Patents

Literature

43results about How to "Guaranteed curvature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Impact-resistant polypropylene composite and preparation method thereof

The invention discloses an impact-resistant polypropylene composite which comprises the following components in parts by weight: 100 parts of polypropylene, 15-25 parts of rubber, 5-10 parts of polyamic acid, 20-35 parts of inorganic filler, 1-3 parts of compatilizer, 0.5-2 parts of antioxygen, 0-1 part of antistatic agent, and 0.1-3 parts of fire retardant. According to the impact-resistant polypropylene composite, the rubber is added to raw polypropylene for modifying polypropylene, and the inorganic filler is added to the components considering that the rubber can obviously reduce flexural modulus, heat resistance and other properties of the composite, so that the prepared composite is good in impact resistance, the curvature and the heat resistance of the composite are ensured, and the composite is easy to form and process, and good in mechanical property, and can be widely applied to the field of automobiles.

Owner:SUZHOU SUNWAY POLYMER

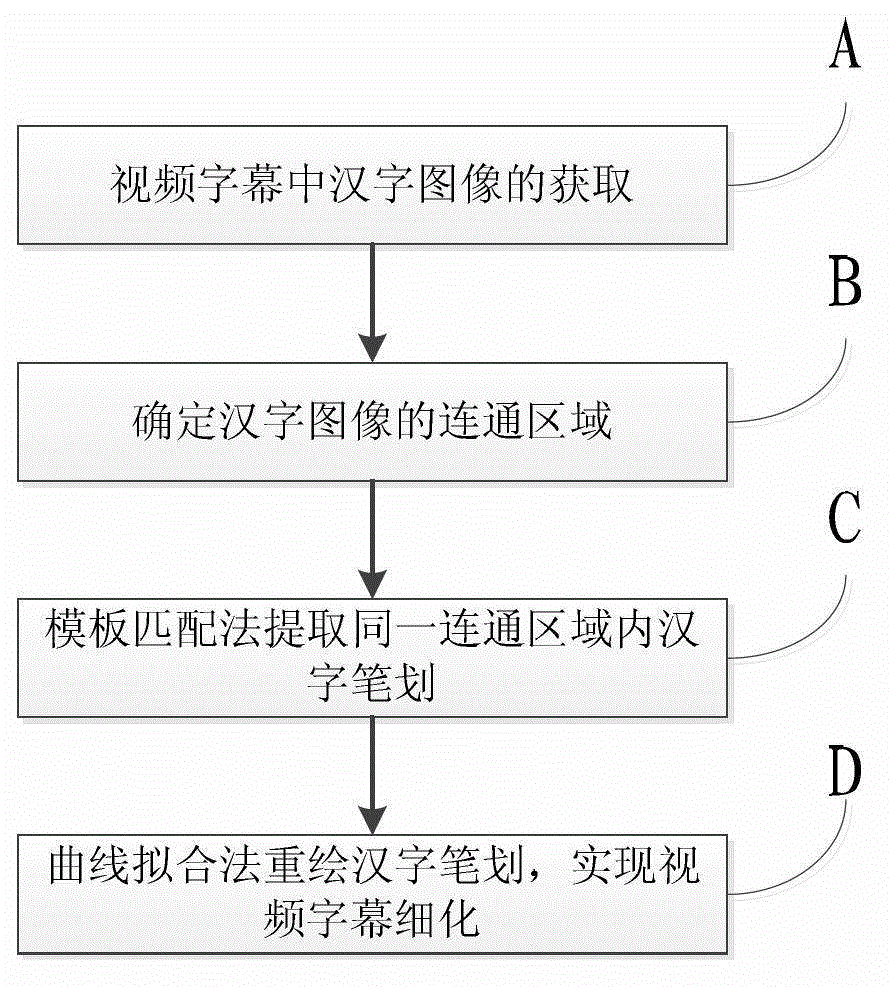

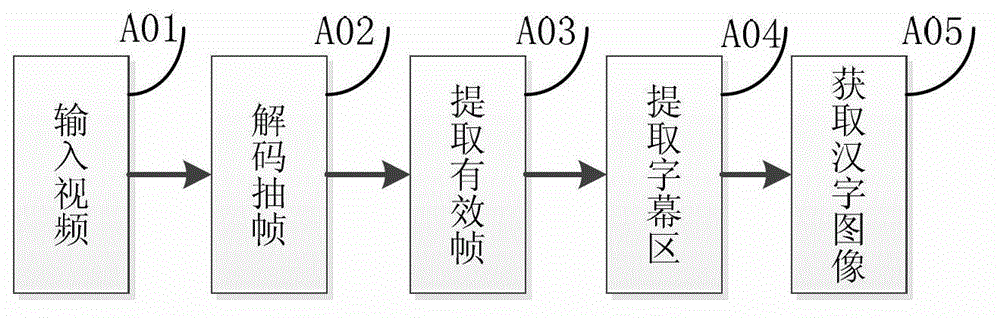

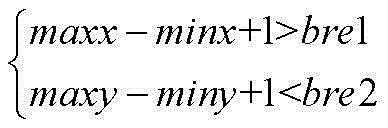

Video subtitle thinning method based on template matching and curve fitting

InactiveCN104021385AImplement refinementKeep shapeCharacter and pattern recognitionTemplate matchingChinese characters

The invention relates to the field of multimedia information processing, and specifically to a video subtitle thinning method based on template matching and curve fitting. According to the video subtitle thinning method, taking structural features of Chinese characters into consideration, strokes of Chinese characters are extracted and redrawn, thereby achieving an effect of thinning the Chinese characters, and solving the problems of stroke distortion and loss and low recognition rate which are generated when other thinning algorithms are used to perform thinning on the objects of the class. The technical points of the video subtitle thinning method in the invention includes: obtaining Chinese character images in video subtitles; determining connected regions of the Chinese character images; proposing a template matching method to extract strokes of Chinese characters in the same connected region; and proposing a method of redrawing horizontal strokes and vertical strokes with horizontal and vertical line segments, redrawing left-falling strokes and right-falling strokes with secondary Bezier curves, and redrawing dot strokes with oblique line segments, thereby realizing a thinning effect of the Chinese character images. The video subtitle thinning method based on template matching and curve fitting in the invention keeps the shapes and the stroke structures of the Chinese characters, thereby preventing a distortion phenomenon; ensures flatness of horizontal strokes, straightness of vertical strokes and bending of left-falling and right-falling strokes, thereby better redrawing the shapes of the Chinese characters; and improves a recognition effect of the video subtitles.

Owner:BEIJING INFORMATION SCI & TECH UNIV

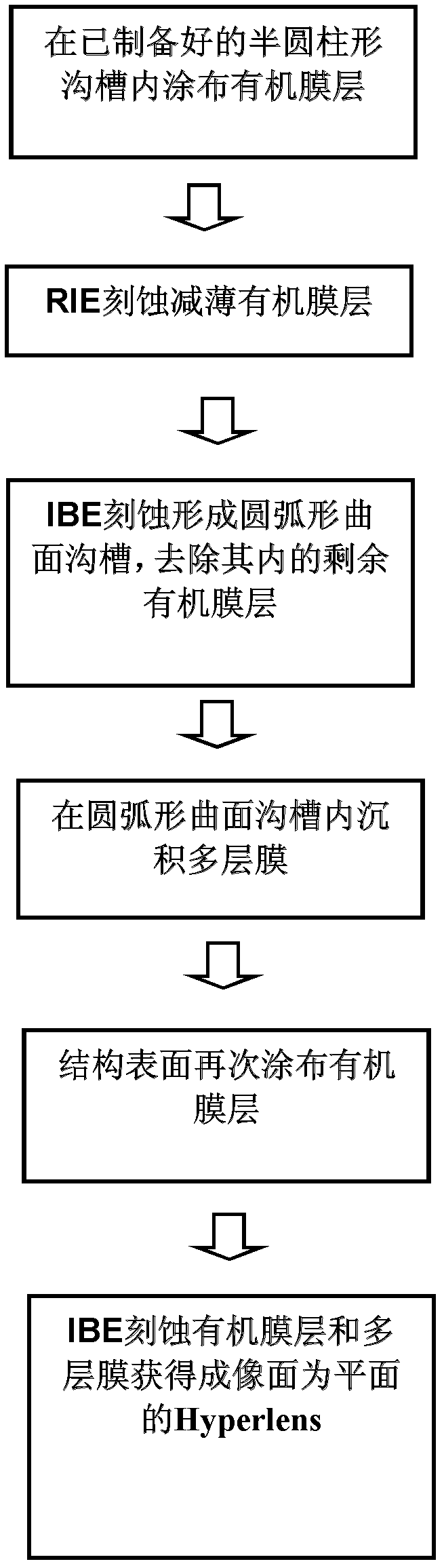

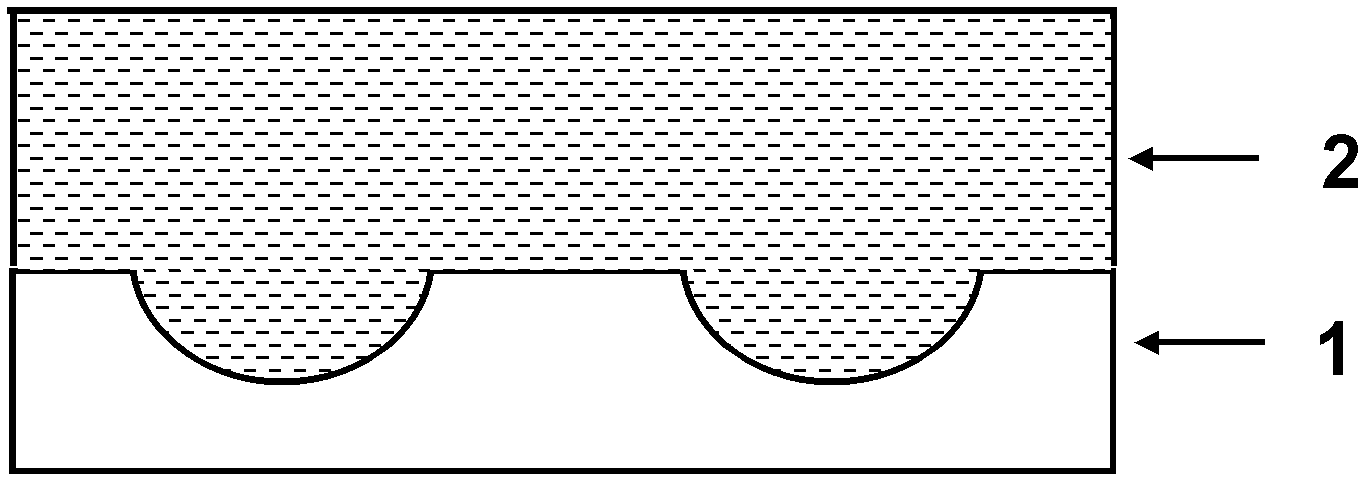

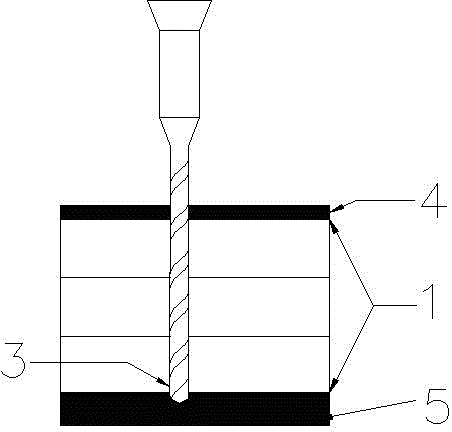

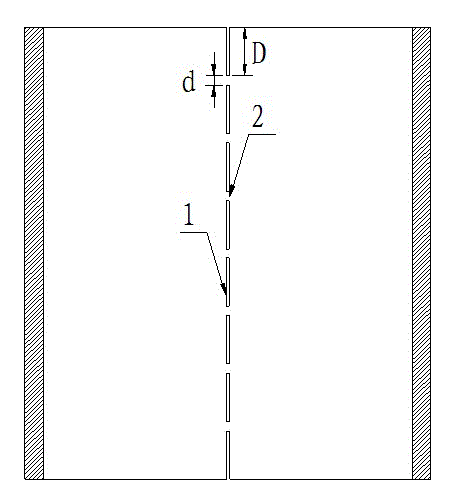

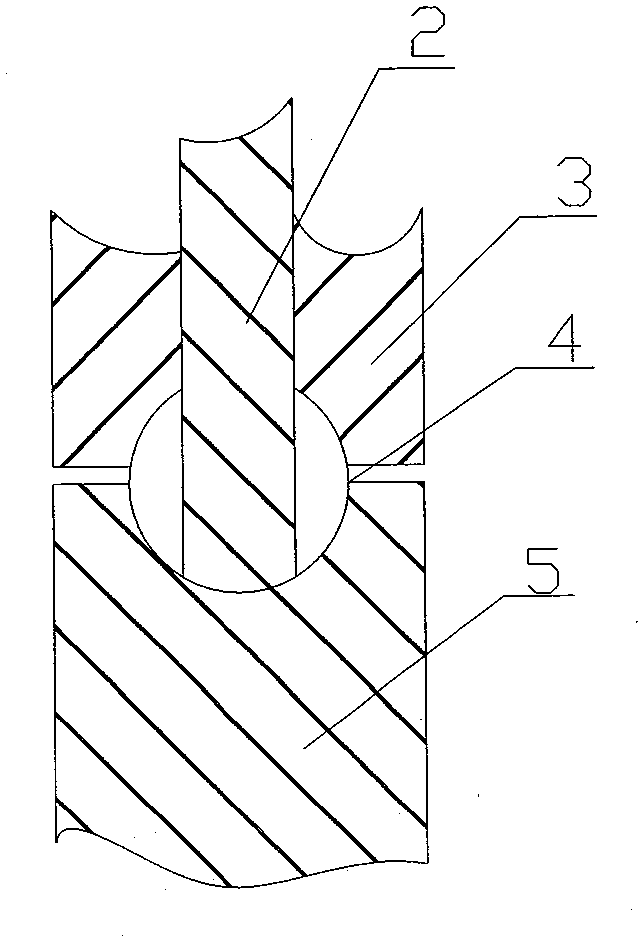

Preparation method for super-lens with plane-shaped imaging surface by using secondary ion beam etching technology

ActiveCN102633229AGuaranteed curvatureGuaranteed shapeDecorative surface effectsChemical vapor deposition coatingReactive-ion etchingIon beam etching

The invention provides a preparation method for a super-lens with a plane-shaped imaging surface by using a secondary ion beam etching technology. The preparation method mainly comprises the following steps of: etching a semi-cylindrical groove by utilizing IBE (Ion Beam Etching) to obtain a circular-arc-shaped curve groove which has the same curvature radius as the semi-cylindrical groove and has a reduced diameter depth; then depositing a plurality of films in the circular-arc-shaped curve groove; and then, etching the plurality of films by utilizing the IBE to obtain the super-lens with the plane-shaped imaging surface. The preparation method can manufacture the plane-shaped super-lens without preparing a thin film with non-uniform thickness, and can obtain the circular-arc-shaped curve groove which has the same curvature as the semi-cylindrical groove and has the random diameter depth; the plurality of films with uniform thickness are deposited on the circular-arc-shaped curve groove and then the super-lens with the plane-shaped imaging surface is prepared on the circular-arc-shaped curve groove through the IBE etching technology. The preparation method only needs to adopt the conventional ion beam etching technology, a thin film depositing technology and a reaction ion etching technology to obtain the circular-arc-shaped curve groove which has the same curvature as the semi-cylindrical groove and has the random diameter depth, and the super-lens with the plane-shaped imaging surface can be prepared on the base.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

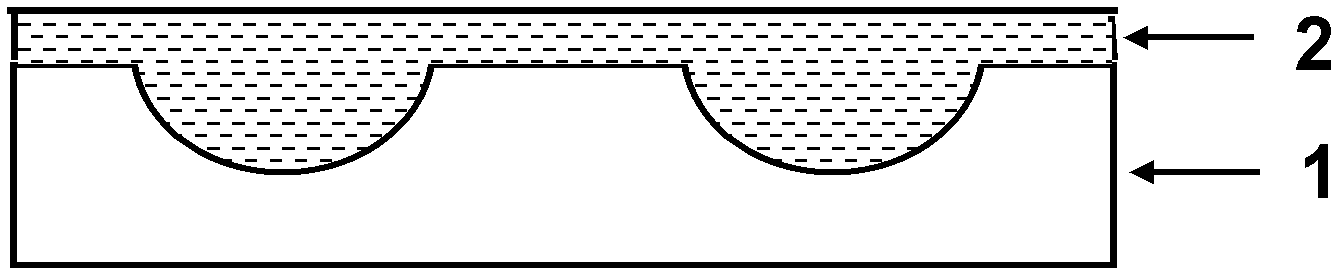

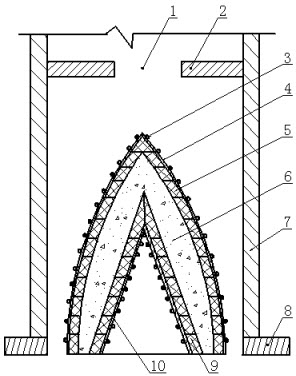

Method for constructing hyperbolic curve funnel wall of tamping coke coaling tower

ActiveCN102373808AGuaranteed fixed precisionCurvature design is scientific and reasonableForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksTowerRebar

The invention relates to a method for constructing a hyperbolic curve funnel wall of a tamping coke coaling tower, which comprises the following steps: (1) manufacturing and pre-installing a template for forming the hyperbolic curve funnel wall; (2) calculating a reinforcing steel bar support frame of a template of an external wall of the hyperbolic curve funnel wall, wherein the distance X between the external wall of the hyperbolic curve funnel wall and the coal tower vertical wall is equal to (d / 2)*e<kcy / 2> when the highness is increased by 500mm each time; (3) manufacturing the reinforcing steel bar support frame, wherein the reinforcing steel bar support frame is made of phi 25 twisted steel, and the gradient of the reinforcing steel bar support frame is the same as the gradient of the external wall of the hyperbolic curve funnel wall when the highness is increased by 500mm each time; (4) installing and fixing a template of an internal wall and the template of the external wall; (5) pouring and casting concrete; and (6) removing the templates and maintaining. The method provided by the invention is simple and easy, the curvature of the external wall of the hyperbolic curve funnel wall can be effectively ensured, the construction speed is improved, the construction quality is guaranteed, and the invention provides the safe and reliable method for constructing the hyperbolic curve funnel wall of the tamping coke coaling tower.

