Method and system for controlling coagulant dosing through on-line prediction of turbidity after flocculation water sedimentation

A coagulant and turbidity technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of insufficient turbidity and accuracy of sedimentation water, so as to improve the quality of water purification, reduce the cost of water purification, and reduce refilling. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

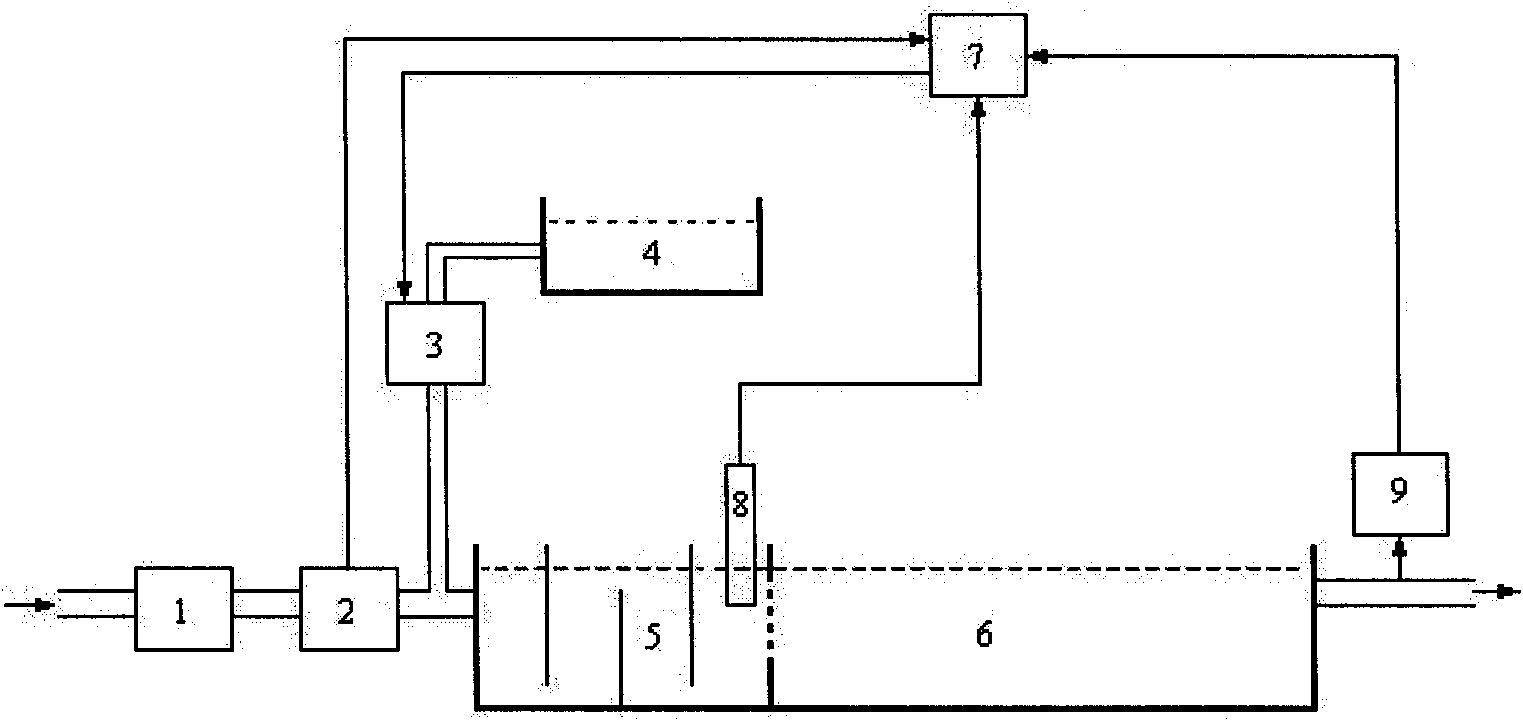

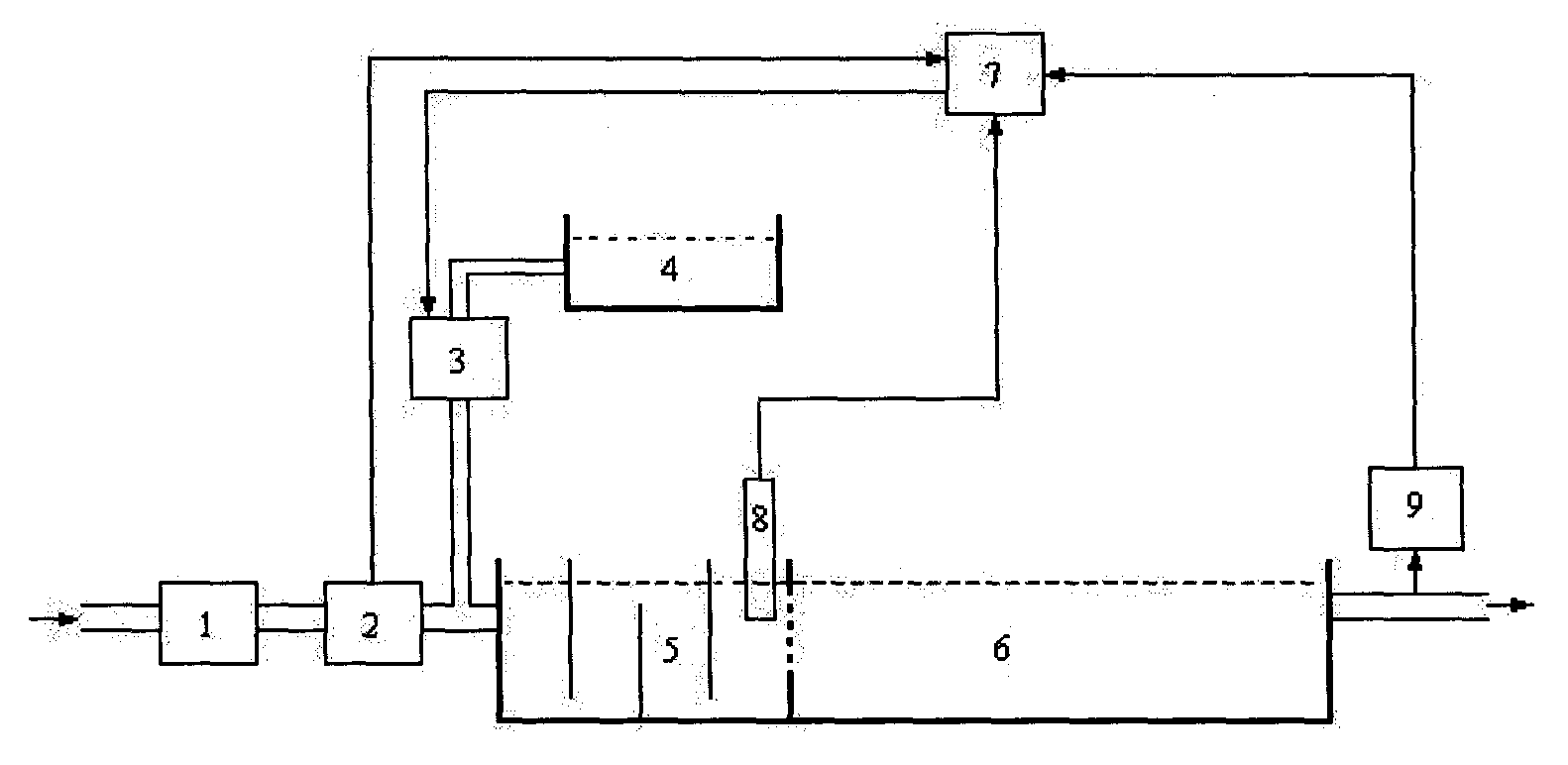

[0039] Embodiment 1: see figure 1 , the method of controlling the amount of coagulant injection by online prediction of turbidity after flocculation water sinking is: the raw water enters the flocculation tank 5 to mix, react, and flocculate with the added coagulant to produce flocs, and the water at the end of the flocculation tank 5 The flocculation water is collected in real time through the sensor 8 for measuring turbidity, and then the turbidity is measured after settling in the sensor 8 for a given settling time; and the measured value is compared with the set value, and the difference is calculated by PID. Obtain the required filling rate, and then multiply it by the flow rate of the incoming water to obtain the filling volume, convert it into a standard current output signal to control the filling volume of the filling pump 3, and perform online coagulant filling.

Embodiment 2

[0041] 1. Raw water enters the flocculation tank, mixes, reacts, and flocculates with the added coagulant to produce flocs. In the method, the flocculation water is collected in real time through sensors underwater at the end of the flocculation tank.

