the heat transferring medium channels via the heat transferring medium shell covers respectively. The molecular sieve adsorption tower is provided with the heat transferring medium channels, so that the molecular sieve can be heated or cooled by the heat transferring medium, molecular sieve regeneration time and adsorption cycle period are shortened, and regeneration gas consumption is reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Cryopump

InactiveUS20100115971A1Efficient dischargeShort timeSolidificationLiquefactionEngineeringRadiant heat

A cryogenic refrigerator of a cryopump generates cryogenic cooling in an expansion volume by reciprocally moving a displacer in a cylinder. A cryopanel and a cup-shaped shield are received in a vacuum chamber of the cryopump and are cooled by the cryogenic cooling. The shield protects the cryopanel from radiant heat of the vacuum chamber. A louver is provided at an upper opening of the shield. A hole is formed at a bottom or side of the cup-shaped shield defining a storage part. Molecules in the vacuum chamber are solidified at or absorbed by the cryopanel and the shield. During regeneration, temperature of the cryopanel and the shield is increased. Water molecules desorbed and liquefied from the louver, the shield or the cryopanel are accumulated during regeneration at the storage part that has enough volume to store the water molecules.

Owner:SUMITOMO HEAVY IND LTD

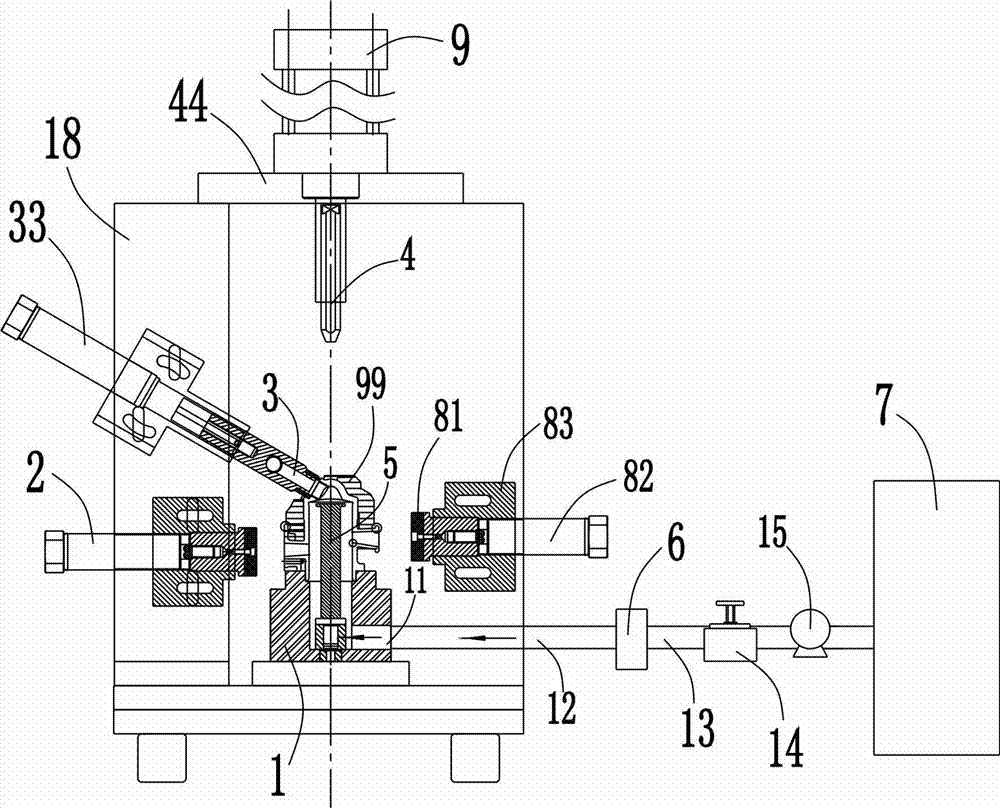

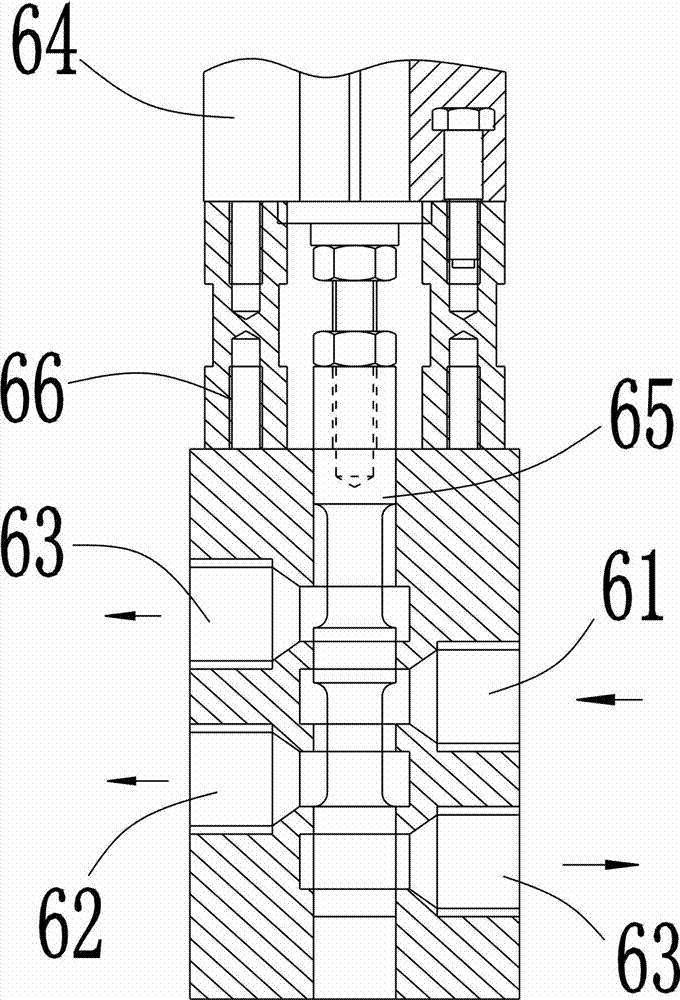

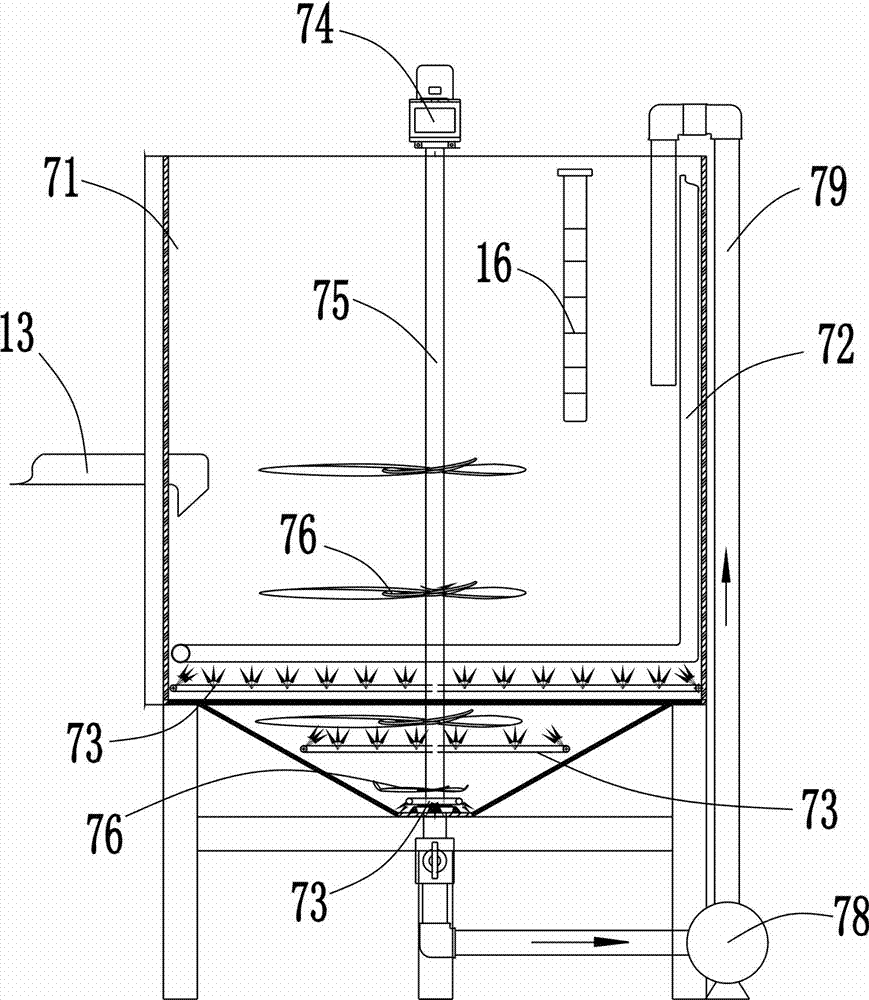

Perfusion type electronickelling and silicon carbide device for air cylinder

The invention discloses a perfusion type electronickelling and silicon carbide device for an air cylinder. The perfusion type electronickelling and silicon carbide device for the air cylinder comprises an electroplating base, an electroplating solution groove, a cathode conducting rod and an anode conducting rod. The air cylinder to be electroplated is placed inversely on the electroplating base which is internally provided with a groove. One end of the anode conducting rod is arranged in the groove, while the other end of the anode conducting rod extends into a chamber of the air cylinder to be electroplated. The cathode conducting rod is arranged above the electroplating base and can move up and down. The electroplating base is provided with a liquid inlet which is communicated with the electroplating solution groove through a flow divider. The flow divider comprises an electroplating solution inlet, an electroplating solution outlet and at least a return opening. The electroplating solution outlet is communicated with a liquid outlet. The electroplating solution inlet and the return opening are communicated with the electroplating solution groove. The perfusion type electronickelling and silicon carbide device for the air cylinder further comprises a drive device which drives the electroplating solution to flow upward along the inner wall of the air cylinder and flow from the top of the air cylinder back to the electroplating solution groove. According to the device, the electroplating solution is less polluted, the life cycle of the electroplating solution is long, the electroplating solutions in grooves are not needed to be prepared, and the regenerating time and cost of the electroplating solution are reduced.

Owner:ZHENGJIANG FENGLONG ELECTRIC CO LTD

Cold trap and cold trap regeneration method

ActiveUS7992394B2Less affectedShorten regeneration timePressurized chemical processSolidificationEngineeringProduct gas