Owner:MCC TIANGONG GROUP

Bender of power transmission circuit externally exposed down lead

ActiveCN103972819AReasonable and reliable structural designQuick and labor-saving bending processApparatus for overhead lines/cablesEngineeringMechanical engineering

The invention particularly relates to a bender of a power transmission circuit externally exposed down lead. The bender of the power transmission circuit externally exposed down lead resolves the problem that when an existing down lead is bent, time and labor are wasted, and the bending effect is poor. The bender comprises two supporting frames distributed in a front and back mode, wherein a supporting plate is fixed between the two supporting frames, a connecting block is arranged under the supporting plate, a round rod penetrates through the connecting block, a pedal is arranged on the round rod on the left side of the supporting plate in a sleeved mode, a pressing plate is arranged on the upper surface of the supporting plate, locking bolts are screwed on the front side and the rear side of the pressing plate, an ejection pressing bolt is screwed on the pressing plate, a bending block is arranged at the front end of the supporting plate, a bending hole is formed in the right end of the bending block, rotary plates are fixed at the front end and the rear end of the bending block, a pin shaft penetrates between each rotary plate and the adjacent supporting frame, a limiting hole is formed in the lateral wall of each pin shaft, a limiting bolt matched with the corresponding hole is screwed on each rotary plate, and an ejection pushing bolt is screwed on each supporting frame. The bender of the power transmission circuit externally exposed down lead effectively improves bending efficiency and guarantees the bending curvature.

Owner:STATE GRID CORP OF CHINA +1

Method for preparing PCB (Printed Circuit Board) aluminum foils by using cast-rolled slabs

ActiveCN104550235AImprove conduction efficiencyReduce the intermediate annealing processMetal rolling arrangementsPrinted circuit boardMechanical properties of carbon nanotubes

The invention discloses a method for preparing PCB (Printed Circuit Board) aluminum foils by using cast-rolled slabs. The method comprises the following steps: (1) smelting, casting and rolling 1050 or 1060 aluminum alloys; (2) roughly rolling, intermediately rolling, longitudinally shearing edges; (3) finely rolling; (4) washing and straightening; (5) cutting, checking and packing to obtain PCB electronic aluminum foils. The mechanical property control deltab of PCB electronic aluminum foils prepared by the method is 190-230MPa; the extension ratio of the PCB electronic aluminum foils is larger than or equal to 2%; the surface hardness value is smaller than 60HV.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

