Deck-liftable operation platform and construction method for marine wind power generation facility

A deck-lifting and operating platform technology, which is applied to wind power generator components, wind power generation, wind power engines, etc., can solve problems such as tower or windmill shaking operations, narrow loading space, and less loading capacity, so as to improve handling efficiency and quickly Suspension and fall-prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to make the above and other objects, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

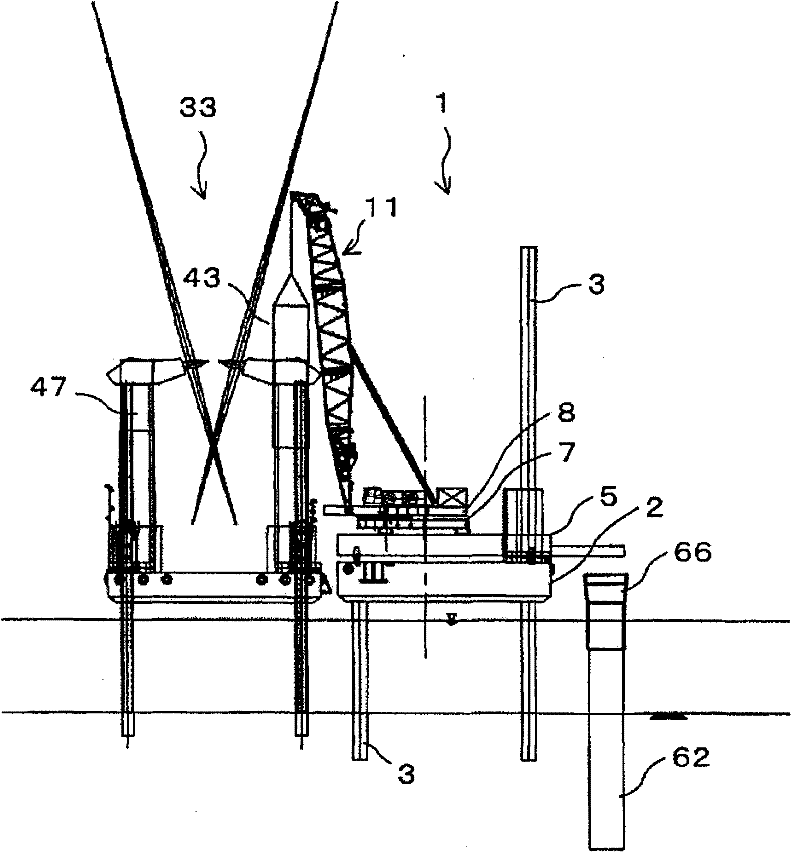

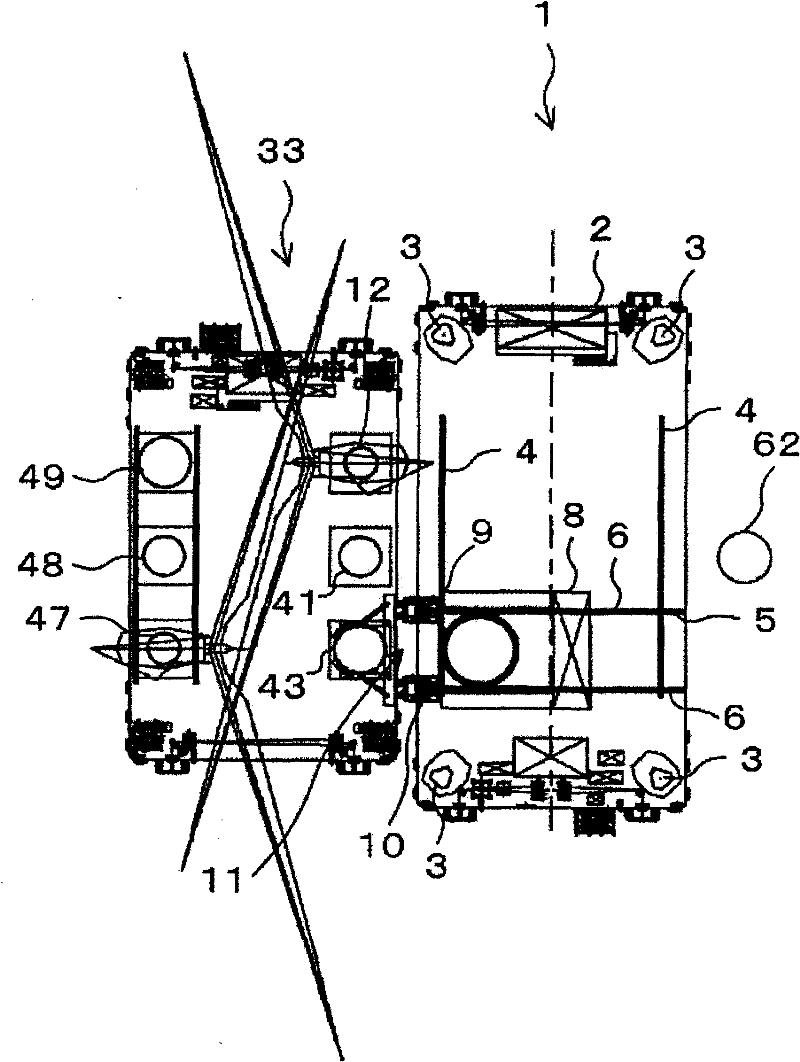

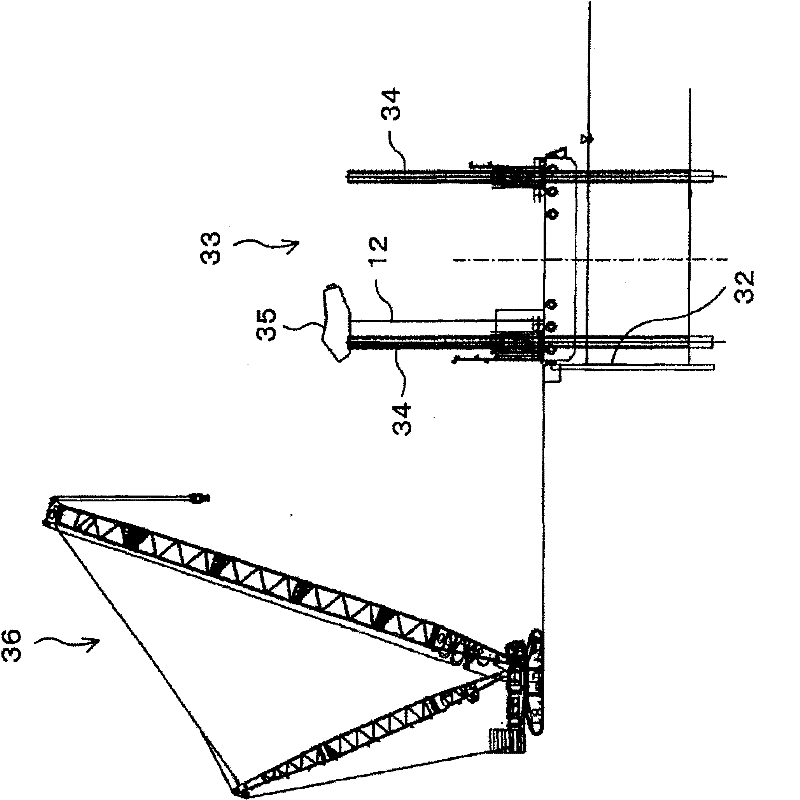

[0078] Please refer to Figure 1A , 1B Among them, the first embodiment of the present invention, which is used for the construction of offshore wind power generation facilities, is mainly disclosed. The deck lift type work platform 1 includes: a platform body 2, which is slightly rectangular in plan view; a pillar 3, which can be inserted arbitrarily and extends vertically at the four corners of the platform body 2 , so that the platform body 2 can be moved up and down arbitrarily by means of an oil hydraulic jack jacking system (the drawing is omitted); the walking track 4 is laid on the deck long axis direction (longitudinal direction) of the platform body 2; Walking beam 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com