Patents

Literature

111results about How to "Construction method safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

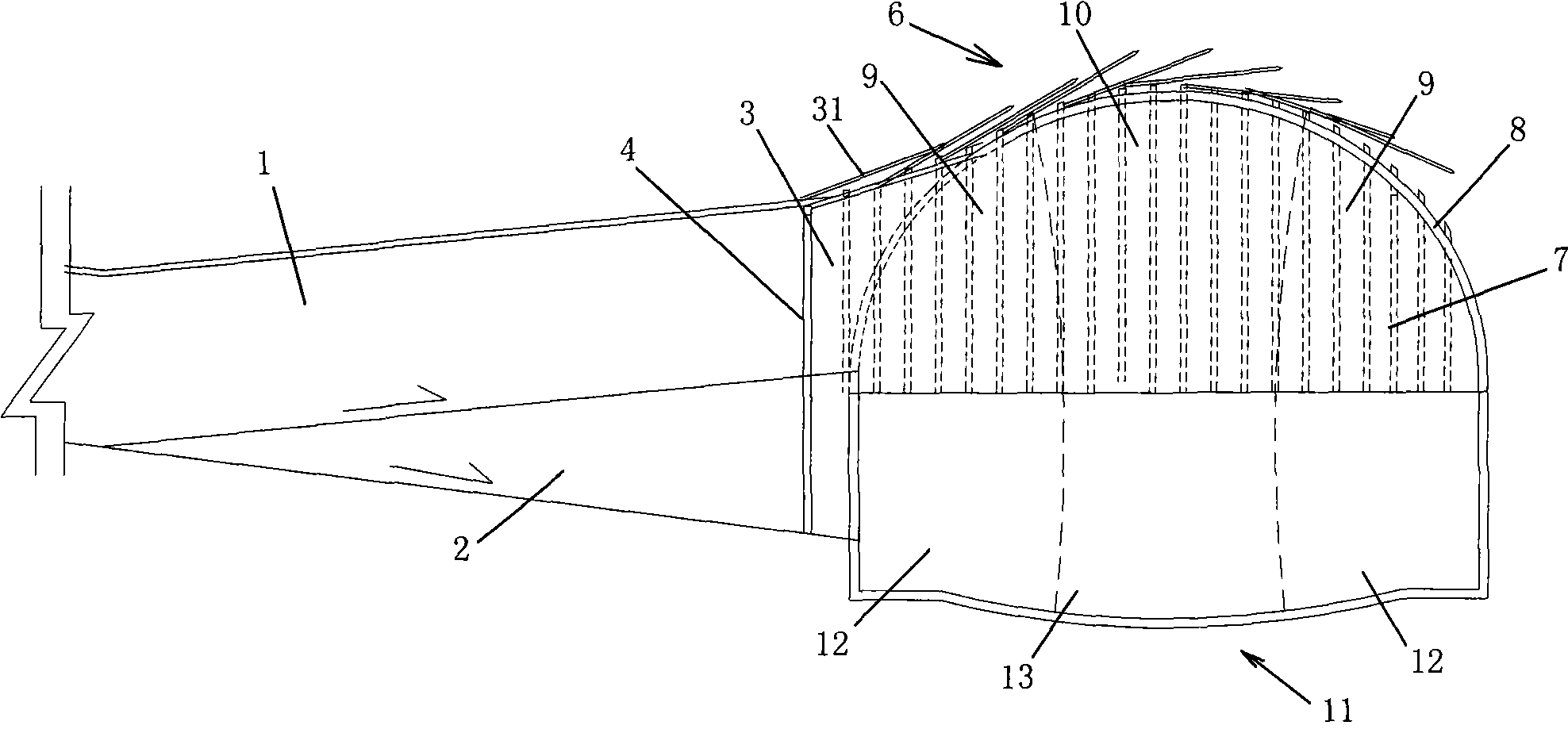

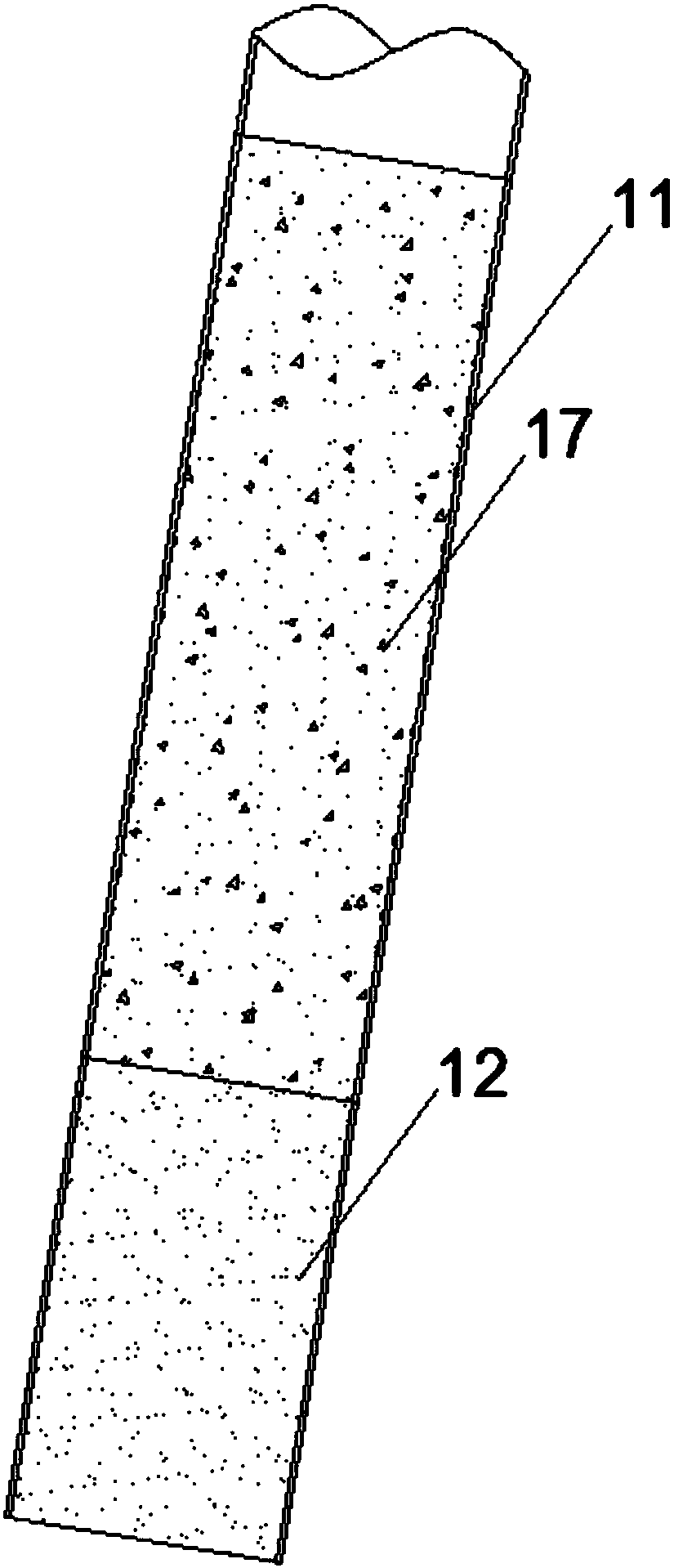

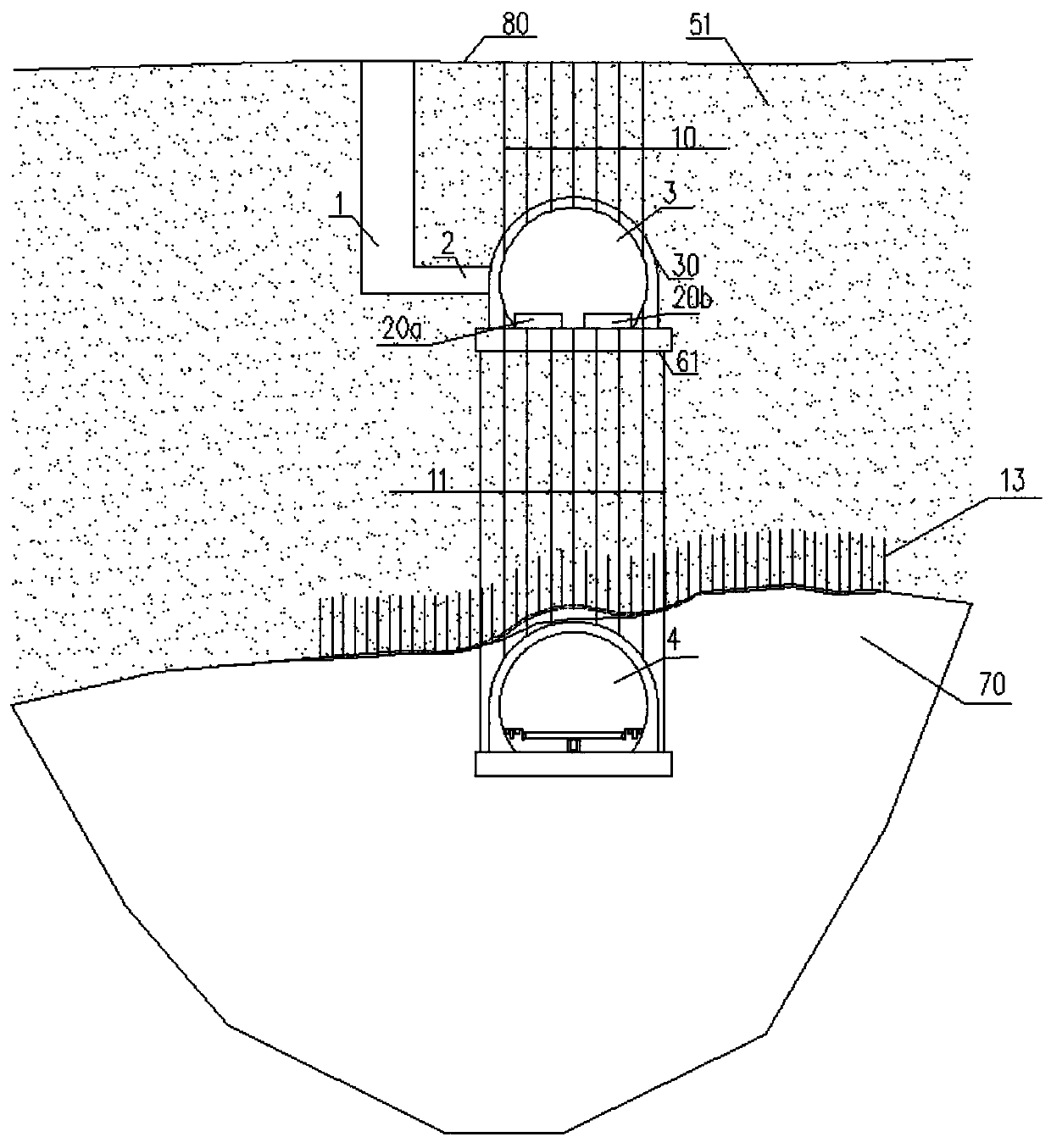

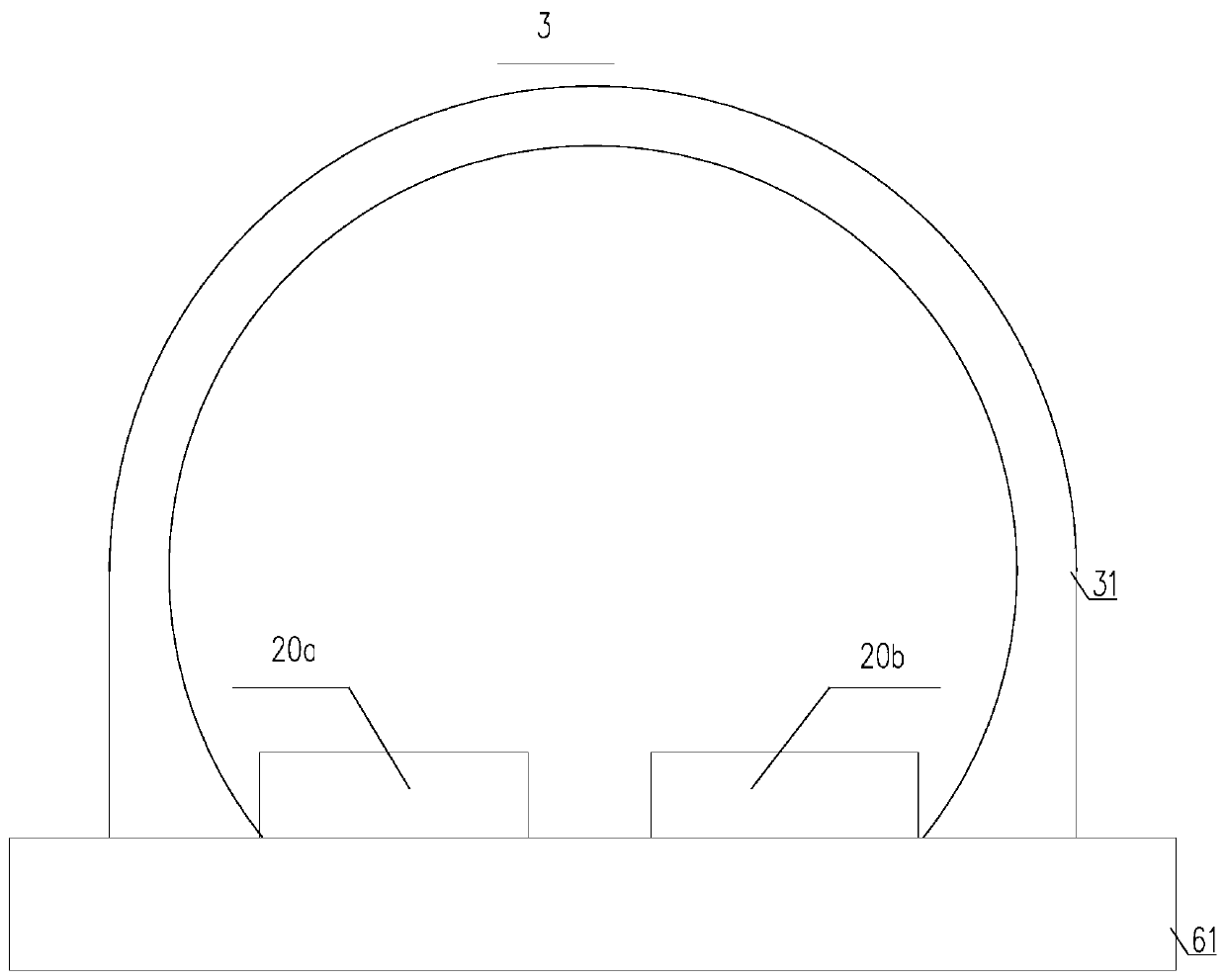

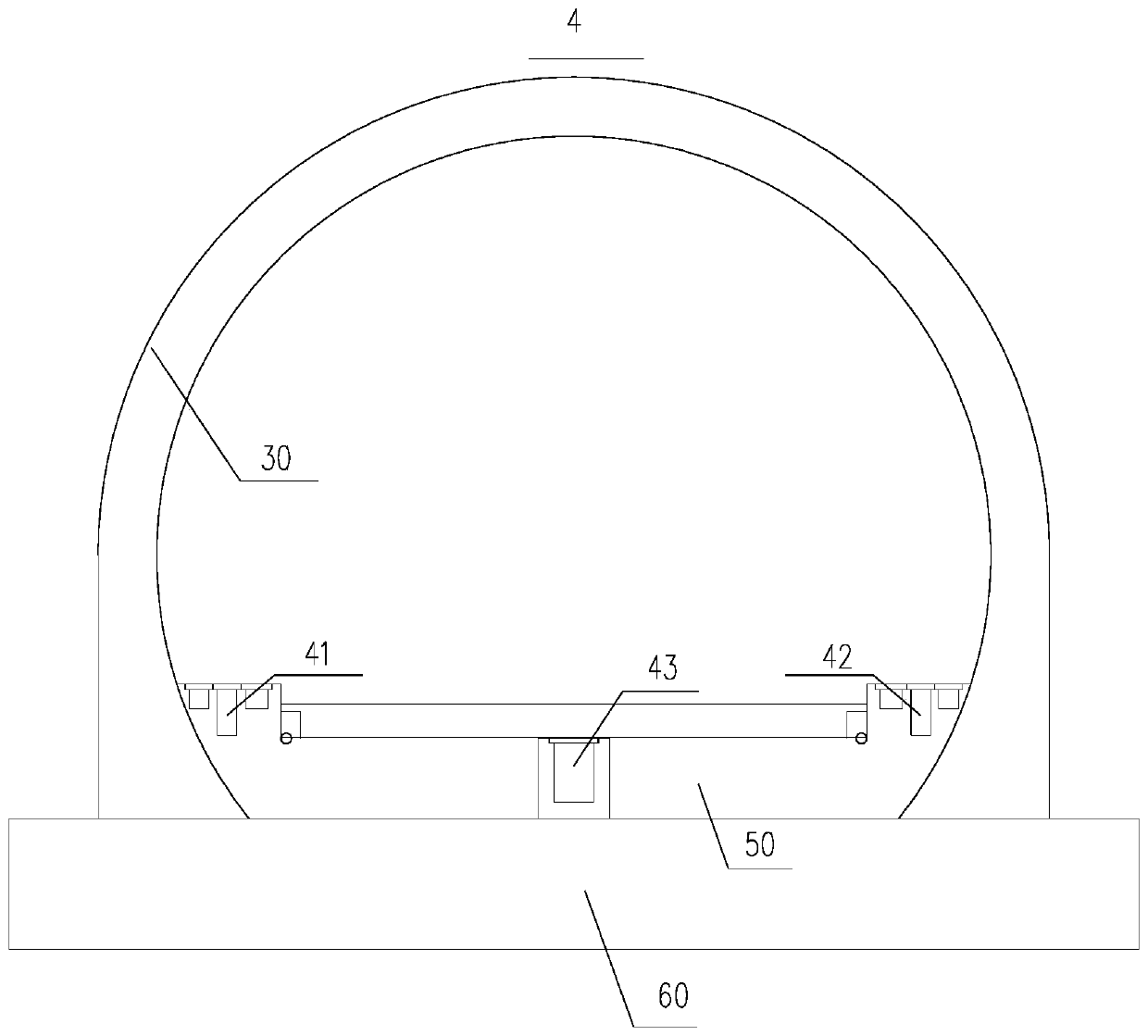

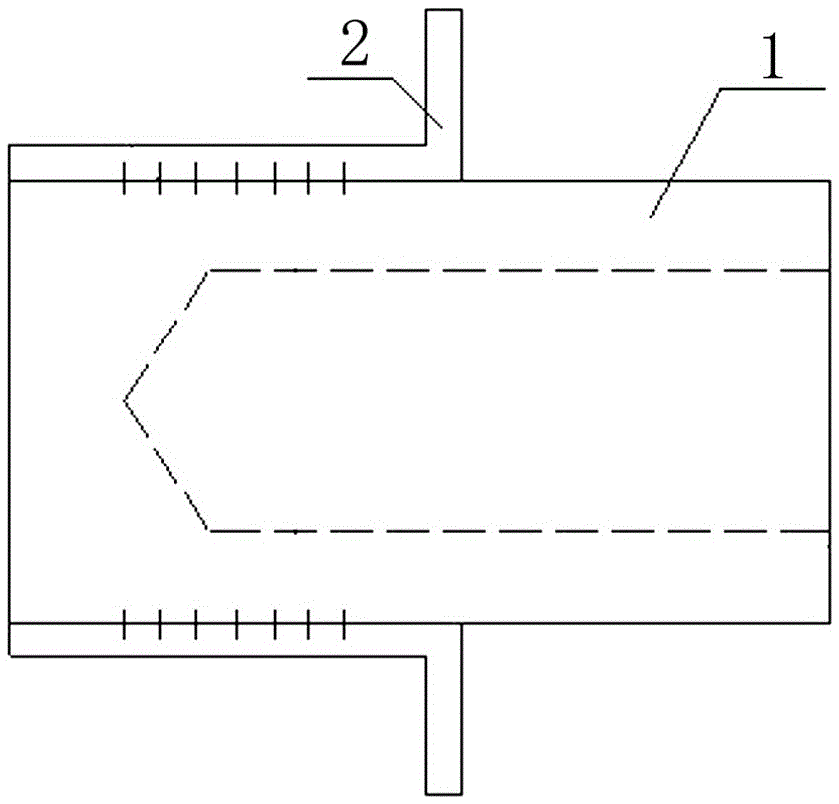

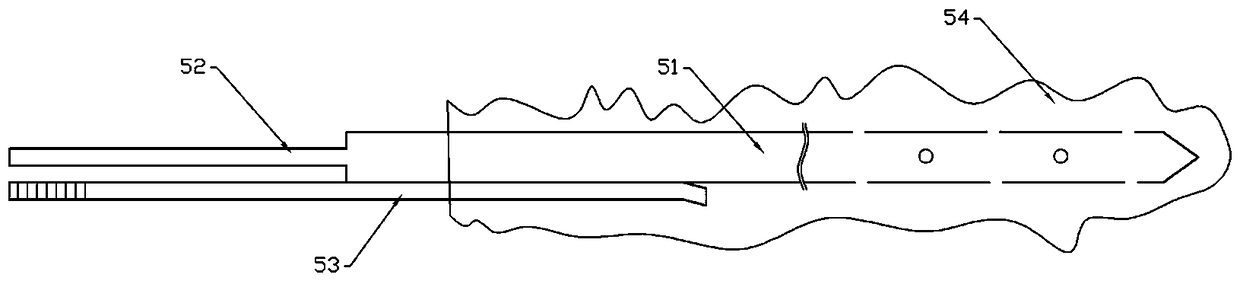

Full-section pre-reinforcing construction method for tunnel free-machining anchor bar

InactiveCN101487393AGood deformation propertiesConstruction method safetyUnderground chambersTunnel liningGlass fiberFiber

The invention discloses a tunnel easy-cutting anchor-rod full-section pre-consolidation construction method, comprising the following steps: firstly, survey design before construction is carried out, pre-consolidation is carried out to a face core body to be excavated by adopting an easy-cutting anchor rod according to the sampling analysis and classification of rock-soil, meanwhile, a measuring instrument is installed to monitor the change thereof, and then full-section excavation is carried out. The construction method takes the problem of how to deal with the 'core body to be excavated' in front of the face as the key for controlling the integral stability of the tunnel, an easy-cutting glass fiber anchor rod which is pre-consolidated along tunnel vertical full-section is used for improving the equivalent stiffness of the 'core body to be excavated' and controlling the deformation of the 'core body to be excavated' so as to cause arching effect around the tunnel to function naturally, thus guaranteeing the full-section, safe and quick excavation and drivage of the tunnel. The construction method is safe and reliable, can realize tunnel full-section mechanized and modernized construction, and has good production efficiency, continuous and stable construction progress, and controllable project cost.