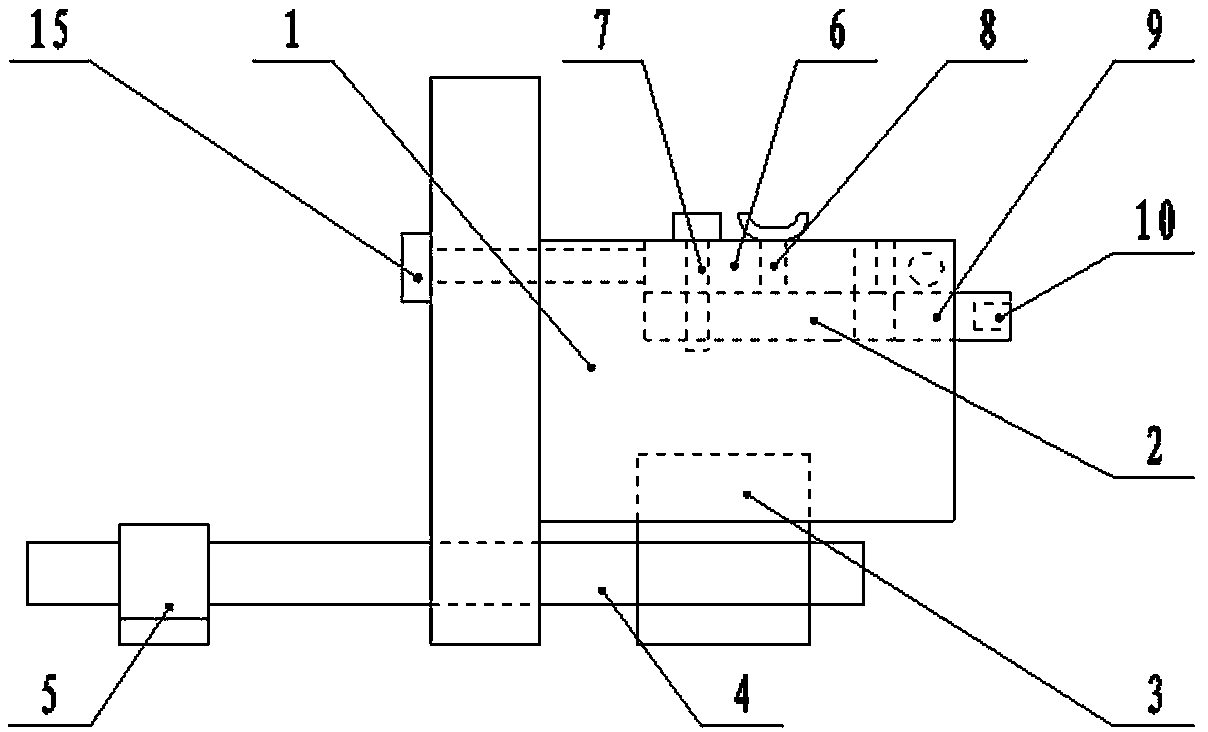

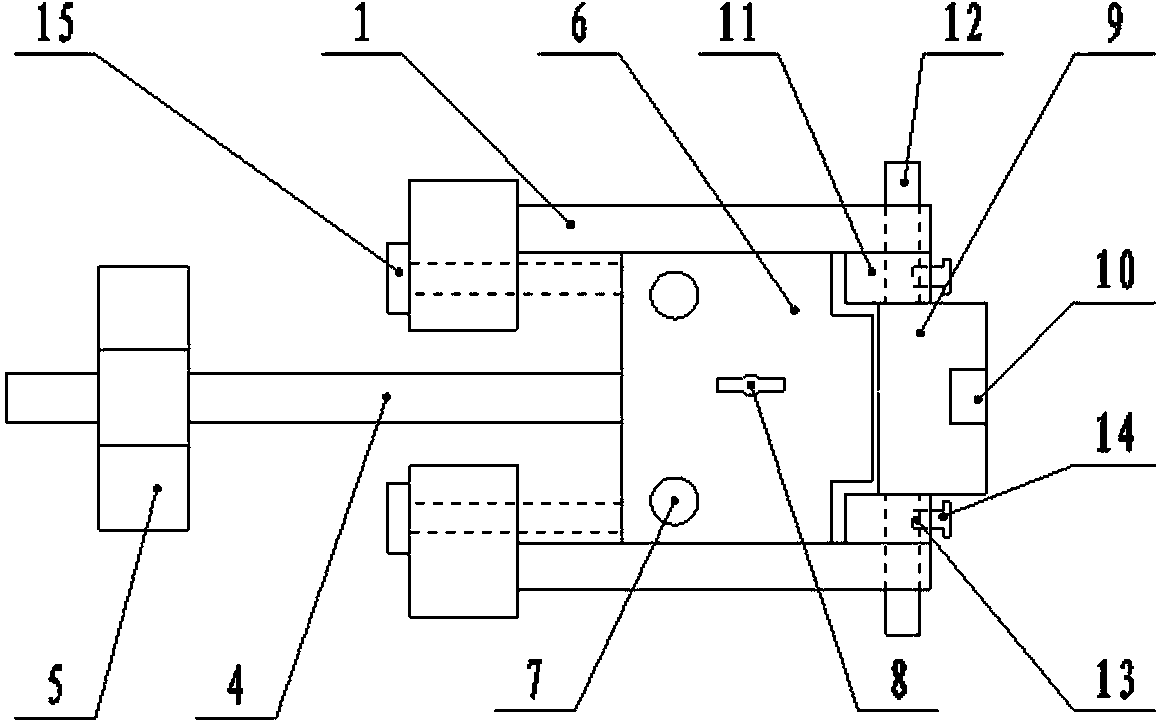

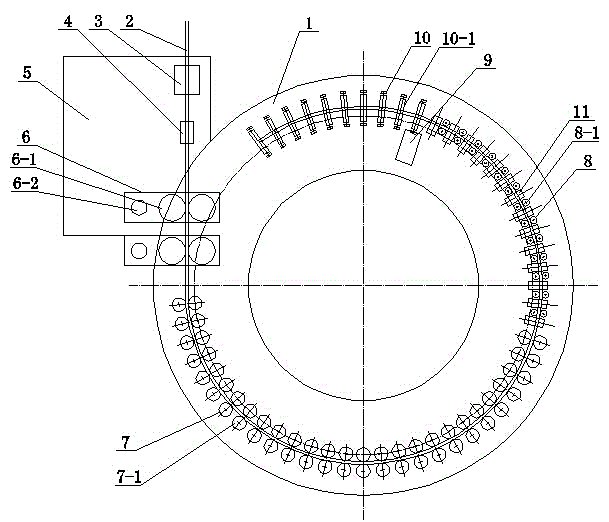

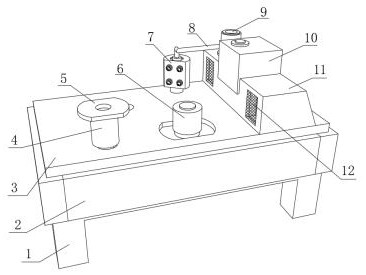

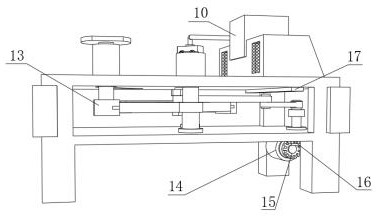

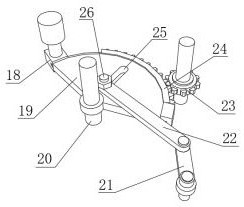

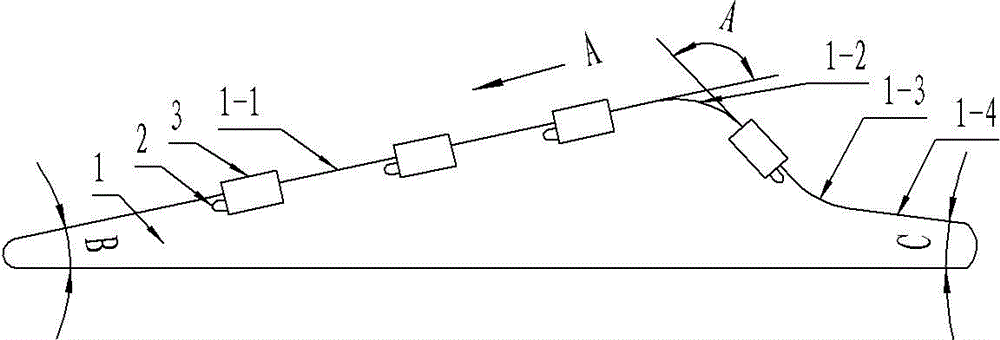

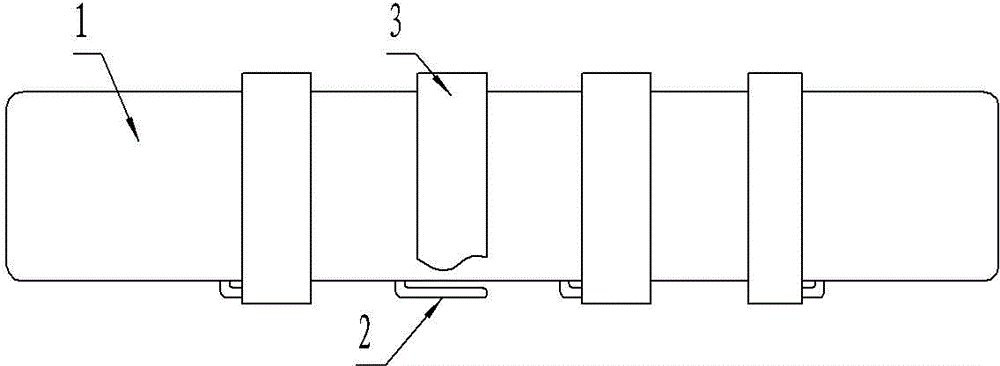

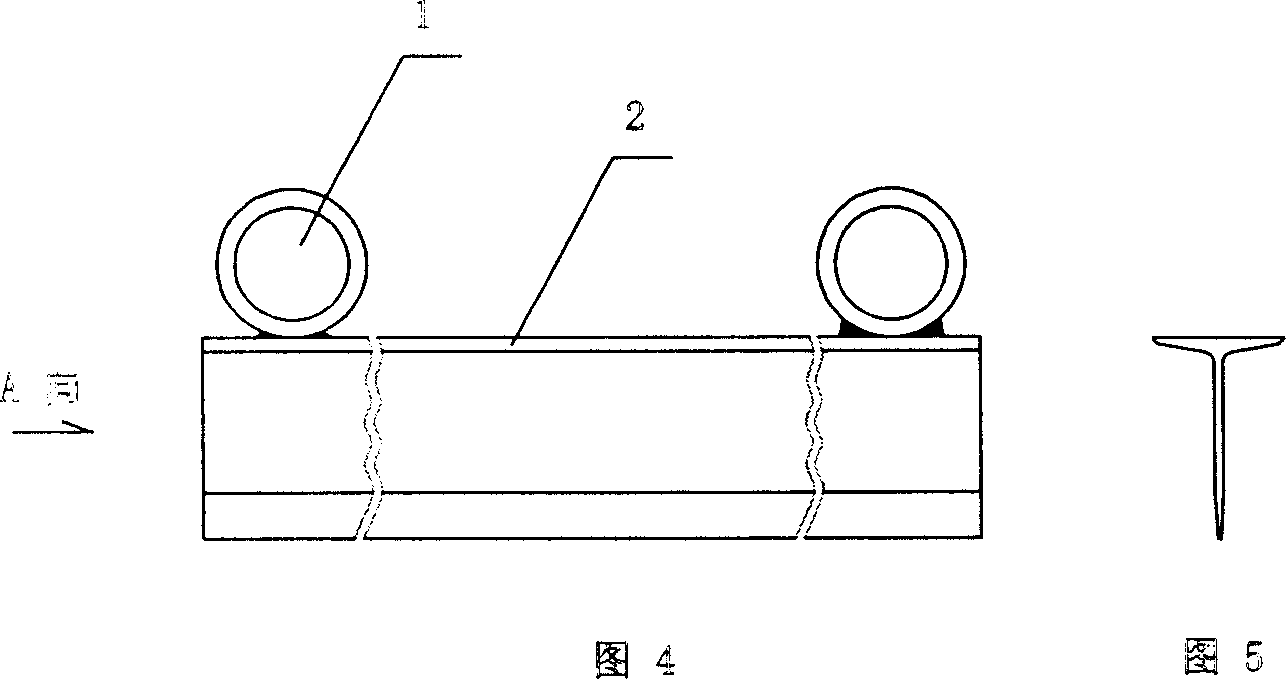

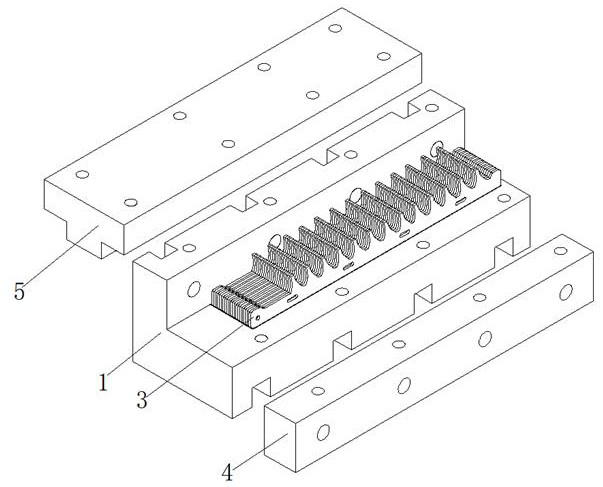

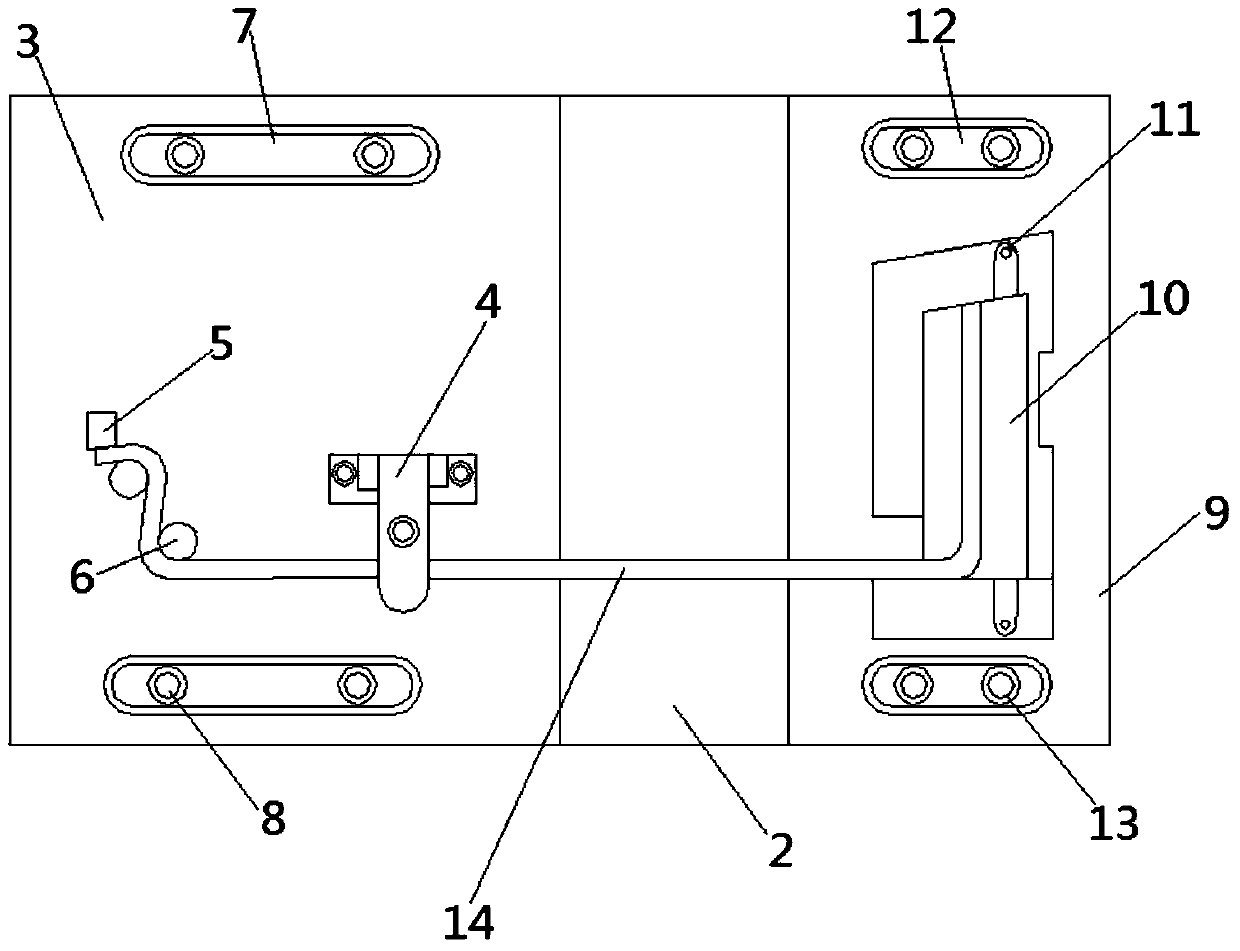

Pre-buried channel arc bending machine

InactiveCN105363851AGuaranteed curvatureGuaranteed flatnessMetal-working feeding devicesOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention provides a pre-buried channel arc bending machine and relates to the structures of arc bending machines. The pre-buried channel arc bending machine comprises a workbench connected with a drive assembly, a first forming assembly, a second forming assembly, a high-speed rotary saw and a discharging supporting assembly. The drive assembly is arranged at the feeding portion of the workbench and comprises drive rolls perpendicularly arranged on the tabletop of the workbench. The first forming assembly is arranged on the discharging side of the drive assembly and comprises multiple pairs of first forming rolls perpendicularly supported on the tabletop of the workbench. The second forming assembly is arranged on the discharging side of the first forming assembly and comprises multiple pairs of second forming rolls perpendicularly supported on the tabletop of the workbench. The discharging supporting assembly is arranged on the discharging side of the second forming assembly and comprises multiple carrier rolls arranged parallel to the tabletop of the workbench. The high-speed rotary saw is arranged on the feeding side of the discharging supporting assembly. By the adoption of the pre-buried channel arc bending machine, raw materials are saved, and the curvature and the quality of a pre-buried channel are stable.

Owner:扬州明博钢结构有限公司

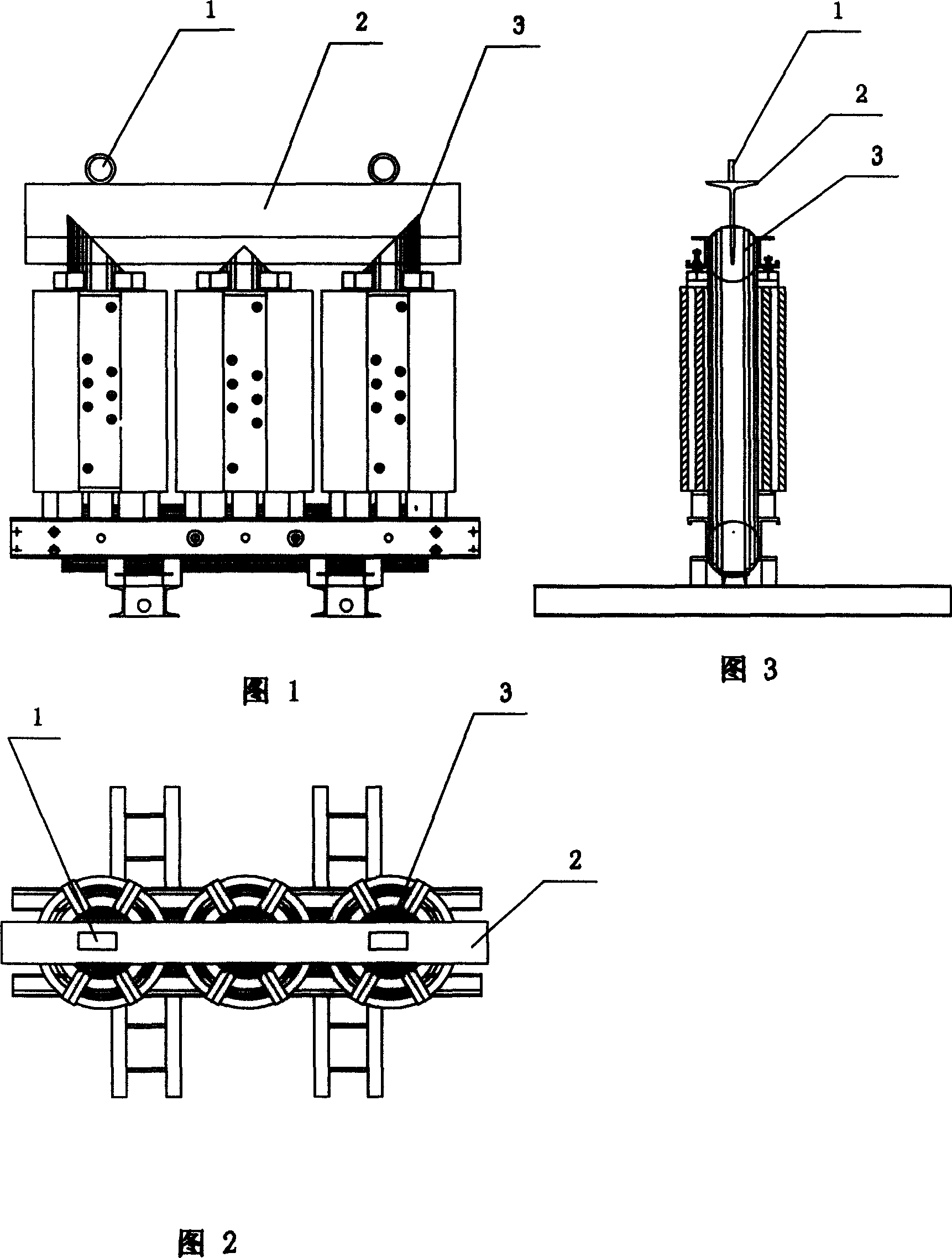

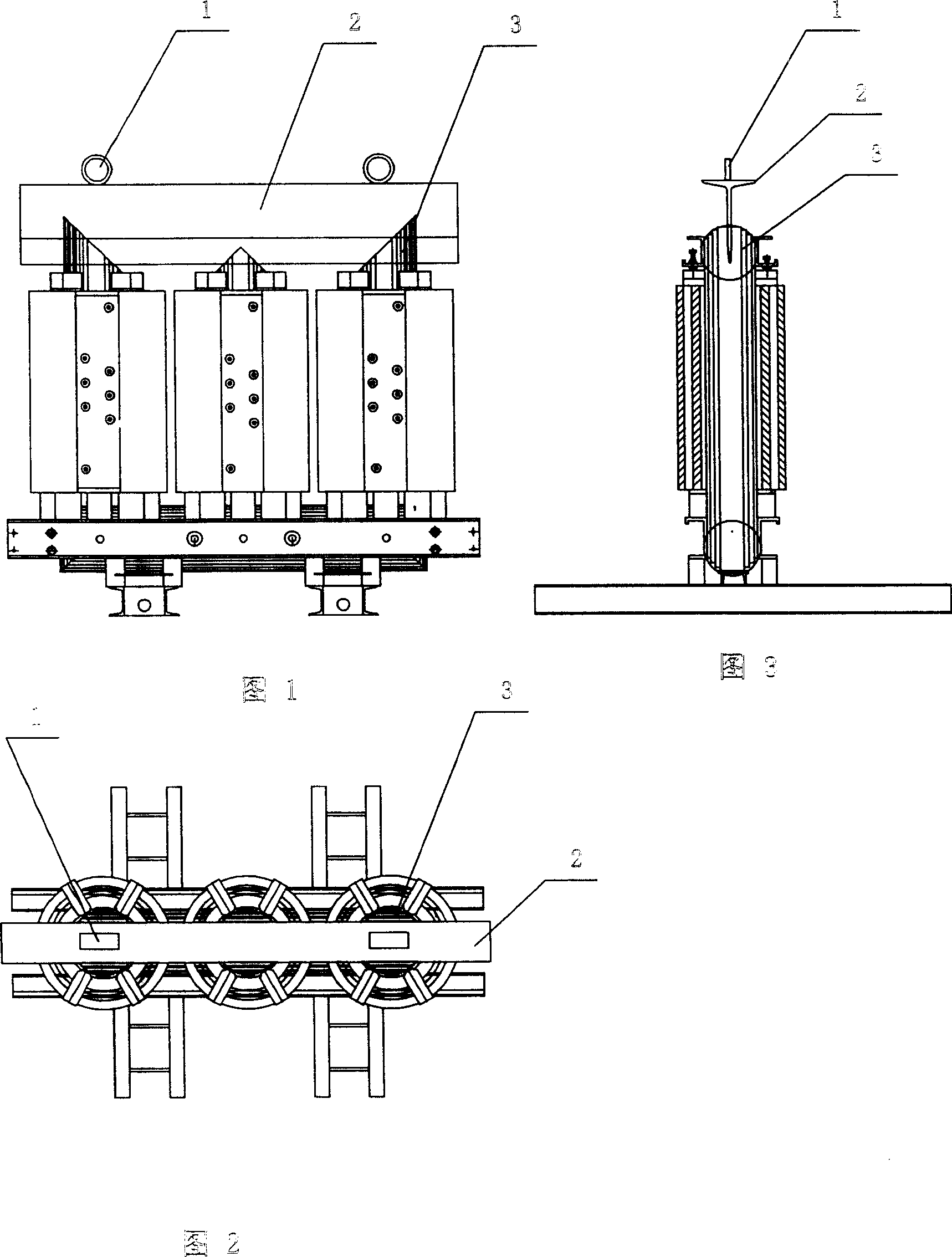

Mounting method for magnetic yoke of transformer

ActiveCN1564282AImprove product qualitySolve the large curvatureInductances/transformers/magnets manufactureTransformerEngineering

Steps for installing iron yoke into iron core stem are as following: inserting T type rack into iron core stem; inserting piece of up iron yoke into iron core stem; picking up T type rack; fastening yoke to complete assembling. Advantages of the method are: simple technique, easy of operation, safe and reliable. The method is especially suitable to assembling up iron yoke on transformer in large capacity.

