Construction method for rapidly passing through high-outburst mine underground gob through advanced bag pre-grouting

A construction method and pre-grouting technology, applied in shaft lining, underground chamber, mining equipment, etc., can solve the problems of easy landslide in excavation, variable gas concentration, gas pressure, unfavorable construction, etc., to ensure construction safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

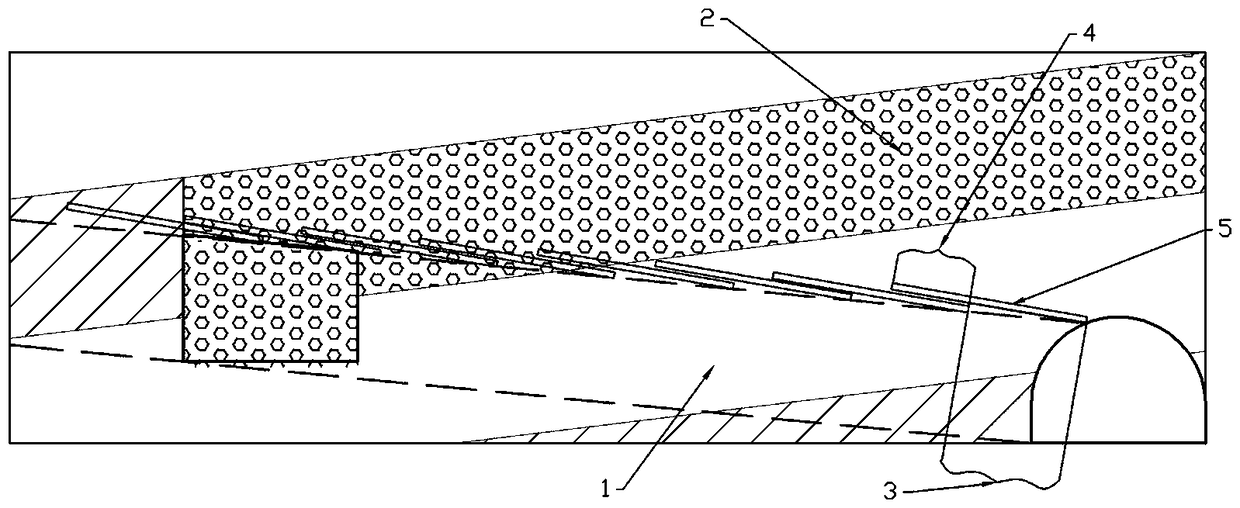

[0034] The specific embodiment of the present invention sees Figure 1-4 :

[0035] A construction method for advanced bag pre-grouting to quickly pass through the underground goaf of high outburst mines, such as Figure 1-4 , including the following steps:

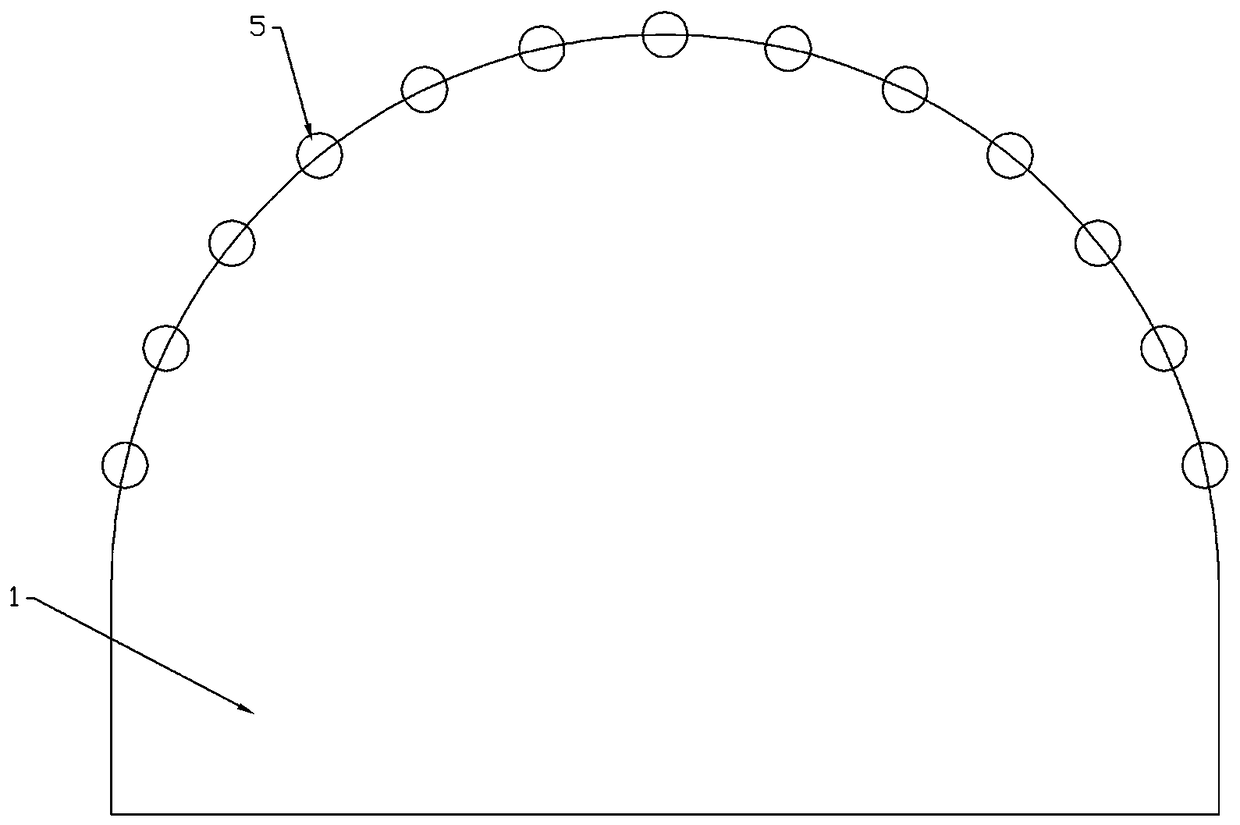

[0036] (1) Determine the path, cross-sectional shape and size of the excavated roadway 1, and the cross-section of the excavated roadway 1 is arched;

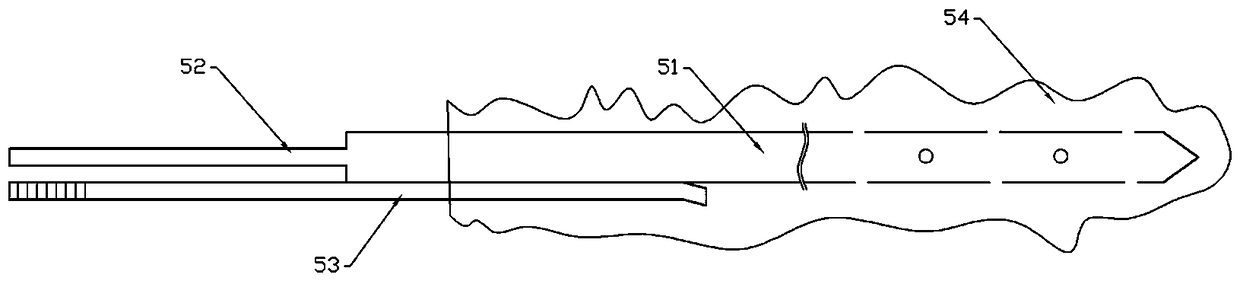

[0037] (2) Manufacture of pipe shed pipe 5: use DN40 welded steel pipe as the grouting pipe 51, the diameter of said pipe shed pipe 5 jack is not less than 55 mm, the tail end of said grouting pipe 51 is processed into a tip closed, said The starting end of the grouting pipe 51 is connected with a pipe diameter less than the grouting pipe 52 of the grouting pipe 51. The grouting hole is arranged at the afterbody of the grouting pipe 51. Exhaust pipe 53, the head of the exhaust pipe 53 is provided with threads and connected to the valve, the tail of the exhaust pipe 53 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com