A cold trap is provided with a cold panel provided in a pumping path such that the panel is exposed, a refrigerator thermally coupled to the cold panel and operative to cool the cold panel; and a controller configured, in a regeneration process for evaporating a gas frozen on the surface of the cold panel and discharging the gas outside using the vacuum pump, to control the refrigerator so as to raise the temperature of the cold panel to a temperature exceeding a non-liquefaction temperature range and to adjust a pressure in the pumping path at the temperature so that the gas frozen on the surface of the cold panel is evaporated without being melted, the non-liquefaction temperature range being a range in which it is guaranteed that a gas frozen on the surface of the cold trap is evaporated without being melted.

Owner:SUMITOMO HEAVY IND LTD

Diagnosis method for an exhaust gas post-treatment system

ActiveUS8286417B2Deficient reduction of nitrogen oxidesEasy to detectAnalogue computers for vehiclesElectrical controlDiagnosis methodsOperation point

The invention relates to a diagnosis method for an exhaust gas post-treatment system for the reduction of nitric oxides in the exhaust gas train of an internal combustion engine by means of selective catalytic reduction. The following steps are provided for easy recognition of errors: definition of at least one threshold value for the Nox concentration for at least one engine operation point; shifting the operational mode of the internal combustion engine into an operational state of diagnosis, wherein in the operational state of diagnosis substantially more Nox emissions are produced than in the normal operational mode; determining an amount of reducing agents corresponding to the increased amount of Nox emisions in the operational state of diagnosis; controlling a dosing device in order to introduce the amount of reducing agents, corresponding to the increased amount of NOx emissions during the operational state of diagnosis, into the wase gas; measuring the concentration of NOx downstream from the post-treatment device; comparing the measured concentration of NOx to the threshold value; taking a decision as to the erroneous or error-free operation of the waste gas post-treatment system based on comparison of the measured concentration of NOx to the threshold value; terminating the operational state of diagnosis.

Owner:AVL LIST GMBH

Apparatus and methods for non-regenerative and regenerative hot gas desulfurization

Owner:TRUSTEES OF TUFTS COLLEGE

Adsorption and moisture removing method for firedamp gas, and apparatus thereof

The present invention relates to an adsorption and moisture removing method for firedamp gas, and an apparatus thereof. According to the present invention, an adsorption tower is arranged on a pipeline between a firedamp gas outlet pipeline and a gas supply pipeline network gas inlet pipeline to carry out a regenerated adsorption and moisture removing treatment for the firedamp gas; the adsorbent comprises at least two adsorbents, and the two adsorbents are placed hierarchically, wherein a mass ratio of the adsorbent in the bottom layer to the adsorbent in the top layer is 5:1-2:1; a regeneration air valve of a high temperature air inlet pipe and an exhausting steam discharge valve of an exhausting steam outlet pipe of the adsorption tower are opened, and high temperature air is introduced to carry out a regeneration treatment for the adsorbents, wherein the adsorption treatment is completed by the adsorption tower. With the present invention, the air is directly heated by the local firedamp combustion with a hot blast stove so as to improve the heat efficiency; the adsorbents are hierarchically placed, such that the flowing direction of the high temperature regeneration air is changed, and the service life of the adsorbent is prolonged; the maintenance and the repair are simple and easy to perform, and the operating cost is low.