Owner:天津市特变电工变压器有限公司 +1

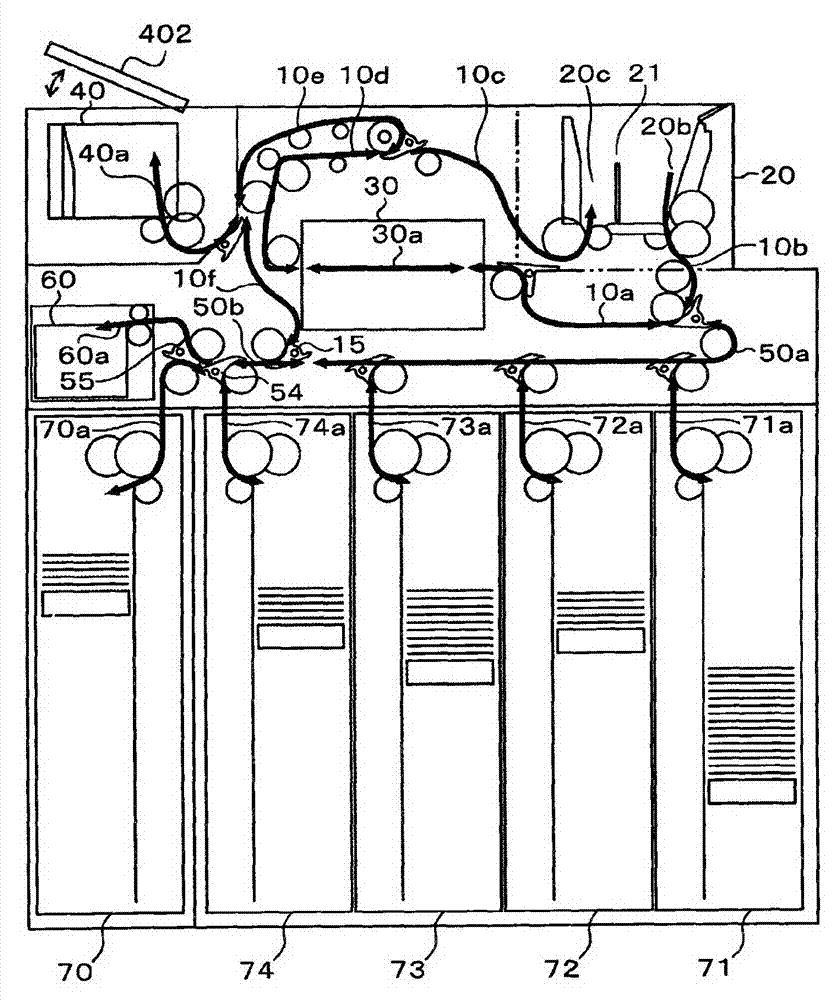

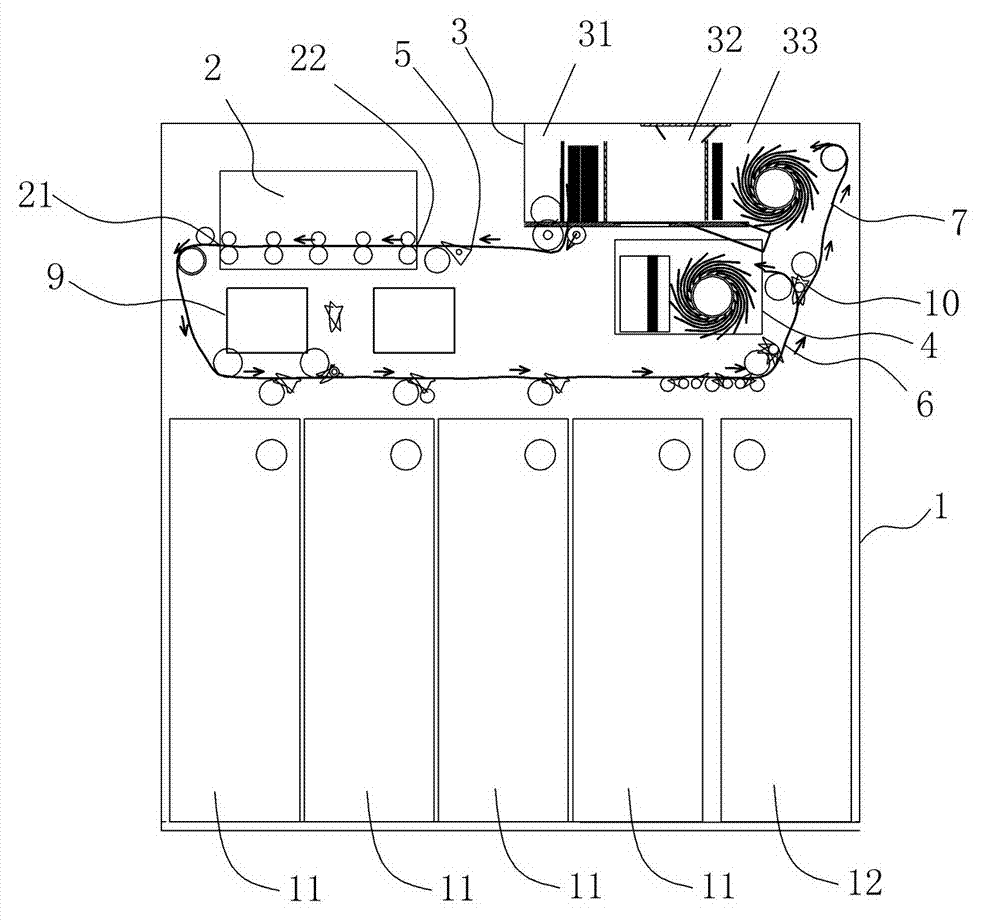

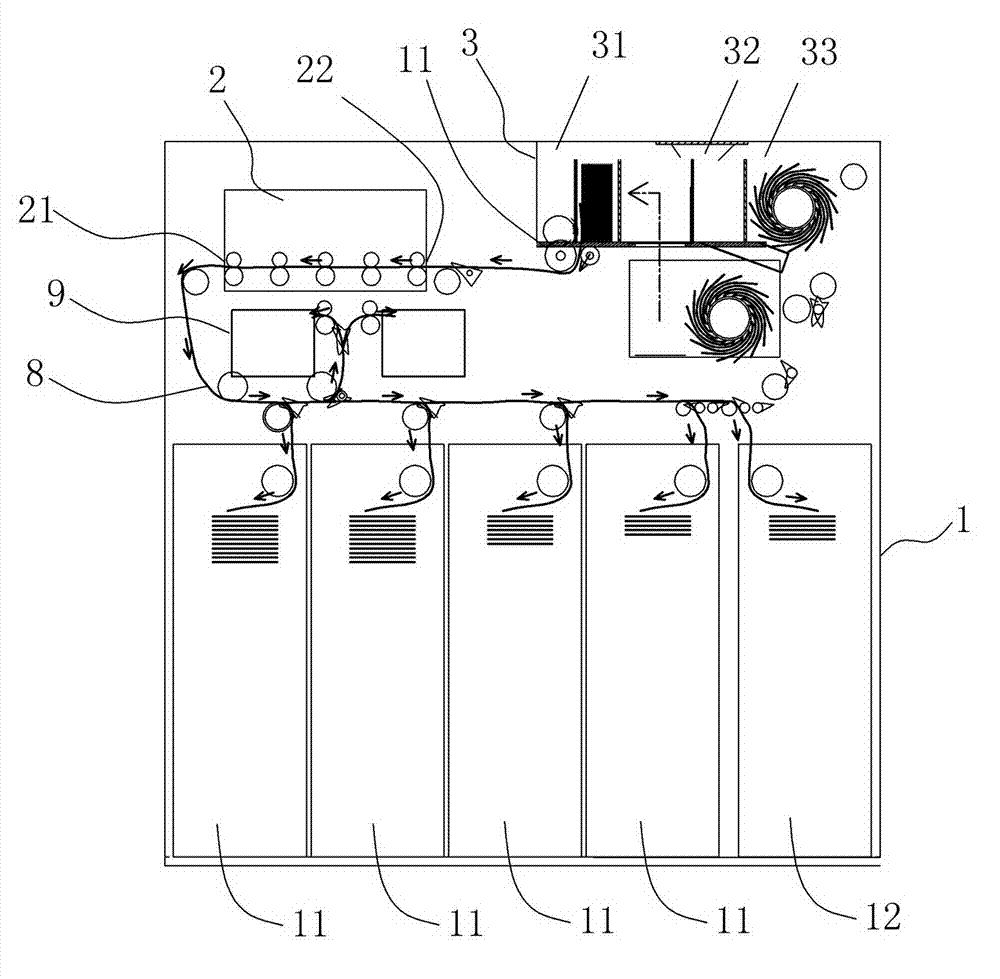

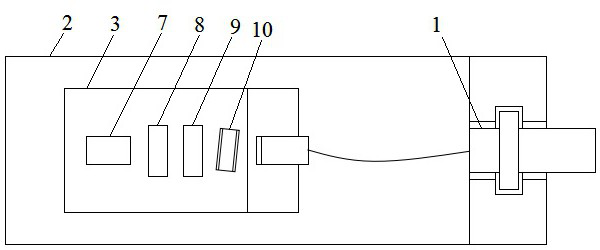

Deposit device of automatic teller machine

InactiveCN103268664BImprove reliabilityEnsure identificationCoin/currency accepting devicesTransmission channelEngineering

The invention discloses a deposit device of an automatic teller machine. Cash storage boxes are arranged on the lower portion of the automatic teller machine, the automatic teller machine further comprises a recognition part and a cash port, the recognition part is arranged at one end of the automatic teller machine, the cash port is arranged at the other end of the automatic teller machine, and a temporary storage part is arranged below the cash port. A first transmission channel is connected to the cash port, extends out from one end of the cash port and is connected with a cash depositing end of the recognition part. A second transmission channel is connected to a cash dispensing end of the recognition part, extends out from the cash dispensing end of the recognition part and is connected with the temporary storage part. A third transmission channel is connected with the cash dispensing end of the recognition part, extends out from the cash dispensing end of the recognition part and is connected with the other end of the cash port. A fourth transmission channel is connected to the cash dispensing end of the recognition part, extends out from the cash dispensing end of the recognition part and is connected to each money storage box. Therefore, a distance is guaranteed to be long enough so that the cash can be recognized, the probability that cash is blocked due to the fact that curving rate is large is decreased, and the reliability of the deposit device of the automatic teller machine is improved.

Owner:广州智萃电子科技有限公司

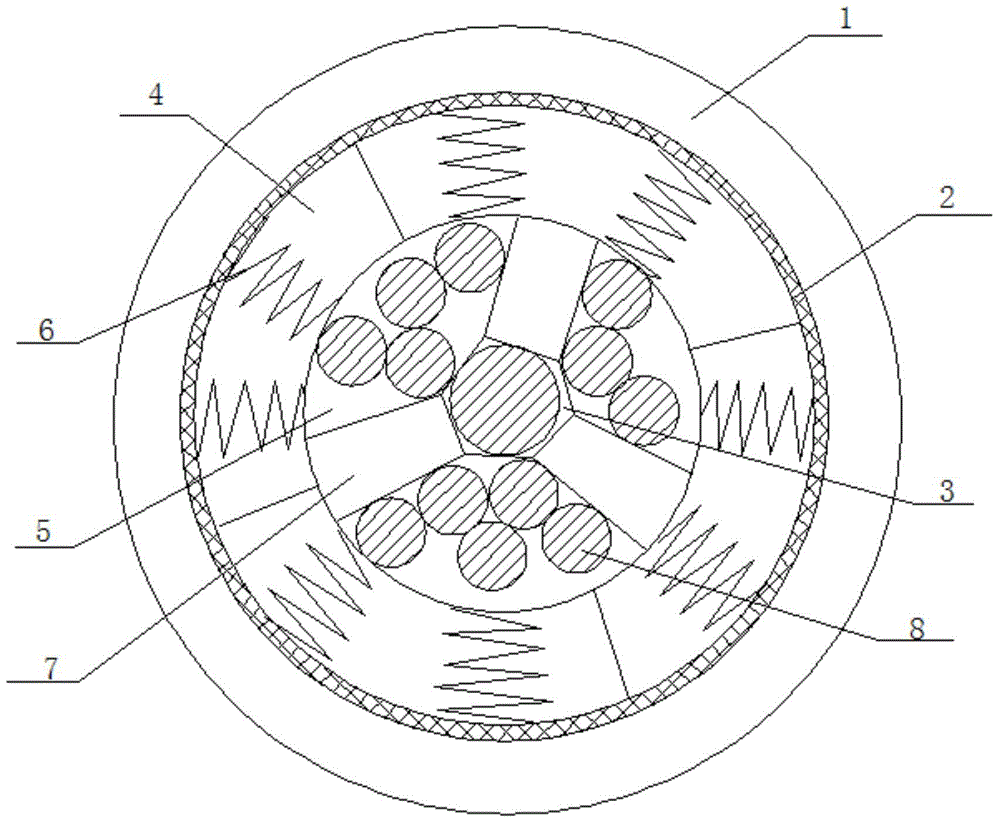

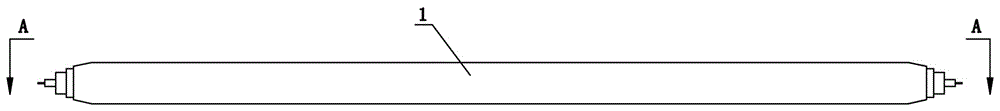

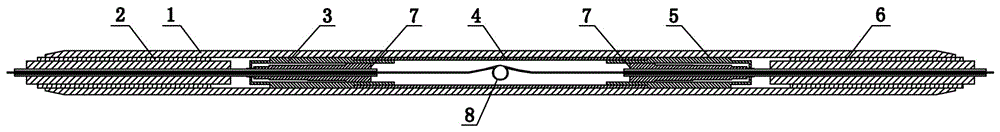

Cable

InactiveCN105761785AImprove firm performanceImprove conductivityInsulated cablesInsulated conductorsElectrical conductorCopper wire

The invention discloses a cable. The cable comprises an insulating sleeve, a conductor sleeve, a branch pipe, prestressed chambers, a copper wire chamber, springs and brackets; the copper wire chamber is of a hollow circular structure; the hexagonal branch pipe is arranged at the inner axis of the copper wire chamber; three brackets are uniformly distributed between the outer wall of the branch pipe and the inner wall of the copper wire chamber; the outer wall of the copper wire chamber is sleeved with three prestressed chambers; the three prestressed chambers are connected together so as to form a ring-shaped structure; two springs are connected between the inner ring wall and lower ring wall of the interior of each prestressed chamber; the exteriors of the prestressed chambers are sleeved with the conductor sleeve; the conductor sleeve is made of a conductor material; and the conductor sleeve is coated with the insulating sleeve. According to the cable of the invention, electric conductivity of the internal structure of the cable is increased, and the bending performance and pressure bearing ability of the cable can be ensured, and therefore, the cable can be applied to production and manufacture more widely. The firmness of the cable is increased.

