High-stability anticorrosive coating for pressure gauge shell and preparation method of high-stability anticorrosive coating

A high-stability, anti-corrosion coating technology, applied in the field of coatings, can solve the problems of affecting the quality and life of use, the general quality of coatings, and the general use effect, etc., and achieve the effect of high use stability, strong continuity and improved use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

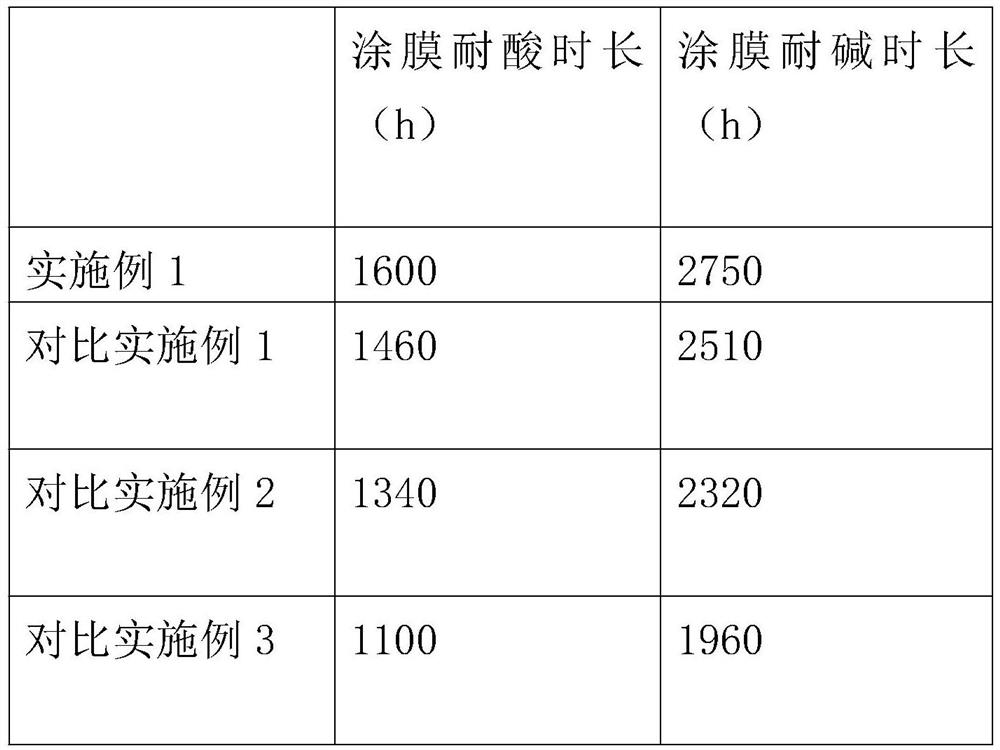

Examples

Embodiment 1

[0023] A high-stability anti-corrosion coating for a pressure gauge housing, made of the following substances in corresponding parts by weight:

[0024] 80 parts of epoxy acrylate, 4 parts of castor oil, 10 parts of ethyl acetate, 3 parts of surfactant, 5 parts of sodium silicate, 4 parts of composite filler, 2 parts of sodium carboxymethylcellulose, 3 parts of chitosan, 1 part peach gum, 4 parts aluminum tripolyphosphate, 60 parts deionized water.

[0025] The surfactant is disodium lauryl sulfosuccinate monoester.

[0026] The composite filler is composed of the following substances in corresponding parts by weight: 2 parts of titanium nitride, 6 parts of montmorillonite, and 10 parts of graphene.

[0027] The particle size of the titanium nitride is 30-65nm.

[0028] The particle size of the montmorillonite is 20-100 μm.

[0029] The particle size of the graphene is 1-2mm.

[0030] A method for preparing a high-stability anticorrosion coating for a pressure gauge housin...

Embodiment 2

[0036] A high-stability anti-corrosion coating for a pressure gauge housing, made of the following substances in corresponding parts by weight:

[0037] 83 parts of epoxy acrylate, 6 parts of castor oil, 13 parts of ethyl acetate, 5 parts of surfactant, 7 parts of sodium silicate, 6 parts of composite filler, 3 parts of sodium carboxymethylcellulose, 5 parts of chitosan, 2 parts of peach gum, 6 parts of aluminum tripolyphosphate, 63 parts of deionized water.

[0038] The surfactant is fatty alcohol polyoxyethylene ether.

[0039] The composite filler is composed of the following substances in corresponding parts by weight: 3 parts of titanium nitride, 8 parts of montmorillonite, and 13 parts of graphene.

[0040] The particle size of the titanium nitride is 30-65nm.

[0041] The particle size of the montmorillonite is 20-100 μm.

[0042] The particle size of the graphene is 1-2mm.

[0043] A method for preparing a high-stability anticorrosion coating for a pressure gauge h...

Embodiment 3

[0049] A high-stability anti-corrosion coating for a pressure gauge housing, made of the following substances in corresponding parts by weight:

[0050] 85 parts of epoxy acrylate, 7 parts of castor oil, 15 parts of ethyl acetate, 6 parts of surfactant, 8 parts of sodium silicate, 8 parts of composite filler, 4 parts of sodium carboxymethylcellulose, 6 parts of chitosan, 3 parts of peach gum, 7 parts of aluminum tripolyphosphate, 65 parts of deionized water.

[0051] The surfactant is disodium coco monoethanolamide sulfosuccinate monoester.

[0052] The composite filler is composed of the following substances in corresponding parts by weight: 4 parts of titanium nitride, 9 parts of montmorillonite, and 15 parts of graphene.

[0053] The particle size of the titanium nitride is 30-65nm.

[0054] The particle size of the montmorillonite is 20-100 μm.

[0055] The particle size of the graphene is 1-2mm.

[0056] A method for preparing a high-stability anticorrosion coating fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com