High-filling-property SCA optical adhesive as well as preparation method and application thereof

An optical glue and filling technology, applied in the field of optical glue, can solve the problems of bubble rebound, low production efficiency, unstable ring measurement, etc., and achieve the effect of increasing filling performance, improving flow performance, and good flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

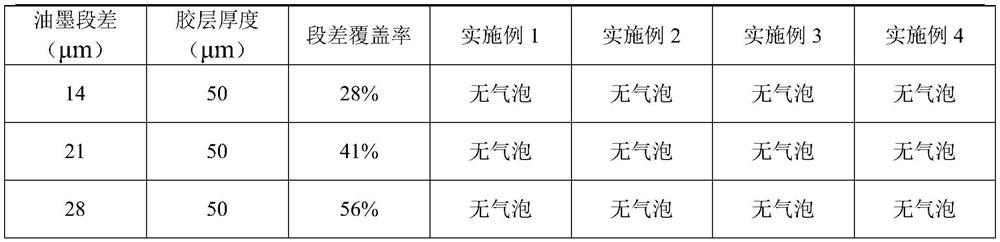

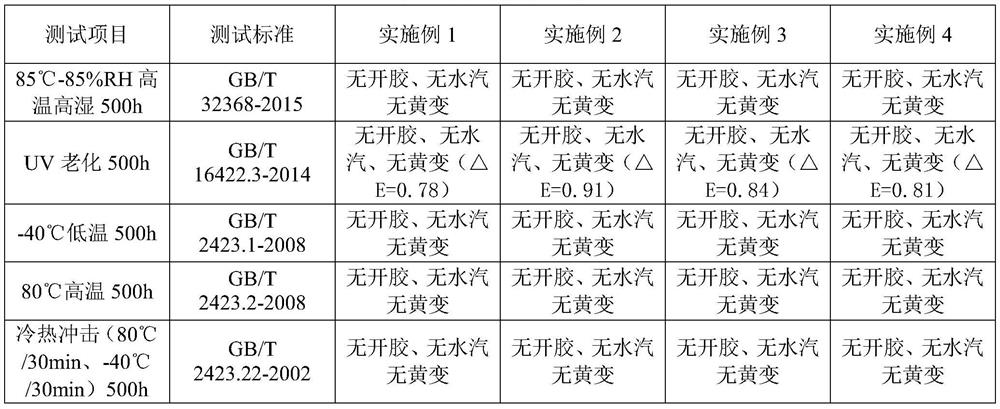

Examples

preparation example Construction

[0027] The preparation method of the highly filling SCA optical glue may further comprise the steps:

[0028] (1) After mixing the EVA resin, cross-linking agent, coupling agent and photoinitiator in their respective proportions, make the microcrystalline wax into powder, add it to the mixed ingredients, and mix again.

[0029] (2) Import the prepared mixture into a twin-screw extruder, extrude it through a melt pump at the end of the extruder, extrude it through a screen change filter, and calender to form a film, and at the same time attach a layer to the front and back of the film The optical adhesive film is prepared by protecting the release film; wherein, the thickness of the optical adhesive layer can be 200 μm.

[0030] The selected VA content of the EVA resin used in the following examples is 28%, and the MI is 15g / (10min).

Embodiment 1

[0031] Example 1: Highly filling SCA optical glue

[0032] In this embodiment, the highly filling SCA optical glue, its components include by mass percentage: EVA resin content of 95%, tert-butyl peroxy-2-ethylhexanoate content of 1%, γ-methacryloyl The content of oxypropyltrimethoxysilane and N-(2-aminoethyl)-3-aminopropyltrimethoxysilane (mass ratio 1:1) is 1%, 1-hydroxycyclohexyl phenyl ketone The content of 2-hydroxy-2-methyl-1-phenyl-1-propanone (mass ratio: 2:1) is 0.5%, and the content of microcrystalline wax is 2.5%.

[0033] The preparation method is as follows:

[0034] (1) After mixing the EVA resin, crosslinking agent, coupling agent and photoinitiator in their respective proportions, the microcrystalline wax is made into powder, added to the mixed ingredients, and mixed evenly again;

[0035] (2) Import the prepared mixture into a twin-screw extruder, extrude it through a melt pump at the end of the extruder, extrude it through a screen change filter, and calend...

Embodiment 2

[0036] Example 2: Highly filling SCA optical glue

[0037] In this embodiment, the highly filling SCA optical glue, its components include by mass percentage: EVA resin content of 98%, tert-butyl peroxy-2-ethylhexanoate content of 0.2%, γ-methacryloyl The content of oxypropyltrimethoxysilane is 0.2%, the content of 1-hydroxycyclohexyl phenyl ketone is 0.1%, and the content of microcrystalline wax is 1.5%.

[0038] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com