Cross-arm bracket and method for replacing cross arm through employing same

A technology of cross arm and bracket, which is used in the installation of cables, cable installation devices, electrical components, etc., can solve the problems of manual support for disassembly and adjustment, increased torque on the human body, and laborious disassembly and adjustment. Cross arm falling off accident, high work efficiency, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

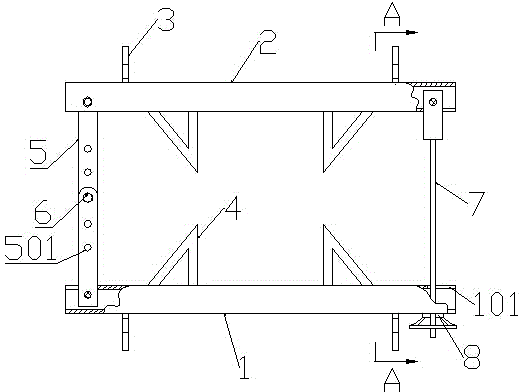

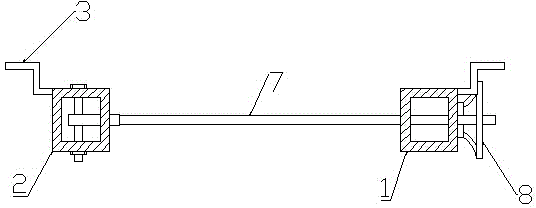

[0016] As shown in the figure, the cross-arm bracket related to the present invention includes two square steel pipes 1,2 placed in parallel in front and back, on the square steel pipes 1,2, an upwardly extending support frame 3 is provided, and the inner side of each square steel pipe 1 is provided with There are two top tensioning frames 4 arranged left and right, two square steel pipes 1 corresponding to one end are hinged with two connecting plates 5 arranged in an upper and lower dislocation, the two connecting plates 5 are provided with a plurality of connection position adjustment holes 501, and Connecting bolts 6 and nuts are installed in the two adjustment holes 501 corresponding up and down, and a lead screw 7 is arranged on the other side of the two square steel pipes 1, and the rear end of the lead screw 7 is hinged on the square steel pipe 2 at the back. There is a notch 101 at one end of the square steel pipe 1 corresponding to the lead screw 7, the front part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com