Owner:中铁西南科学研究院有限公司

Integral lowering and demolition method for continuous beam bridge

InactiveCN106758887AReduce disturbanceSafe and quick removal methodBuilding repairsBridge strengtheningContinuous beamCost savings

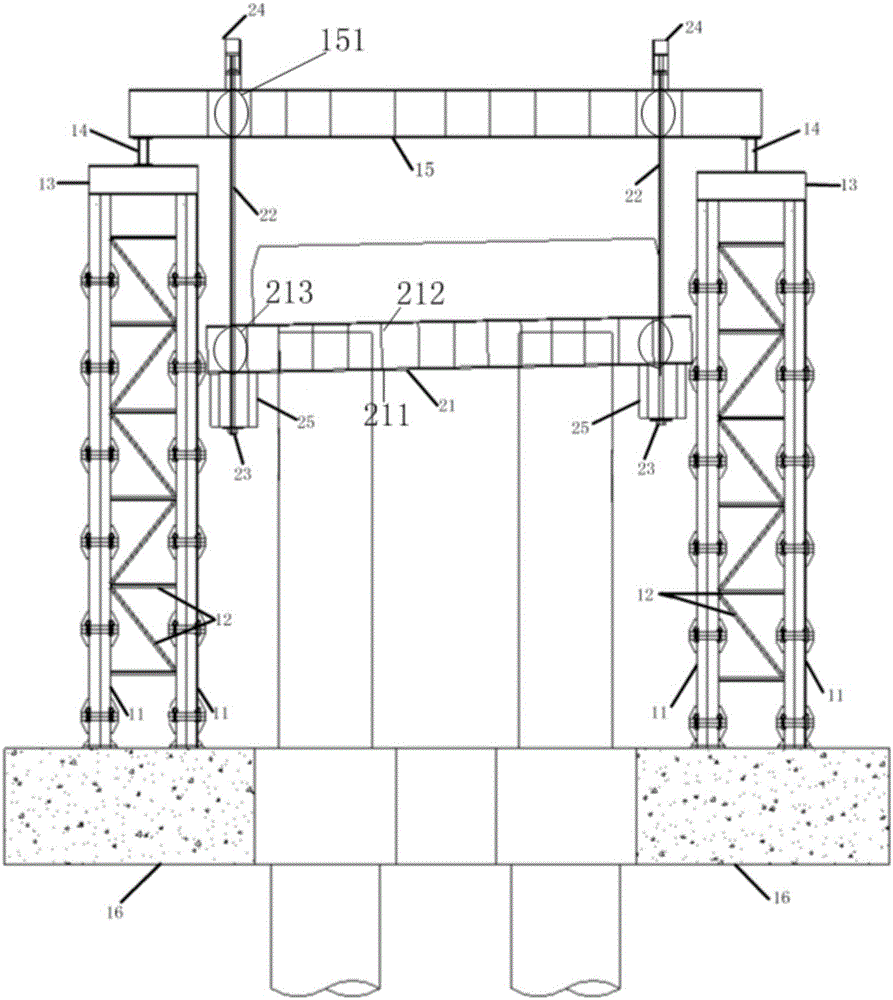

The invention discloses an integral lowering and demolition method for a continuous beam bridge. The method adopts a pier system module and a lowering system module and includes steps: step one, preparing; step two, mounting an integral demolition temporary pier system; step three, mounting temporary piers and cutting main beam flanges; step four, mounting a integral lowering system; step five, synchronously lowering, lifting, constructing and the like. The pier system module comprises steel pipe piles, temporary pier parallel connectors, transverse connection beams, longitudinal distribution beams and the like. The lowering system module comprises dragging beams, a steel stranded lifting rope anchor system, anchor plates, continuous lifting jacks and supporting blocks. The method is applicable to demolition of the high-pier continuous beam bridge large in clearance of span and has advantages of quickness in demolition, safety in construction and cost saving.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

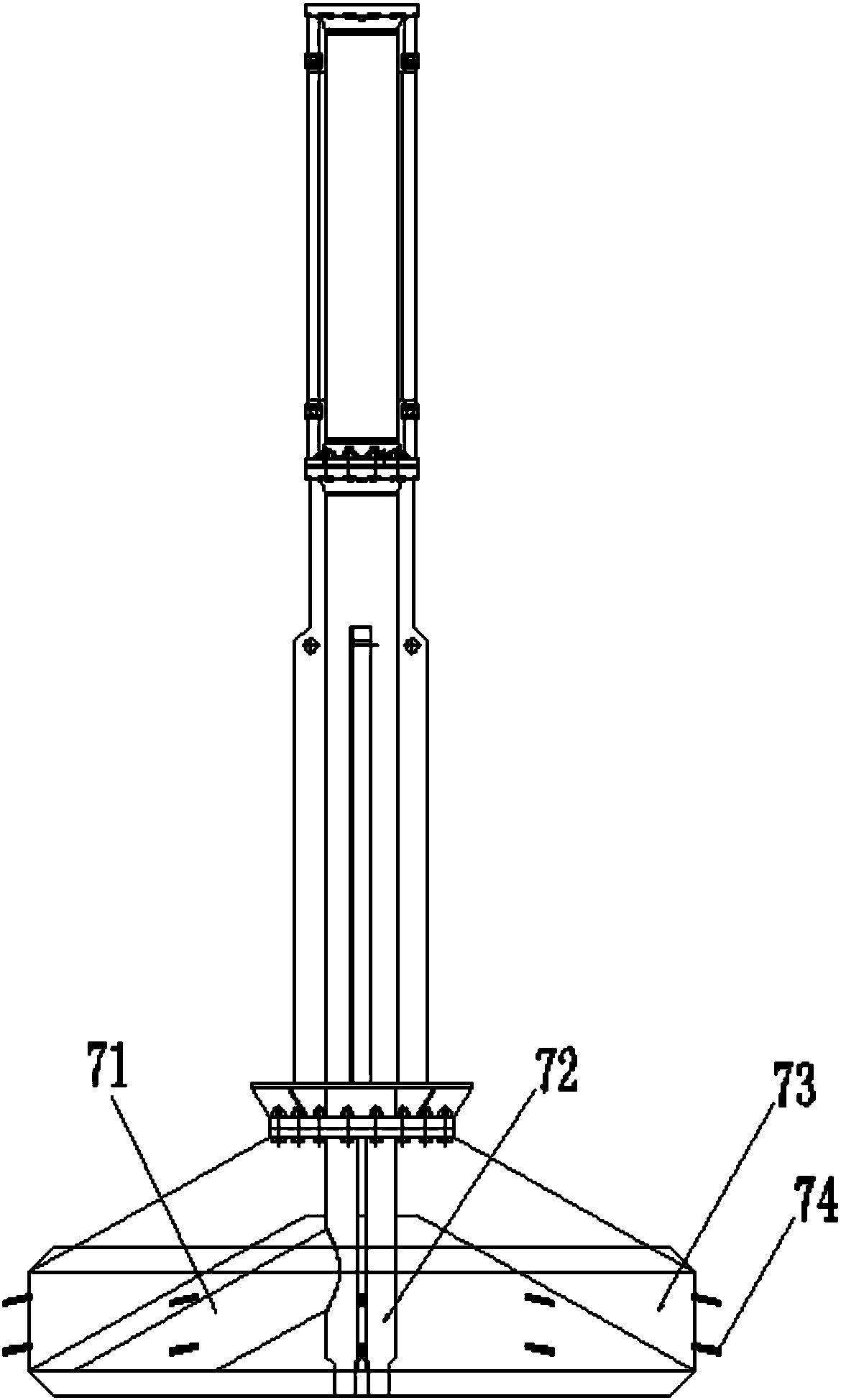

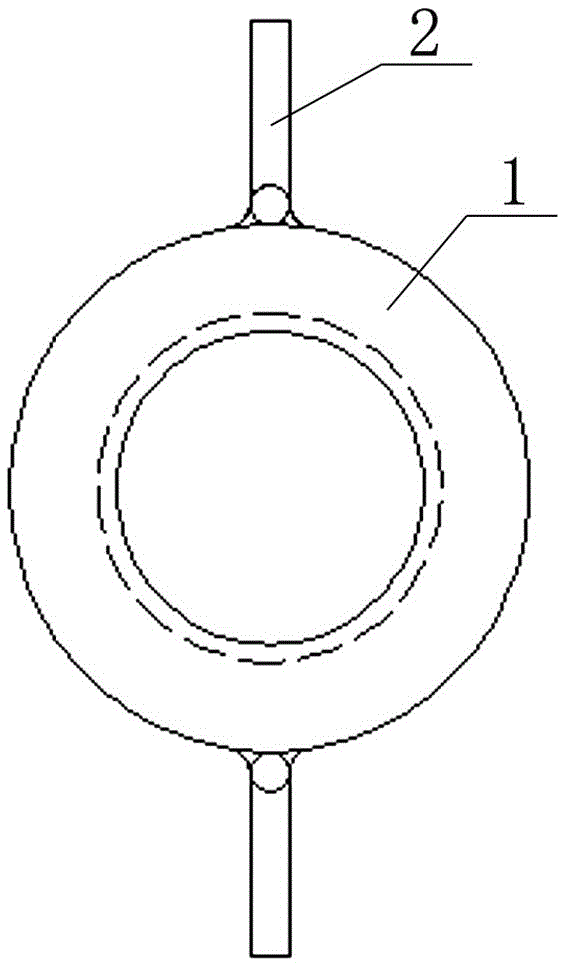

Local buoyancy ocean platform of offshore wind power, bridge and ocean structure, and construction method

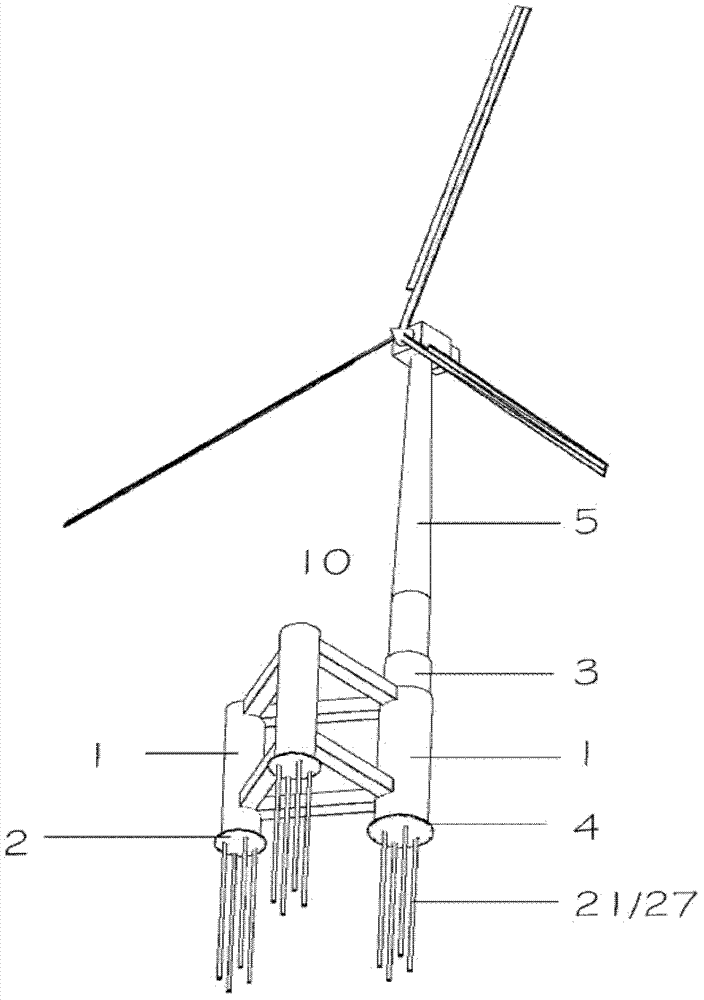

ActiveCN103362113AIncrease horizontal resistanceImprove stabilityArtificial islandsUnderwater structuresMarine architectureMulti platform

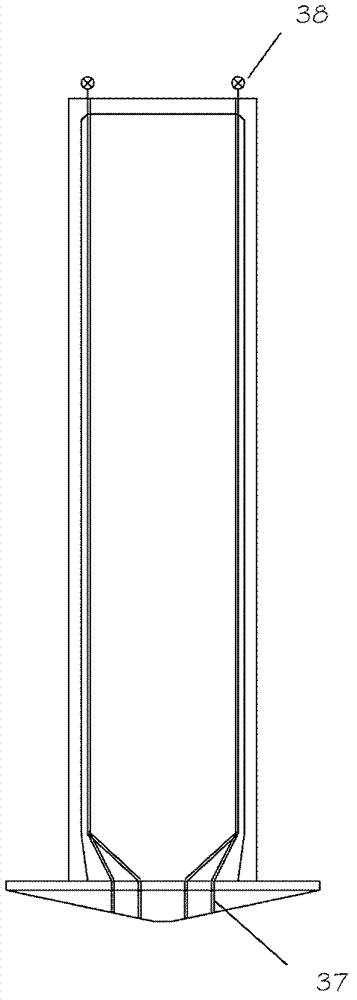

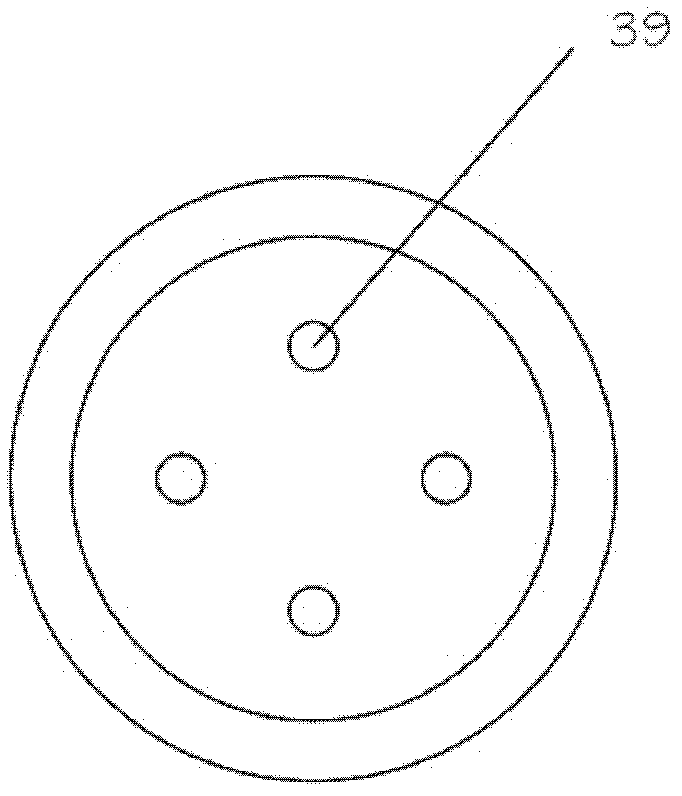

The invention discloses a local buoyancy ocean platform of offshore wind power, a bridge and an ocean building, and a construction method. The platform comprises at least one buoyancy cylinder, wherein the buoyancy cylinders are arranged vertically; the bottoms of the buoyancy cylinders are conical; and the buoyancy cylinders are hollow cylinders. Buoyancy of the buoyancy cylinders can be used for offsetting the weight of partial hydraulic buildings; small-bore bored piles or small-bore driven piles are arranged at the bottoms of the buoyancy cylinders, and fixed with seabed bed rock or a supporting layer, and support an external force together with a soil layer at the conical bottoms of the buoyancy cylinders; a tilting load borne by a whole foundation is converted into a vertical pressing and up-pull load of a single buoyancy cylinder foundation by a multi-buoyancy-cylinder space structure; the bearing capacity and the tilting resistance of the foundation are very high; multiple platforms can be connected into a multi-platform system; the platform can be cast in land, prefabricated, or assembled on a coast, and then hauled, towed and floated to a mounting position; and the platform is applied to ocean green energy sources such as the offshore wind power, the bridge and the ocean building with a soil layer of above 5m and water depth of about 5m to 50m, and has great potential economic benefits.

Owner:黄灿光 +1

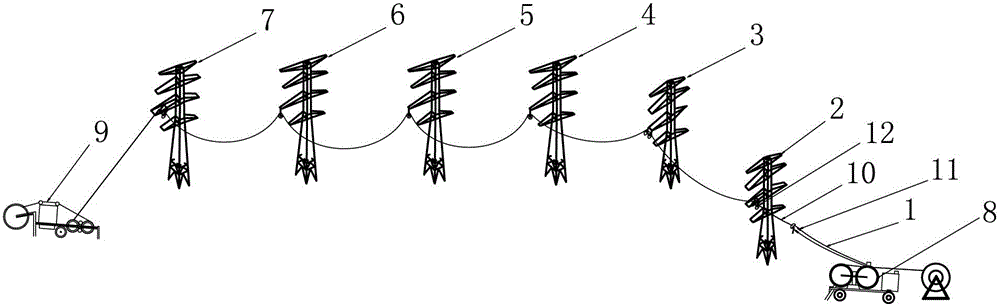

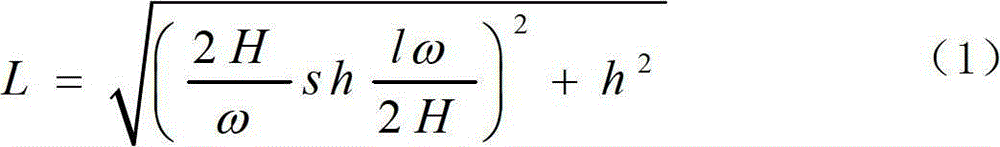

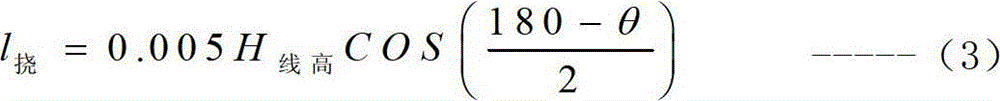

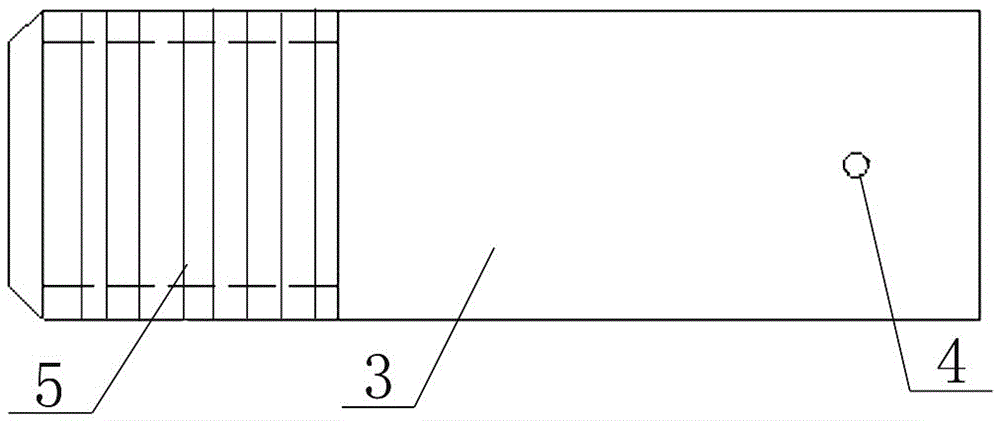

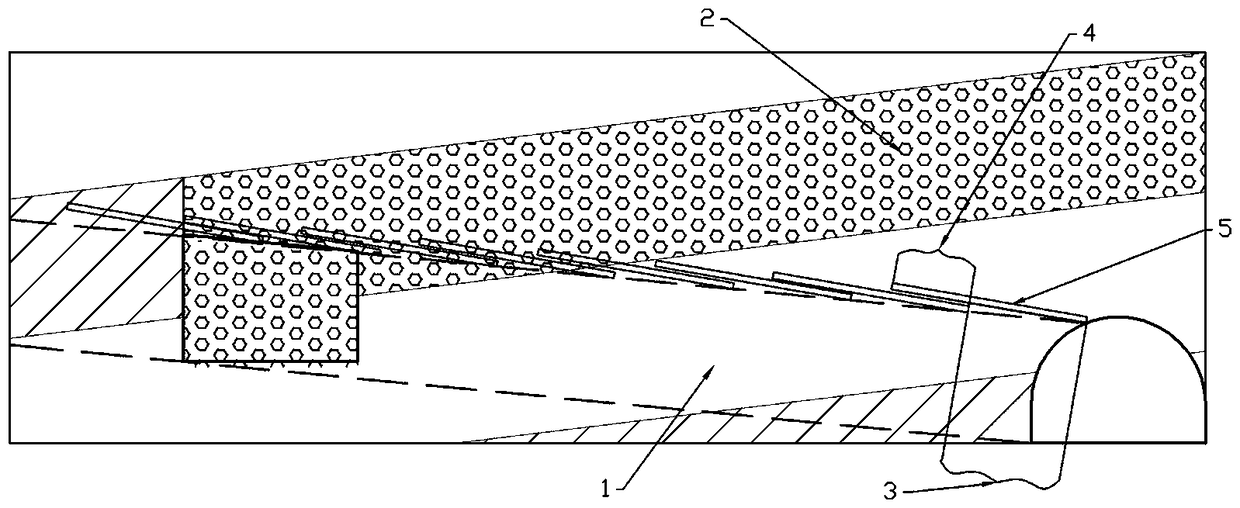

Continuous strain section assembly type wiring method for ultrahigh-strength aluminum conductor steel supported wires

InactiveCN102723679AControl loss and wasteGuaranteed crimp qualityApparatus for overhead lines/cablesArchitectural engineeringAluminium

The invention discloses a continuous strain section assembly type wiring method for ultrahigh-strength aluminum conductor steel supported wires. The method includes the steps: 1) calculation of the length of a strain section of a wire; 2) calculation of the manufacturing wire length; 3) utilization of strain hardware; and 4) an assembly type wiring process. By the method, wire loss and waste are effectively controlled, compression quality is guaranteed, and aloft operation is reduced. Further, the method is an accurate, efficient and safe construction method.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +2