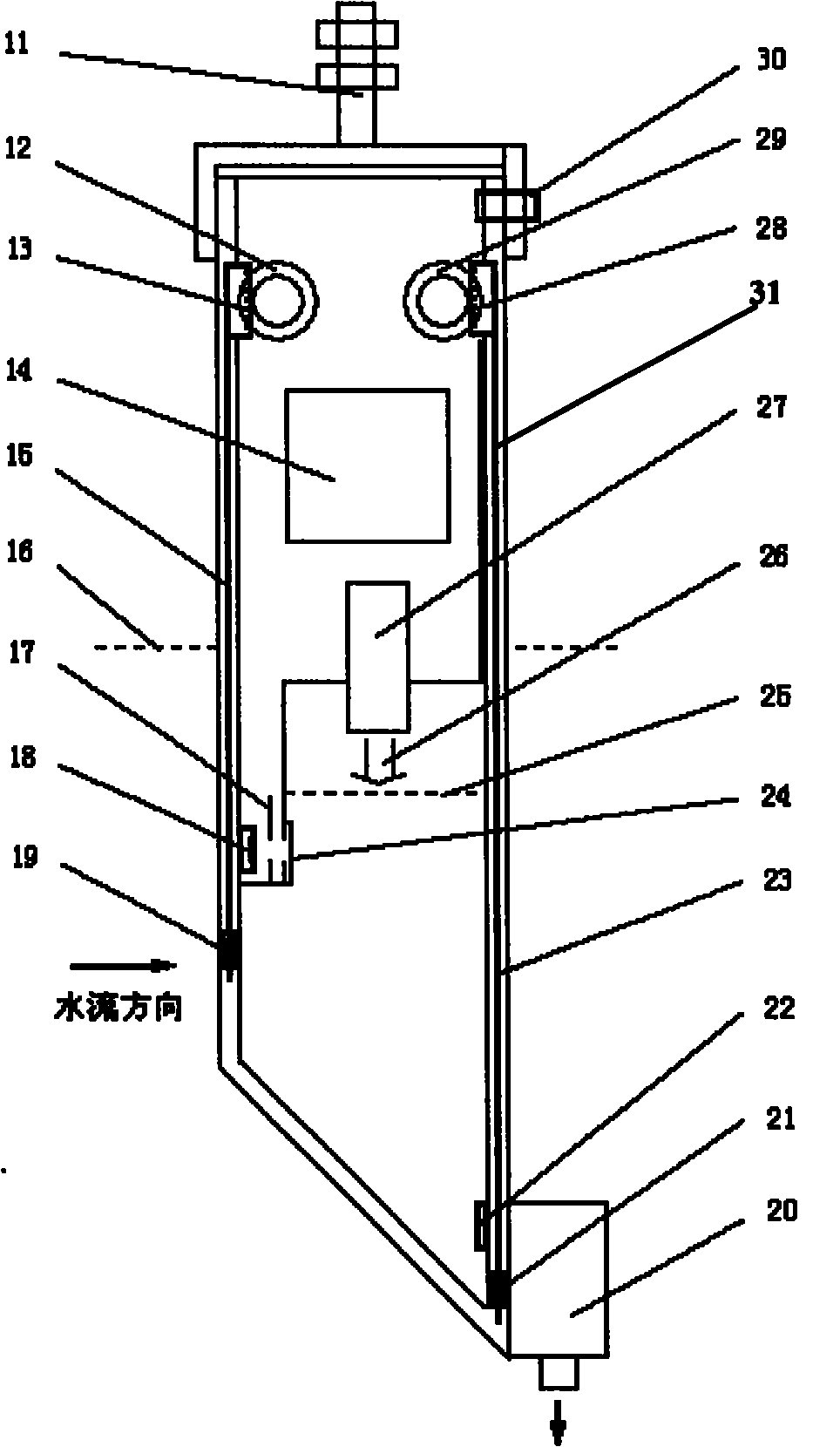

[0042] 2. The water flows in slowly from the water inlet hole. After the water level in the sensor reaches the measured water level, close the gate valve of the water inlet hole to keep the water level unchanged. After the sedimentation time in the sensor settles, measure the turbidity of the water 2cm below the water level.

[0043] 3. After a measurement is completed, the gate valve of the water outlet hole is opened, and the submersible pump works at a low speed to pump out the water in the sensor. When the water surface drops to the vicinity of the water inlet hole, the water inlet hole is opened, so that water flows in from the water inlet hole and flows out of the water outlet hole. , the water level remains basically unc...

Embodiment 3

[0049] Embodiment 3: see figure 1 , the system used in the above method to control the amount of coagulant injection by online prediction of the turbidity after the flocculation water sinks, including a sedimentation tank 6, a flocculation tank 5, a coagulant tank, the flocculation tank 5 and the sedimentation tank 6 Connected in parallel and integrated, a turbidity meter 9 is installed at the outlet of the sedimentation tank 6, a sensor 8 for measuring turbidity is inserted at the end of the flocculation tank 5, and the water inlet pipe passes through an inlet pump 1 and a flow meter 2. Connect the water inlet of the flocculation tank 5, and the outlet of the coagulant tank 4 is connected to the water inlet of the flocculation tank (5) through a filling pump 3; a microprocessor 7 is electrically connected to the flow rate Meter 2, filling pump 3, sensor 8 and turbidity meter 9 for measuring turbidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com