Owner:天津顺业电气设备有限公司

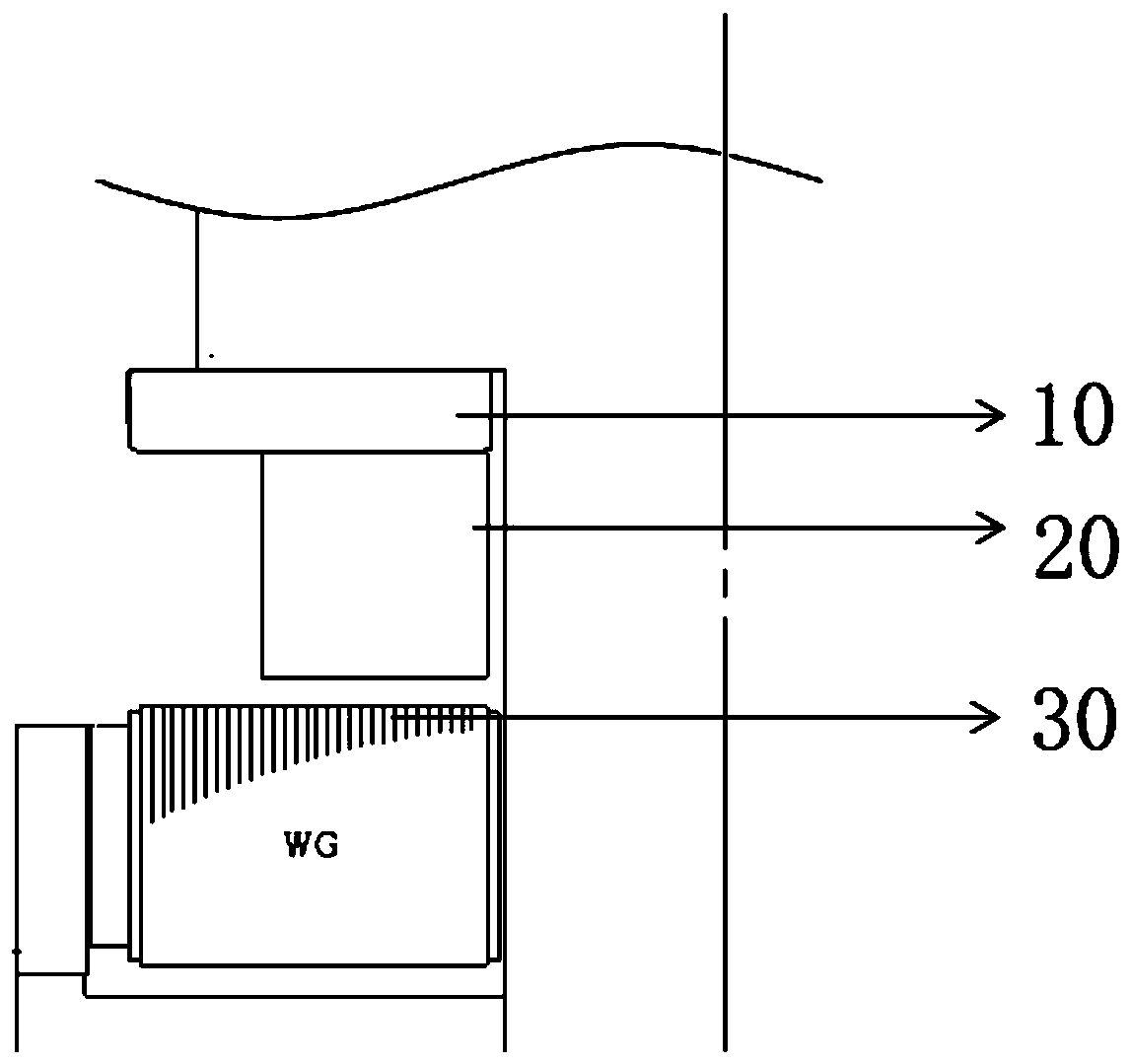

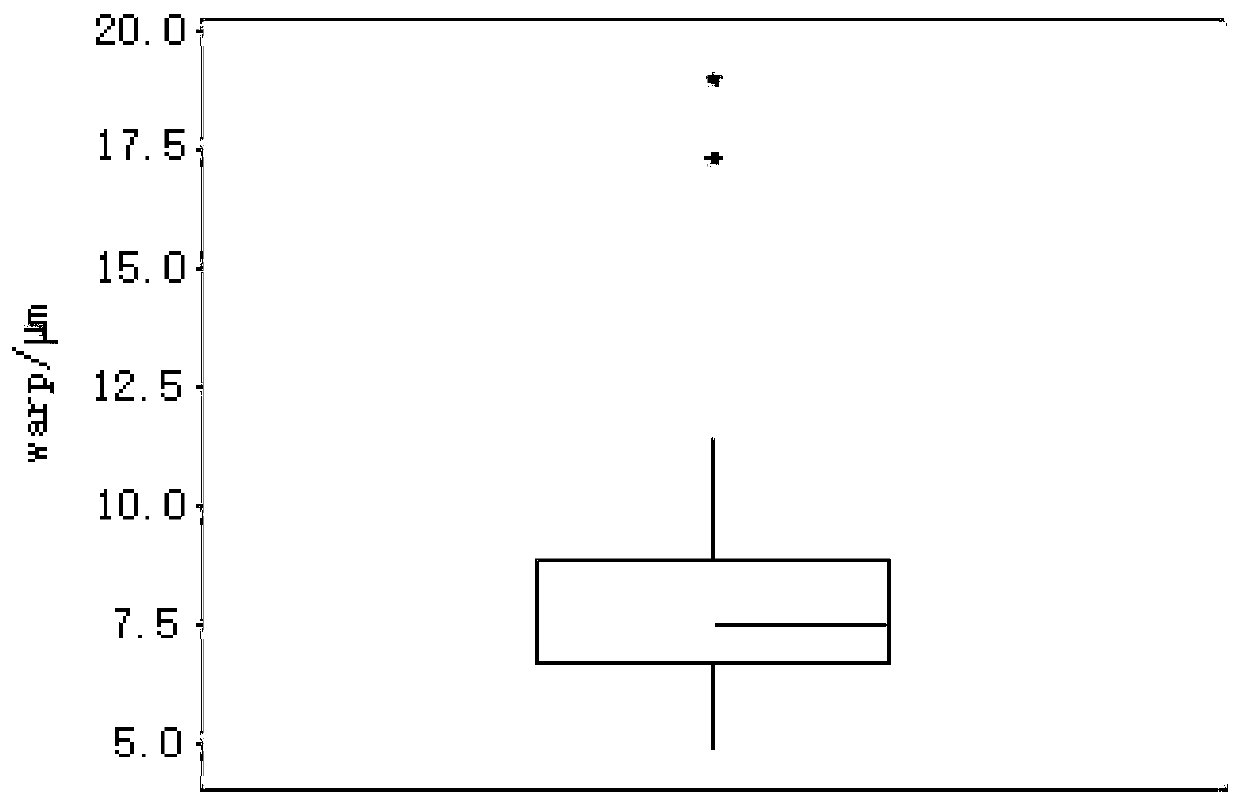

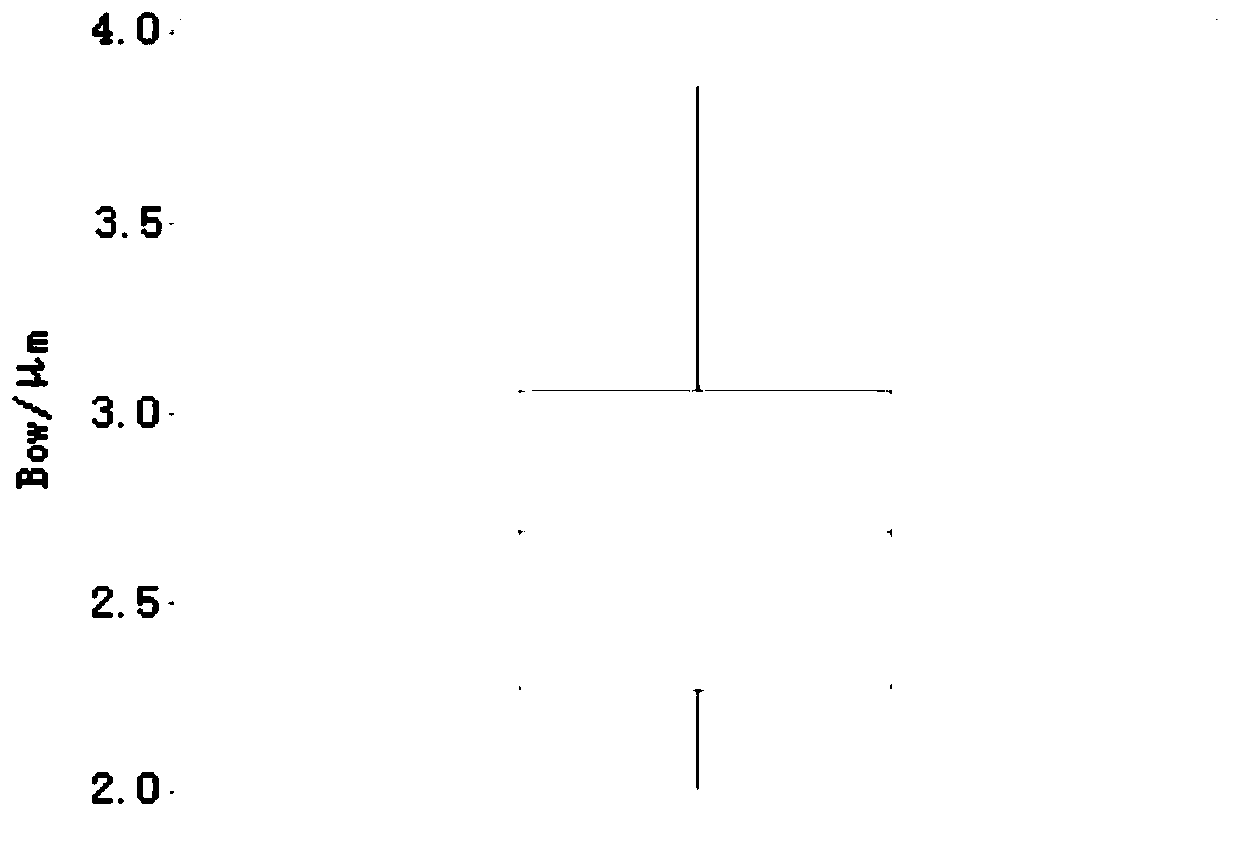

Cutting process for large-size silicon wafer

InactiveCN110587837AGood surface morphologyEasy to cleanWorking accessoriesFine working devicesRound barLarge size

The invention provides a cutting process for a large-size silicon wafer. The third step of the process is that mortar online cutting is performed on a silicon round bar with the diameter of 300 mm ona cutting machine and the silicon wafer is obtained; in a cutting process, the feeding speed of the silicon round bar is 0.22-0.47 mm / min; the wire diameter of the steel wire is 0.16 mm, the cutting speed is 600-800 m / min, the wire supply amount is 0.46-0.74 km / pcs, the supply and return tension is 24-28 N, and the wire arch is smaller than 3 mm; and the flow rate of mortar is 82-145 Kg / min, and the flow fluctuation value is + / -3 Kg / min. The cutting process for the large-size silicon wafer is particularly suitable for mortar online cutting of the silicon round bar with the diameter of 300 mm,the geometric parameters such as warping degree and bending degree of the silicon wafer are guaranteed, and the large-size silicon wafer with excellent surface morphology and convenient to clean is obtained.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH

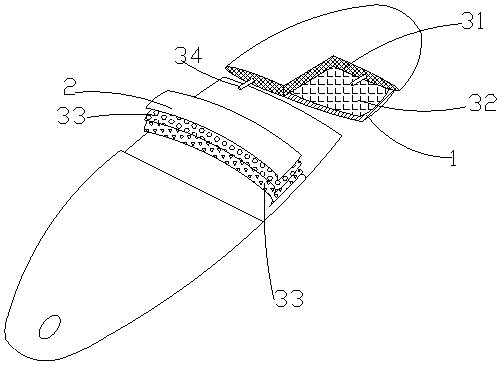

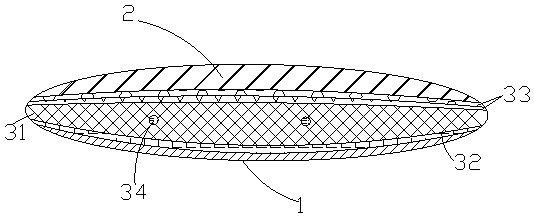

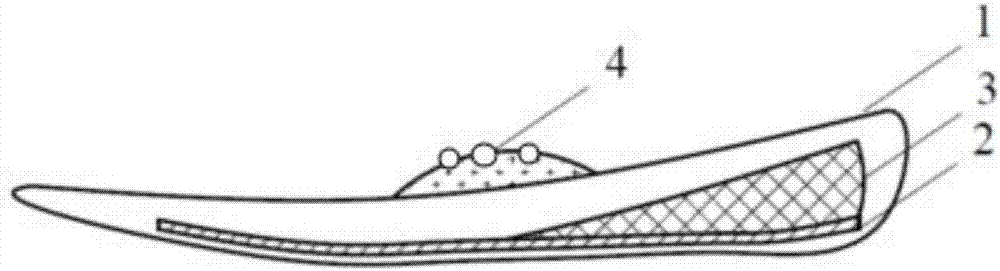

Surfboard and manufacturing method thereof

PendingCN112046690AStable bottomGuaranteed curvatureWaterborne vesselsWater sport boardsGlass fiberFiber

The invention provides a surfboard and a manufacturing method thereof. The surfboard comprises a surfboard body, a bottom board layer and a protective layer, wherein the bottom board layer and the protective layer are arranged on the two sides of the surfboard body. The surfboard body comprises a first glass fiber layer arranged on the bottom board layer, a foam board arranged on the first glass fiber layer and a second glass fiber layer arranged on the foam board and connected with the protective layer. A plurality of reinforcing ribs are arranged in the foam board. The bottom board layer made of pc materials is arranged at the lower end of the surfboard body, so that the bottom of the surfboard is firmer, the protective layer made of EVA or PE is arranged at the upper end of the surfboard body, the surface of the surfboard is protected, and the surface of the surfboard is prevented from being damaged due to treading in the using process. The upper surface and the lower surface of thesurfboard body are respectively connected with glass fiber cloth, so that the connection between the bottom board layer and the surfboard body and connection between the surfboard body and the protective layer are more stable, and the reinforcing ribs made of glass fiber rods or carbon fiber rods are arranged in the foam board, so that the surfboard body is firmer and more stable.

Owner:中山蜻蜓体育器材有限公司

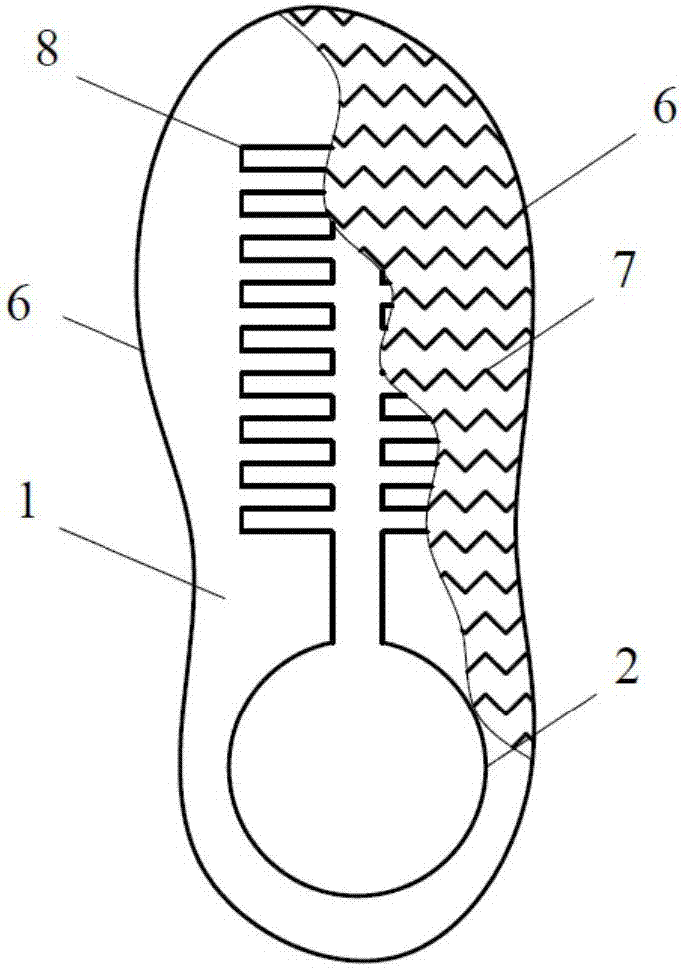

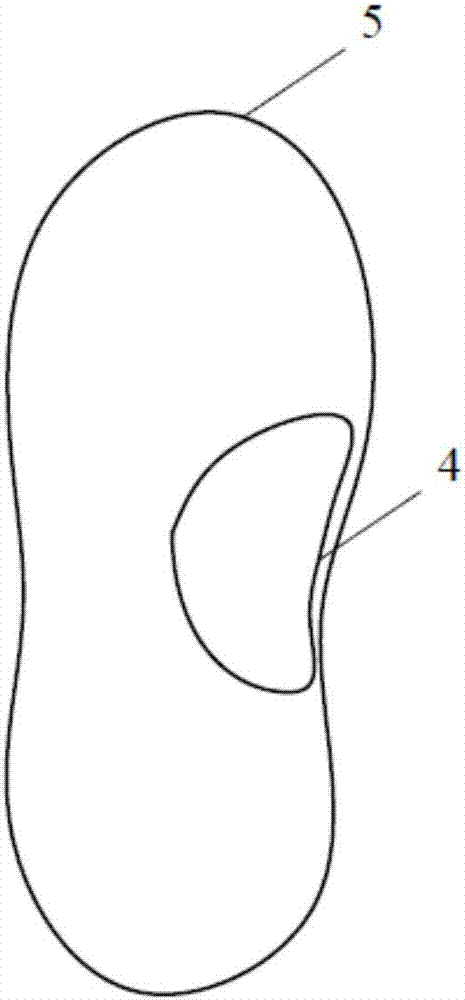

Foot orthotics insole and preparation method thereof

InactiveCN107280142AComfort hardnessImprove buffering effectElectrotherapyInsolesKnee orthosisEngineering

The invention discloses a foot orthotics insole and a preparation method thereof. The foot orthotics insole comprises an insole base, a reinforcing portion, a filling portion and an orthotics portion, wherein the insole base is made of starch-base antibacterial foam composite materials and provided with a first surface and a second surface opposite to the first surface. The first surface acts on a sole of a human body, and the second surface contacts with the inner bottom of a shoe. The insole base wraps the reinforcing portion and the filling portion, and the filling portion closely fits with the upper portion of the reinforcing portion. The smoothly projecting orthotics portion is arranged on the first surface, acts on a foot arch and fits with the foot bottom at the position of the foot arch. As the orthotics insole base is made of the starch-base antibacterial foam composite materials, the insole has comfortable hardness and excellent buffer performance and durability, and orthotics treatment effects are improved.

