Heat exchange mechanism for preparing lipid drugs

A technology of drugs and lipids, which is applied in the field of heat exchange, can solve the problems of phospholipid molecules transforming into gel and affecting the delivery efficiency, and achieve the effects of improving flow performance, increasing contact area, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

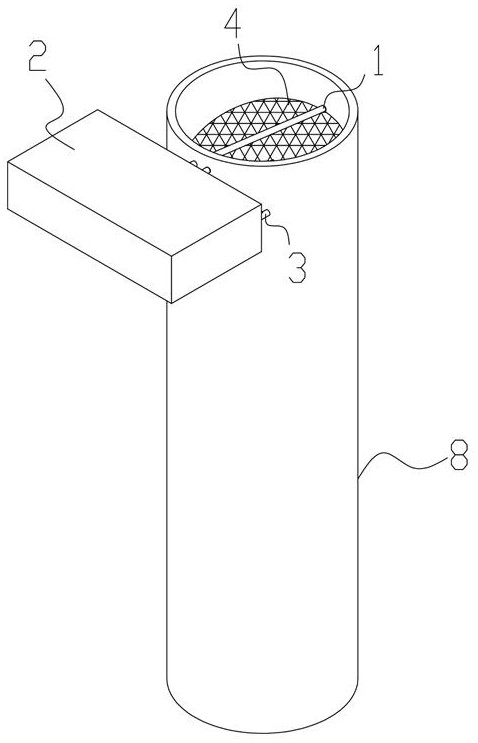

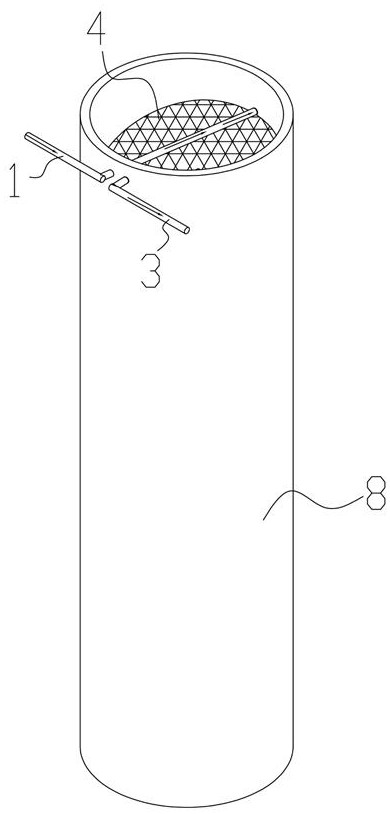

[0038] In another embodiment, the hot air blower 2 is an electromagnetic hot air blower 2 . The hot air blower 2 with electromagnetic heating is used because of its high conversion rate, long service life, convenient temperature control and good insulation.

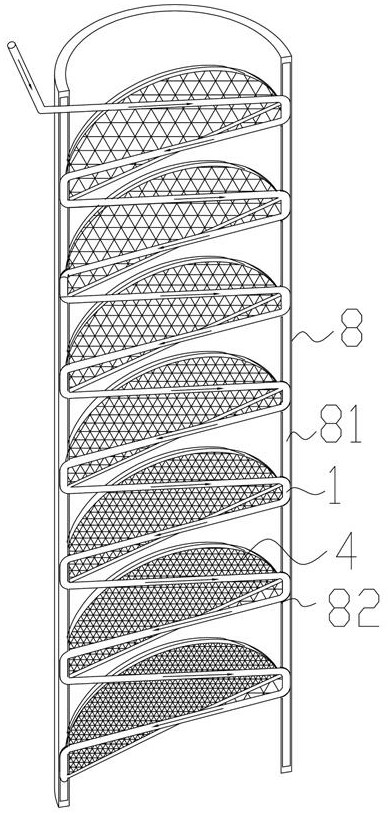

[0039] In another embodiment, such as image 3 As shown, in order to facilitate the circulation of grease and at the same time cut the fat in block form, the slitting mesh 4 is a filter mesh structure formed by a plurality of metal wires. The metal wire cuts the blocky grease. Since the slitting mesh 4 is in contact with the air supply duct 1, the metal has a heat conduction effect, and the heat on the air supply duct 1 is absorbed to the metal wire by means of heat transfer. Then the block grease is divided by wire.

[0040] In another embodiment, such as image 3 As shown, in order to increase the contact surface between the slitting screen 4 and the grease, the slitting screen 4 is arranged coaxially with the grease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com