Method for replacing tension insulator of extra-high-voltage direct-current whole tower

A technology of tension insulators and UHV DC, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high replacement rate, high self-explosion rate, complicated process of glass insulators, etc., to reduce the difficulty of replacement, improve construction efficiency, and construction methods Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

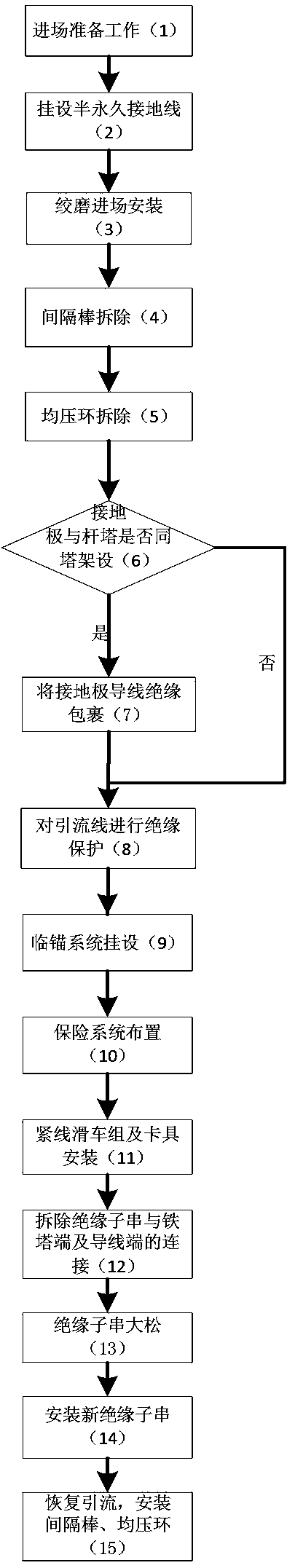

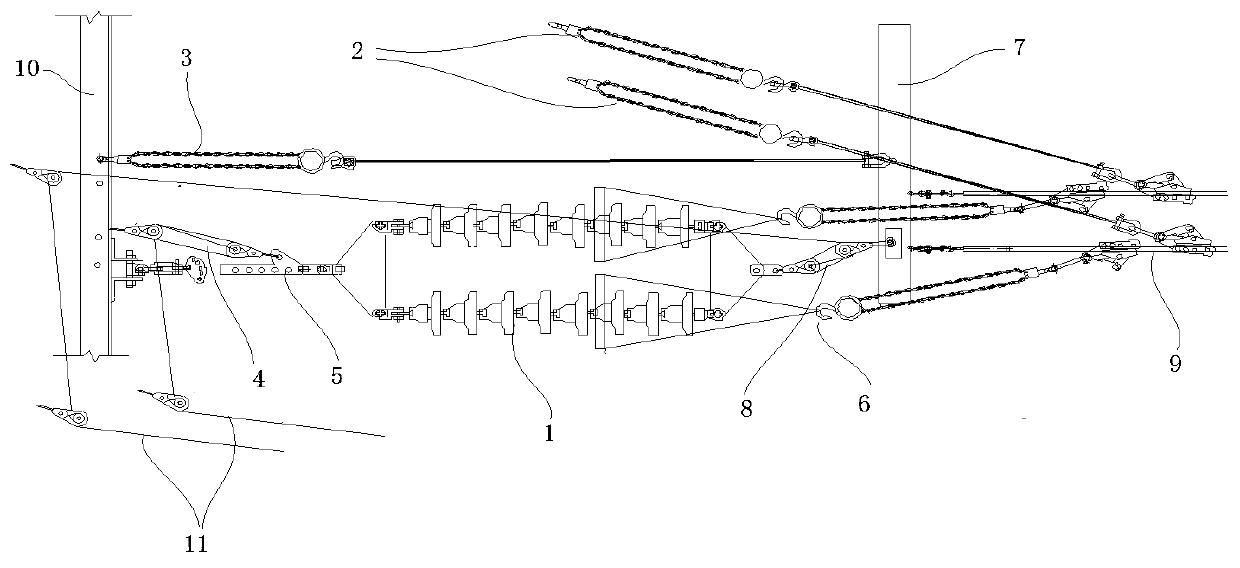

[0031] Such as Figure 1-2 As shown, a method for replacing tension insulators in the whole tower of UHV DC includes the following steps:

[0032] 1) When insulators and construction tools enter the site, arrange the construction tools neatly and conveniently for use; make safety preparations on site, including making construction site fences, placing safety production ten not dry signs clearly, and covering the site with colored strips of cloth ;Assemble the insulator on site for standby;

[0033] 2) Hang semi-permanent grounding wires on the front tension tower and rear tension tower adjacent to the construction tension tower, and use the Dinima rope as an anti-drop safety rope;

[0034] 3) Do ground anchor excavation and buried depth work well before the winching mill enters the site, and set up the pulley group at the steel wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com