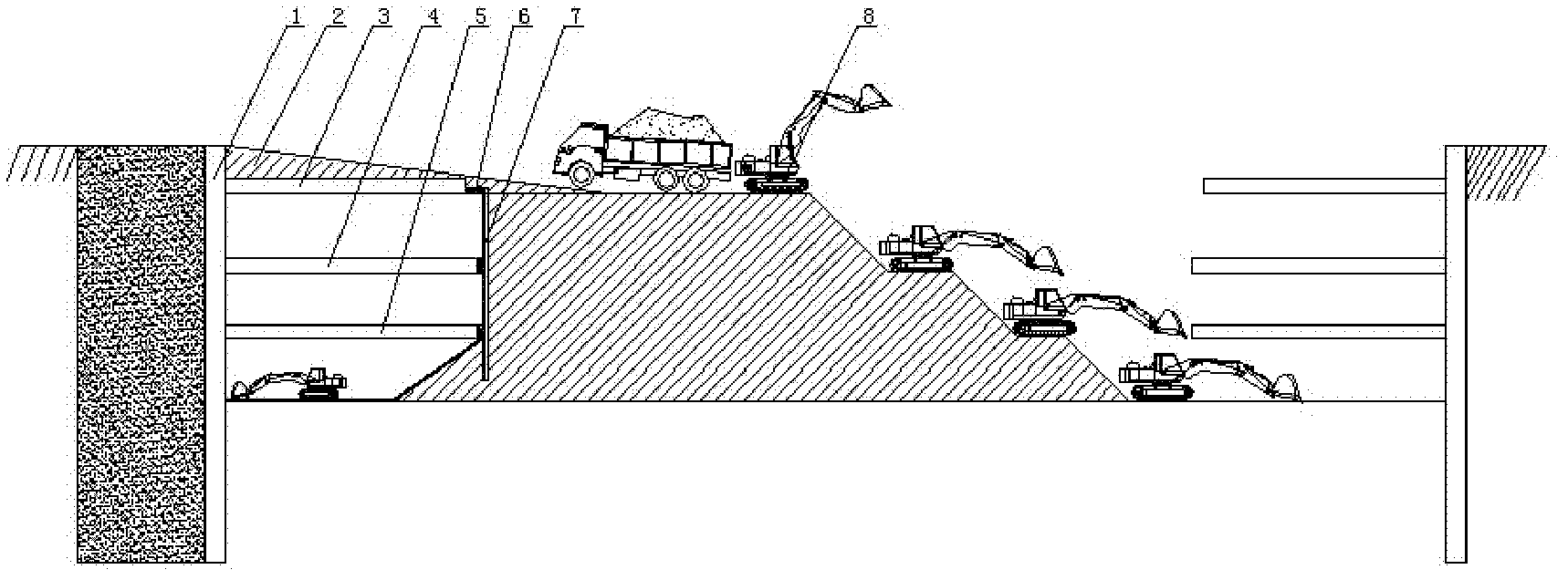

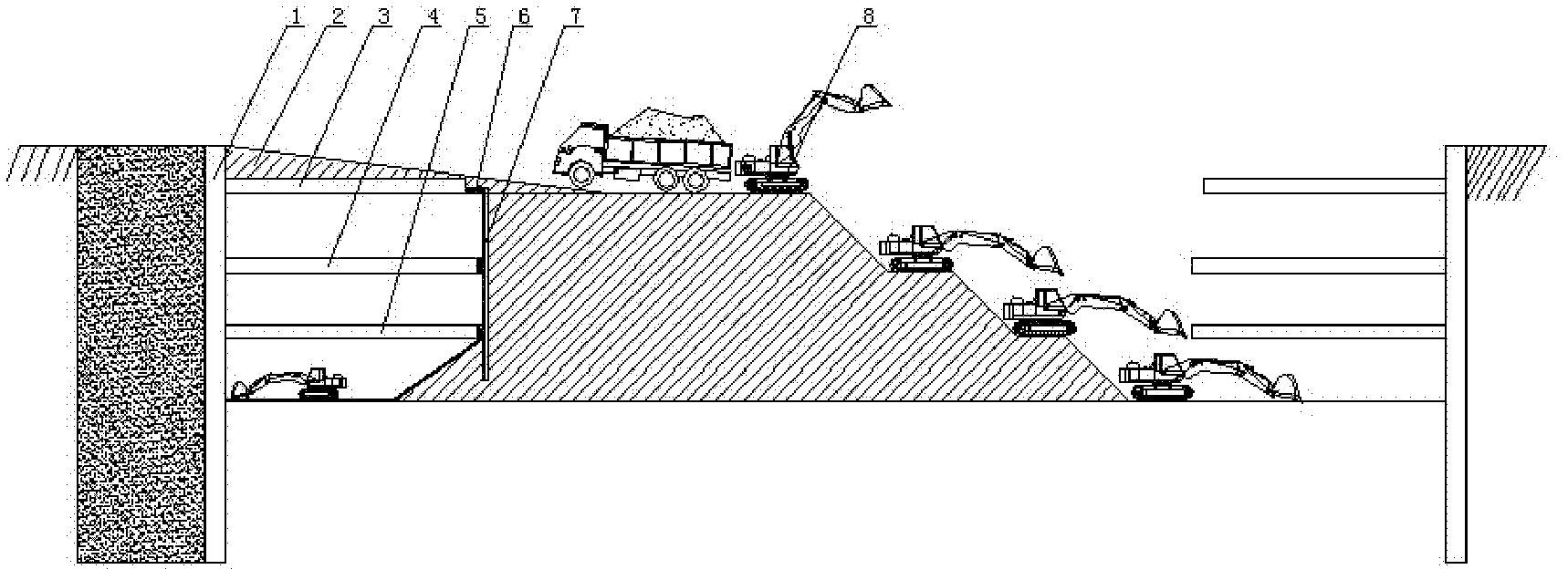

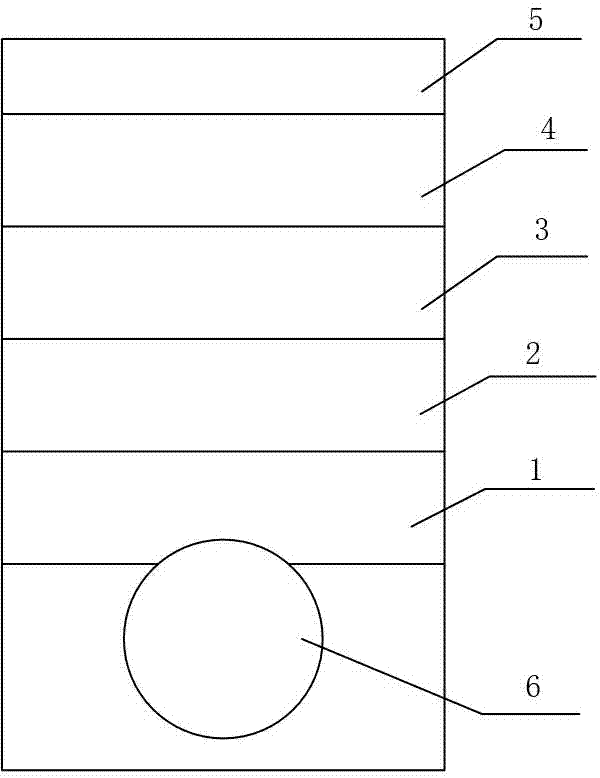

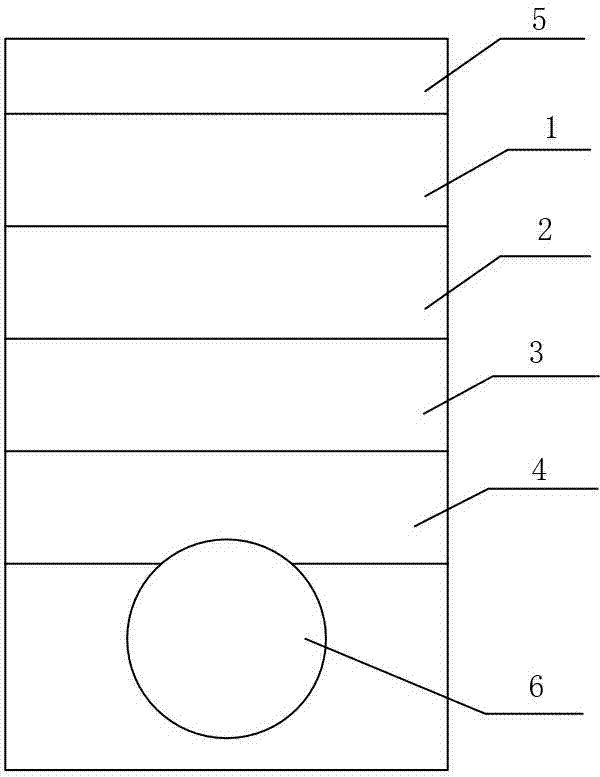

Deep foundation pit earthwork digging method

ActiveCN102425173AEnsure safetyAvoid repeated digging and fillingExcavationsBulkheads/pilesBuilding constructionSteel plates

The invention relates to a deep foundation pit earthwork digging method. The method comprises the following steps of: (1) after paying-off measurement of a deep foundation pit is finished, designing N layers of horizontal supporting steel plates according to the deep foundation pit engineering conditions in the deep foundation pit from top to bottom, and digging the foundation pit earthwork layerby layer by adopting an island type digging method, wherein N is more than or equal to 1 and less than or equal to 20; (2) downwards driving an outside steel plate pile along the wall of the deep foundation pit; and (3) digging the earthwork above the first layer of horizontal supporting steel plate, welding one end of the first layer of horizontal supporting steel plate to the outside steel plate pile, downwards driving an inside steel plate pile at the other end of first layer of the horizontal supporting steel plate and the like, constructing the Nth layer of horizontal supporting steel plate, building a ramp, digging the earthwork below the Nth layer of horizontal supporting steel plate, regressing, digging the ramp, removing the inside steel plate pile, digging the rest earthwork, and thus finishing digging the earthwork of the deep foundation pit. The construction method is simple and feasible; a trestle is not required, the construction period is effectively quickened, and the digging cost of the earthwork of the deep foundation pit is reduced; and the deep foundation pit earthwork digging method is safe and reliable.

Owner:MCC TIANGONG GROUP

Execution method for feeding tiny tunnel into ultra heavy section tunnel transversally

InactiveCN101545376AConstruction method safetyImprove construction progressTunnelsLower zoneBuilding construction

Owner:THE FOURTH ENG CO LTD OF CTCE GRP

Pile bearing caisson seawall and construction method thereof

InactiveCN102080364AImprove carrying capacityImprove stabilityDamsClimate change adaptationSea bottomSeawall

The invention relates to a seawall and a construction method thereof, and aims to provide a seawall with better stability, taking a large-diameter cast-in-site concrete cylindrical pile as a basis, and a construction method of the seawall, wherein the upper part of the seawall is connected with a caisson platform. The pile bearing caisson seawall comprises the caisson platform positioned on a submarine soft soil foundation in coastal engineering, wherein, the bottom of the caisson platform is equipped with at least two rows of erected bearing piles which are used for bearing the platform and are embedded into sea bottom; and the sides of the caisson platform near sea and land are equipped with the erected bearing piles which are embedded into the sea bottom as well as transverse suppression layers positioned on the top ends of the bearing piles. The seawall and the construction method have the beneficial effects that the bearing capacity and stability of the seawall are improved; and in addition, the caisson platform can be utilized as a construction platform so as to construct according to an overland construction method after construction machinery is placed on the platform, which reduces offshore ship operation and lowers construction cost, thus being capable of being widely applied to coastal dam construction engineering.

Owner:浙江海桐高新工程技术有限公司

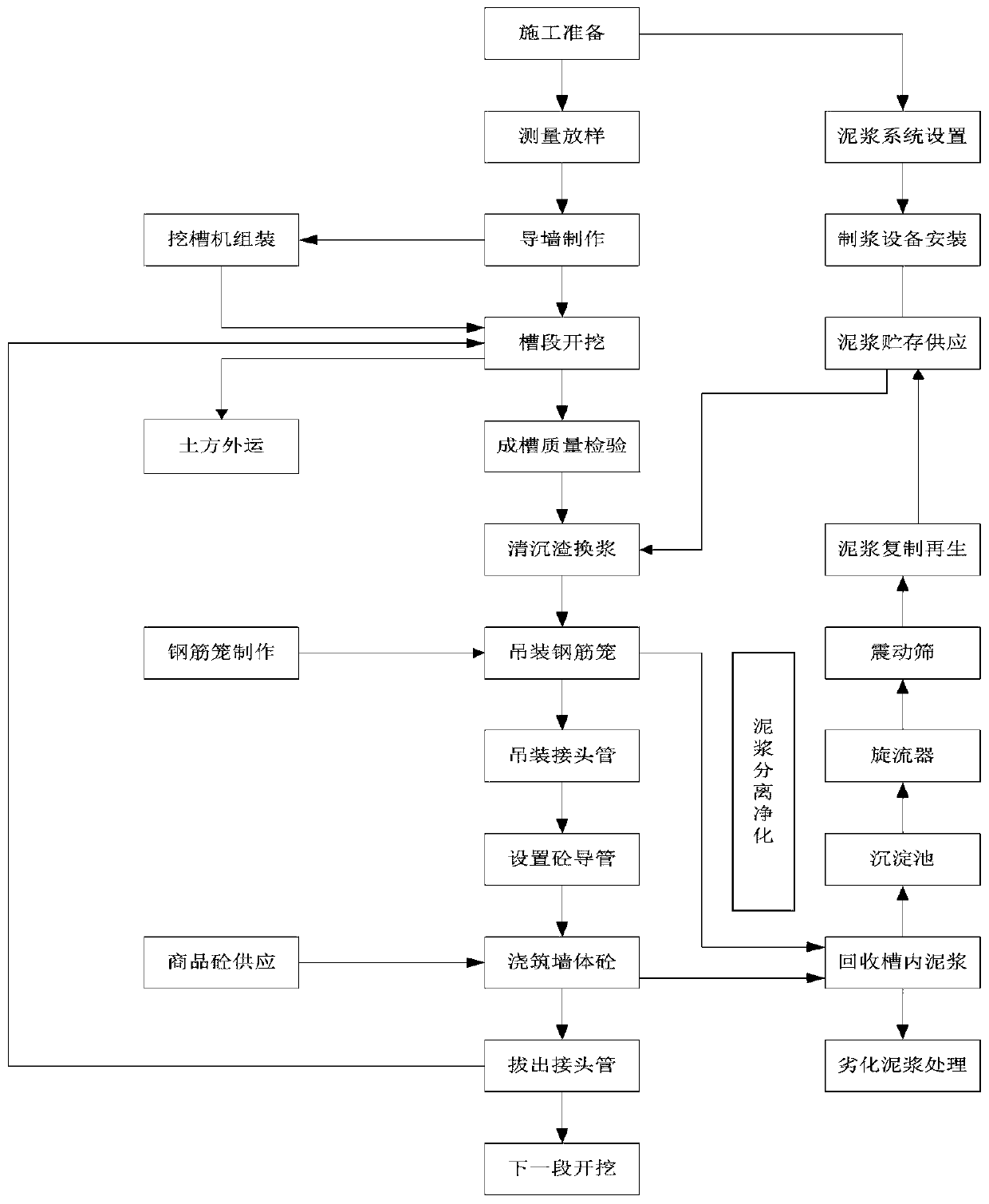

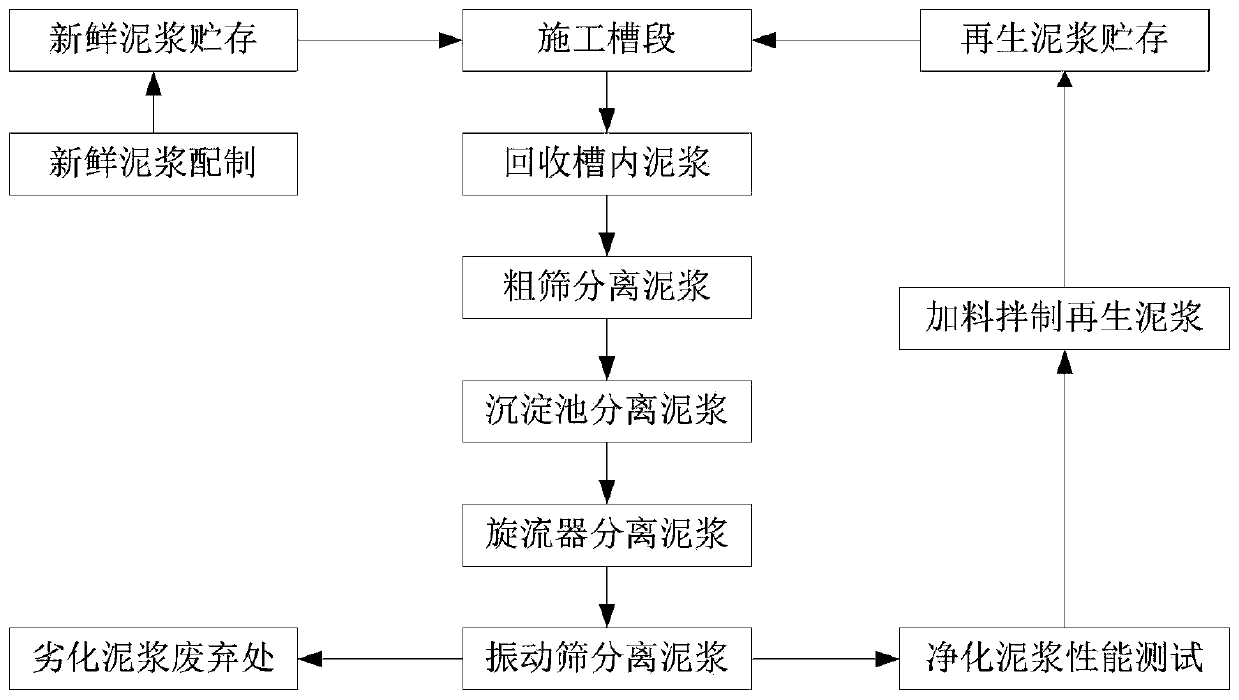

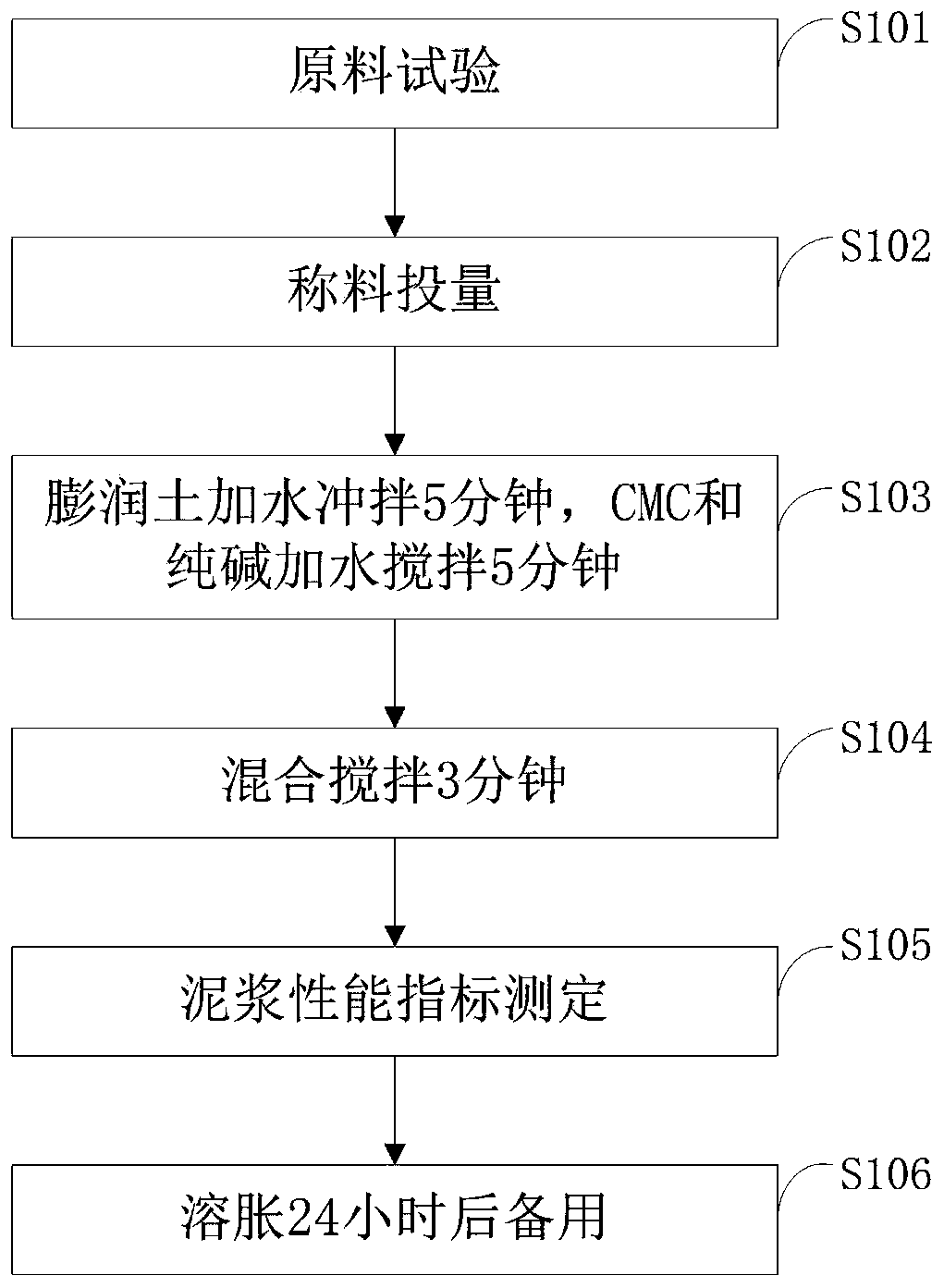

Construction method of underground diaphragm wall of railway transit engineering

InactiveCN109972609AConstruction method safetyApplicable construction methodExcavationsBulkheads/pilesMud systemsSlurry wall

The invention belongs to the technical field of underground engineering construction, and discloses a construction method of an underground diaphragm wall of railway transit engineering. The construction method of the underground diaphragm wall of the railway transit engineering specifically comprises the step: construction preparation, guide wall construction, mud system, channel section excavation, channel section examining, bottom clearing for mud replacing, wall brushing, reinforcement cage manufacturing, reinforcement cage hoisting, concrete pouring, joint treatment, embedded part arrangement and control protection measure, and wastewater and waste mud treatment. The method is safe, economical, applicable, reasonable, high in quality, efficient and advanced in technology; on the basisof sufficient field visit and traffic study, a construction scheme is reasonably compiled, thus is scientific and applicable, and considers factors such as economy of construction in particular, andthus the scheme is scientific, economical, applicable and safe; and based on normalized and standardized construction, the scientific and advanced construction method is selected preferentially, and the engineering quality and the construction period are guaranteed, and comprehensive, reliable and operable safety-ensuring measures are established.

Owner:SOUTHWEST FORESTRY UNIVERSITY

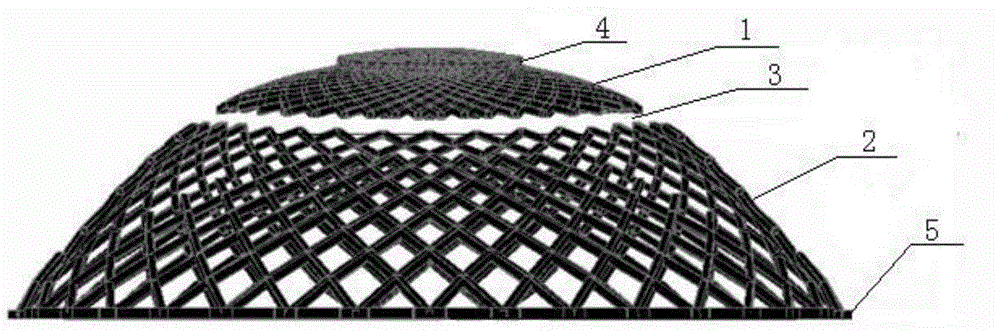

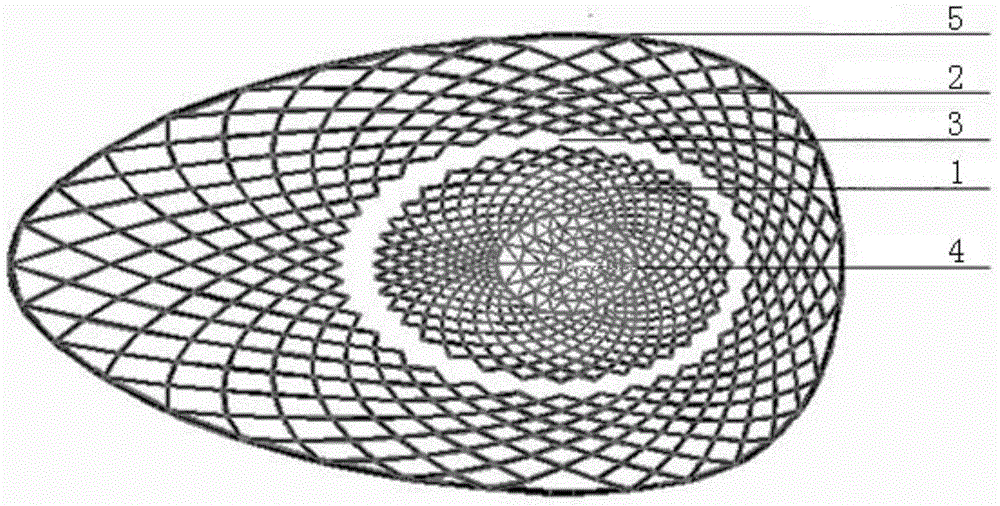

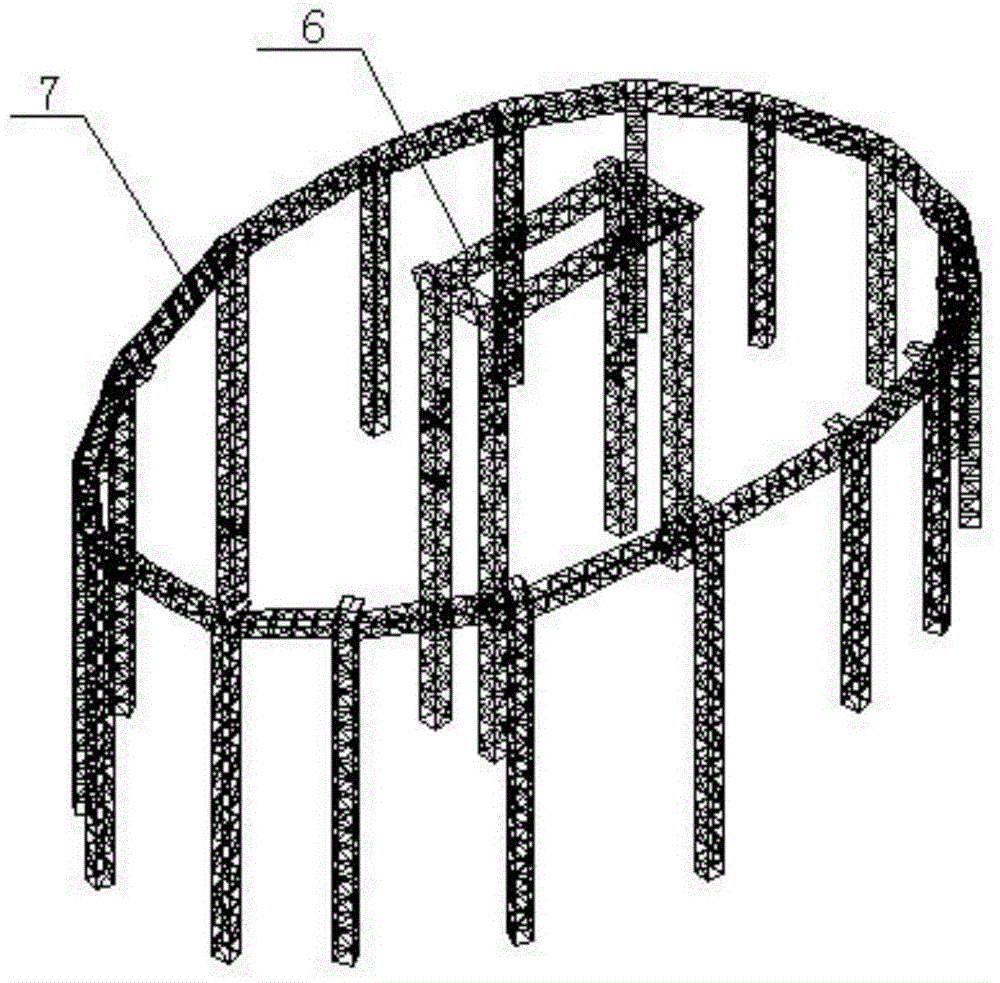

Construction method of large-scan single-layer latticed shell steel structure

InactiveCN104652831AReduce deformationEnsure stability and securityBuilding material handlingMono layerLifting equipment

The invention provides a construction method of a large-scan single-layer latticed shell steel structure. According to the construction method, during construction, the single-layer latticed shell steel structure is sequentially divided into three areas, namely a lifting area, an inlaying area and a splicing area from top to bottom, wherein rod pieces in the lifting area are installed on a bed-jig group of the lifting area lower than a design height, and are entirely lifted after installation. Therefore, the installation precision and quality can be ensured, and the construction security is improved. The construction method avoids the problems in the traditional bed-jig support method that a mass of bed-jig need to be erected and large-tonnage hoisting equipment needs to be used, and the stability of the bed-jigs is difficult to ensure. The invention provides the safe and reliable construction method with lower cost.