Owner:北京时代桃源环境科技股份有限公司

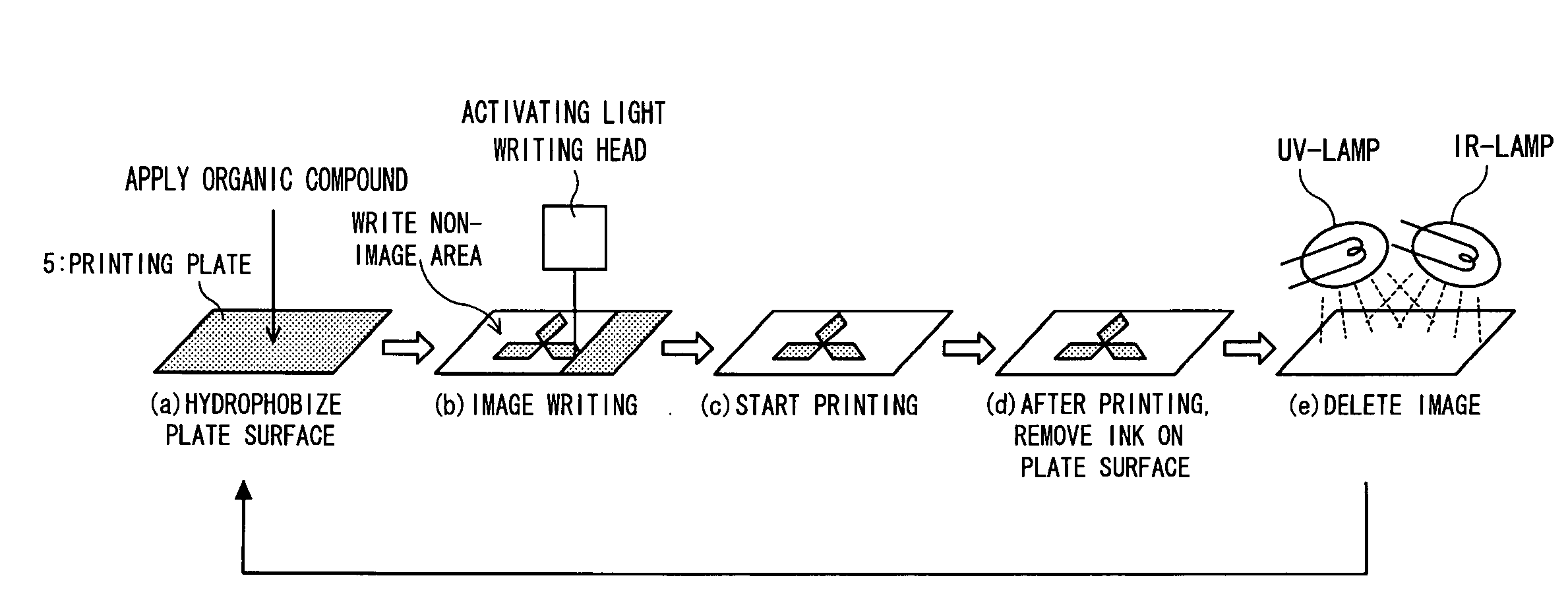

Method for regenerating lithographic printing plate, regenerating device, printer, lithographic printing plate and its production method, and layered structure body and its production method