Owner:苏州峰佳医疗科技有限公司

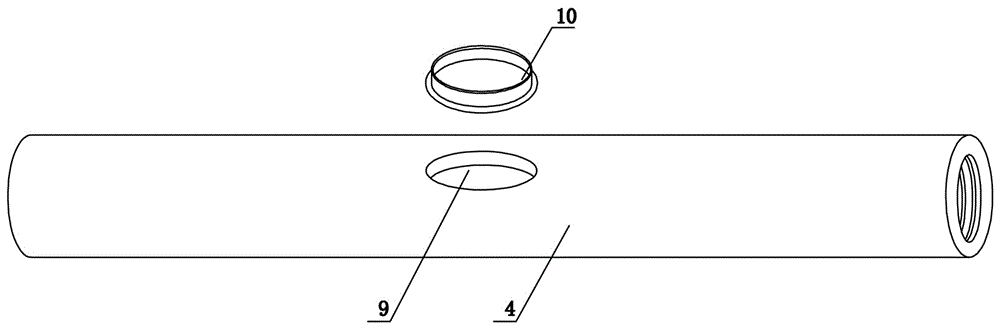

Connector for carbon-fiber composite-core optical-fiber wires

InactiveCN106772825AAvoid damagePrevent moisture corrosion problemsCoupling light guidesFiberMechanical engineering

The invention belongs to the technical field of carbon-fiber wires and particularly relates to a connector for carbon-fiber composite-core optical-fiber wires. The connector comprises an outer pressure connecting tube and is characterized in that the outer pressure connecting tube is of a hollow structure, a first lining tube, a first wedge clamp support, a connecting tube, a second wedge clamp support and a second lining tube are sequentially arranged in the outer pressure connecting tube from left to right, matched wedge clamps are arranged in the first wedge clamp support and the second wedge clamp support, the front end face of the connecting tube is provided with an operation hole, the inner wall of the connecting tube is provided with rubber coating, and the operation hole is provided with a sealing cover. The connector has the advantages that fast reconnection of the carbon-fiber composite-core optical-fiber wires is achieved by the operation hole, and the effect of long-distance and high-performance signal transmission is guaranteed.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

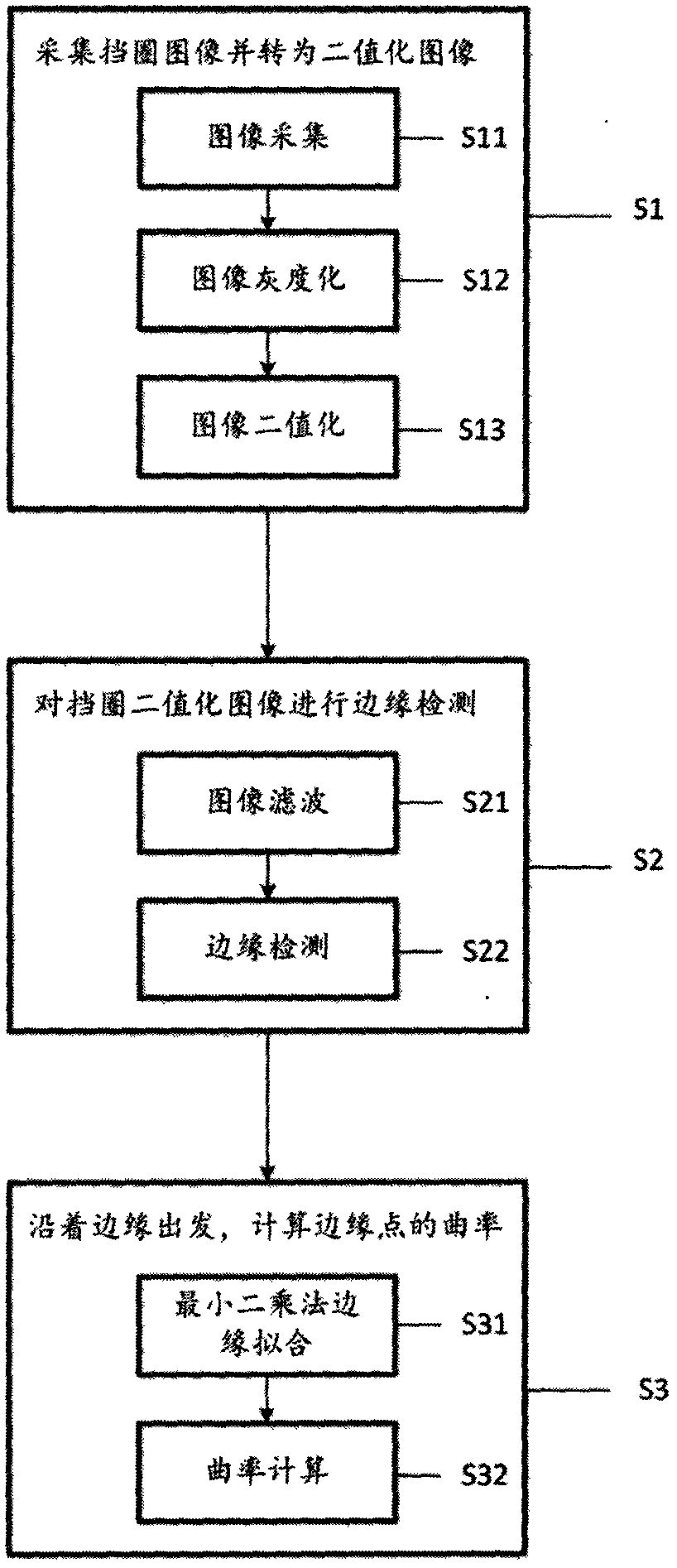

Method for detecting quality of check ring based on machine vision

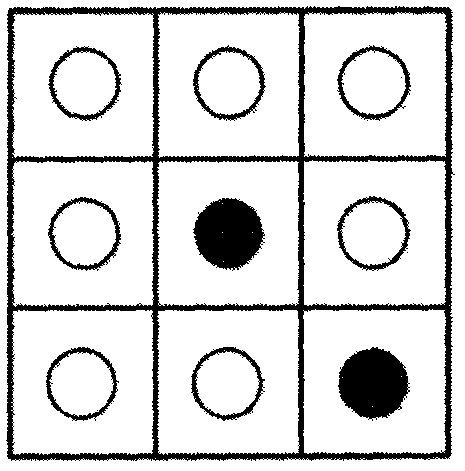

InactiveCN108230285AEasy to detectAchieving identifiabilityImage analysisPattern recognitionImaging processing

The invention discloses a method for detecting the quality of a check ring based on machine vision. The method comprises the steps of S1, collecting an image of the check ring, and converting the image into a binary image; S2, performing edge detection on the binary image of the check ring; and S3, calculating the curvature of edge points along the edge. According to the scheme of the invention, automatic detection and recognition for the check ring are achieved through a series of operation processes such as image acquisition and image processing and recognition, and the process does not needmanual participation. Meanwhile, an edge curve of the image of the check ring is found out through curve fitting, and the curvature of all edge points of the check ring is calculated according to theedge curve, so that omnidirectional check ring curvature detection is achieved, and the curvature of the check ring in all directions is ensured to meet quality detection requirements.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Steel bar hoop-bending machine for steel bar processing

The invention discloses a steel bar hoop-bending machine for steel bar processing, relates to the technical field of steel bar hoop bending, and aims to solve the problem of inaccurate steel bar curvature caused by high temperature. The steel bar hoop-bending machine specifically comprises a workbench; a supporting base is welded to the outer wall of the bottom of the workbench; baffles are fixedto three circumferential outer walls of the workbench through bolts; a mounting plate is fixed to the outer wall of the front face of the workbench through bolts; a chassis is fixed to the outer wallof one side of the top of the workbench through bolts; two air outlets are arranged on the outer wall of one side of the chassis; a water tank is clamped to the outer wall of the top of the chassis; awater pump is fixed to the outer wall of the side, close to the water tank, of the chassis through bolts; an arc-shaped intermittent mechanism is arranged on the inner wall of the bottom of the workbench; an air guide opening is arranged on the inner wall of the top of the side, close to the chassis, of the workbench; and an arc-shaped slideway is arranged on the outer wall of the top of the workbench. According to the steel bar hoop-bending machine provided by the invention, the curvature of steel bars can be guaranteed, the working efficiency of workers is promoted to a certain extent, andthe efficiency and quality of steel bar hoop bending are improved.

Owner:冠县德汇商贸有限公司

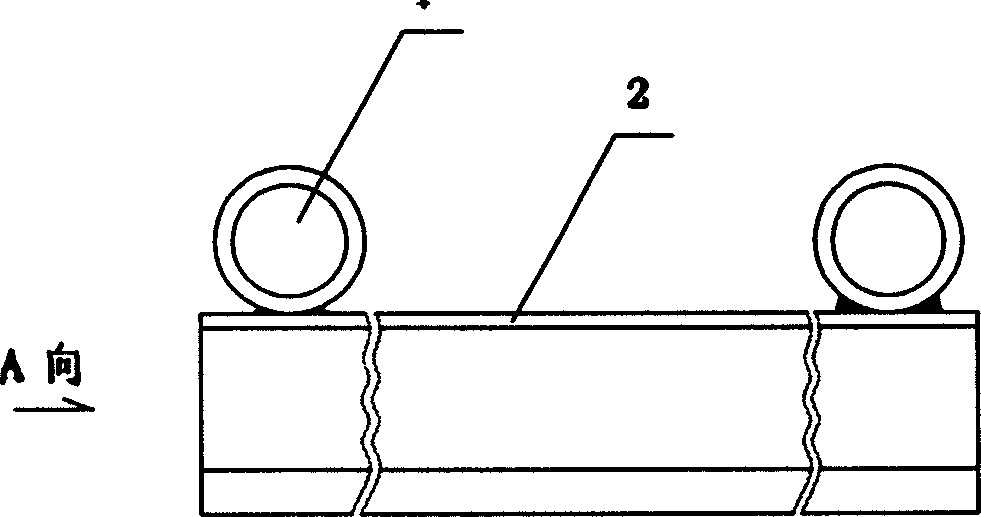

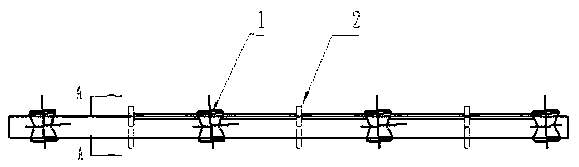

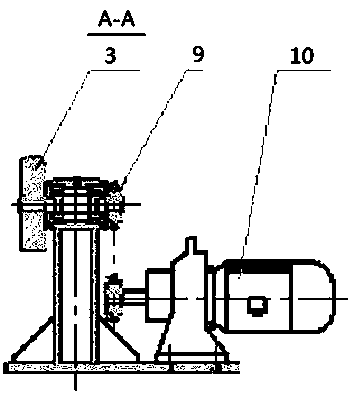

Method and special device for relieving steel pipe heat treatment curvature

InactiveCN109295294AGuaranteed curvatureSolve the problem of increased curvatureFurnace typesHeat treatment furnacesHeat treatedMaterials science

The invention discloses a method and special device for relieving the steel pipe heat treatment curvature. The method comprises the following steps that a steel pipe is conveyed to a lifting rotary carrier roller mechanism through conveying roll gangs after being discharged from a furnace, a rotary roll and an atomization spraying sprayer act at the same time, rotation and spraying of the steel pipe are stopped before a next steel pipe is discharged from the furnace, and the steel pipe is conveyed to a cold bed through the conveying roll gangs (1). The device comprises the conveying roll gangs(1); the lifting rotary carrier roller mechanism (2) is arranged between the conveying roll gangs (1); the atomization spraying sprayer (5) is arranged above the rotary roll of the lifting rotary carrier roller mechanism (2); and water baffles (7) are arranged on two sides of the lifting rotary carrier roller mechanism (2). The bending problem caused by conveying after heat treatment of the steelpipe is well solved, the quality of the steel pipe is improved, the equipment investment is reduced, and the good popularization value is achieved.

Owner:烟台鲁宝钢管有限责任公司

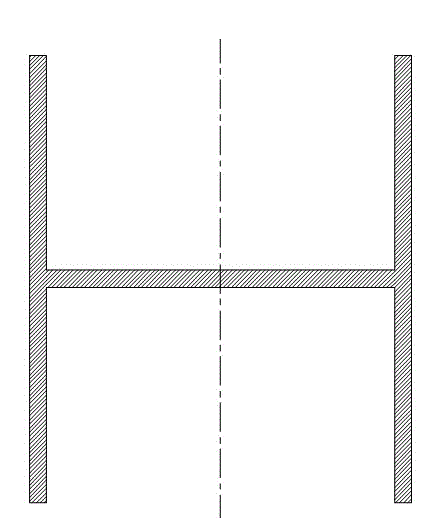

Anti-deformation crisscross column

The invention relates to an anti-deformation crisscross column. An H-shaped steel structure is cut along the centre line to form two pieces of T-shaped steel, the two pieces of T-shaped steel are welded to form a crisscross column, the H-shaped steel structure is cut along the center line to form a cutting line, the connection is kept along the center line to form a connecting part, and then the H-shaped steel structure is cut along the center line to form a cutting line, the cutting operation is carried out repeatedly for times, and finally the two pieces of T-shaped steel connected in a completely symmetric manner are finally formed. According to the anti-deformation crisscross column, the two pieces of T-shaped steel connected in a completely symmetric manner are formed through cutting, the two pieces of T-shaped steel are spliced into a crisscross column, and then the connecting part is cut open, so that the heating area is greatly reduced, the verticality and flexure are effectively guaranteed, and the structure can be utilized to machine a T-shaped column, a crisscross column, nonstandard channel steel, nonstandard large angle steel and the like.