Owner:CHINA RAILWAY CONSTR ENG GROUP

Construction method of concrete used for reinforcing underwater pier

InactiveCN101603290AImprove construction efficiencyStrong continuous operationBridge structural detailsBridge erection/assemblyBaseboardFoam rubber

The invention belongs to the technical field of bridge construction, in particular relates to a construction method of concrete used for reinforcing an underwater pier; the method is to install a foam rubber, a rubber sheet and an orientation positioning device on a steel cofferdam, and is to use an underwater non-segregation concrete to replace general underwater concrete to complete the construction of concrete used for reinforcing the underwater pier. The method has the following construction steps: A, installing the foam rubber at the bottom surface of the steel cofferdam before the steel cofferdam enters water; B, installing the orientation positioning device on the inner wall of the steel cofferdam before the steel cofferdam enters water; C, installing the rubber sheet on the internal edge of the baseboard of the steel cofferdam before the steel cofferdam enters water; D, installing a concrete pouring pipeline before the steel cofferdam sinks to the preset position; E, installing a pouring funnel on the top of the concrete pouring pipeline and pouring underwater non-segregation concrete; F, removing the pouring funnel and the concrete pouring pipeline to complete the construction of concrete used for reinforcing the underwater pier. The invention successfully solves the difficult problem of the construction of concrete used for reinforcing the underwater pier, creates a safe, reliable, economical, convenient and fast construction method of concrete used for reinforcing the underwater pier.