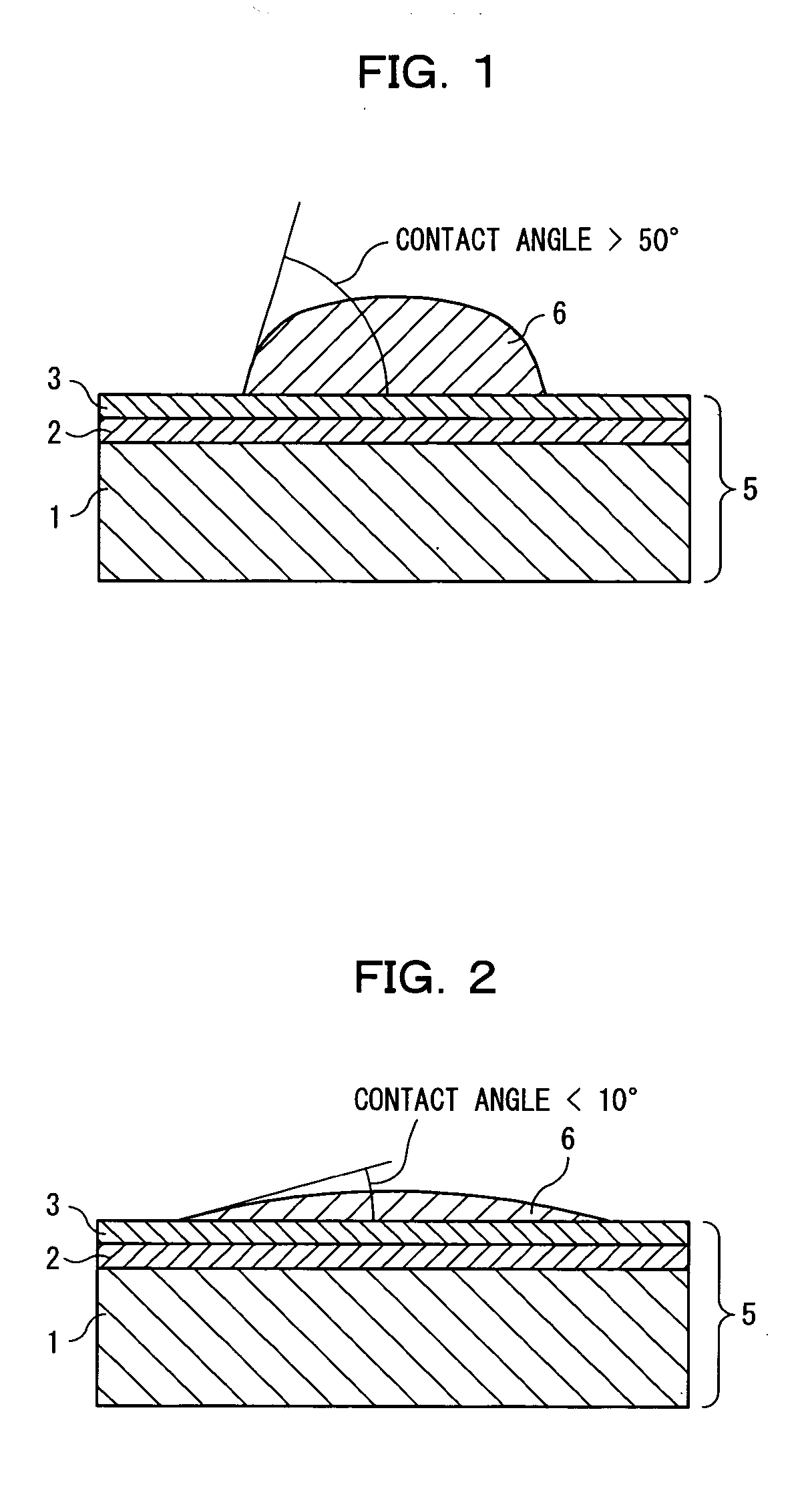

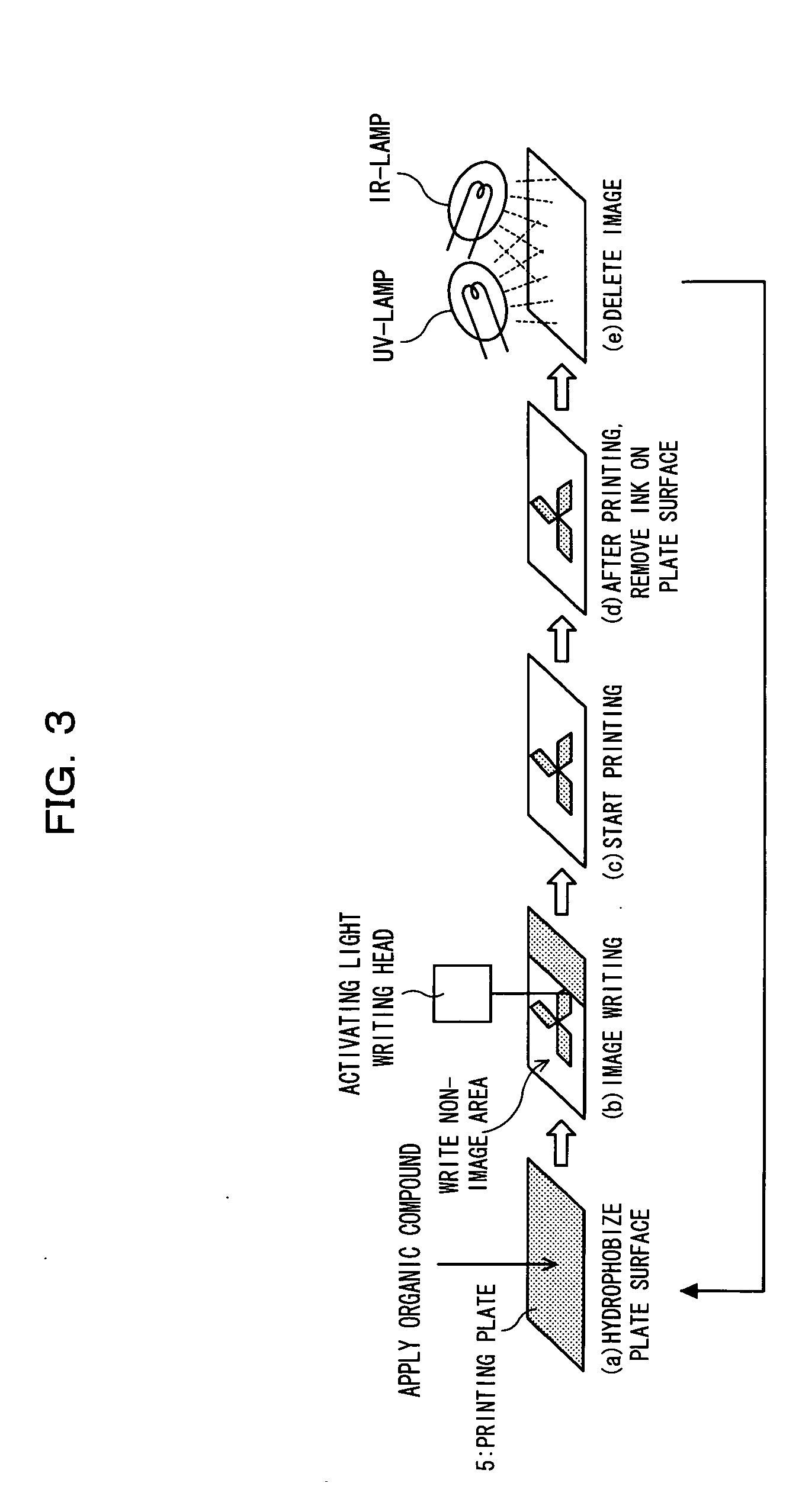

InactiveUS20050139110A1Promoting hydrophilizationHigh photocatalyst activationPrinting platesPlate printingEngineeringPrinting press

The present invention relates to a method of regenerating a printing plate, a regenerating apparatus, and a printing press which make it possible to regenerate a printing plate for repetitive use and shorten the time of plate regeneration. In particular, the present invention intends to make it possible to shorten a time for decomposing and removing an image area formed with an organic compound under irradiation of an activating light. Furthermore, the present invention relates to a printing plate, a method of fabricating the printing plate, a layered formation, and a method of fabricating the layered formation. The present invention is arranged to include a photosensitive layer containing a photocatalyst and when the photosensitive layer is applied on the surface thereof with an activating light having an energy level higher than the band gap energy of the photocatalyst under a heating atmosphere, the surface of the photosensitive layer can be swiftly hydrophilized.

Owner:MITSUBISHI HEAVY IND LTD

Green cucumber high-frequency regeneration method

InactiveCN101449658ANot easy to cloneReduce concentrationCultivating equipmentsHorticulture methodsBudCucumber family

The invention discloses a cucumber high frequency plant generative method, composed of exophytic preparation of Flamingo-bill, inducement and increasement of indefinite buds, radication and transplantation and the like. According to the invention, only one phytohormone is used during the process of tissue culture, density is lower, clone generation of somatic cells are not easy to be induced, technical cost is saved; technical link is few, operation is simple, producing efficiency is increased; only 45 d are required from inoculability to formation of the full plant, thereby greatly shortening generative time of the plant.

