Construction method of large-scan single-layer latticed shell steel structure

A technology of single-layer reticulated shell and construction method, which is applied in the direction of building structure, construction material processing, construction, etc., can solve the problems of difficult guarantee of safety and stability, high construction cost, etc., and achieve the improvement of construction safety, safety and reliability Cost, effect of ensuring installation accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] With the construction method described in the present invention, the construction of the station house cover of the Beijing-Tianjin intercity Yujiabao Station has been completed. The specific description will be given below.

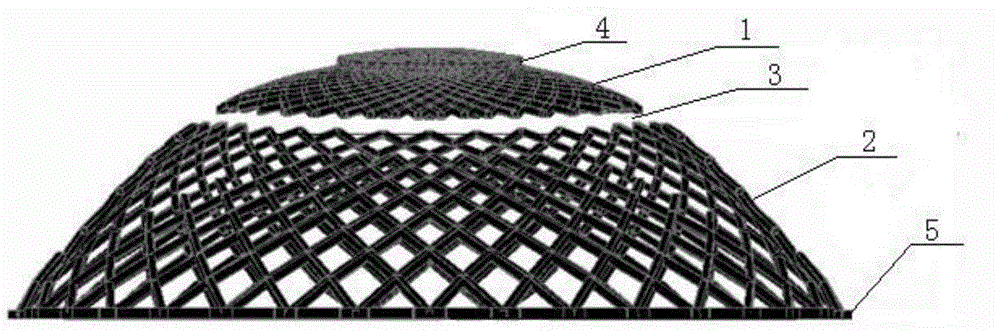

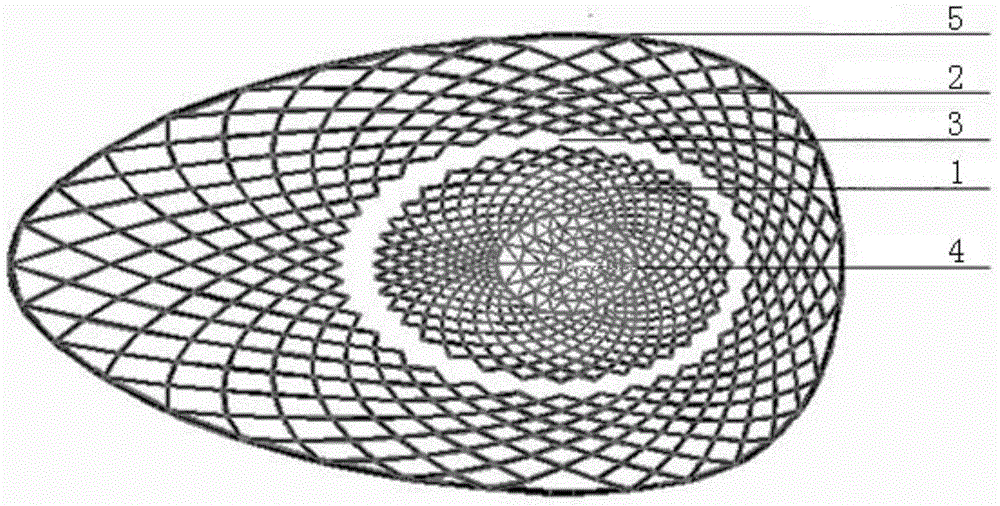

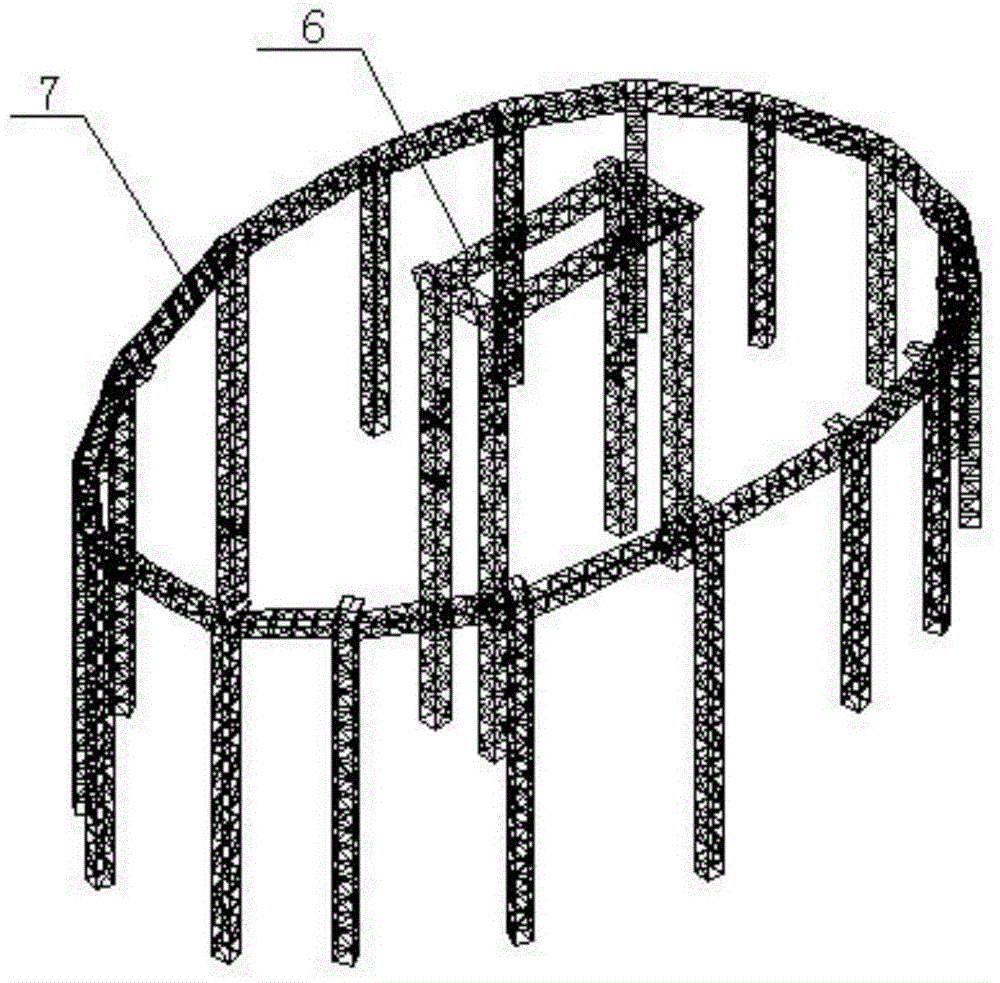

[0036]The design shape of the roof is a single-layer reticulated shell steel structure, which has a shell-shaped hyperboloid formed by cross-braiding 36 clockwise and 36 counterclockwise spatial spiral box-section rods, and its planar design size is 143m×80m, the design height is 25.8m, without any vertical support inside. Below the roof is the waiting hall on the first floor and the track area on the second floor. The height of the waiting hall and the track area are both 10 meters.

[0037] During construction, the single-layer reticulated shell steel structure is sequentially divided from top to bottom as follows: figure 1 , 2 The lifting area 1, interlocking area 3, and loose patching area 2 shown in the three areas are under construction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com