Owner:四川路桥建设集团股份有限公司 +1

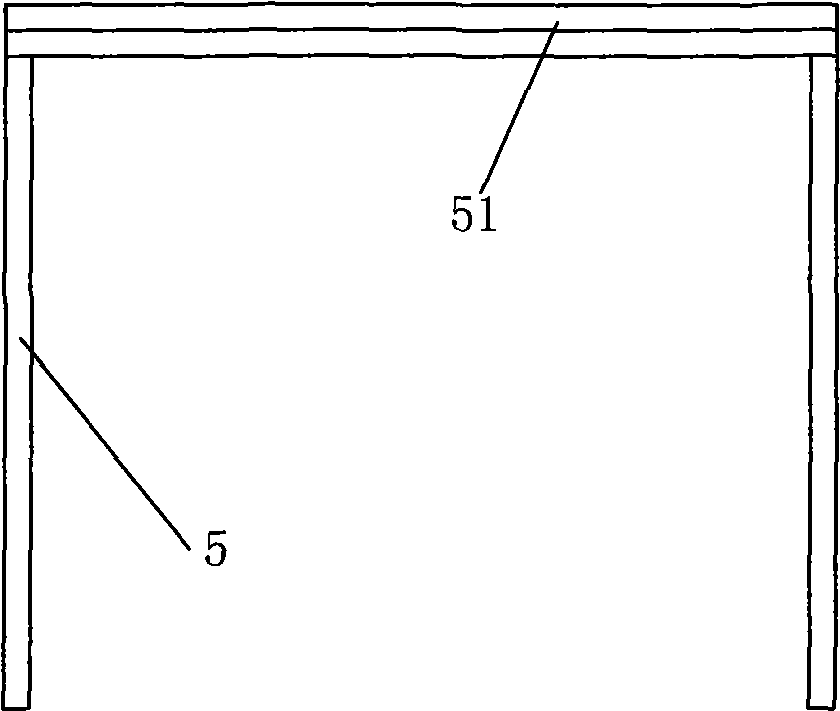

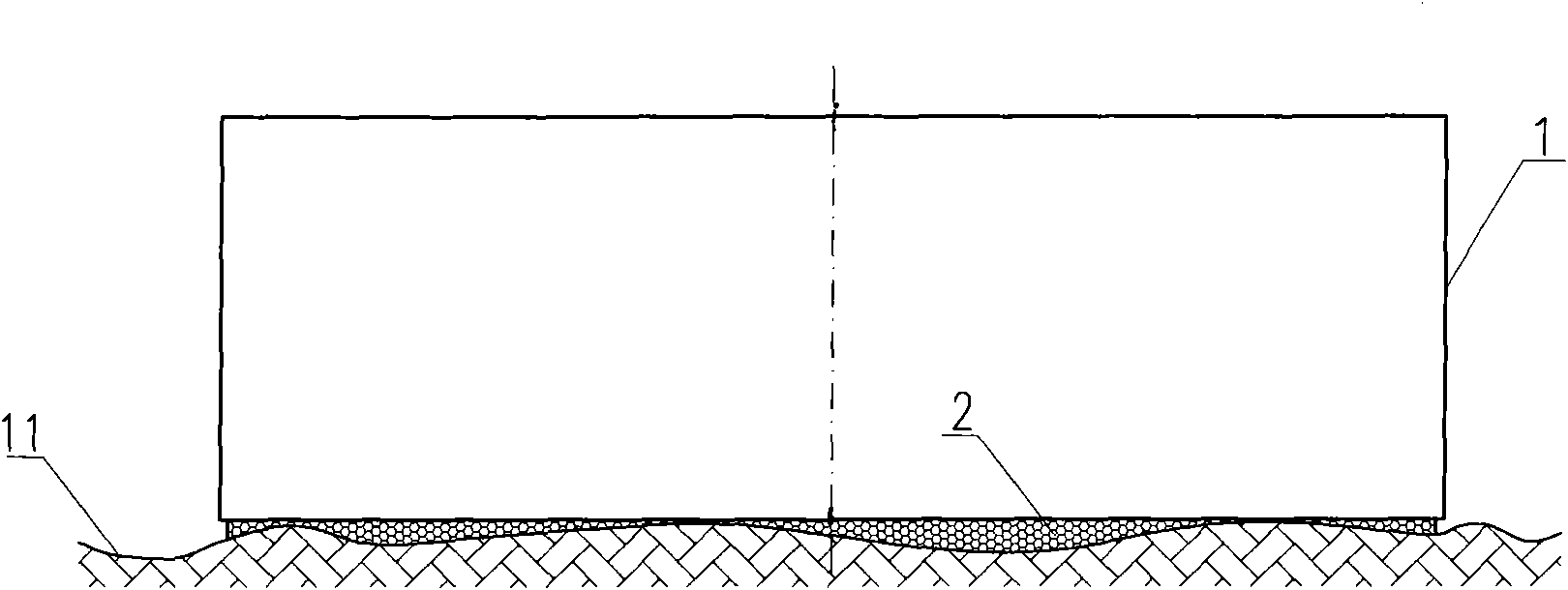

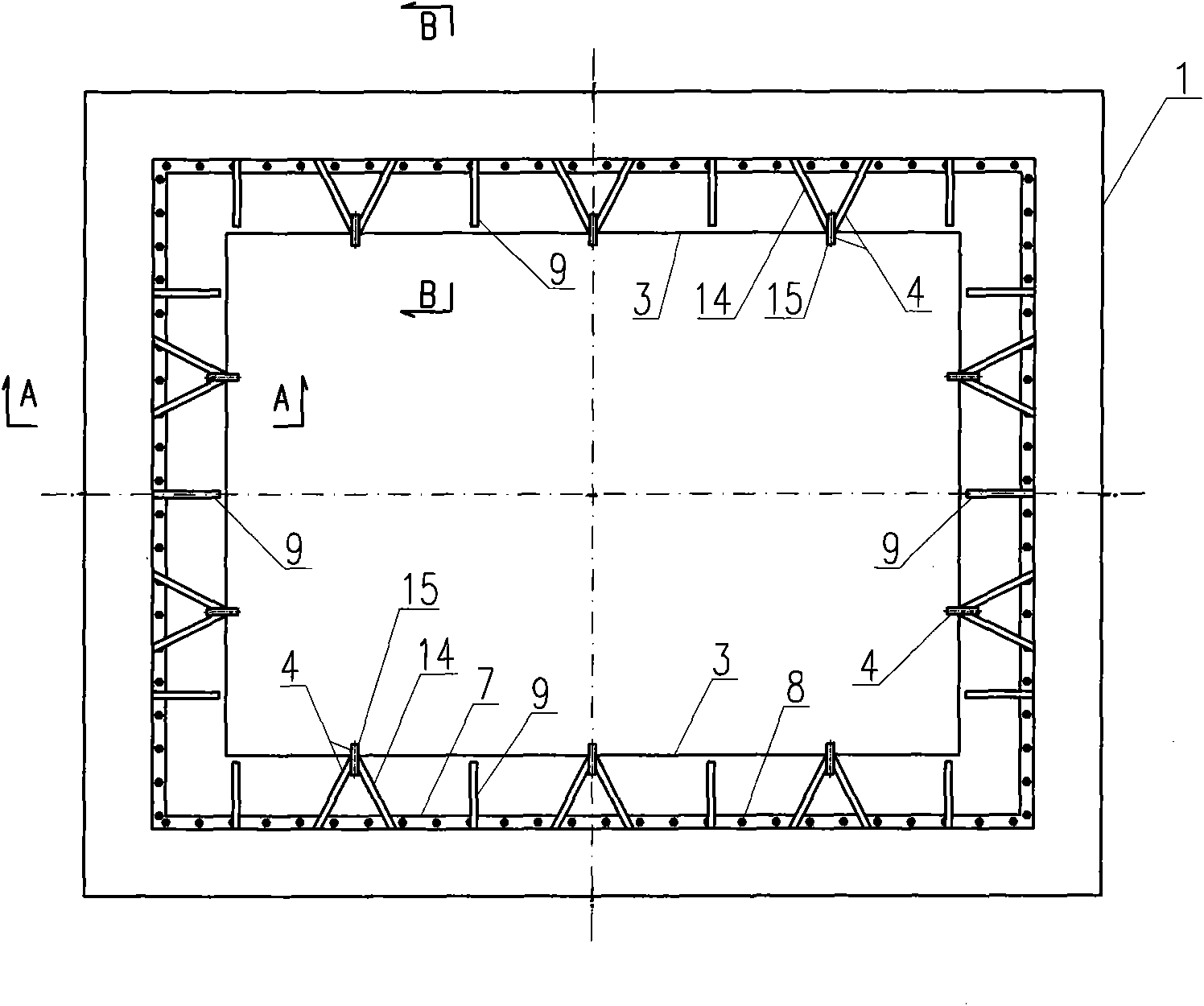

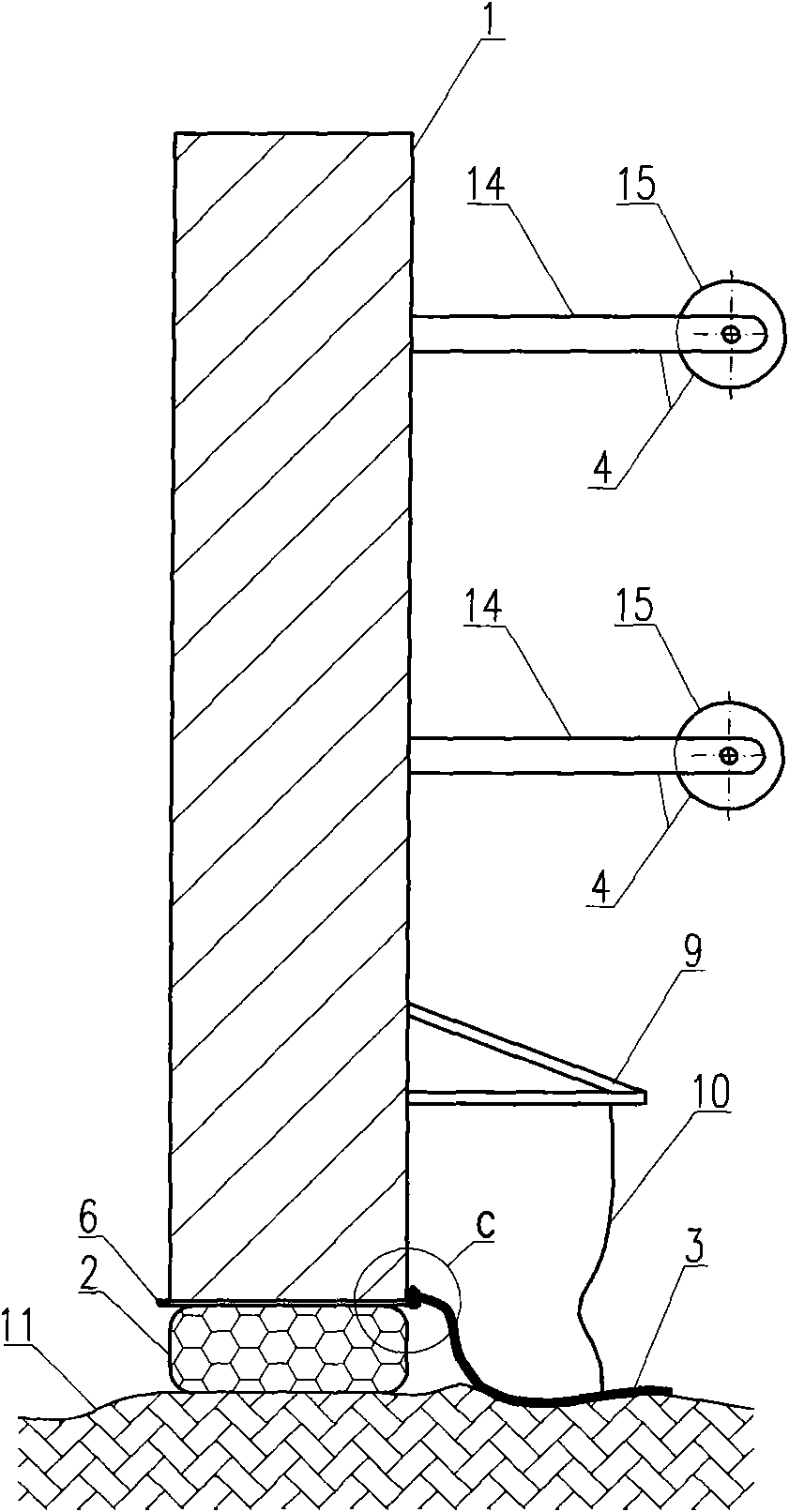

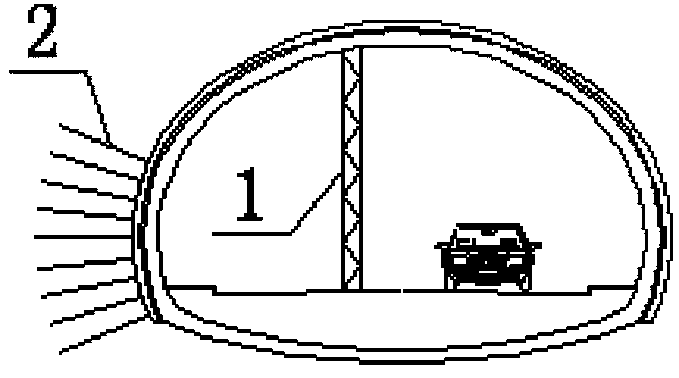

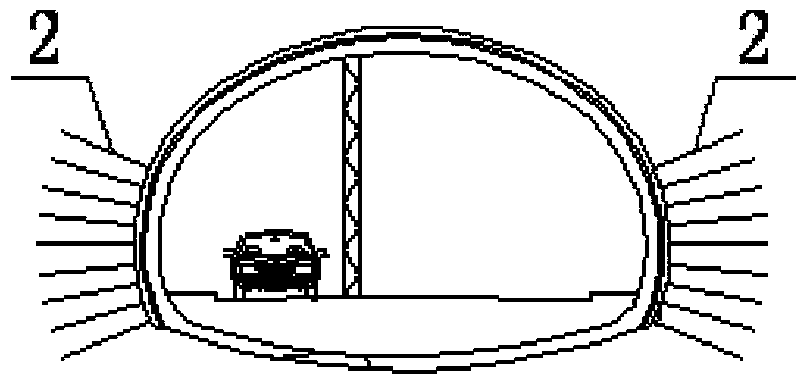

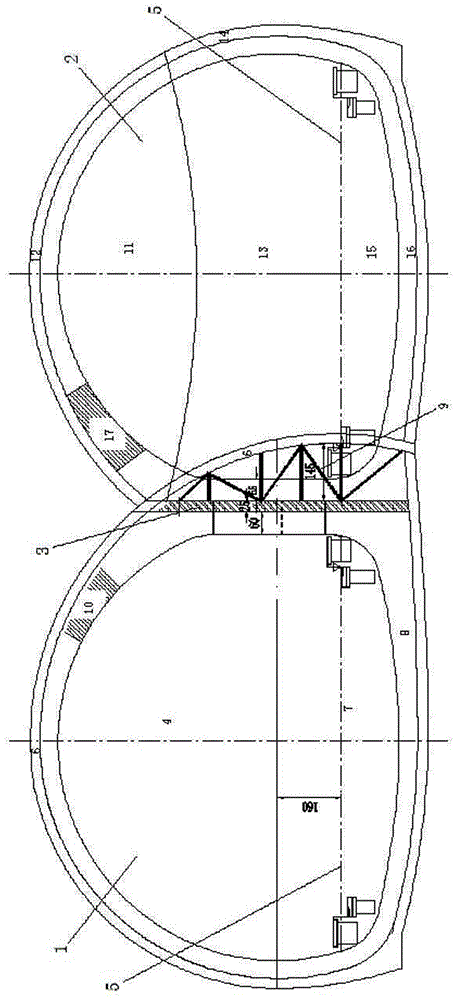

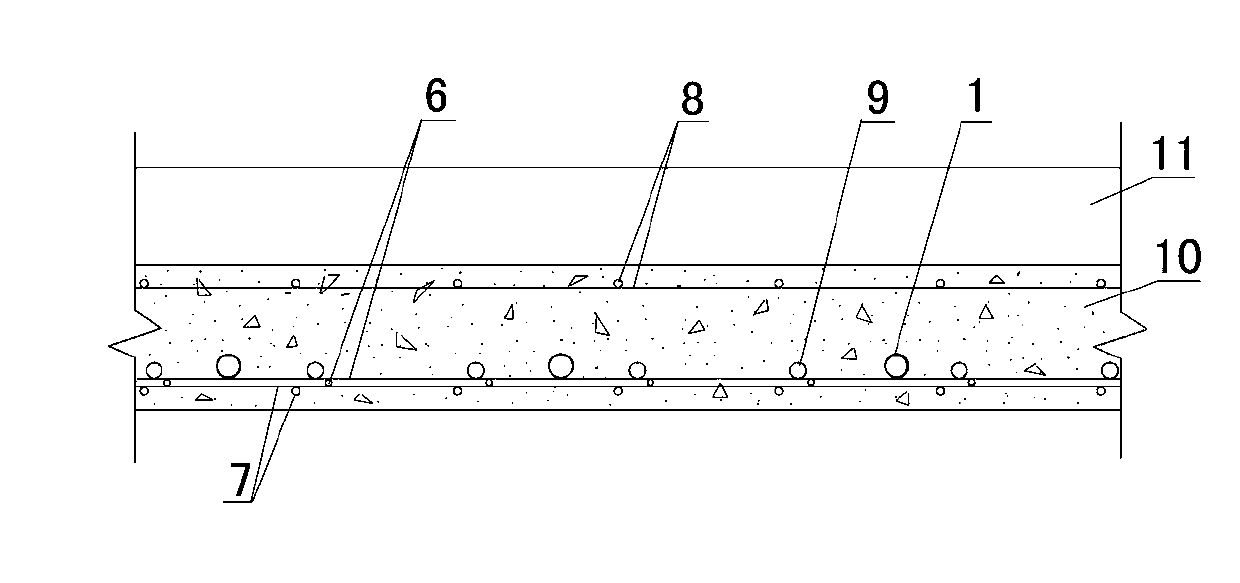

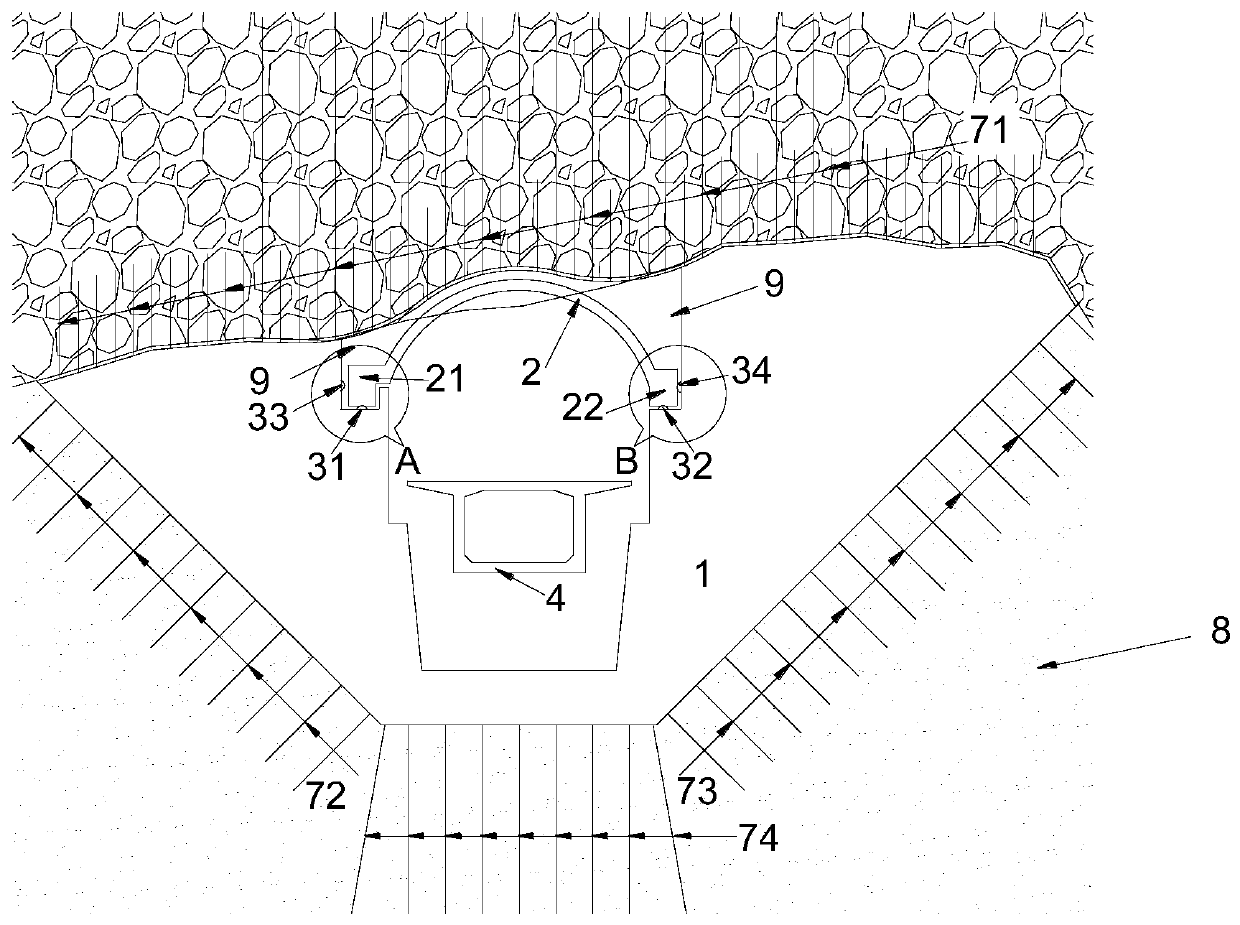

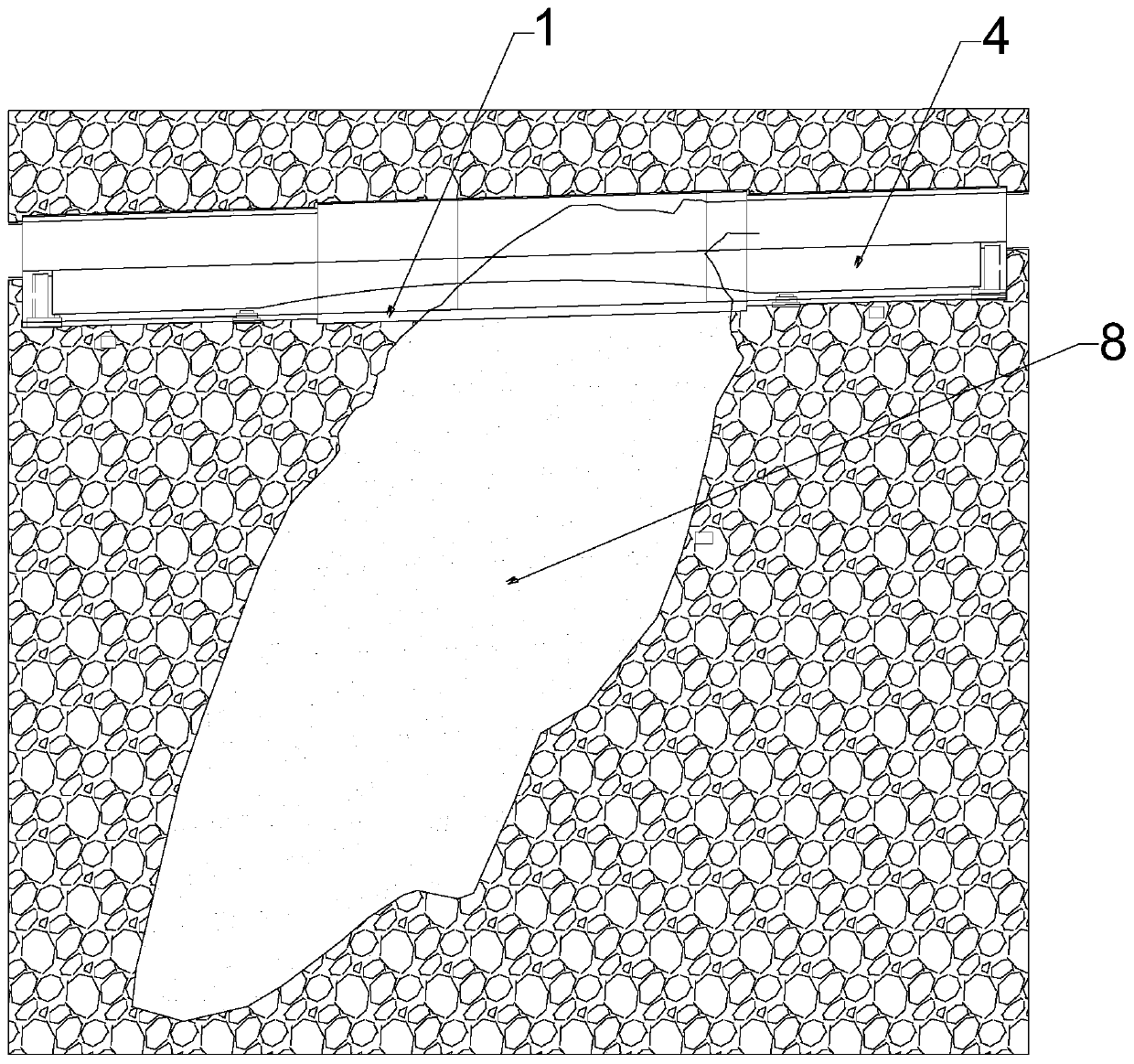

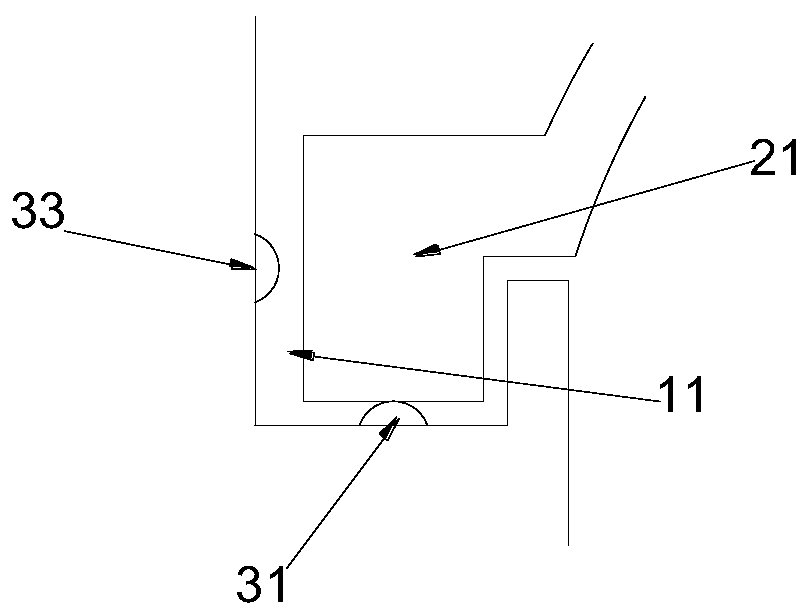

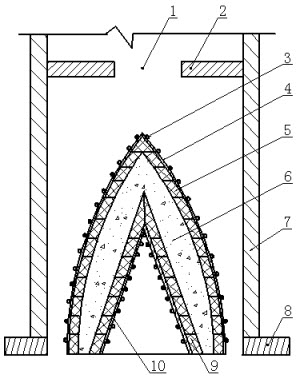

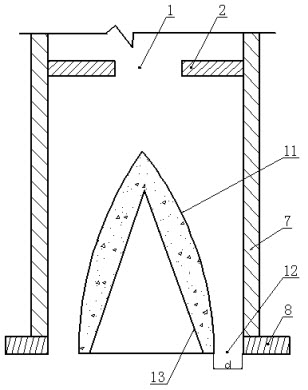

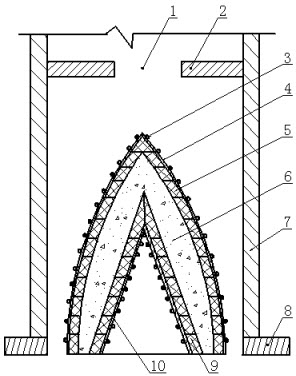

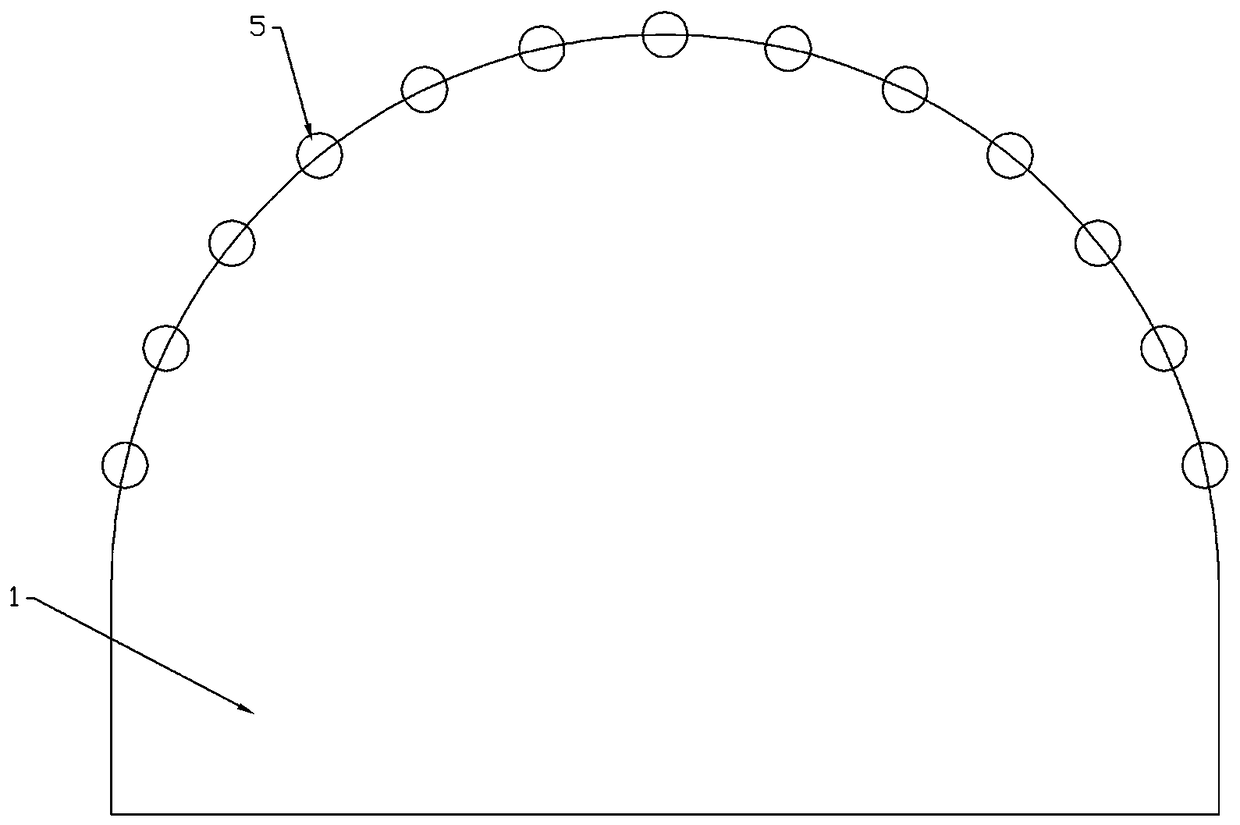

Existing tunnel down-digging extension construction method without traffic interruption

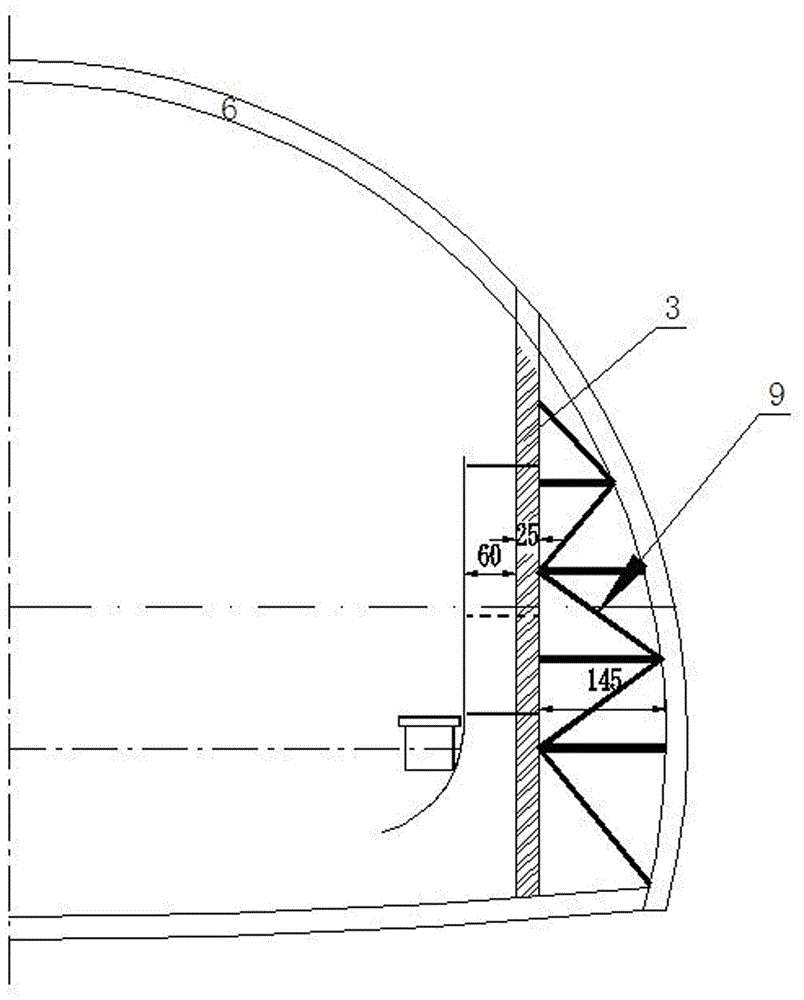

The invention discloses an existing tunnel down-digging extension construction method without traffic interruption, which is mainly alternately implemented on the left side and the right side in an existing tunnel hole. The existing tunnel down-digging extension construction method without traffic interruption comprises the following steps: firstly, establishing a partition fence (1), and adding anchor rods (2) on a haunch and an arch springing; then, carrying out down-digging extension, adding a waterproof layer till the lateral drain on the bottom of an extension tunnel on the inner side of the secondary lining of the existing tunnel, and adding a third lining (7); finally, pouring a vertical wall (9) and a reinforced concrete road slab (10), removing the partition fence (1) in the hole, and restoring the normal traffic. The construction method is scientific, reasonable, safe and reliable, the safety problem of the existing tunnel structure in the construction process is effectively solved, the integrity of the tunnel structure is guaranteed, and the traffic interference caused by the extension construction is reduced.

Owner:CHANGAN UNIV +1

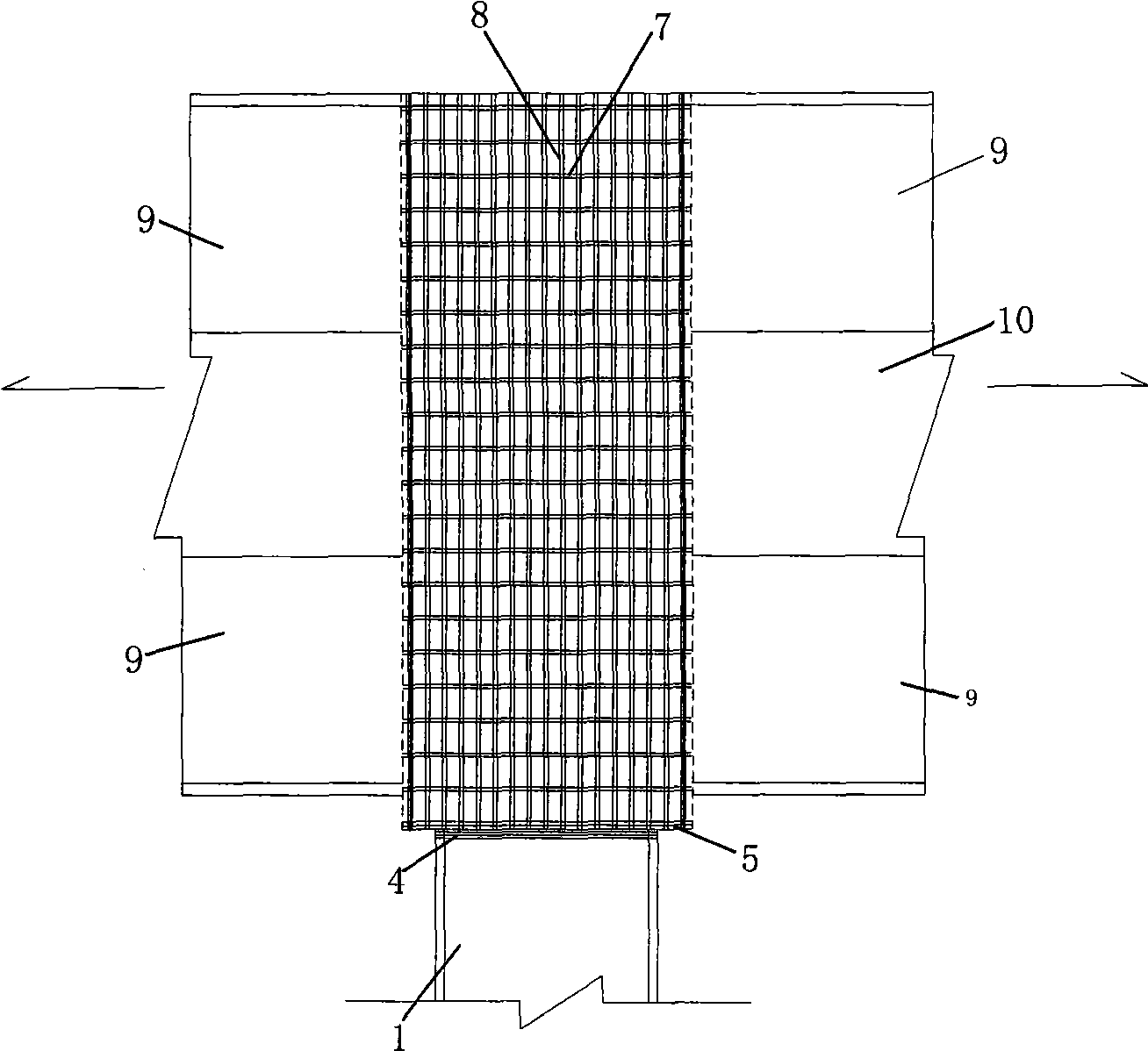

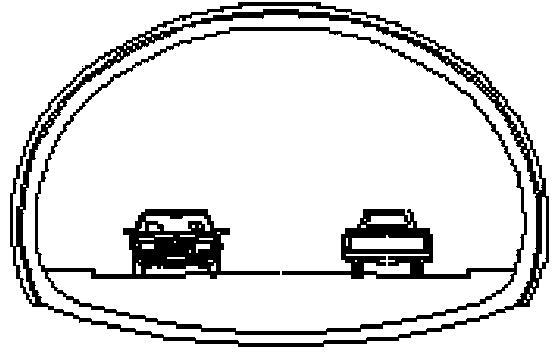

Construction method of double arch tunnel auxiliary middle wall without middle pilot tunnel

ActiveCN106761836AEnsure safetyConstruction method safetyUnderground chambersTunnel liningSteel frameEngineering

The invention discloses a construction method of a double arch tunnel auxiliary middle wall without a middle pilot tunnel. According to the technical points, firstly, an upper step of a left side tunnel is constructed, then a primary support is constructed, and a lower step of the left side tunnel is excavated; the auxiliary middle wall is conducted, specifically, a vertical steel frame is constructed in the corresponding position of an inverted arch, after concrete of the inverted arch is constructed, an inclined strut on the right side of the steel frame is constructed, and a horizontal transverse-strut steel frame is constructed; rebars are fixed on the steel frame in a quincuncial mode; meanwhile, double layers of reinforcement fabrics are hung on the horizontal transverse-strut steel frame; then sprayed concrete is constructed on the steel frame, and a secondary lining of the left side tunnel is constructed on the left side of the concrete; and a right side tunnel is constructed, specifically, an upper step is excavated, then a primary support is constructed, a middle step is excavated, a primary support of the middle step is constructed, a lower step is excavated, the primary support and the inclined strut on the right side of the middle wall are dismantled, an inverted arch of the right side tunnel is constructed, and finally a secondary lining of the right side tunnel is constructed . Middle pilot tunnel construction is omitted, the construction safety of a main tunnel is guaranteed, an existing construction method is fully utilized, construction efficiency is improved, and the construction period is shortened.