Owner:HENAN AGRICULTURAL UNIVERSITY

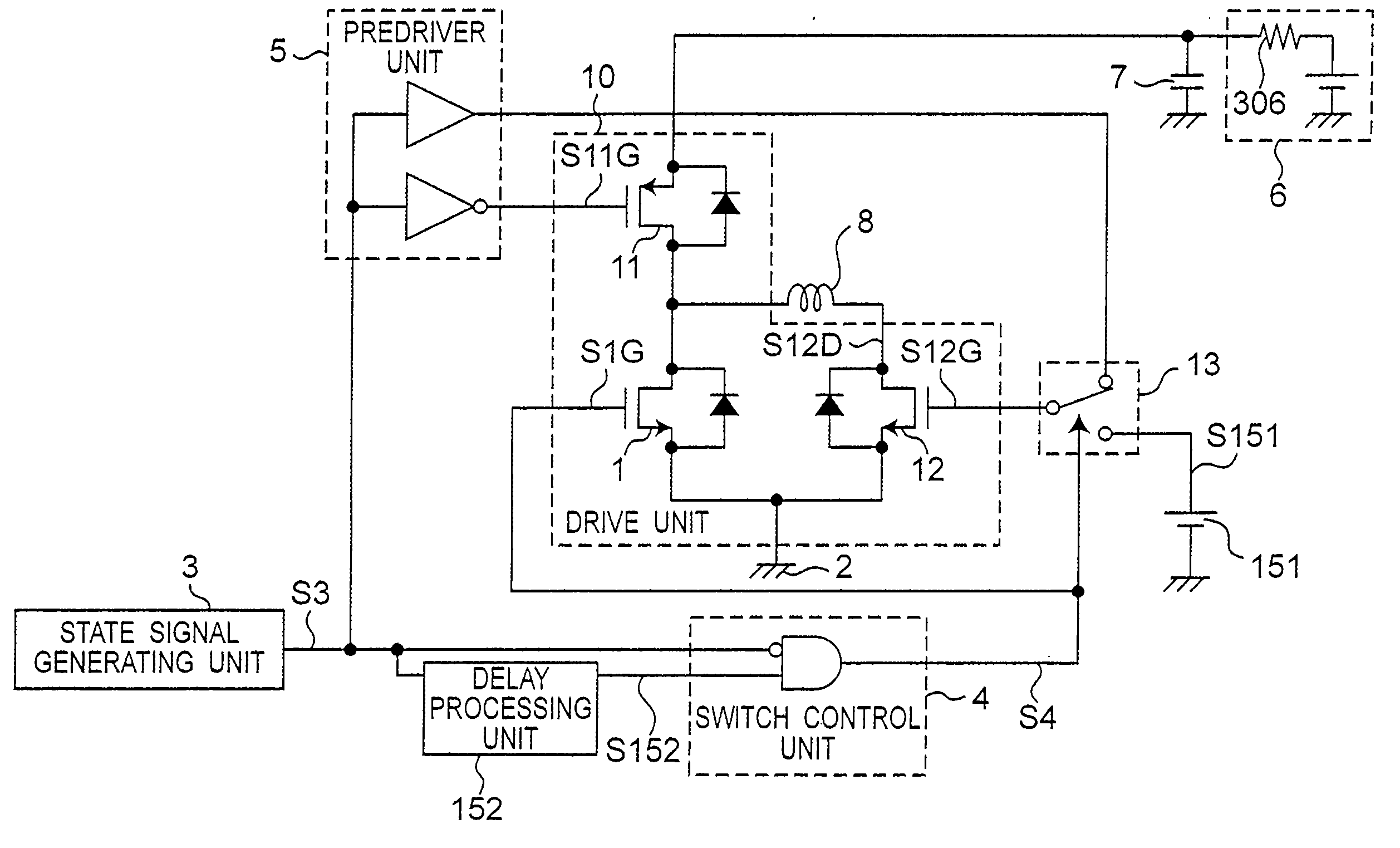

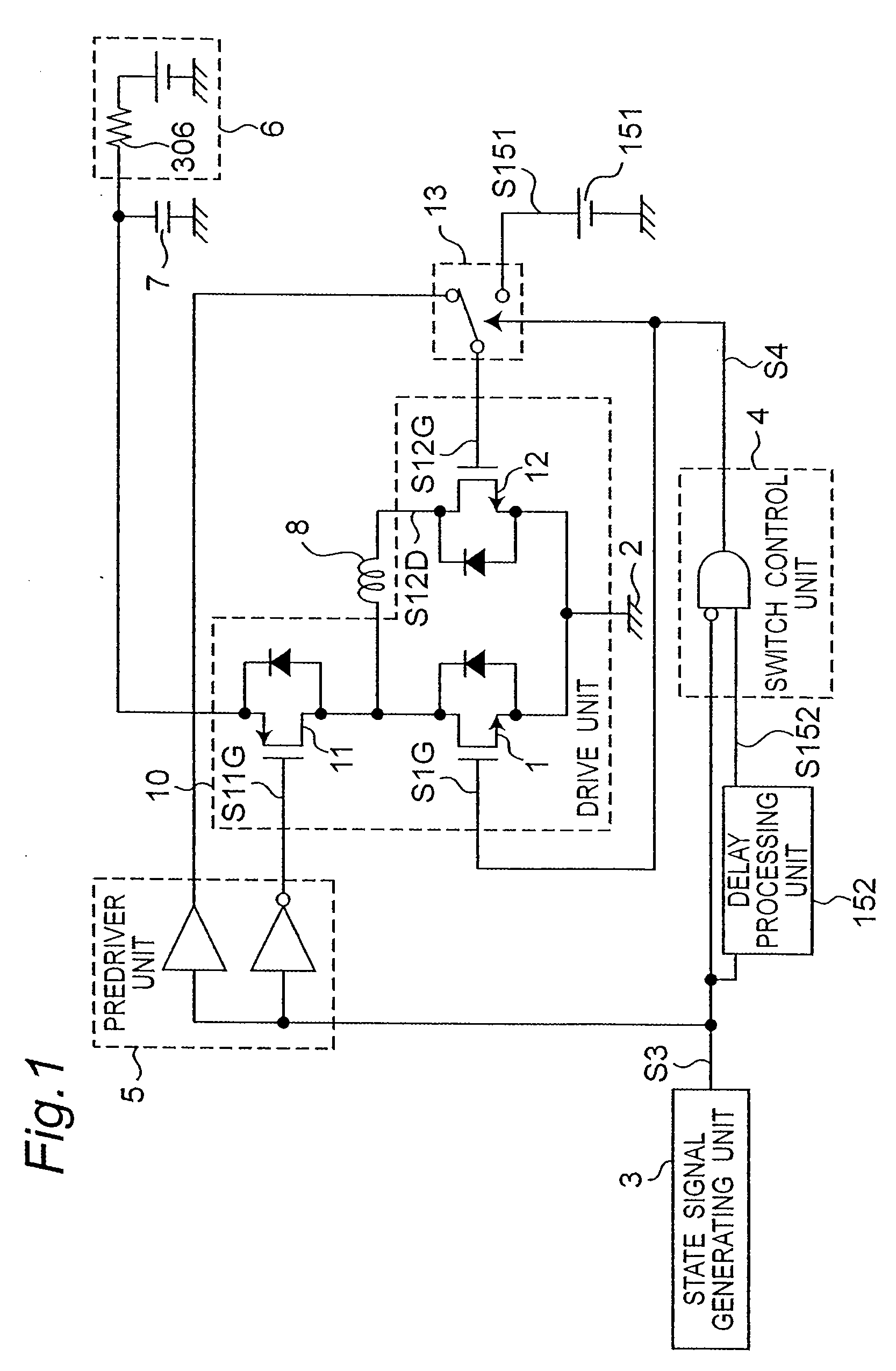

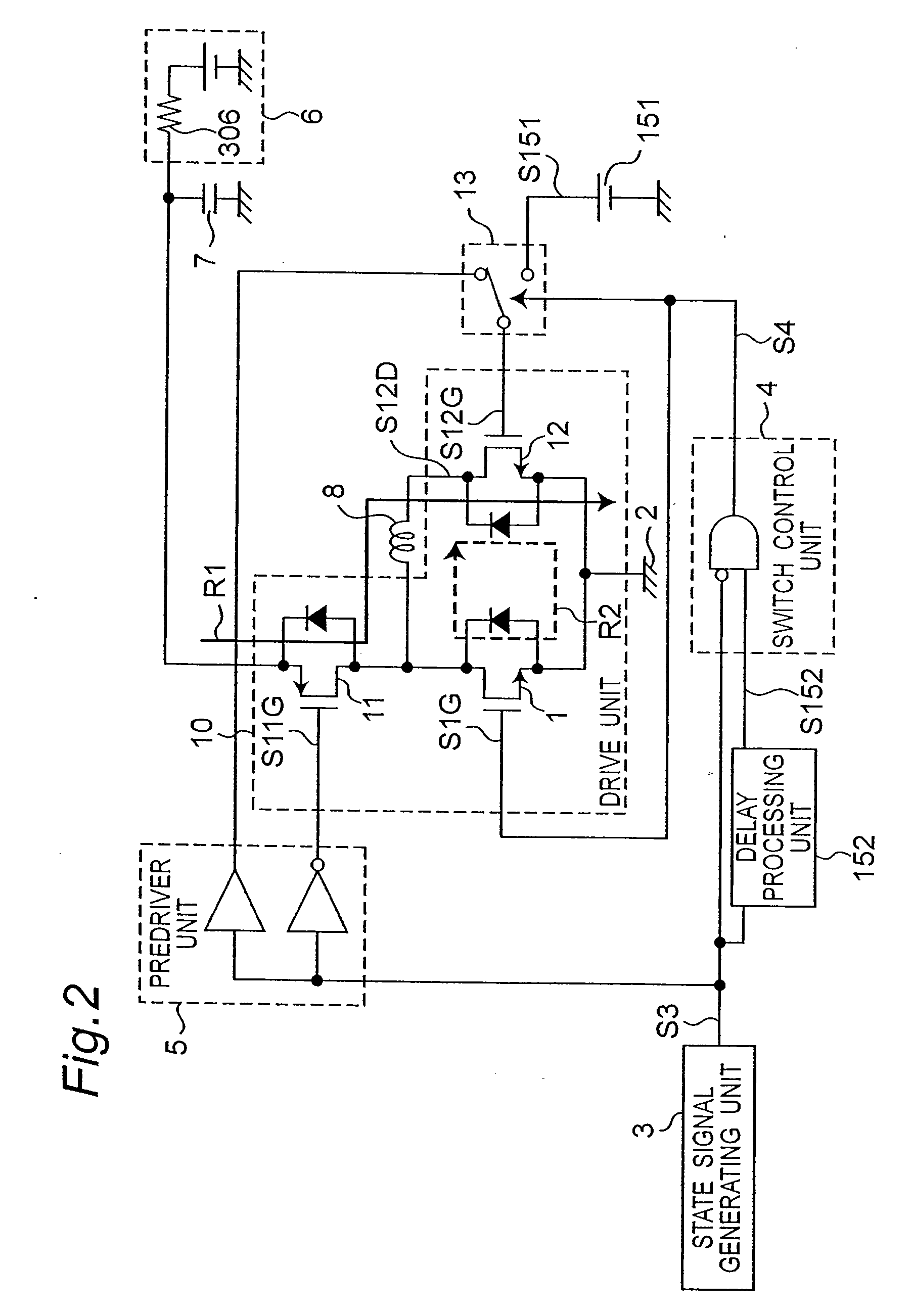

Inductive load drive device and drive method

InactiveUS20070097587A1Shorten attenuation timeWithout increase capacitanceTransistorElectronic switchingInductive loadCapacitance

An inductive load drive device for driving an inductive load shortens the attenuation time of the regenerative current produced in the inductive load without increasing capacitance between the power supply and ground. A drive signal generating unit produces a drive signal denoting a logic level of the drive state and regeneration state. A drive unit is controlled based on the drive signal to an OFF state, a high resistance ON state having a high ON resistance, or a low resistance ON state having a low ON resistance, to produce the drive power. The drive unit has a high potential side switching unit group and a low potential side switching unit group. In the regeneration state either the high potential side switching unit group or the low potential side switching unit group is OFF and at least one switching unit of the other switching unit group is on.

