Method for improving filling property of rigid polyurethane foam plastics

A technology of rigid polyurethane and foamed plastics, which is used in household refrigeration devices, lighting and heating equipment, and other household appliances, etc., can solve the problems of poor filling and low flow properties of rigid polyurethane foaming plastics, and reduce the filling amount. , Solve the effect of low flow performance and improve filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

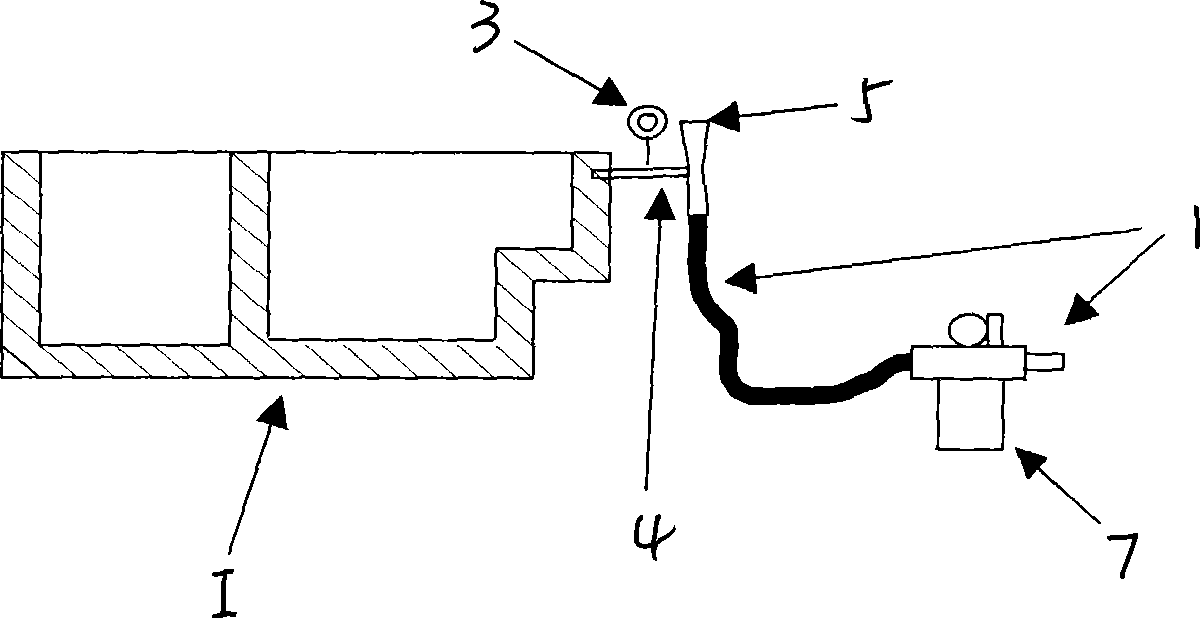

[0078] Mix the above-mentioned POL-1: 100 parts, HCFC-141b: 22 parts, and mix with 44V-20L (isocyanate) at the tip of the gun to foam. The measured fiber time is: 55 seconds, and the free rise density is: 24.5kg / m 3 . Foaming in a mold of the same size according to this formula, (mold size: 1900×700×65), using Picture 1-1 The air-entraining method controls the gauge pressure of the foaming cavity and observes the foaming situation. See Table 2 below.

[0079] Table 2

[0080] Numbering P-1 P-2 P-3 P-4 P-5 P-6 P-7 Injection time, seconds 6.12 6.12 6.12 5.5 5.3 5.1 4.83 gauge pressure (MPa),

max

min

0.065

0

0.05

0

0.03

0

0.02

0

0.01

0

0

0

0

-0.019

Filling

from mold

top 17cm,

9% did not

full from mold top

2.2cm, yes

1.2% uncharged

Full

Overfill

1.5%

exactly charge

...