Owner:HUNAN INSTITUTE OF ENGINEERING

Construction method for ceiling radiant heating/cooling coil

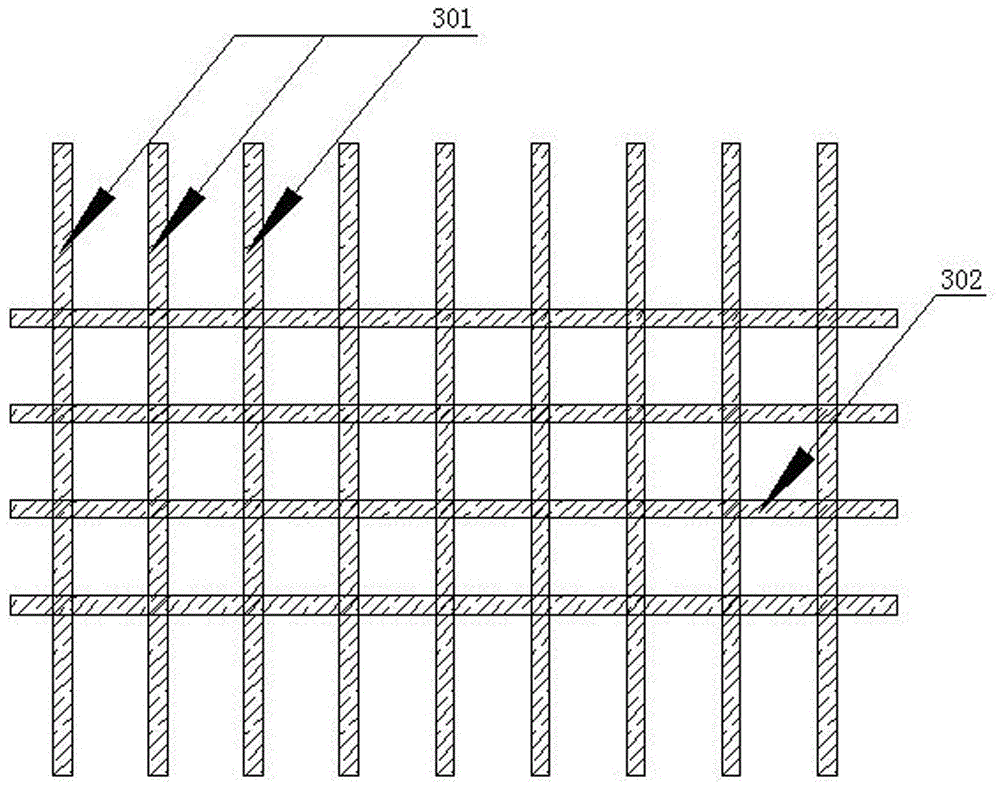

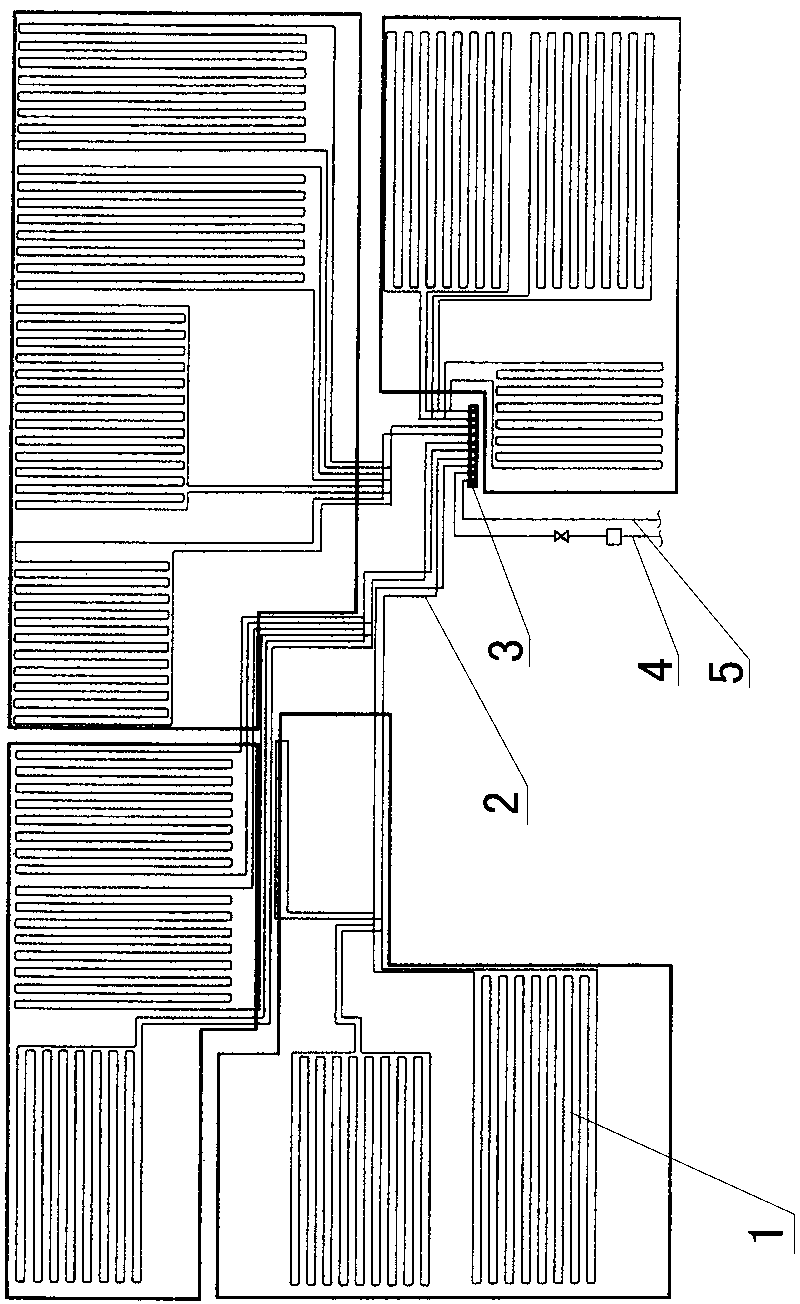

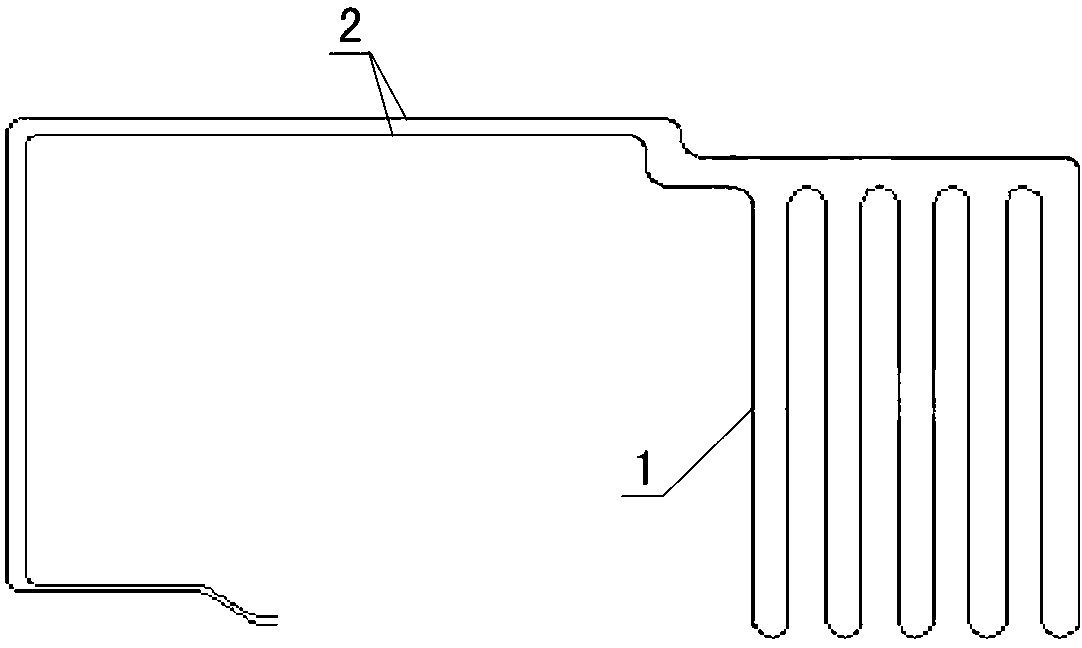

InactiveCN102995896ASimple construction methodConstruction method safetyDucting arrangementsBuilding material handlingCooling coilRebar

The invention discloses a construction method for a ceiling radiant heating / cooling coil, comprising the following steps of: firstly, binding a reinforcing mesh pat and the ceiling radiant heating / cooling coil at an open place; secondly, bracing a floorslab template on a floorslab construction field; thirdly, positioning by marking; fourthly, binding a bottom reinforcement of a floorslab; fifthly, transporting the reinforcing mesh pat to the floorslab construction field and carrying out field tube arrangement and installation, wherein the ceiling radiant heating / cooling coil is bound on the reinforcing mesh pat; sixthly, carrying out a hydraulic test; seventhly, laying a vacuum tube; eighthly, binding a top reinforcement of the floorslab; ninthly, pouring the floorslab by using concrete; and tenthly, releasing pressure and dismounting a water collector. The construction method for the ceiling radiant heating / cooling coil is simple, safe and efficient; and by using the construction method, the problem of overlong construction time on a tube laying field of the ceiling radiant heating / cooling coil is solved, and the structure of the ceiling radiant heating / cooling coil is kept safe and lossless from a pre-burying process to a running process.

Owner:THE FIRST CONSTR ENG COMPANY LTD OF CHINA CONSTR SECOND ENG BUREAU +1

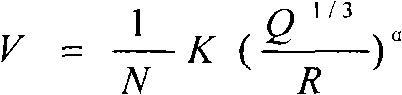

Blast construction method for penetrating complex building group by submarine tunnel at land region section

InactiveCN101936687AIncrease the speed of excavationReduce the amount of charge in the stageExplosive chargesBlasting cartridgesPunchingBlasting vibration

The invention discloses a blast construction method for penetrating a complex building group by a submarine tunnel at a land region section, and aims to solve the problem of a particular construction process that the fractional blasting frequency and the maximum section explosive charge are not determined according to a vibration velocity control index and measured indexes in the prior art. The method comprises the following steps of: measuring a geological coefficient K and a vibration damping index a of a rock body at a construction engineering land section; selecting a vibration monitoring scheme; calculating the maximum section explosive charge; punching on a tunnel face to form periphery holes, cut holes and tunneling holes; machining bamboo sections, wooden sticks or a water stemming material, of which the diameter is less than that of the periphery holes serving as blast holes, into objects with lengths of 5 to 10cm and assembling the machined objects into the hole bottoms of the periphery holes serving as the blast holes; binding the machined objects by an air-spaced binding method to form a blasting cartridge strip, inserting the blasting cartridge strip into the periphery holes serving as the blast holes and sealing the periphery holes with the stemming material; forming the wedged cut holes; and performing the blasting on the tunnel face. A simple, safe, economic and practical construction method is provided for penetrating the building group by a long and big tunnel by controlling the blasting vibration.

Owner:CHINA RAILWAY 19TH BUREAU GRP FIFTH ENG CO LTD +1

Construction method for prefabricating directly-buried uncompensated centralized heat supply pipeline by electrically preheating

InactiveCN102444750AImprove running stabilityGuaranteed elongationPipe laying and repairElectricityEngineering

The invention relates to a construction method for prefabricating a directly-buried uncompensated centralized heat supply pipeline by electrically preheating. The method comprises the following steps of: (1) grooving, adjusting the coordinate and scale height of the heat supply pipeline, and computing the preheating temperature and the designed elongation of the heat supply pipeline; (2) controlling the sand refilling height at a half to three quarters of the pipeline height H; (3) connecting the same-side end of the heat supply pipeline with preheating equipment through a cable respectively, and short-circuiting the other side of the heat supply pipeline through a cable; (4) arranging temperature sensors on the heat supply pipeline respectively; (5) recording the initial temperature of the heat supply pipeline and the initial position of a measuring point, starting temperature raising, controlling the temperature raising gradient within 1 DEG C per hour, and preserving heat after a preheating temperature is reached; (6) refilling sand into both sides of the heat supply pipeline, tamping, and controlling the preheating temperature within the range of + / -2 DEG C; (7) after the designed elongation is reached, shutting down the preheating equipment; and (8) performing subsequent construction according to the steps (1)-(7). The construction method disclosed by the invention is safe, reliable, easy and practical, is easy for accurately controlling construction equipment, and is consistent with the national policy of energy saving and emission reduction.

Owner:MCC TIANGONG GROUP

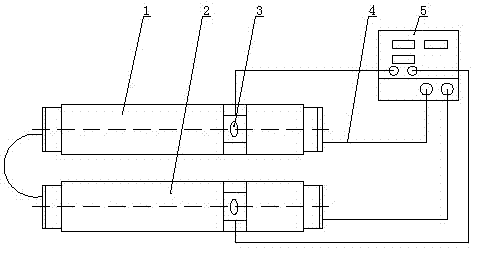

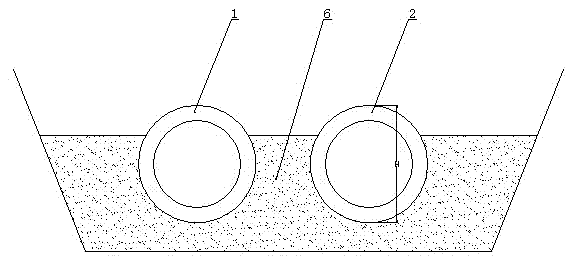

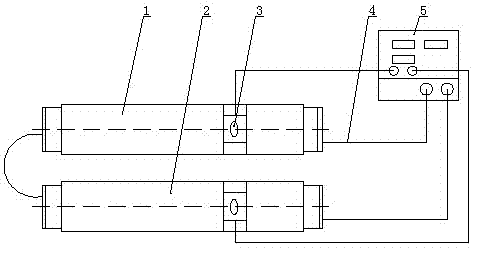

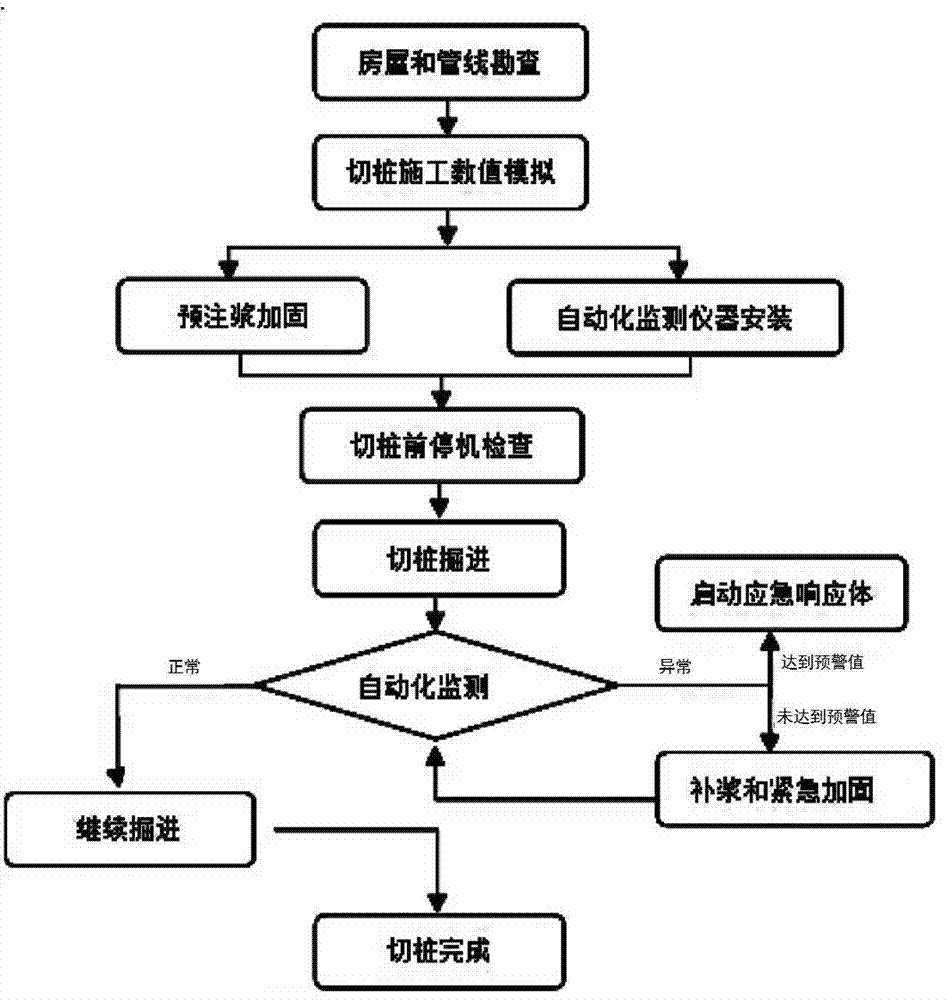

Construction method of shield and continuous cutting pile foundation for penetrating through residential building group

ActiveCN104847364AFew constraintsImprove applicabilityTunnelsArchitectural engineeringConstruction management

The invention relates to a construction method of a shield and continuous cutting pile foundation for penetrating through a residential building group. The construction method comprises the following steps that the first step, house investigation and investigation of pipelines around houses are conducted; the second step, pile cutting construction numerical simulation is conducted; the third step, an automatic monitoring instrument is installed; the fourth step, pre-grouting reinforcement is conducted, wherein the reinforcement range includes buildings, the pipelines and planning tool changing points, and the reinforcement mode is a retrograde grouting mode; the fifth step, shutdown and inspection of a shield machine are conducted before pile cutting is conducted; the sixth step, pile cutting tunneling and pipe sheet splicing are conducted; the seventh step, grout supplement and emergent reinforcement are conducted. According to the construction method, pile cutting and penetration can be directly conducted without the operation that the existing buildings are demolished, the idea of energy conservation and environmental protection is met, the investment cost can be substantially reduced, the negative influence caused by demolition is reduced, and the number of the constraint factors of metro line selection is reduced; in addition, shield construction parameters and grouting parameters can be guided according to data which are fed back in real time through automatic monitoring, a comprehensive dynamic construction management system is implemented, the engineering risk is controllable, and the construction cost can be substantially reduced.

Owner:CHINA CONSTR COMM ENG GRP UNITED

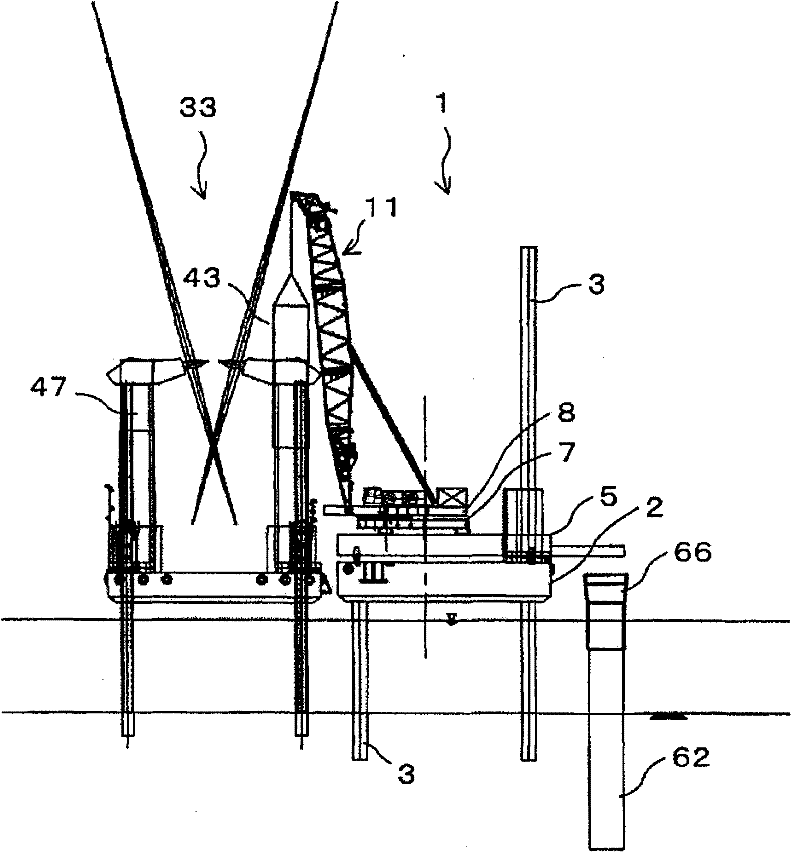

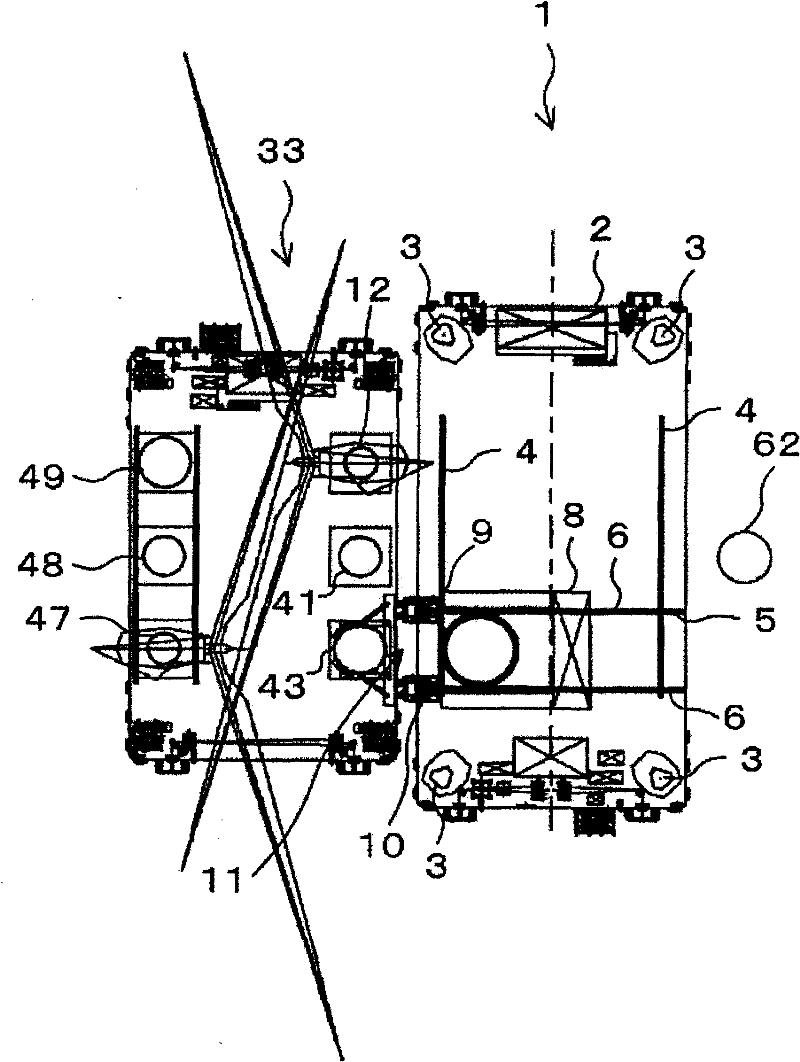

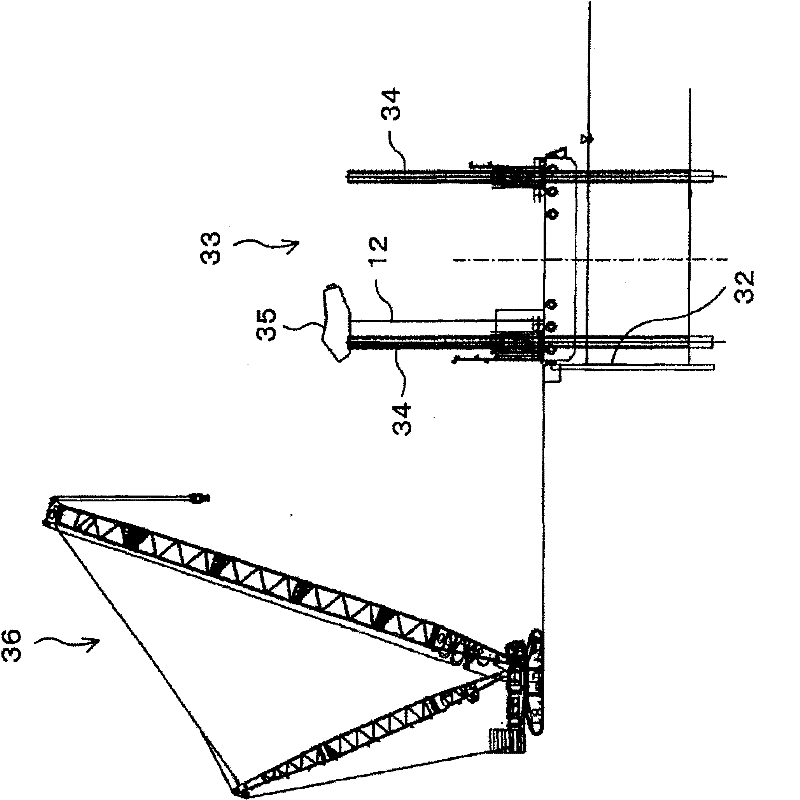

Deck-liftable operation platform and construction method for marine wind power generation facility

InactiveCN102191767AGood working efficiencyGood stabilityArtificial islandsWaterborne vesselsRotary stageTransverse axis

A deck-liftable operation platform comprises the following components: a platform body which forms a rectangular shape in plane view; a plurality of columns which are provided at four corner parts of the platform body through a mode of random insertion and extension in a vertical direction are allowed, while a hydraulic jack jacking system causes the platform body to move liftably; a walking cross beam which can randomly move on two walking rails that are laid in a long axis direction of the deck of the platform body; a moving operation trolley which is provided on the walking cross beam and can randomly move in a moving track that is laid in the long axis direction of the deck of the platform body; a suspension rod rotation platform which is rotatably provided on the moving operation trolley; and two suspension rods which are provided in a left-and-right direction and forms a pair for being mounted on the suspension rod rotation platform. Therefore the deck-liftable operation platform with high operation efficiency, high stability and high safety is provided.

Owner:DAIICHI KENSETSU KIKO +2

Open cut tunnel structure of simply supported arch of tunnel traversing huge karst cave and construction method thereof

PendingCN111396095AStable supportAchieve separationUnderground chambersMaterial fill-upArchitectural engineeringKarst

The invention relates to the field of karst tunnels, in particular to an open cut tunnel structure of a simply supported arch of a tunnel traversing a huge karst cave and a construction method thereof. The structure comprises a U-shaped substrate, an arch part simply supported arch, a vault backfill body and a bridge beam plate. The tops of two sides of the U-shaped substrate are in contact with upper surrounding rocks, a slot I is formed in one side of the inner wall of the U-shaped substrate, and a slot II is formed in the other side of the U-shaped substrate; the vault backfill body fills aspace among the upper surrounding rocks of the arch part simply supported arch; a side substrate I and a side substrate II are separately arranged on two sides of the arch part simply supported arch;the side substrate I is placed in the slot I and can shift vertically and transversely in the slot I; the side substrate II is placed in the slot II and can shift vertically and transversely in the slot II; and the bridge beam plate is placed in a space encircled by the arch part simply supported arch and the U-shaped substrate, and two ends of the bridge beam plate are located on stable foundations at two ends of the karst cave. The construction method is used to construct the structure. The open cut tunnel structure achieves dynamic and static separation and can avoid excessive structural settlement caused by dynamic and static load coupling.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Tower anchor-dock anchor combined rapid construction method for self-anchored suspension bridge

InactiveCN109137739ASolve balance problemsAvoid settingSuspension bridgeBridge erection/assemblyEngineeringTower

The invention provides a tower anchor-dock anchor combined rapid construction method for a self-anchored suspension bridge. The method comprises the following steps: step 1, synchronously constructinga main girder and a bridge tower of a side span; 2, installing a tower-beam thrust connecting device to temporarily connect the main girder of the side span with the bridge tower; 3, erecting a maincable and hoisting 60% of the number of the middle-span main beam segments, so that the horizontal component force exerted by the main cable on the main beam of the side span is jointly borne by the bridge pylon; 4, installing a pier-beam thrust connection device according to the method of the step 2 to temporarily connect the main girder of the side span with the pier; 5, hoisting the remaining middle-span main girder segments according to the method of the step 3, so that the horizontal component force exerted by the main cable on the side-span main girder is jointly borne by the bridge tower and the pier; 5, sequentially remove that pier-beam thrust connecting device and the tower-beam thrust connecting device, and completing the system conversion; and 6, tensioning the boom, dismantling the support, and completing the construction.