Owner:PANASONIC CORP

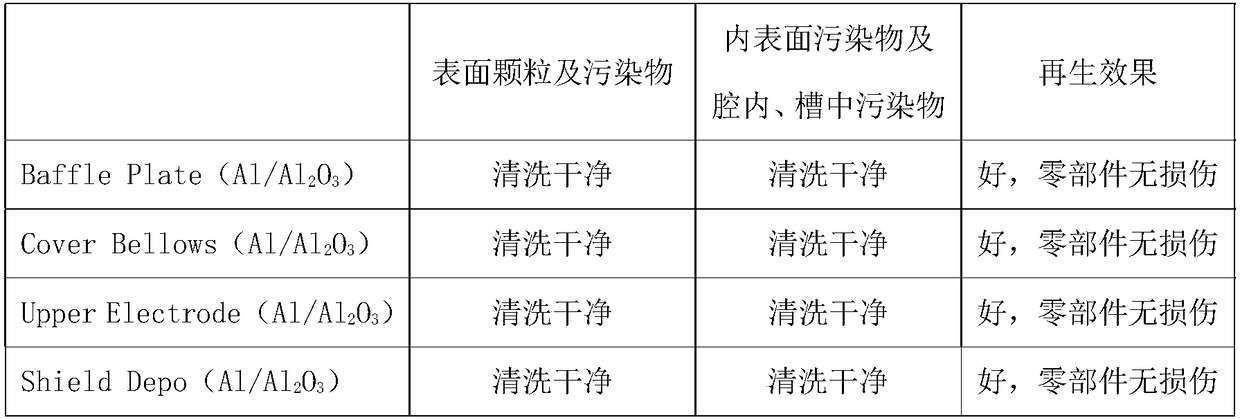

Regenerating method for Al/Al2O3 part of TD/DRM process of semiconductor 8-inch wafer film process

ActiveCN108573855AFast migrationLow viscositySemiconductor/solid-state device manufacturingEnvironmental resistanceThermal energy

The invention relates to a regenerating method for an Al / Al2O3 part of a TD / DRM process of a semiconductor 8-inch wafer film process. The method comprises the steps that dry ice particles are sprayedand cleaned to regenerate the surface of the part; local temperature difference change formed by thermal energy absorption of dry ice during a sublimation process is used to generate a 'shear stress'between a substrate and a cleaned object, and the cleaned object is quickly peeled off from the surface of the substrate; a Venturi nozzle can generate a carbon dioxide gas stream containing more dryice particles; ultrasonic assisted supercritical CO2 cleaning regenerates the inner surface, the chamber and the groove of the part; and supercritical CO2 easily penetrates into the micropores and thechamber or groove of the part to dissolve pollutants, so that the pollutants migrate fast in supercritical CO2 to achieve the purpose of cleaning. Ultrasonic assisting further improves the cleaning effect and efficiency. The regeneration time and cost are shortened. The regenerating method has the advantages of simple process, environmental protection, being pollution-free and good regeneration effect, does not damage the semiconductor part, and has no impact on the performance of the part.

Owner:苏州珮凯科技有限公司

Adsorptive permeation hollow fiber membrane, method of manufacturing the same, and gas adsorptive/desorptive separation system utilizing the same

ActiveUS9446349B2Maximize efficiencyImprove adsorption capacityMembranesSemi-permeable membranesFiberHollow fibre membrane

Disclosed are an adsorptive permeation hollow fiber membrane formed by uniformly dispersing an adsorbent capable of selectively adsorbing only a specific gas in mixed gas components inside a porous hollow fiber membrane having a sponge structure capable of non-selectively permeating a mixed gas in a powder or crystalline powder form, a method of manufacturing the same, and a gas adsorptive / desorptive separation system utilizing the same.

