Movable railway comprehensive operation vehicle and operation method

A working vehicle and mobile technology, which is applied in the fields of railway car body parts, transport passenger cars, transportation and packaging, etc., can solve the problems of inability to realize continuous operation of vehicles and rapid switching of vehicles, and achieve a high degree of automation and high operating efficiency. The switching process is simple and fast, and the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

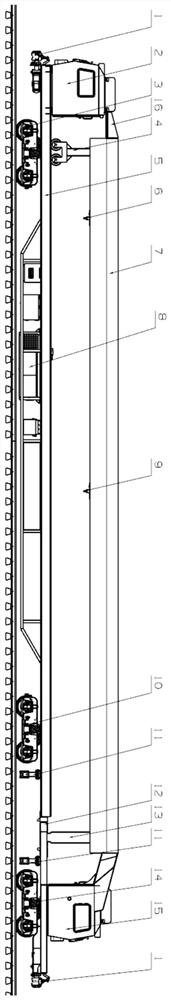

[0044] Combine below Figure 1-10 Describe in detail the preferred technical scheme of the mobile integrated railway operation vehicle:

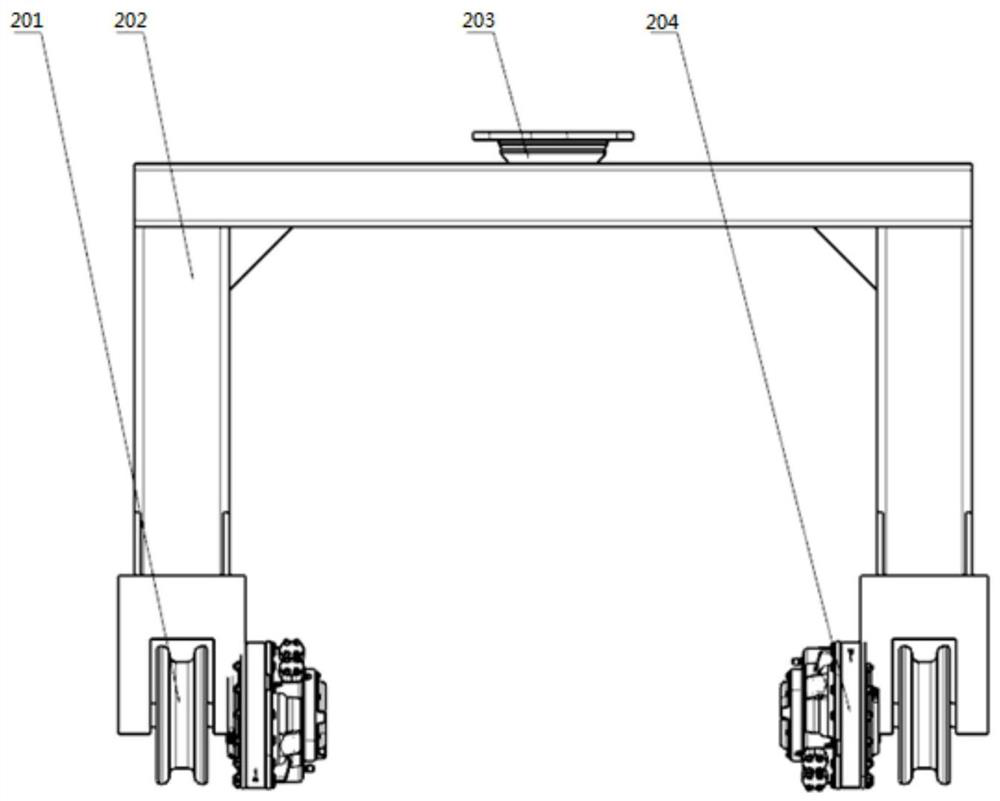

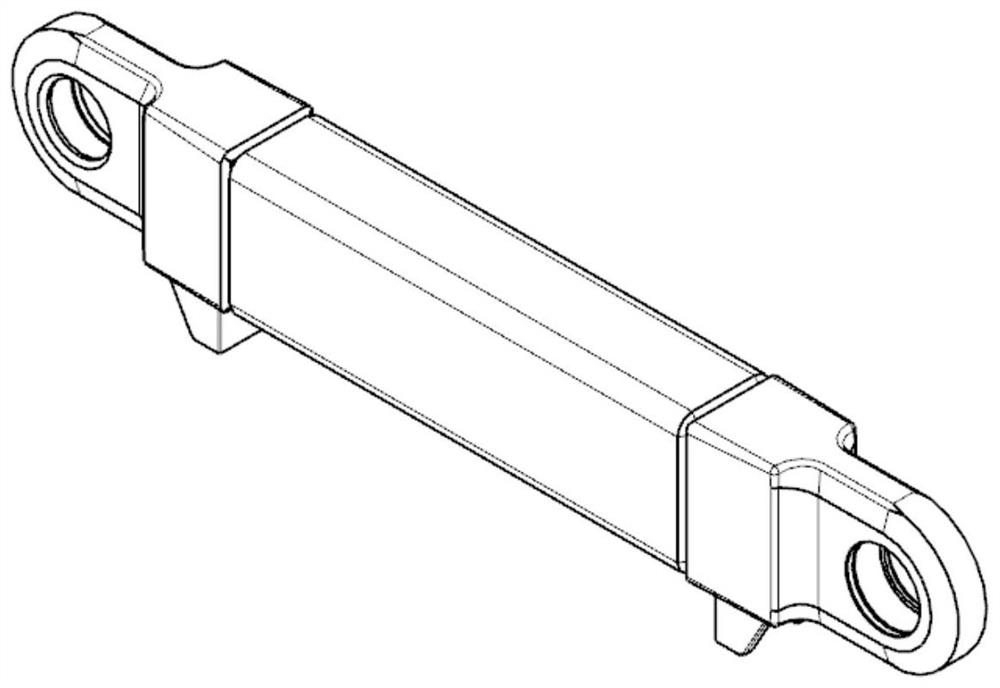

[0045] A mobile comprehensive railway operation vehicle, comprising a main vehicle and an auxiliary vehicle, the main vehicle includes a main vehicle frame 5, one end of the main vehicle frame 5 is provided with a main vehicle driver's cab 2, and the upper part of the main vehicle frame 5 is fixedly installed There are running rails, and the lower part of the main vehicle frame 5 is provided with an active bogie 3, a main vehicle power transmission system, on-board tools 8, and a driven bogie 10; the auxiliary vehicle includes an auxiliary vehicle frame 13, a workshop 7 ( The side wall part of the workshop is not shown), the auxiliary vehicle frame 13 end is provided with an auxiliary vehicle driver's cab 15, the lower part of the auxiliary vehicle frame 13 is provided with a traveling drive part 14, and a telescopic beam is provided under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com