Owner:CHANGAN UNIV

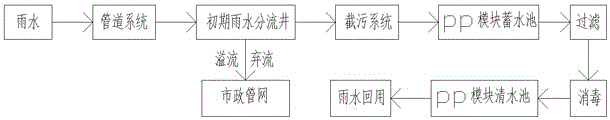

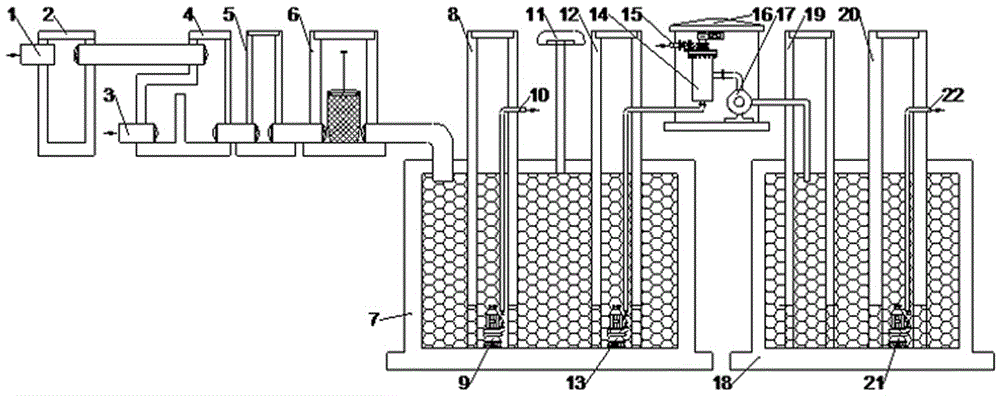

Urban building sewage treatment system, construction method and filter element material preparation process

ActiveCN106145478AAchieve reuseAchieve adsorptionFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationMaterials preparationWater treatment system

The invention relates to an urban building sewage treatment system, a construction method and a filter element material preparation process. The urban building sewage treatment system comprises a settling basin, a split well, a distributing well, a sewage intercepting well, a reservoir, a fine filtration device, a sterilization device and a clean water basin, the side face of the settling basin is provided with a water inlet pipe allowing building rain sewage to flow into conveniently, and the clean water basin is internally provided with a clean water recycling device. The urban building sewage treatment system is reasonable in design, reutilization of sewage is achieved, and the water quality of reuse water is effectively guaranteed.

Owner:ZHONGHUAN BUILDING FUJIAN CO LTD

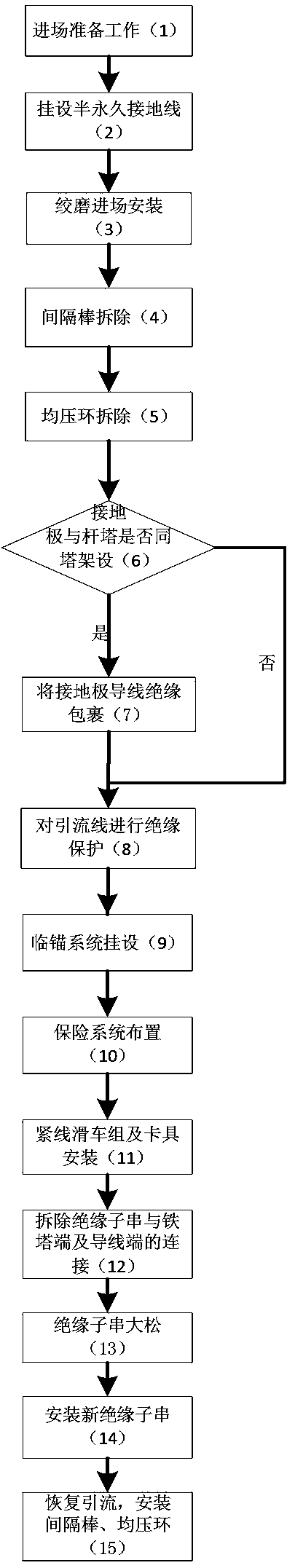

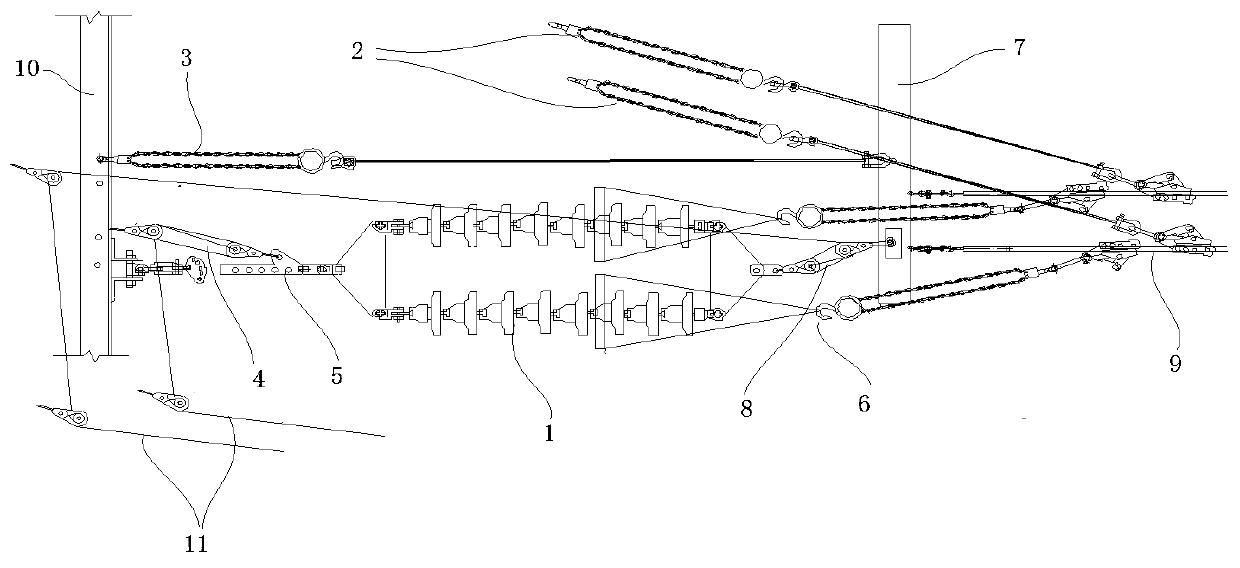

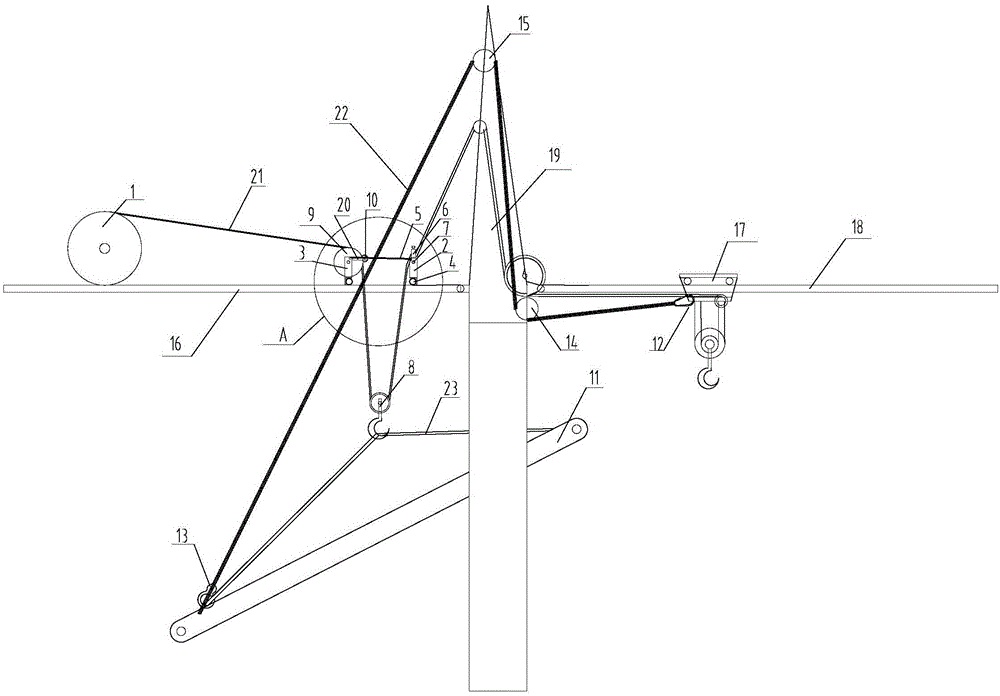

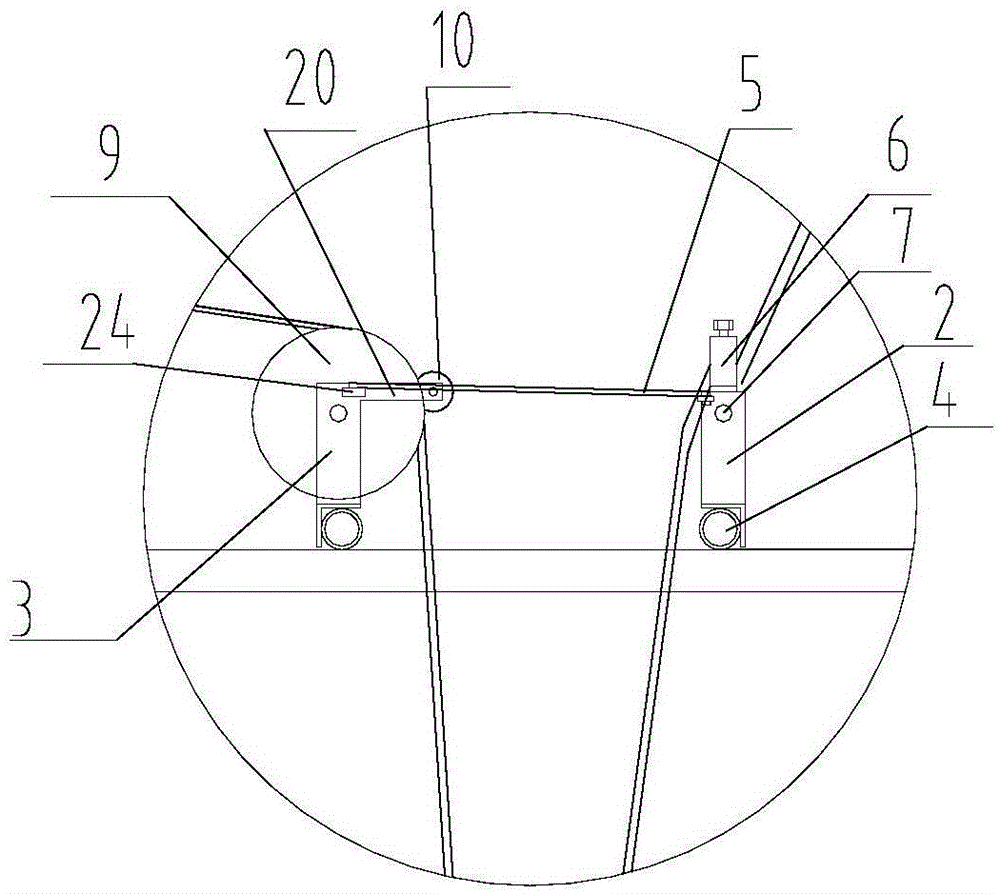

Method for replacing tension insulator of extra-high-voltage direct-current whole tower

ActiveCN110932168AEasy to replaceReduce the difficulty of replacementApparatus for overhead lines/cablesHigh-voltage direct currentPower grid

The invention discloses a method for replacing a tension insulator of an extra-high voltage direct current whole tower, and relates to the technical field of power grid transmission line maintenance.The self-explosion rate of the glass insulator is high, the design strength and the boundary dimension of the hardware fittings and the insulator in the extra-high voltage line are greatly improved compared with those of a traditional high voltage line, so the glass insulator of the extra-high voltage direct current whole tower is difficult to replace. The method mainly comprises: performing entering preparation; hanging a semi-permanent grounding wire; winching and mounting; disassembling the spacer; removing the grading ring; if the grounding electrode and the tower are erected on the same tower, insulating and wrapping the grounding electrode wire; carrying out insulation protection on drainage absorption; hanging a temporary anchoring system, and arranging a safety system; installing astringing pulley block and a fixture; removing the connection of the insulator string; removing the insulator chain loosely; installing a new insulator string; and recovering drainage, and installingthe spacer and the grading ring. According to the method, replacement of the extra-high-voltage direct-current whole-tower strain insulator is conveniently achieved, the replacement difficulty is reduced, safety and reliability are achieved, and the construction efficiency is improved.

Owner:浙江省送变电工程有限公司 +2

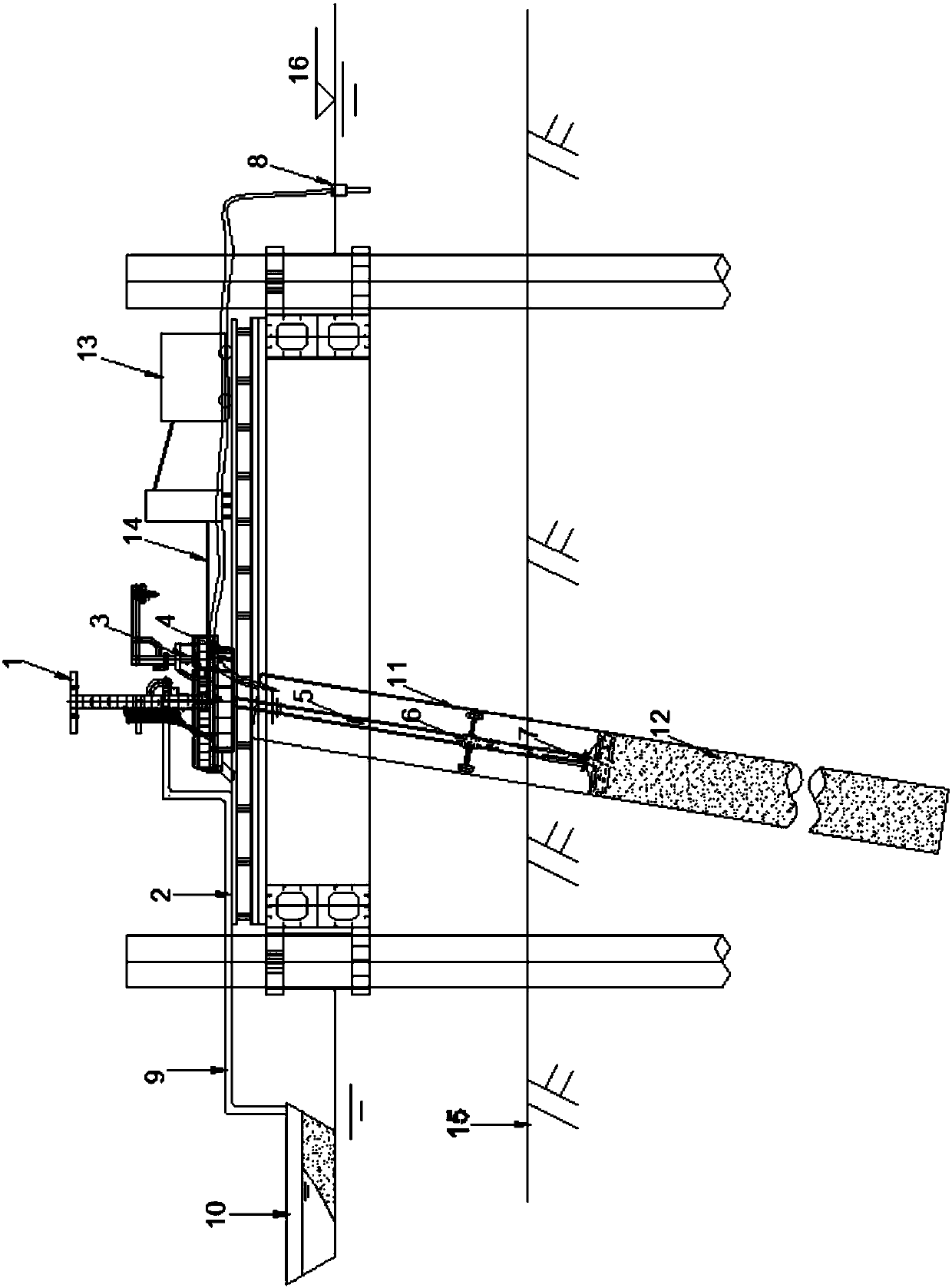

Disassembling and installation method for tower crane attachment

ActiveCN105060138AImprove construction efficiencyEnsure construction safetyCranesPulleyArchitectural engineering

The invention provides a disassembling and installation method for a tower crane attachment. The disassembling and installation method comprises a steel wire rope fixing frame, a fixed pulley device, a fixed pulley B, a fixed pulley C and an installation rope, wherein the steel wire rope fixing frame and the fixed pulley device are sequentially fixedly arranged on a balance arm of a tower crane and between a lifting hoist and a tower cap, the steel wire rope fixing frame is installed on one side close to the tower cap, the fixed pulley B is fixed at the lower end of the joint of a crane beam and the tower cap, the fixed pulley C is fixed at the upper end of the tower cap, an installation lasso steel wire rope passes by the fixed pulley B and the fixed pulley C, and a grabber at one end is connected with a luffing trolley. Compared with the prior art, the disassembling and installation method provided by the invention achieves the installation and disassembling for the crane attachment by additionally arranging two pulley devices on the crane, and utilizing the lifting steel wire rope of the tower crane simultaneously, and the construction method is safe and reliable, and high in construction efficiency, so that the construction progress can be effectively promoted, and the construction safety can be ensured.

Owner:REAL ESTATE CONSTR ANGANG GROUP

Construction method and system for hole cleaning and sediment thickness reducing of inclined steel pipe pile

ActiveCN107816324AGuaranteed flatnessImprove pile end bearing capacityDrilling rodsFlushingDrill holeRiver water

The invention discloses a construction method and system for hole cleaning and sediment thickness reducing of an inclined steel pipe pile, and relate to the field of pile foundation construction. Themethod includes the following steps of S1, drilling holes through a reverse circulation drilling machine, and starting a gas lifting reverse circulation system to conduct sediment cleaning; S2, conducting sampling in a sediment discharge pipe after clean water flows out of the sediment discharge pipe, meanwhile the sand content of discharge, and stopping the gas lift reverse circulation system when the sand content is measured to be lower than 0.5%; S3, adding an alum or polyacrylamide solution into the inclined steel pipe pile, and starting the reverse circulation drilling machine to make theadded alum or polyacrylamide solution circulate and flow; S4, standing for 2-4 fours, and then starting the gas lift reverse circulation system for thoroughly removing sediments. By means of the method, the influences of hole drilling by means of turbid river water under silty-fine sand and intermediate-fine sand stratum structural conditions can be overcome, the good flatness of a soil insertingsurface is guaranteed, and the pile end bearing capacity is effectively improved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Anchor cable opposite-puling type supporting and protecting structure system and construction method thereof

PendingCN111412002AImprove the force characteristicsSolve problems such as uneven settlement deformationMaterial fill-upAnchoring boltsArchitectural engineeringStructure system

The invention relates to a tunnel supporting and protecting system, in particular to an anchor cable opposite-puling type supporting and protecting structure system and a construction method thereof.The supporting and protecting structure system comprises a vertical guide hole, a main tunnel, a first opposite-pulling anchor cable and a second opposite-pulling anchor cable; the vertical guide holeis arranged in a rock body above the main tunnel and is arranged parallel to the main tunnel; the first opposite-pulling anchor cable is arranged from top to bottom; the upper end of the first opposite-pulling anchor cable is fixed to the ground surface; the lower end of the first opposite-pulling anchor cable is fixed to the vertical guide hole; the second opposite-pulling anchor cable is arranged from the top to the bottom; the upper end of the second opposite-pulling anchor cable is fixed to the vertical guide hole; and the lower end of the second opposite-pulling anchor cable is fixed tothe main tunnel. The construction method is used for constructing the supporting and protecting structure system. The supporting and protecting structure system and the construction method provided bythe invention can effectively control the overall settlement of a tunnel structure, ensure the operating safety, and provide a new idea and a new method for a tunnel penetrating through a giant cavern hall.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