Owner:TONGLING FERROUS CONSTR & INSTALLATION STEEL STRUCTURE

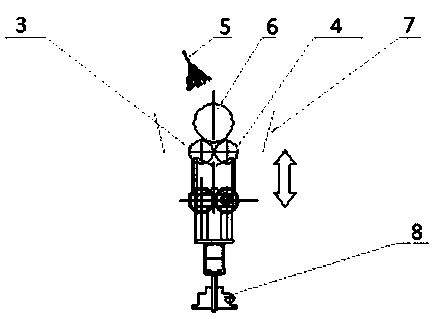

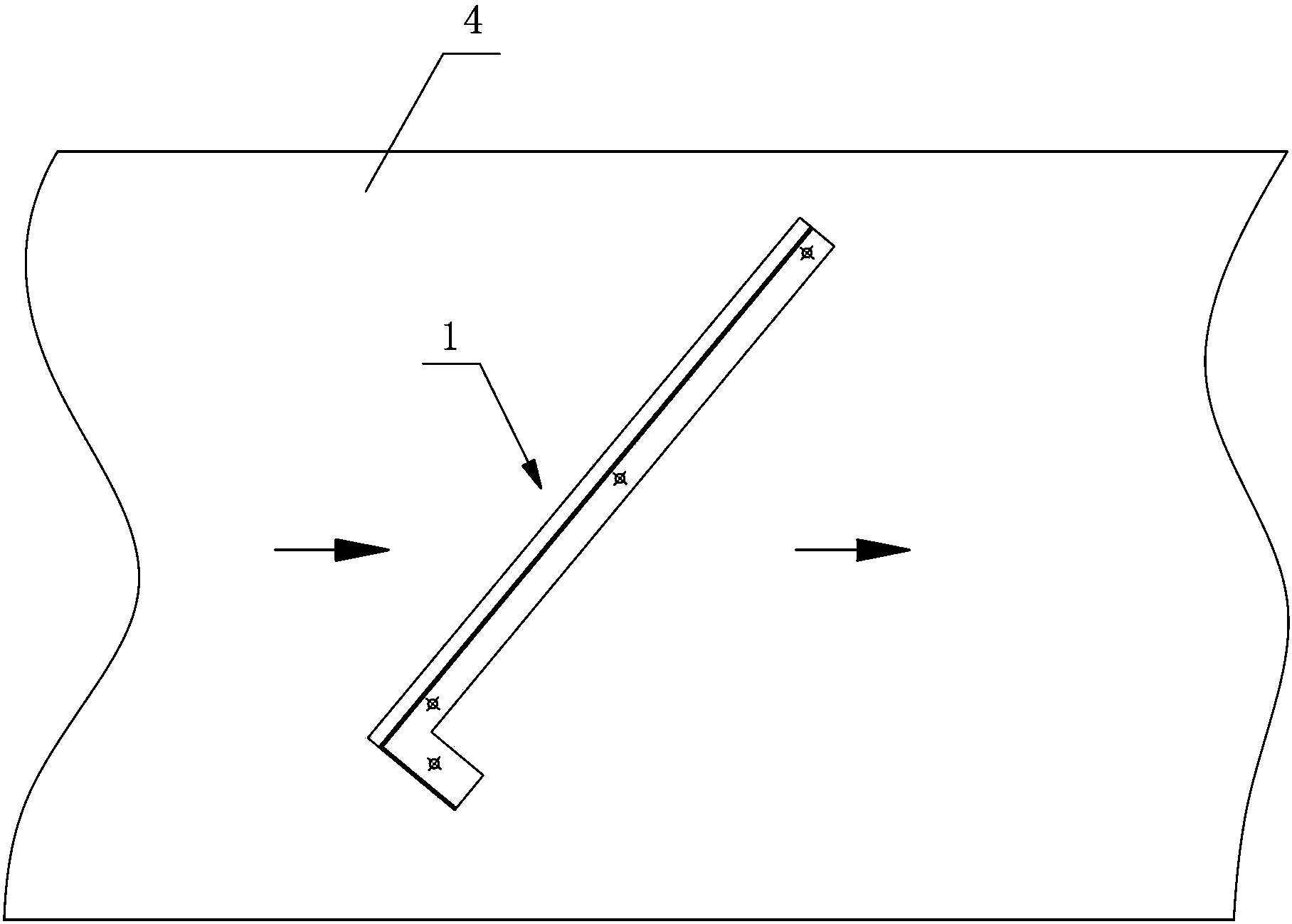

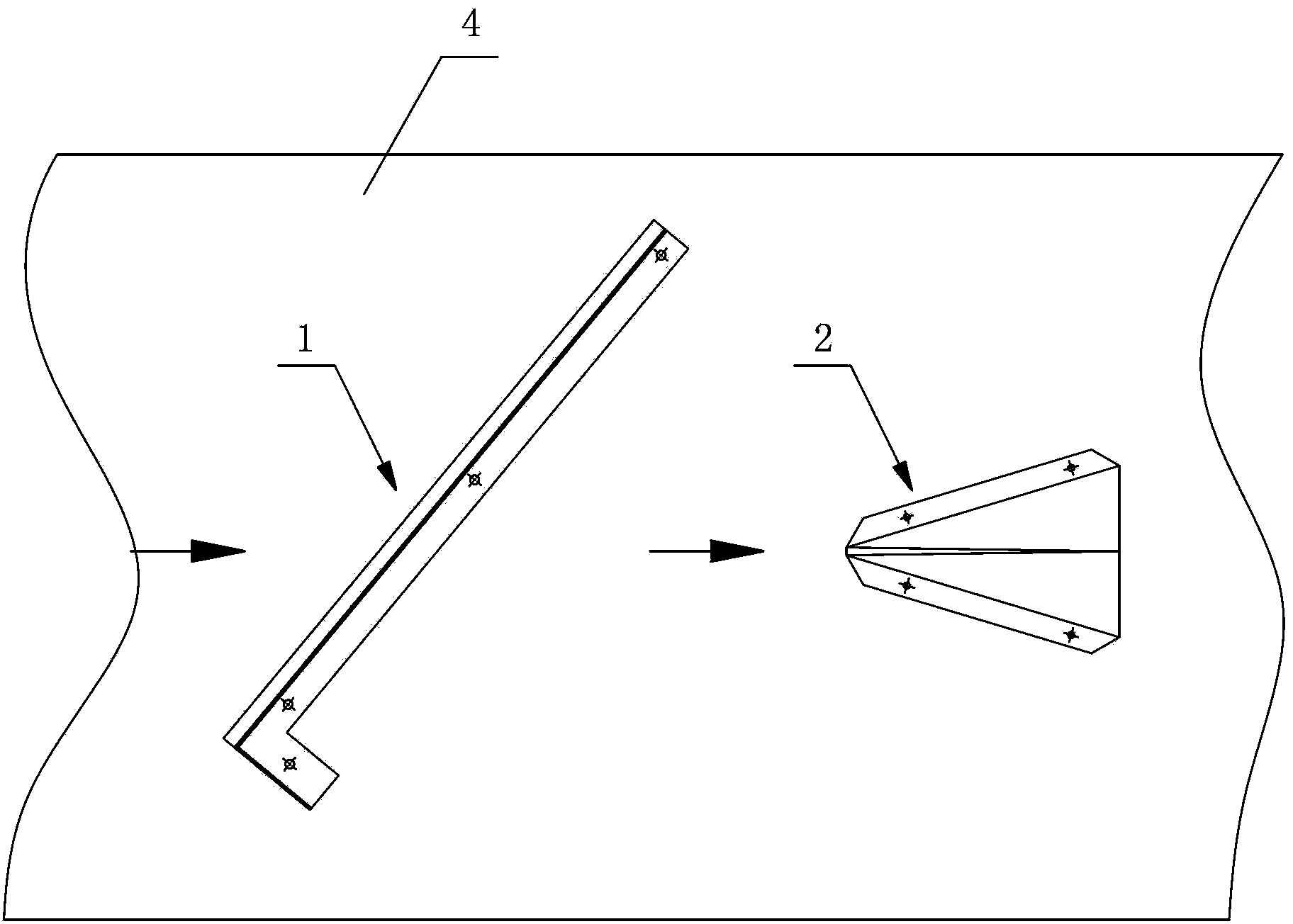

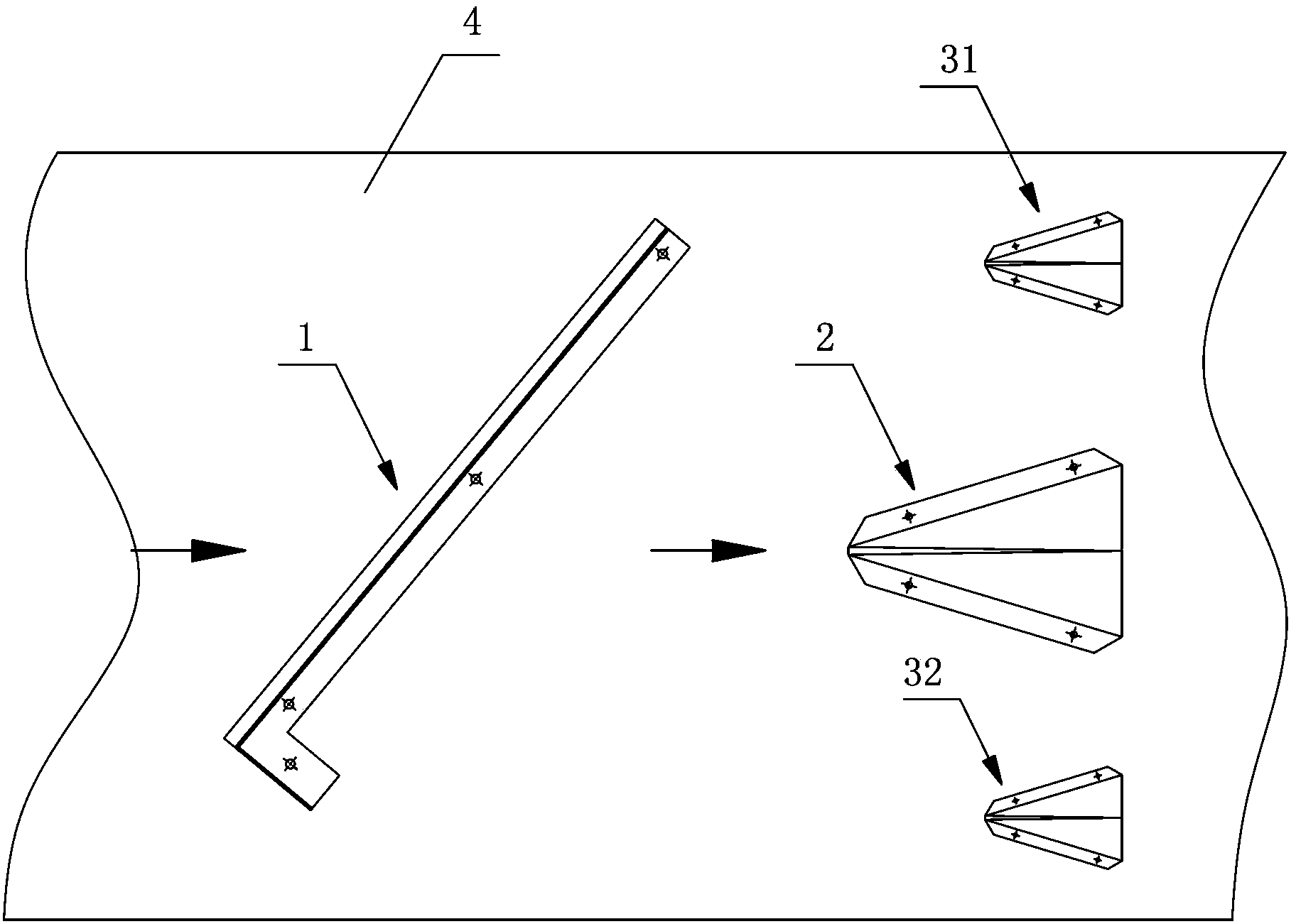

Refining device for tobacco shred conveyer

InactiveCN102849410BEvenly distributedPlay the role of diversionJigging conveyorsWater contentWaste management

Owner:CHINA TOBACCO SHANDONG IND

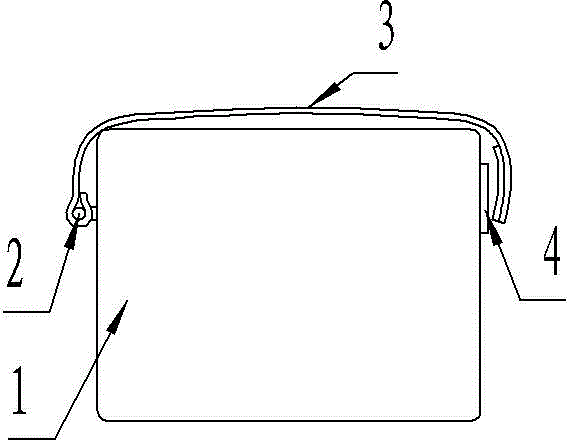

Fixator for artery puncture

InactiveCN104939928AGuaranteed curvatureImprove comfortDiagnosticsSurgical needlesArtery punctureBandage

The invention discloses a fixator for artery puncture. The fixator for the artery puncture comprises a long support pad and bandages arranged on the support pad. An inclined plane used for upward supporting the arm of a patient, a protruding portion used for supporting the wrist to keep crooked and a concave portion used for the placement of the palm and the fingers of the patient are arranged on the upper end face of the support pad from rear to front in sequence. The inclined angle between the inclined plane of the support pad and the horizontal plane ranges from 25 to 30 degrees. The inclined angle between the rear side face and the front side face of the protruding portion ranges from 55 to 65 degrees. The front portion and the rear portion of the support pad are both provided with a bandage. Compared with the prior art, the fixator for the artery puncture can solve the problems that existing artery puncture cannot fix the arm and the wrist of the patient effectively, the success rate of the artery puncture is influenced, and the manpower of medical workers is imposed.

Owner:LIUZHOU PEOPLES HOSPITAL

Impact-resistant polypropylene composite and preparation method thereof

The invention discloses an impact-resistant polypropylene composite which comprises the following components in parts by weight: 100 parts of polypropylene, 15-25 parts of rubber, 5-10 parts of polyamic acid, 20-35 parts of inorganic filler, 1-3 parts of compatilizer, 0.5-2 parts of antioxygen, 0-1 part of antistatic agent, and 0.1-3 parts of fire retardant. According to the impact-resistant polypropylene composite, the rubber is added to raw polypropylene for modifying polypropylene, and the inorganic filler is added to the components considering that the rubber can obviously reduce flexural modulus, heat resistance and other properties of the composite, so that the prepared composite is good in impact resistance, the curvature and the heat resistance of the composite are ensured, and the composite is easy to form and process, and good in mechanical property, and can be widely applied to the field of automobiles.

Owner:SUZHOU SUNWAY POLYMER

Method for making suit sleeves

The invention discloses a method for making suit sleeves. The method is characterized by including the steps of 1), drawing a sleeve cap curve line of a top sleeve body; 2), drawing a sleeve valley curve line of an under sleeve body; 3), drawing front bending joints of the top sleeve body and the under sleeve body by determining partial sleeve points of cuffs of the top sleeve body and the under sleeve body; 4), determining the length of the sleeve bodies; 5), determining back bending joints of the top sleeve body and the under sleeve body; 6), determining hemlines of the cuffs to complete thesleeves. The hemlines are concealed in position, which is reasonable in processing; the curve lines M1T and the rear bending joints are intersected at the T-point, included angles on two sides are favorably close to 90 degrees, cuff vents are configured, and the sleeves are completed. The method is convenient and simple in processing and high in efficiency.

Owner:谢亚平

Mounting method for magnetic yoke of transformer

ActiveCN1322522CImprove product qualityGuaranteed curvatureInductances/transformers/magnets manufactureTransformerEngineering

Owner:天津市特变电工变压器有限公司 +1

Tail fiber fixing clamp and fixing method of light emitting sub-module

The invention belongs to the technical field of optical communication, and particularly relates to a tail fiber fixing clamp of a light emitting sub-module. The tail fiber fixing clamp comprises a fixing clamp body, wherein a first adapter groove and a tail fiber groove are formed in the top surface of the fixing clamp body, and a crystal head placing table is arranged on the side surface of the fixing clamp body; one end of the tail fiber groove is communicated with the first adapter groove, and the other end extends to the side surface; and the tail fiber groove is bent. The invention further provides a tail fiber fixing method which comprises the following steps of assembling an adapter with a tail fiber on the tail fiber fixing clamp, then, inversely buckling the whole tail fiber fixing clamp on the module shell, so that the crystal head and the adapter are respectively aligned with the crystal head groove and a second adapter groove on the module shell, baking the crystal head and the adapter together to cure glue after pressing, and finally, removing the tail fiber fixing clamp. The tail fiber fixing clamp can automatically adapt to the length of the tail fiber, guarantees that the tail fiber maintains a fixed bending degree after being assembled so as to absorb the tensile force borne by the tail fiber in the using process, can also guarantee that the optical fiber is not excessively bent, and prevents the optical power from falling off due to excessive bending.

Owner:武汉英飞光创科技有限公司

Method for preventing rolled hot steel billet from bending

InactiveCN111041174AGuaranteed curvatureEasy to useFurnace typesHeat treatment process controlMetallurgyIngot

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

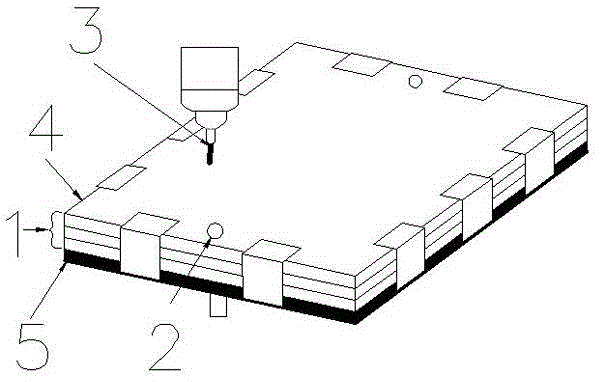

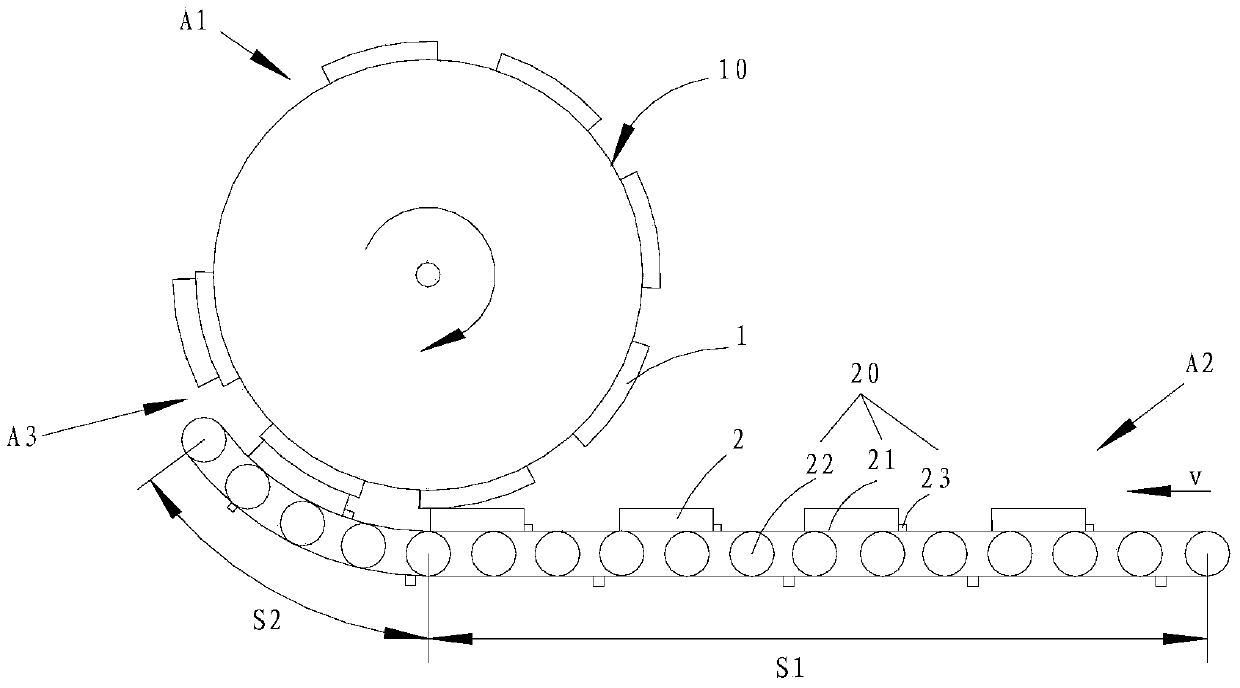

A curved screen bonding device and a curved screen bonding method

ActiveCN105644105BGuaranteed fitting accuracyGuaranteed curvatureLaminationLamination apparatusEngineeringSurface cover

