Method for constructing hyperbolic curve funnel wall of tamping coke coaling tower

A construction method and hyperbolic technology, applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, it can solve the problem of affecting the use effect, affecting the installation of equipment, Slow construction progress and other issues, to achieve the effect of reducing labor intensity, ensuring construction quality, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

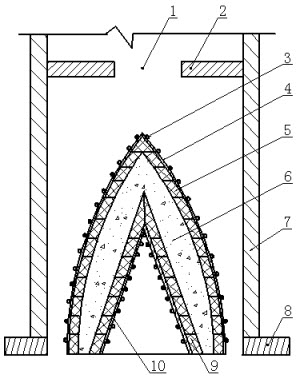

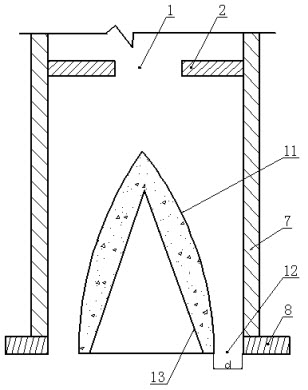

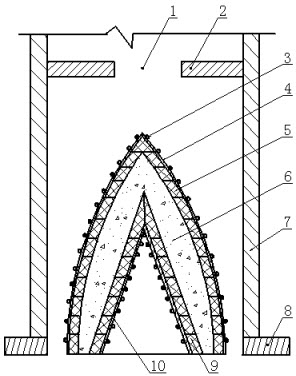

[0018] A method for constructing a hyperbolic funnel wall of a tamping coking coal tower. The tamping coking coal tower includes a coal tower top plate 2, a feeding port 1, a coal tower vertical plate 7, a long-span beam 8 and a hyperbolic funnel wall. The hyperbolic funnel wall includes The inner wall 13 and the outer wall 11, the outer wall of the hyperbolic funnel wall and the vertical wall of the coal tower form a funnel, and the steps of the construction method for tamping the hyperbolic funnel wall of the coking coal tower are as follows:

[0019] ⑴. Making and pre-installing templates for forming the hyperbolic funnel wall: making the inner wall template 9 and the outer wall template 5 according to the shape of the inner wall and oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com