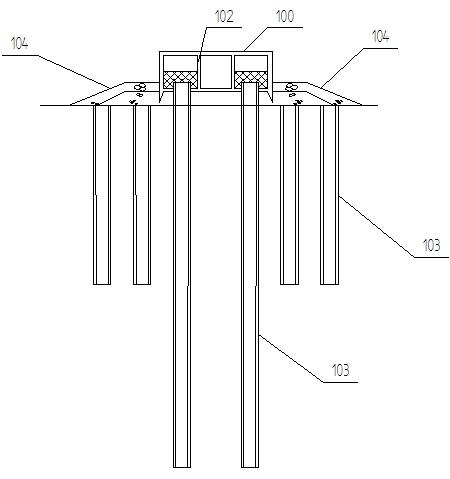

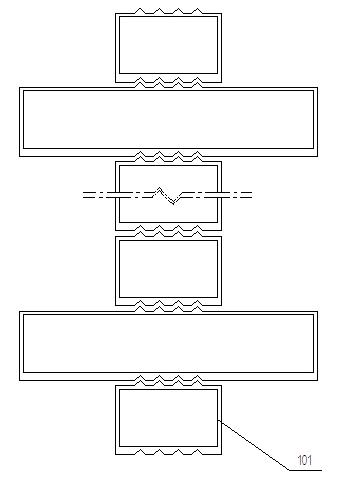

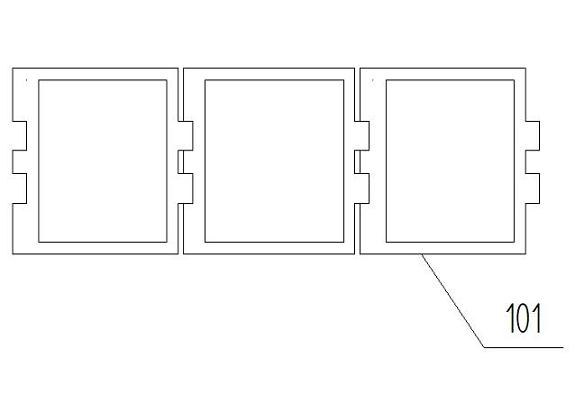

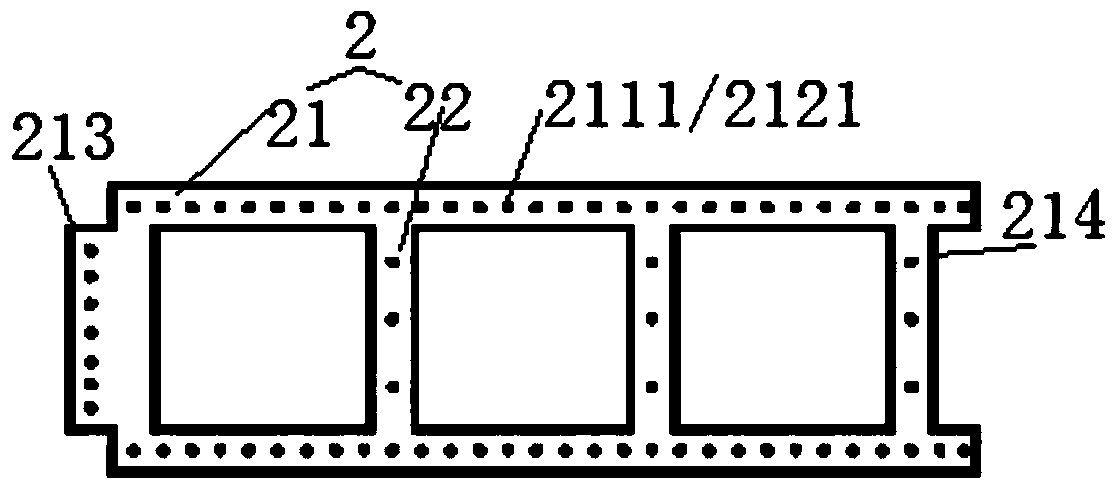

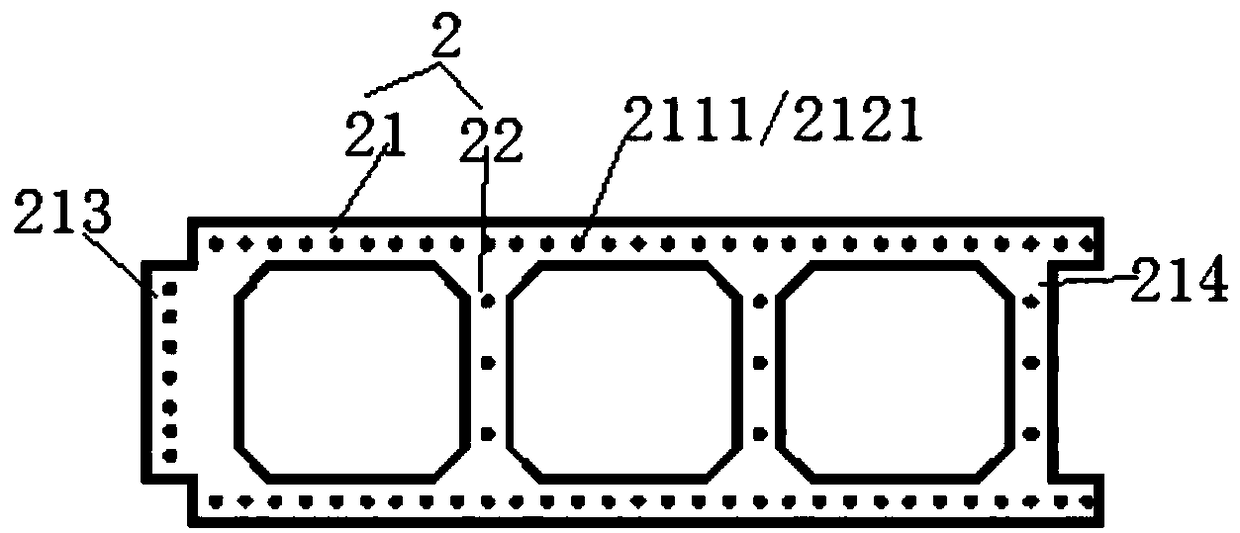

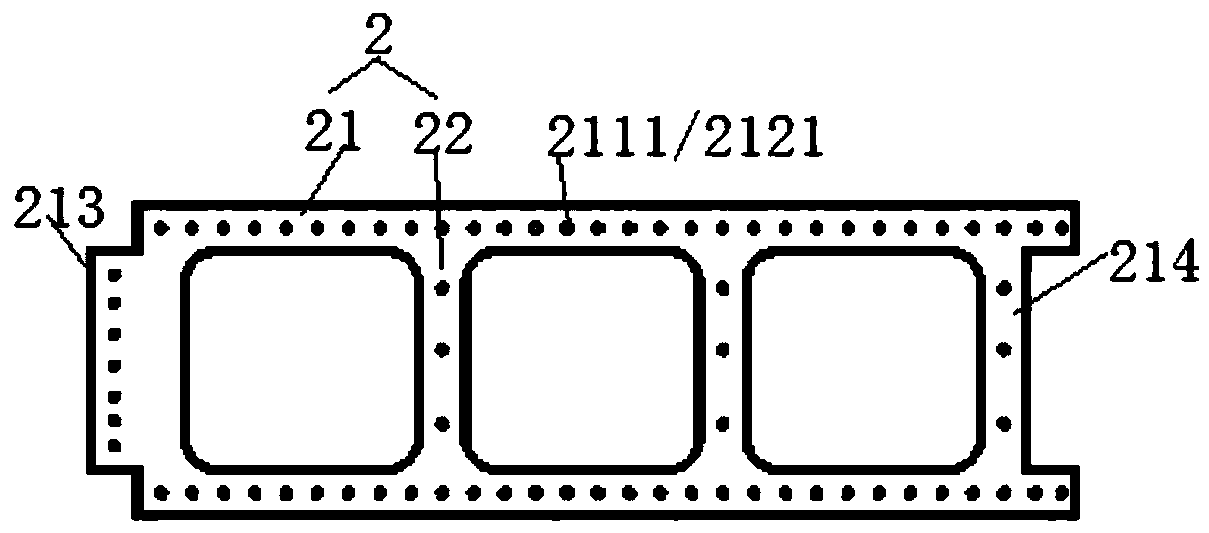

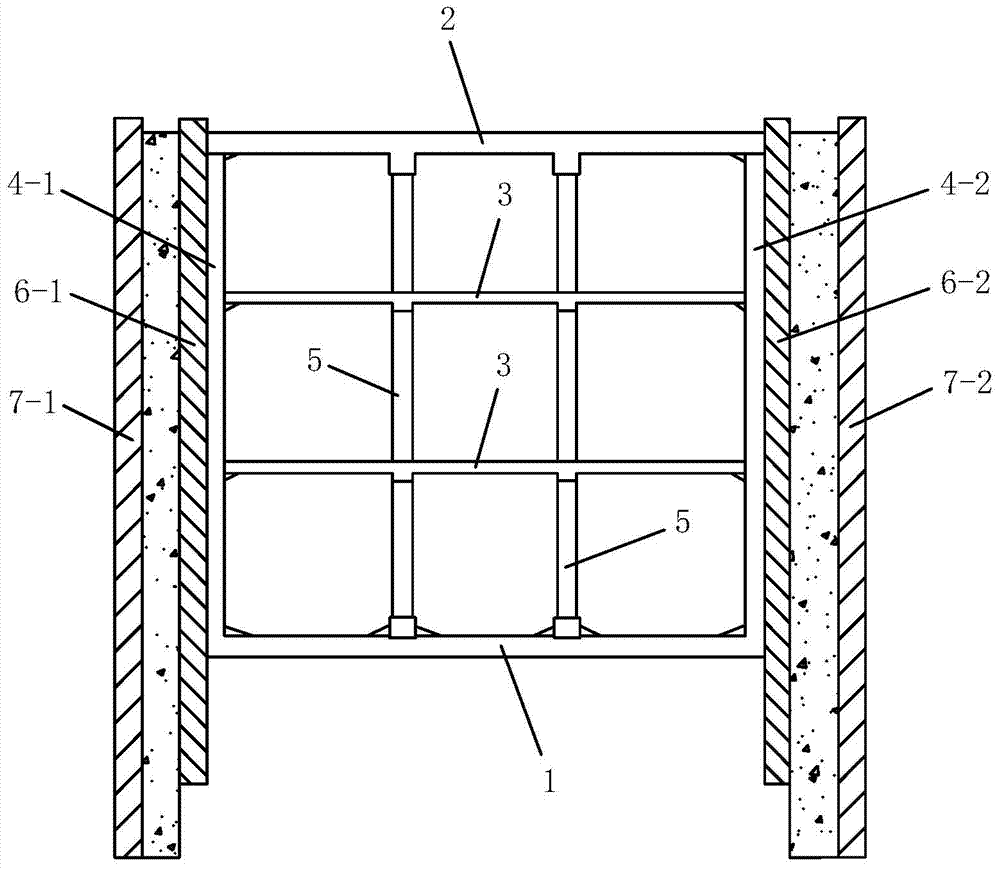

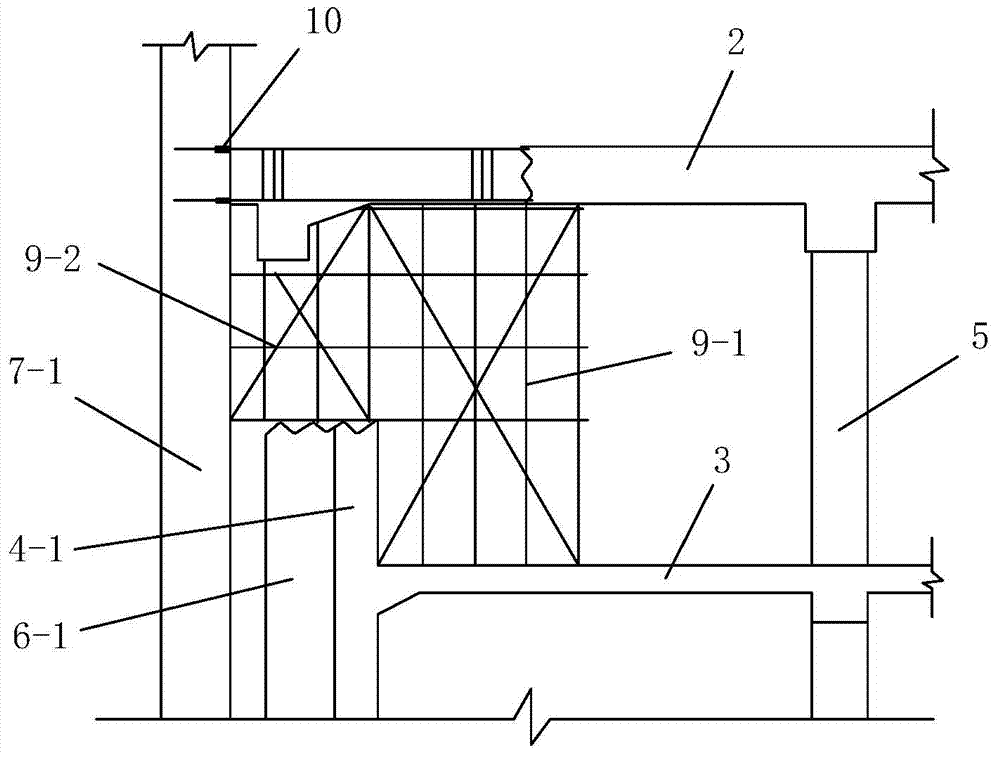

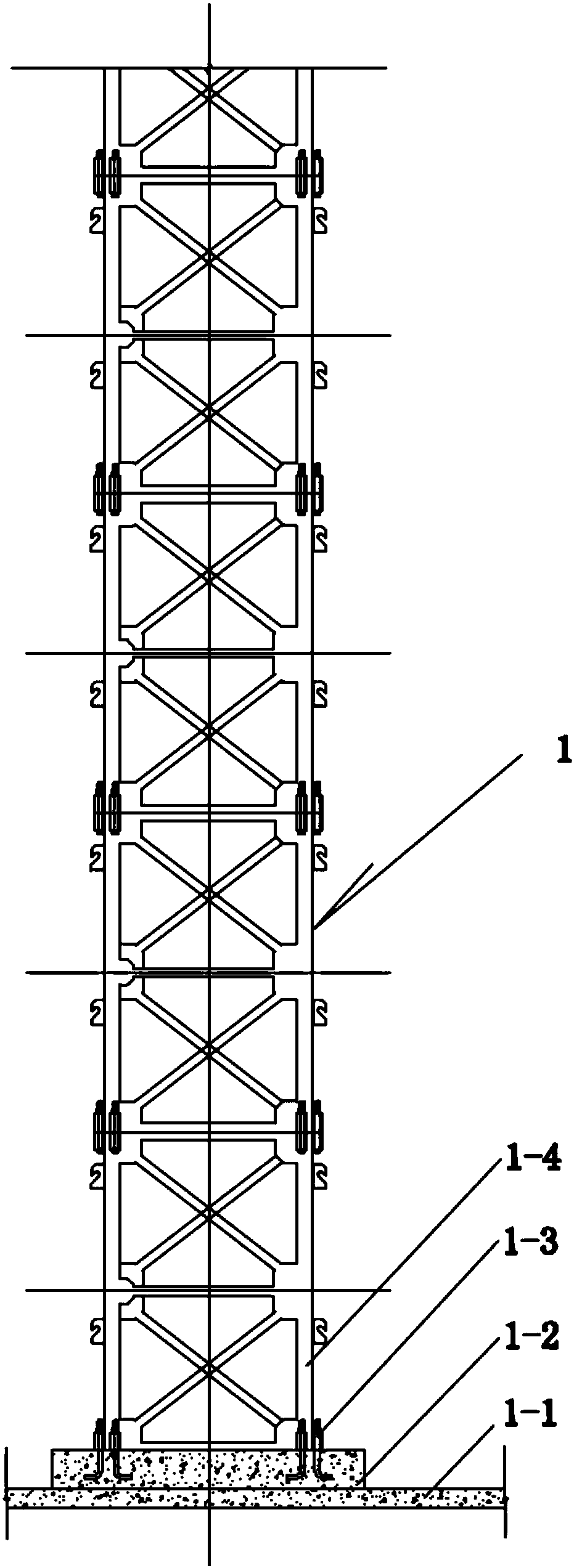

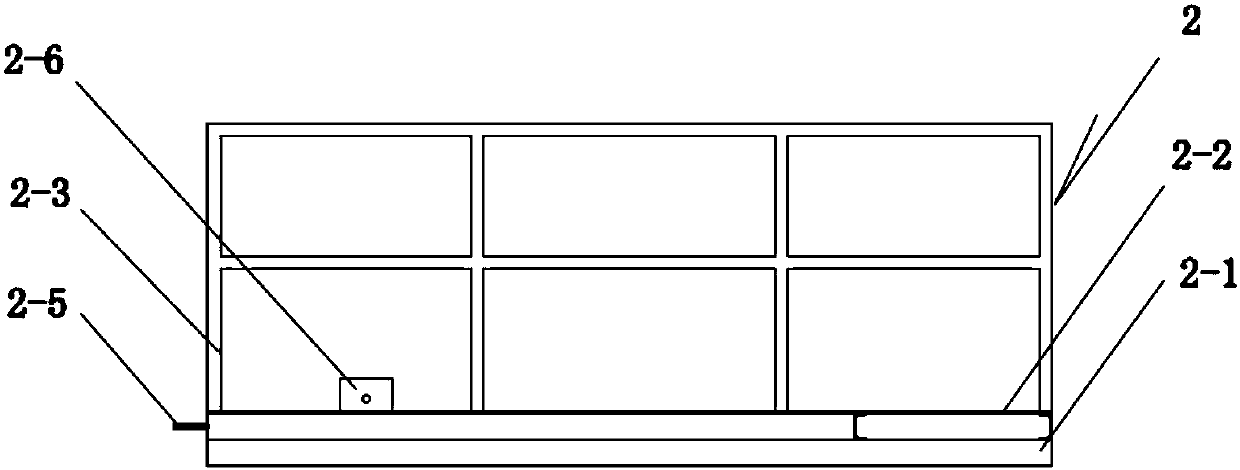

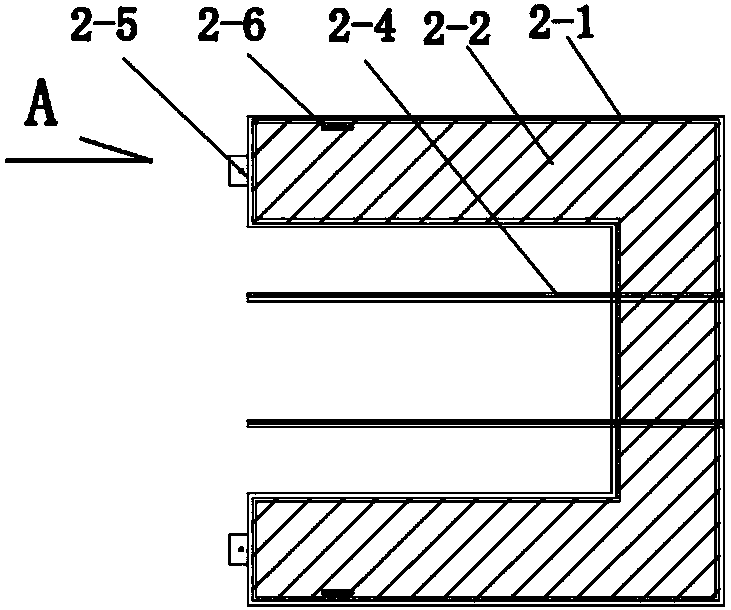

Prefabrication combined box type underground diaphragm wall and construction method thereof

PendingCN109281313ASafety and civilized construction optimizationLabor savingBulkheads/pilesConstrictionSlurry wall

The invention discloses a prefabrication combined box type underground diaphragm wall comprising prefabrication box type underground diaphragm wall components as foundation pit retaining structures. Each prefabrication box type underground diaphragm wall component comprises a box provided with a hollow part, and a web arranged in the box, wherein the vertical two ends of the box are provided withfirst tenons or first mortises, and the transverse two ends of the box are provided with second tenons or second mortises. Adjacent prefabrication box type underground diaphragm wall components are connected through mortise-tenon structures to form a combined box type underground diaphragm wall body. The invention further discloses a construction method of the prefabrication combined box type underground diaphragm wall. For the prefabrication combined box type underground diaphragm wall and the construction method thereof, the box type underground diaphragm wall components made through factory-like concentrated prefabrication are adopted for plane and vertical combined assembly of a foundation pit, any foundation pit plane forms can be formed, flexibility is achieved, prefabrication quality is high, constriction quality is stable, stress participation can be conducted in time, a large amount of labor force is saved, and cost is reduced.

Owner:GUANGZHOU METRO DESIGN & RES INST

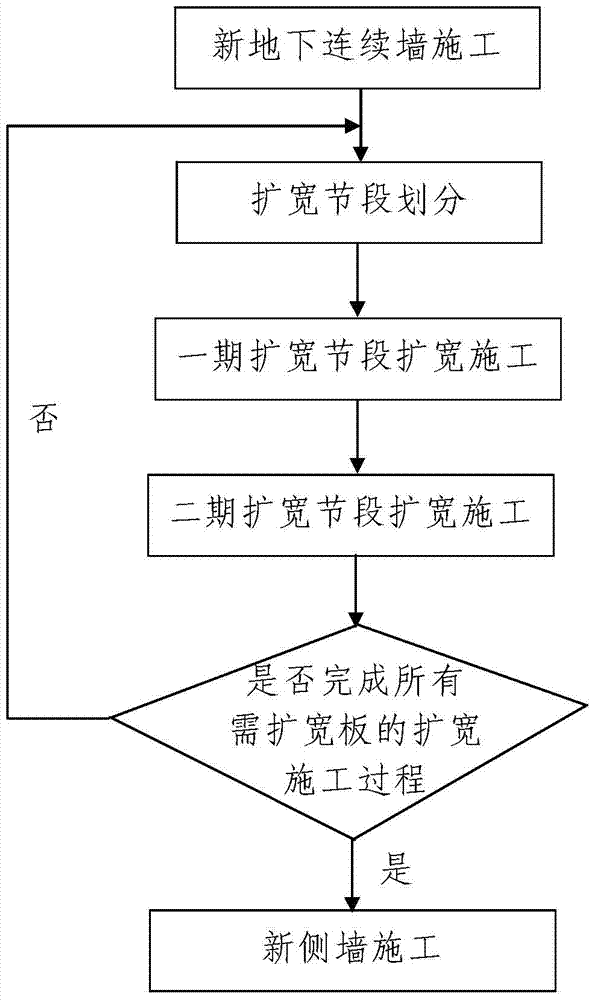

Safe stress conversion construction method for improvement on main structure of subway station

ActiveCN103485366ASimplify construction stepsEasy constructionArtificial islandsUnderwater structuresSlurry wallSubway station

The invention discloses a safe stress conversion construction method for the improvement on a main structure of a subway station. The safe stress conversion construction method comprises the following steps: the first step is construction of a novel underground diaphragm wall; the second step is broadening construction, wherein a top plate, a middle plate and a bottom plate are respectively broadened from top to bottom, the top plate, the middle plate and the bottom plate all need broadening, and the broadening construction method of the top plate, the broadening construction method of the middle plate and the broadening construction method of the bottom plate are the same; an actual broadening construction process comprises broadening segment division, first-stage broadening segment broadening and second-stage broadening segment broadening; the third step is construction of a novel side wall, wherein a second left side wall and a second right side wall are constructed on the left side and the right side of the multiple broadened plates respectively after broadening construction in the second step is completed. According to the safe stress conversion construction method for the improvement on the main structure of the subway station, the steps are simple, the design is reasonable, implementation is convenient, investment cost is low, construction progress is fast, the construction effect is good, and the improvement process of the main structure of the subway station can be completed simply, conveniently and quickly.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

Construction method of transfer layer bailey frame platform of high-rise building

ActiveCN108019040AEasy to guarantee the construction periodGuaranteed construction periodBuilding material handlingHigh riseBuilding construction

The invention relates to a construction method of a transfer layer bailey frame platform of a high-rise building and belongs to the technical field of building construction. The construction method mainly comprises the steps that lattice columns are mounted; bailey frames are erected; I-shaped beams are hoisted; crossbeam formwork bottoms are built; sandwich plates are built; and transfer layers are constructed. Compared with the prior art, under the premise that the quality can be guaranteed, the construction method has the multiple remarkable advantages of convenient implementation, safety and reliability.

Owner:JIANGSU HUAJIAN CONSTR

Method for constructing hyperbolic curve funnel wall of tamping coke coaling tower

ActiveCN102373808AGuaranteed fixed precisionCurvature design is scientific and reasonableForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksTowerRebar

The invention relates to a method for constructing a hyperbolic curve funnel wall of a tamping coke coaling tower, which comprises the following steps: (1) manufacturing and pre-installing a template for forming the hyperbolic curve funnel wall; (2) calculating a reinforcing steel bar support frame of a template of an external wall of the hyperbolic curve funnel wall, wherein the distance X between the external wall of the hyperbolic curve funnel wall and the coal tower vertical wall is equal to (d / 2)*e<kcy / 2> when the highness is increased by 500mm each time; (3) manufacturing the reinforcing steel bar support frame, wherein the reinforcing steel bar support frame is made of phi 25 twisted steel, and the gradient of the reinforcing steel bar support frame is the same as the gradient of the external wall of the hyperbolic curve funnel wall when the highness is increased by 500mm each time; (4) installing and fixing a template of an internal wall and the template of the external wall; (5) pouring and casting concrete; and (6) removing the templates and maintaining. The method provided by the invention is simple and easy, the curvature of the external wall of the hyperbolic curve funnel wall can be effectively ensured, the construction speed is improved, the construction quality is guaranteed, and the invention provides the safe and reliable method for constructing the hyperbolic curve funnel wall of the tamping coke coaling tower.

Owner:MCC TIANGONG GROUP

Rear concrete thermal curtain wall connecting piece and construction method

The invention discloses a rear concrete thermal curtain wall connecting piece and a construction method. The connecting piece comprises a pre-buried supporting base and a connection rod, the pre-buried supporting base comprises a connector and connection steel ribs, and the connector is fixed to a surface layer steel rib of a main body concrete structure through the connection steel ribs; the tail end of the connector is pre-buried in the main body concrete structure, and the open end of the connector is attached to the inner surface of a formwork of the main body concrete structure; an internal thread is disposed on the inner wall of the connector, the outer wall of one end of the connection rod is provided with an external thread matched with the inner thread, and a through hole is formed in the other end of the connection rod. The pre-buried portion and the connection portion of the connecting piece are of a split structure, the pre-buried supporting base is buried in the main body concrete structure, the formwork for main body concrete construction is not damaged, and loss of the formwork is avoided; the connection rod and the pre-buried supporting base are fixedly installed together through the threads, and the connecting piece is higher in standardization degree, safer, more reliable and firmer in structure. The construction method is safer, quicker to implement and higher in efficiency.

Owner:HENAN NO 1 CONSTR ENG GRP +2

Construction method for rapidly passing through high-outburst mine underground gob through advanced bag pre-grouting

InactiveCN109488340ASolve support problemsEnsure construction safetyUnderground chambersTunnel liningSlurryCement grout

The invention relates to a construction method for rapidly passing through a high-outburst mine underground gob through advanced bag pre-grouting. Pressurized by a grouting pump, cement grout is filled into bags via a grouting pipe to form cylindrical cement columns around the contour of roadway extraction to support and reinforce the roof and the surrounding rocks of a roadway and further to forma layer of waterproof and stable bearing case on the surrounding rocks of the pre-excavated roadway; meanwhile, lapped sections can serve as advanced anchor bolts to achieve the aim of prolonging theself-stabilization time of the rocks, improving the self-stabilization capacity of the surrounding rocks of an excavated surface and limiting stratum loosened deformation.

Owner:PINGMEI SHENMA CONSTR ENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com