Vibration forming mold as well as pressure head assembly and pressure head thereof

A technology of indenters and components, applied in manufacturing tools, metal processing equipment, grinding devices, etc., can solve problems such as poor quality of grinding wheels, and achieve the effects of uniform distribution, improved flow performance, and dense powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

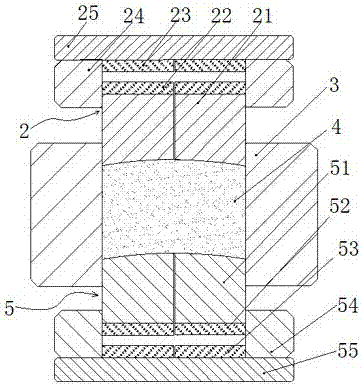

[0044] Embodiment 2 of the vibration forming mold of the present invention: the difference from Embodiment 1 is only that the arrangement of each sub-indenter in the upper and lower indenter bodies is different, and the specific structure of the upper indenter body 21 is as follows Figure 5 As shown, the gaps between the eight upper sub-indenters 211 extend along the axial direction of the indenters, and a plurality of gaps are arranged at intervals along the circumference of the indenters.

Embodiment 3

[0045] Embodiment 3 of the vibration forming mold of the present invention: the difference from Embodiment 1 is only that the arrangement of each sub-indenter in the upper and lower indenter bodies is different, and the specific structure of the upper indenter body 21 is as follows Figure 6 As shown, the gaps between the 8 upper sub-indenters 211 intersect with the axial direction of the indenters obliquely. Specifically, the gaps between the upper sub-indenters 211 and the axial direction of the indenters form an angle of 135 degrees. The gap between the heads is at an angle of 45 degrees to the axial direction of the indenter. The form in which the gaps between the sub-indenters obliquely intersect with the axis of the indenters is conducive to smooth transition of the pressing surface of the abrasive block surrounded by the plurality of sub-indenters, and is beneficial to reducing vibration during the grinding process.

Embodiment 4

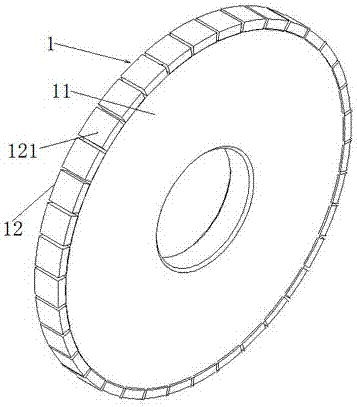

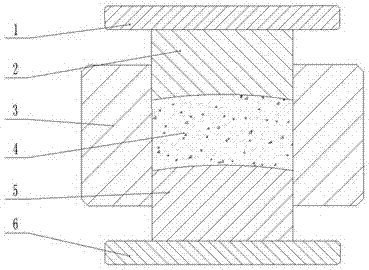

[0046] Embodiment 4 of the vibration molding mold of the present invention: the difference from Embodiment 1 is that the abrasive block to be prepared is an integral ring-shaped abrasive ring, and the mold sleeve accordingly includes an outer cylinder 32 and an inner cylinder coaxially sleeved 31. The annular gap between the inner cylinder 31 and the outer cylinder 32 forms a through hole for inserting the upper and lower pressure head bodies. At this time, the upper and lower indenter bodies are all made up of three ring-shaped sub-indenters in turn, and the electromagnet and magnet are also annular rings that match the shape and size of the corresponding sub-indenters. Correspondingly prepared abrasive ring 12 is also a ring with imaginary part 123 and real part 122 alternated. The specific structure of the grinding tool and the prepared abrasive ring is as follows: Figure 7 and Figure 8 shown.

[0047] In other embodiments: the indenter body can also be an integral stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com