Owner:SEPRATEK

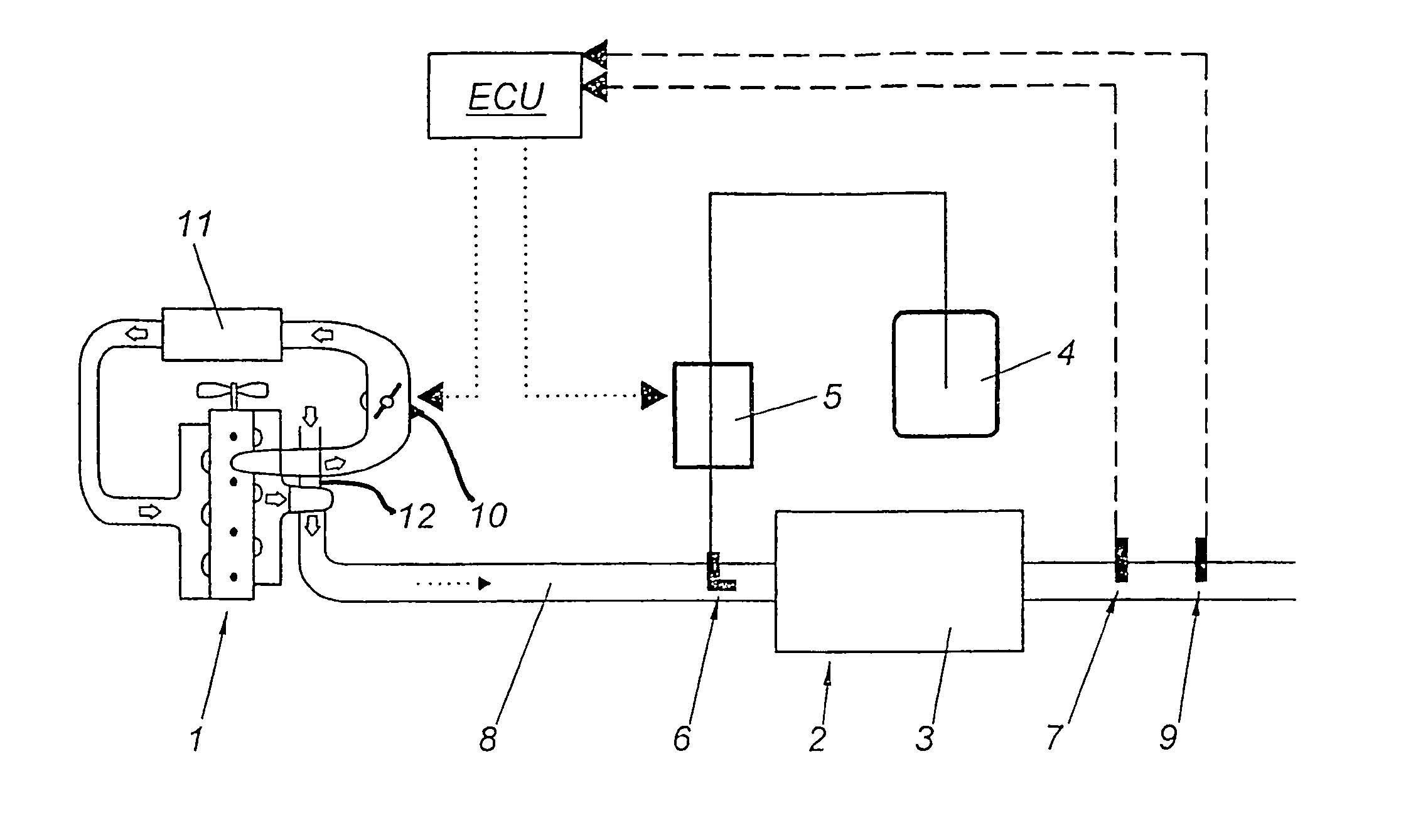

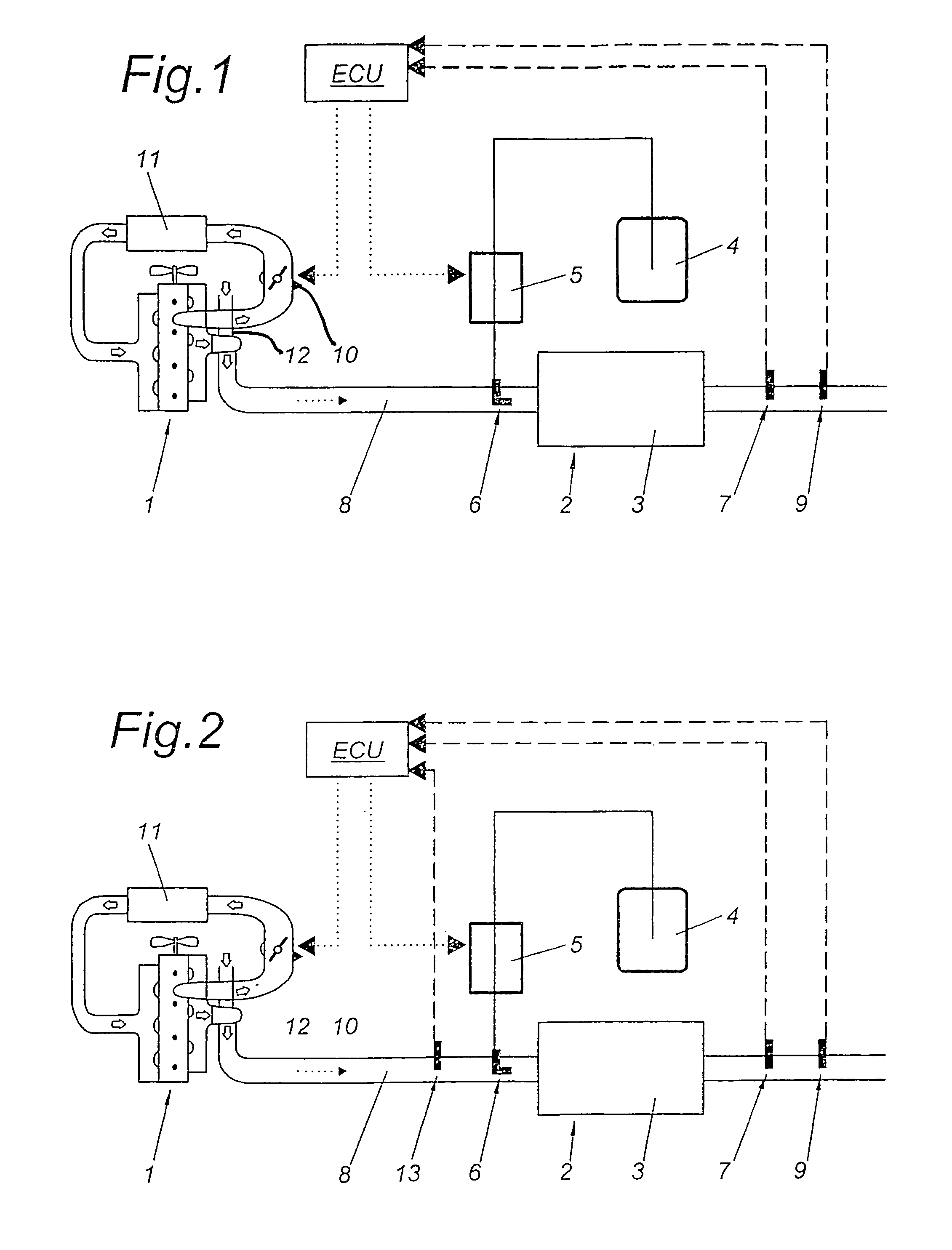

Motor control apparatus for a hybrid vehicle

InactiveUS7694510B2Shorten the time periodIncrease of load can be suppressedElectrical controlInternal combustion piston enginesParticulatesElectrical battery

A motor control apparatus for a hybrid vehicle with a diesel engine provides for a reduced compulsory regeneration time period so as to achieve enhancement of the fuel cost. The motor control apparatus includes a filter for collecting particulate matter in exhaust gas of the diesel engine, a compulsory regenerator for compulsorily regenerating the filter, and a battery charger for converting the output power of the diesel engine into electric power based on a charged state of the battery, and for charging the battery with the electric power. When the compulsory regeneration is executed, the supply of electric power to the battery by the engine is inhibited.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

Cooling trap unit

InactiveUS20090107154A1Shorten regeneration timeConducive to liquefactionSolidificationLiquefactionProduct gasEngineering

A cooling trap unit including a vacuum vessel with a drain port, a refrigerator connected to the vacuum vessel such that an endothermic unit is located on a vacuum side, and a cooling panel which is fixed to the endothermic unit to be in tight contact with it and condenses or solidifies gas, includes a water reservoir unit capable of storing liquefied liquid in the vacuum vessel, when liquefying the gas condensed or solidified by the cooling panel and discharging the liquid outside the vacuum vessel, such that the liquefied liquid is in contact with the cooling panel, and a detection unit for discharging the liquid stored in the water reserving unit through the drain port based on a detection signal which is obtained by detecting a change in temperature of the liquid and indicates that the temperature reaches a predetermined value

Owner:CANON ANELVA CORP

Cold trap and cold trap regeneration method

ActiveUS20110265495A1Less affectedShorten regeneration timePressurized chemical processSolidificationProduct gasRefrigerated temperature

A cold trap is provided with a cold panel provided in a pumping path such that the panel is exposed, a refrigerator thermally coupled to the cold panel and operative to cool the cold panel; and a controller configured, in a regeneration process for evaporating a gas frozen on the surface of the cold panel and discharging the gas outside using the vacuum pump, to control the refrigerator so as to raise the temperature of the cold panel to a temperature exceeding a non-liquefaction temperature range and to adjust a pressure in the pumping path at the temperature so that the gas frozen on the surface of the cold panel is evaporated without being melted, the non-liquefaction temperature range being a range in which it is guaranteed that a gas frozen on the surface of the cold trap is evaporated without being melted.

Owner:SUMITOMO HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com