Method and equipment for treating volatile organic compounds by low-temperature plasma coupling adsorption

A low-temperature plasma and volatile organic technology, applied in separation methods, auxiliary pretreatment, chemical instruments and methods, etc., can solve the problems of inability to break through the law of adsorption and analysis, increase in investment and operating costs, difficulty in achieving benzene emission limits, etc. problem, to achieve the effect of prolonging the regeneration cycle, improving the utilization rate of ozone, and reducing the amount of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

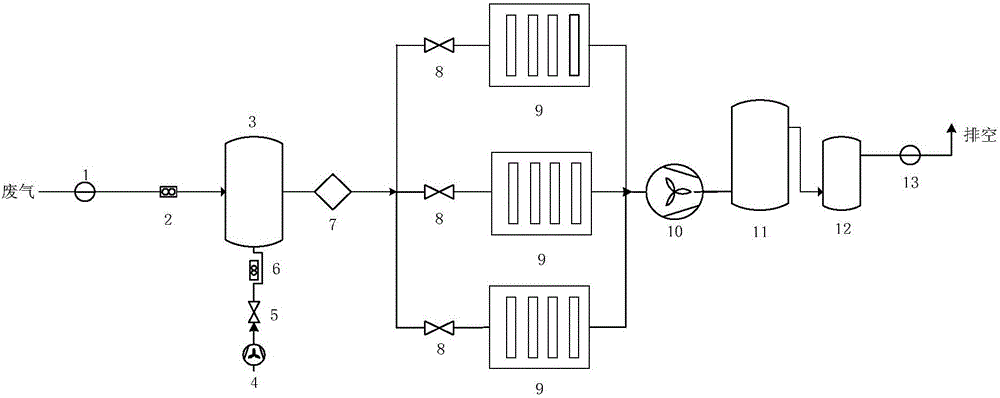

[0025] The invention provides a device for low-temperature plasma coupling adsorption treatment of volatile organic waste gas and malodorous gas, which includes a low-temperature plasma device and an adsorption device. Volatile organic waste gas and malodorous gas are first processed by the low-temperature plasma device and then enter the adsorption device deal with.

[0026] The malodorous gas is specifically inorganic waste gas, such as ammonia and hydrogen sulfide.

[0027] The equipment can be used to treat organic waste gas and malodorous gas with a concentration of less than 6000ppm and hydrogen sulfide less than 100ppm, and the gas volume can be from 1 to 20000Nm 3 / h.

[0028] The equipment also includes inlet total hydrocarbon analyzer, exhaust gas flow meter, buffer tank, air distribution fan, air electric butterfly valve, air flow meter, dehumidifier, exhaust gas electric butterfly valve, induced draft fan, ozone decomposition tower and outlet total hydrocarbon ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com