Embodiment 2

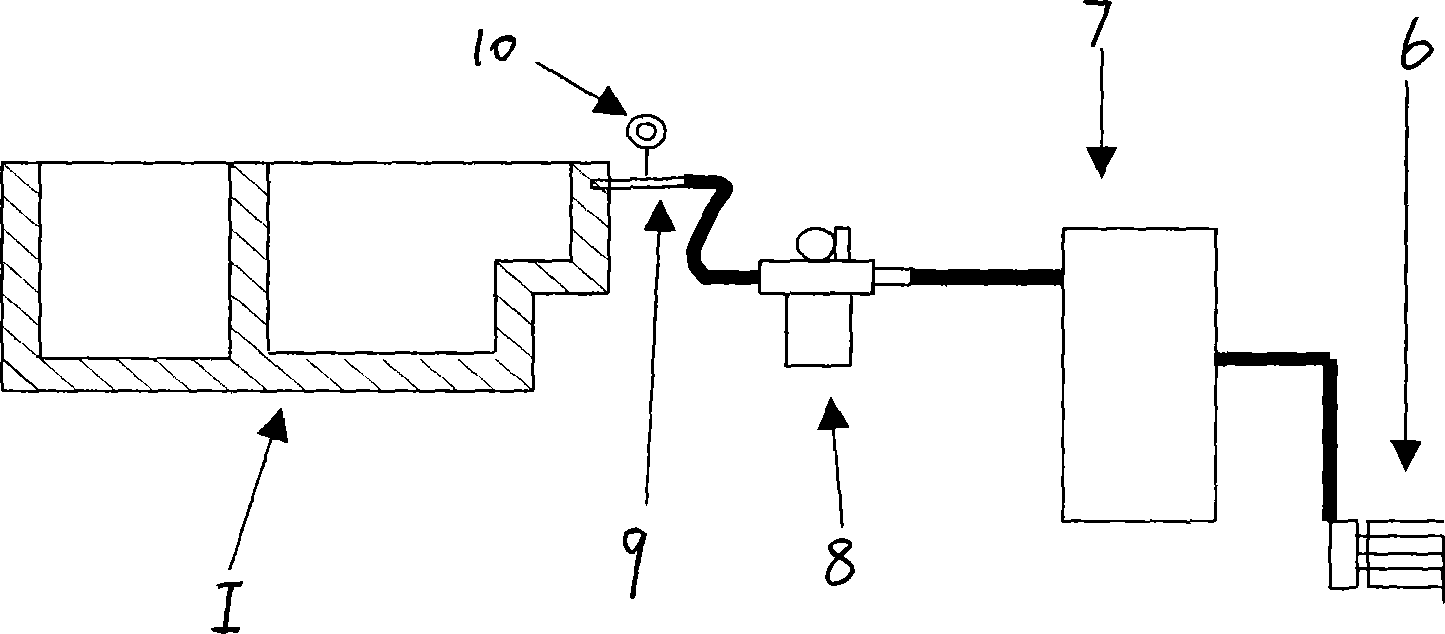

[0084] Mix the above POL-5: 100 parts, cyclopentane: 18.5 parts, and foam with 44V-20L. The fiber time is 15 seconds, and the free rise density is 22.8kg / m 3 . Mix the above POL-8: 100 parts, cyclopentane: 18.5 parts, and foam with 44V-20L. The fiber time is 55 seconds, and the free rise density is 23.5kg / m 3 . Use the above formula to foam in a mold of the same size, (mold size: 1850×700×65), using Figure 1-2 The air-entraining method controls the gauge pressure of the foaming cavity and observes the foaming situation.

[0085] table 3

[0086] P-8 P-9 P-10 P-11 P-12 P-13 Injection time, seconds 3.95 4.54 3.80 4.37 4.54 4.60 gauge pressure (MPa),

max

min

0

0

0

0

0

-0.02

0

-0.02

0.07

0

0

0

Filling

Just fill

15% overfill

exactly charge

fill

15% over

filling from mold top

22cm, yes

11.5% unc...

Embodiment 3

[0091] Take 100 parts of each of the above POL-2, POL-3, POL-4, POL-6, and POL-7, add different foaming agents, react with isocyanate, control the fiber time to 20-23 seconds, and press this The formulation is foamed in a mold of the same size, (mold size: 1850×700×65), using Picture 1-1 The air-entraining method controls the gauge pressure of the foaming cavity and observes the foaming situation.

[0092] Table 4

[0093] P-14 P-15 P-16 P-17 P-18 P-19 POL-2 100 POL-3 100 POL-4 100 POL-6 100 POL-7 100 100 HFC-365mfc 26 26 Cyclopentane / Isopentane

(7:3)

15

15

HFC-245fa 22 22 44V-20L 133 133 133 133 133 133 GT, seconds 30 32 28 26 18 18 Gauge pressure (MPa)

Max

Min

0.008

0

0

-0.02

0.02

0

0

-0.016

0

0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com