Adsorption and moisture removing method for firedamp gas, and apparatus thereof

A gas and gas technology, applied in the field of gas adsorption and dehumidification methods and devices, can solve problems such as limited moisture absorption capacity and defects in adsorbent recycling methods, and achieve extended life, simple maintenance and maintenance, and low operating costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

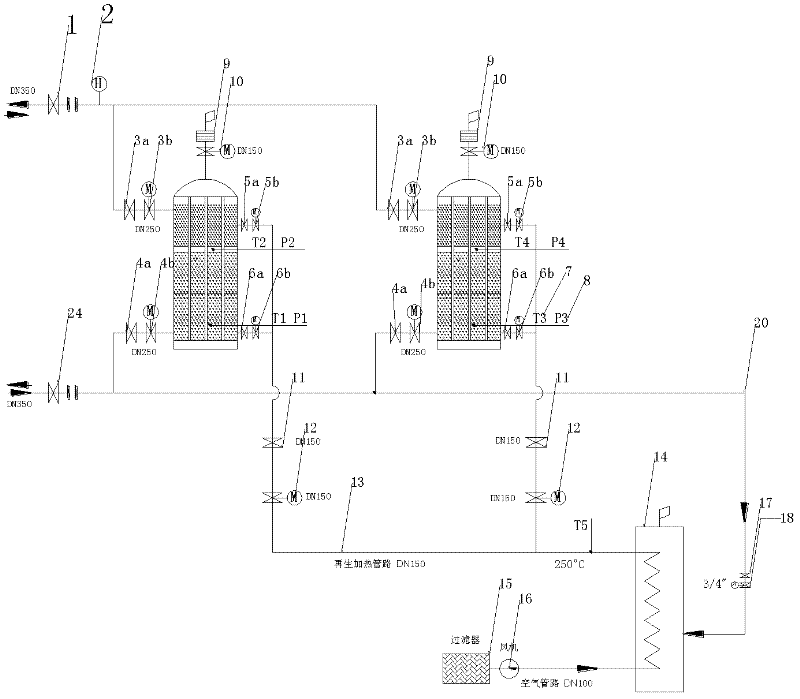

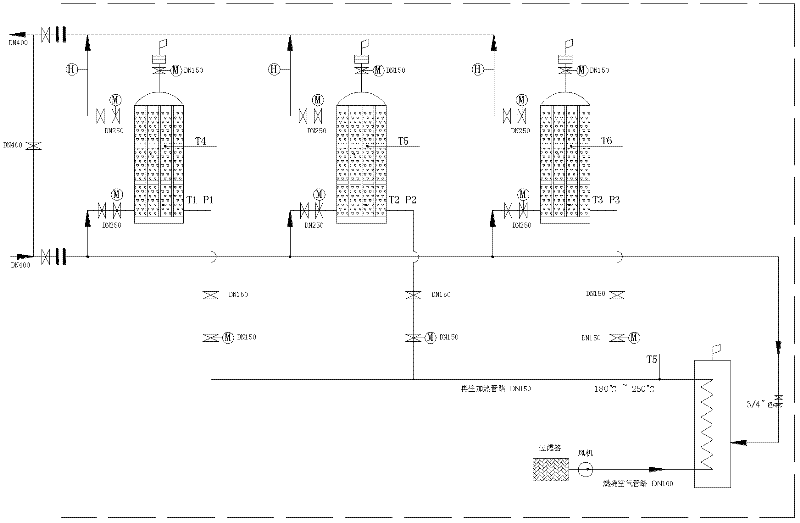

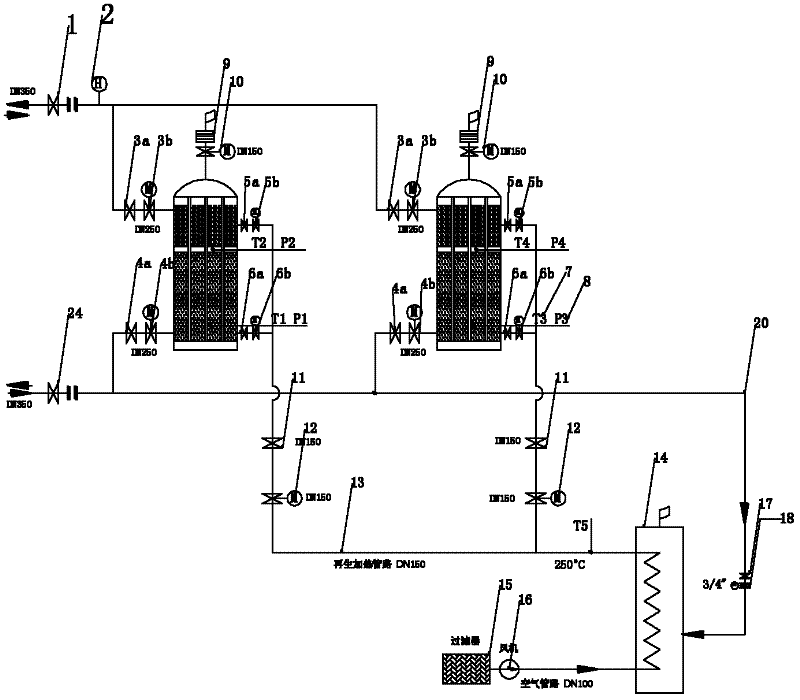

[0049] The method and device for adsorption and dehumidification of gas provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0050] Such as figure 1 As shown, in the gas adsorption and dehumidification device of the present invention, the gas outlet pipeline 24 of the gas cabinet and the gas supply pipeline network inlet pipeline 1 are arranged in parallel between the gas outlet pipeline 24 and the gas supply pipeline network inlet pipeline 1 Two adsorption towers 6 parts and hot blast furnace 14 on the pipeline between, the gas inlet valve 4a, 4b is set on the gas inlet pipeline of this adsorption tower 6; Gas outlet valve 3a, 3b is set on its gas outlet pipeline; A group of temperature sensors and pressure sensors are respectively provided at the gas inlet and outlet of the adsorption tower; the adsorption tower 6 is connected to the high-temperature air inlet pipeline 13 through the regeneration air valves 5a, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com