The invention discloses a curved-surface screen laminating device which is used for laminating curved-surface cover plate glass and a display module. The curved-surface screen laminating device comprises a rotary table mechanism for transporting the cover plate glass, and a belt transmission mechanism for transporting the display module, wherein the belt transmission mechanism comprises a flat part with a top surface which is a plane and an arc-shaped surface part with a top surface which is an arc-shaped surface; the peripheral surface of the rotary table mechanism and the arc-shaped surface part are concentrically arranged, and linear speeds of the peripheral surface of the rotary table mechanism and the arc-shaped surface part are the same; the display module is transported from the flat part to the arc-shaped surface part; and the sum of the thicknesses of the cover plate glass and the display module is equal to the distance between the peripheral surface of the rotary table mechanism and the arc-shaped surface part. The invention further discloses a curved-surface screen laminating method. The belt transmission mechanism is used for transporting the display module with a display screen and the cover plate glass is transported by using the rotary table mechanism; and the arc-shape outer surface of the rotary table mechanism and the arc-shaped surface part of the belt transmission mechanism are used for extruding and laminating the cover plate glass and the display module, so that the laminating precision and the curvature of the cover plate glass and the display module can be guaranteed, and the production efficiency is greatly improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

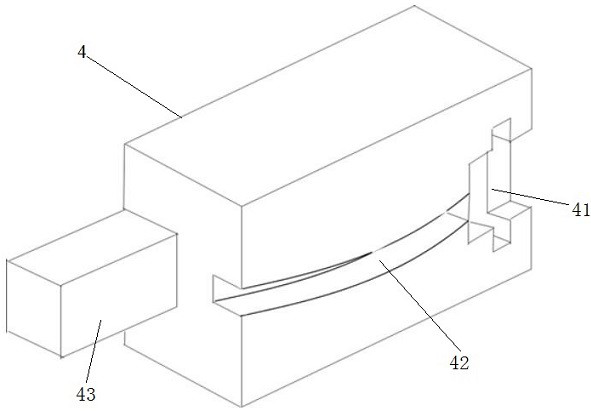

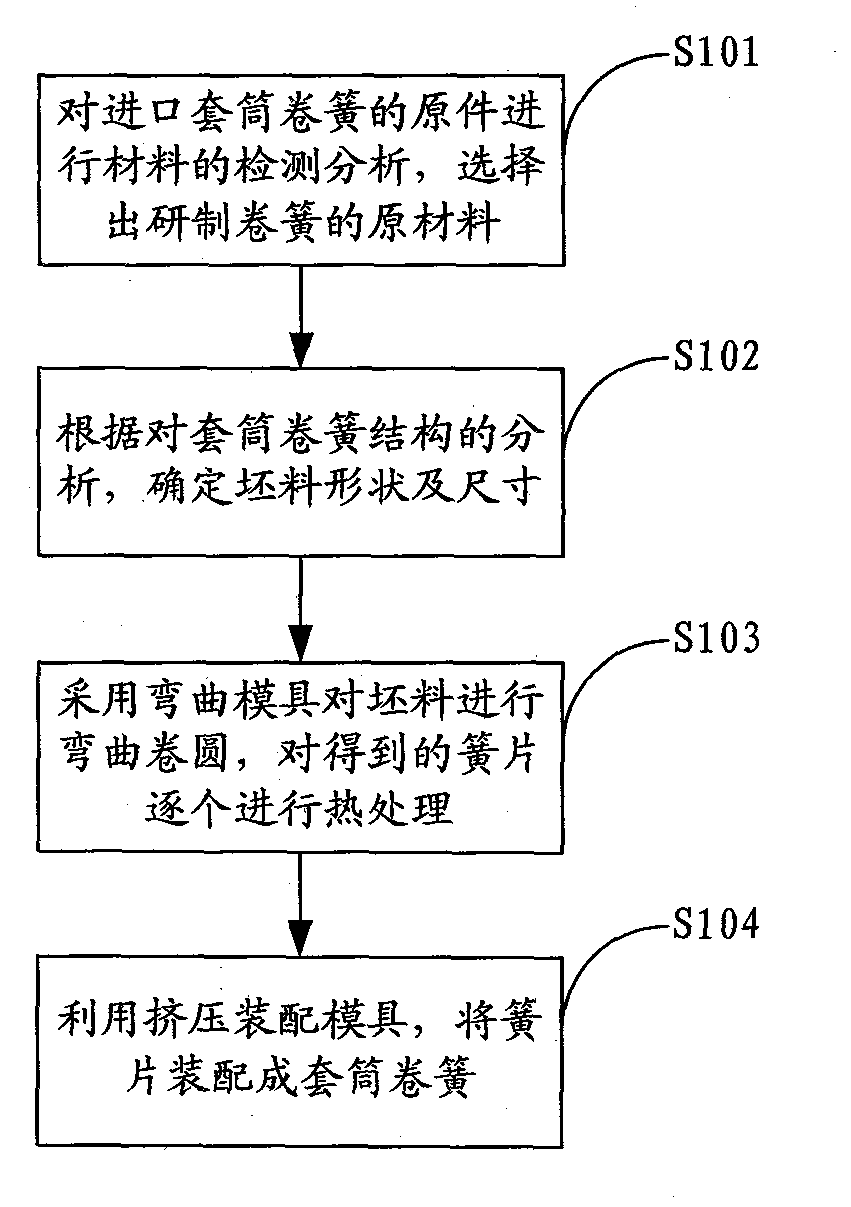

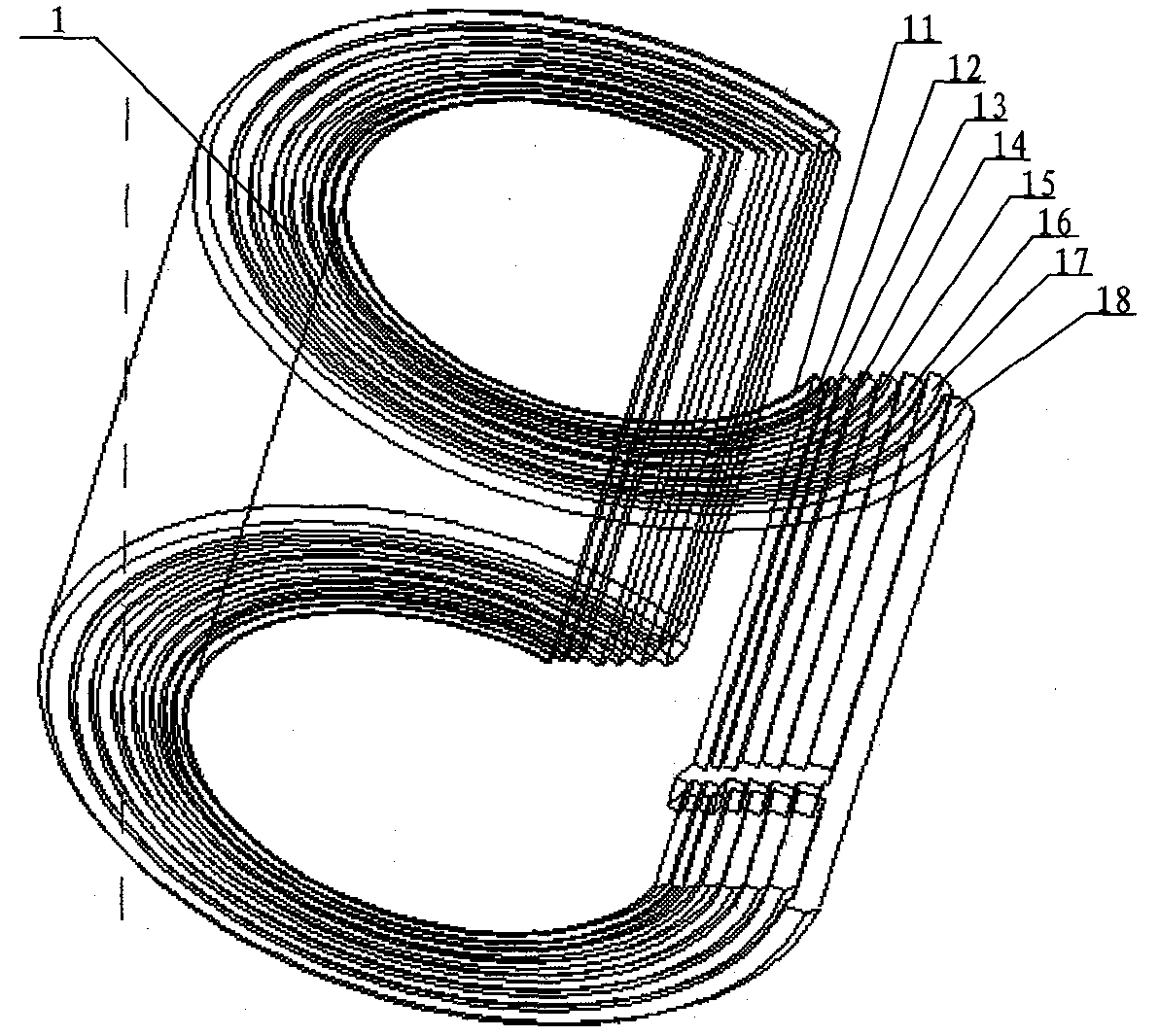

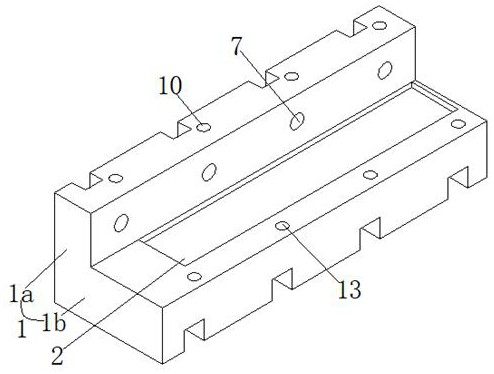

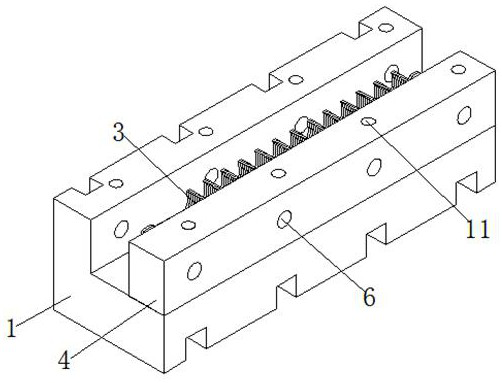

Sleeve coil spring for damper and manufacturing method thereof

InactiveCN102305258BGuaranteed accuracyGuaranteed concentricityShaping toolsLow internal friction springsCoil springHigh dimensional

The invention relates to the field of coil spring production, and provides a manufacturing method of a sleeve coil spring for a damper. The manufacturing method comprises the following steps of: testing and analyzing the material of the original imported sleeve coil springs, to select the raw material for developing coil springs; based on the analysis on the structure of the sleeve coil springs, determining the shape and size of a blank; bending and curling the blank to be round by means of a bending mould; carrying out heat treatment on obtained spring strips; and assembling the spring strips into sleeve coil springs by means of a assembly mould. According to the invention, a spring strip bending mould with high dimensional accuracy and good surface quality is used for carrying out bending treatment on the spring strips in the method for bending treatment of the spring strips, which ensures the concentricity and curvature of coil springs of different thickness; and an extrusion-assembly mould is utilized for the assembly of the spring strips, which ensures rational assembly intervals between each of the spring strips and the accuracy of coil spring assembly, thus filling a gap in the diesel engine industry of China, improving the domestic capability of researching and developing coil springs for high-performance diesel dampers, and increasing the production and preparation level of sleeve coil springs of dampers.

Owner:ZHONGBEI UNIV

Hedge trimmer blade shaping and tempering tool

InactiveCN111826510ASimple structureEasy to operateFurnace typesHeat treatment furnacesEngineeringStructural engineering

The invention provides a hedge trimmer blade shaping and tempering tool. The tool comprises an L-shaped mounting plate, wherein the L-shaped mounting plate comprises a vertical plate and a transverseplate; the transverse plate is provided with a placement groove, the placement groove is provided with a plurality of hedge trimmer blades, and the plurality of hedge trimmer blades are arranged at the end far away from the transverse plate in a regular stacked mode; and a first clamping plate is detachably arranged on one sides of the plurality of hedge trimmer blades, a second clamping plate isdetachably arranged at the top ends of the plurality of hedge trimmer blades, and the first clamping plate, the second clamping plate and the L-shaped mounting plate form a concentric-square-shaped structure. The hedge trimmer blade shaping and tempering tool is simple in structure and convenient to operate, the first clamping plate and the second clamping plate are adopted for two-face pressing,and the first clamping plate and the second clamping plate are locked through screws after being pressing by a hydraulic machine, so that the side faces and the top faces of the hedge trimmer blades are fixed, 60 hedge trimmer blades can be clamped at a time, and the bending degree of the straightness of the products can be guaranteed after tempering and discharging.

Owner:安庆锦泰金属材料科技有限公司

A jig for bending and forming notebook antennas

InactiveCN106475490BRealize modular functional designQuickly realize bending workEngineeringMachining

The invention relates to a jig used for bending forming of a laptop antenna. The jig comprises a jig body, a bending size control module arranged on the jig body, and an antenna workpiece fixing module arranged on the jig body. The bending size control module and the antenna workpiece fixing module are oppositely arranged and are arranged on the jig body through slide rails in a sliding manner correspondingly. An antenna workpiece pick-up area is arranged between the bending size control module and the antenna workpiece fixing module. Compared with the prior art, the jig is simple and compact in overall structure, economical, practical, low in manufacturing cost, capable of conveniently conducting the bending operation, capable of achieving rapid positioning and fixing and conducting bending work on an antenna workpiece, capable of effectively ensuring the bending degree and size precision requirements for the antenna workpiece and suitable for mass industrial machining, and has very good application prospects.

Owner:YUANRANG IND SHANGHAI

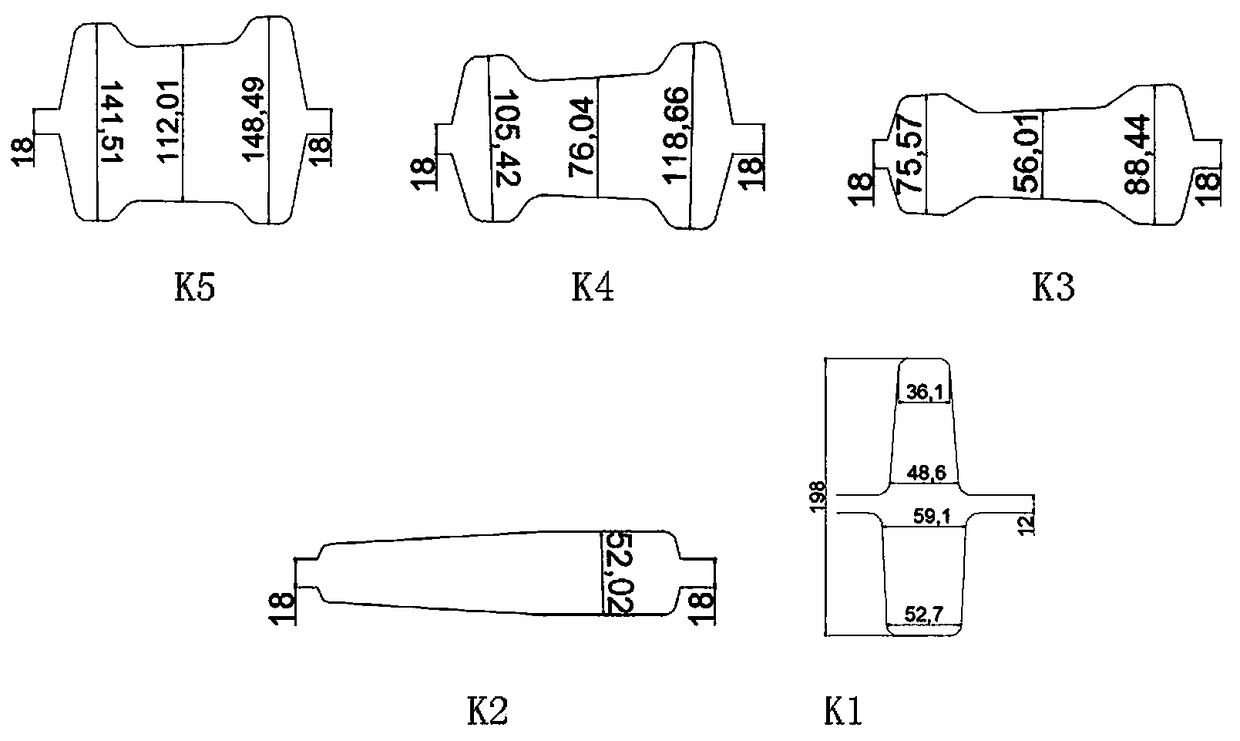

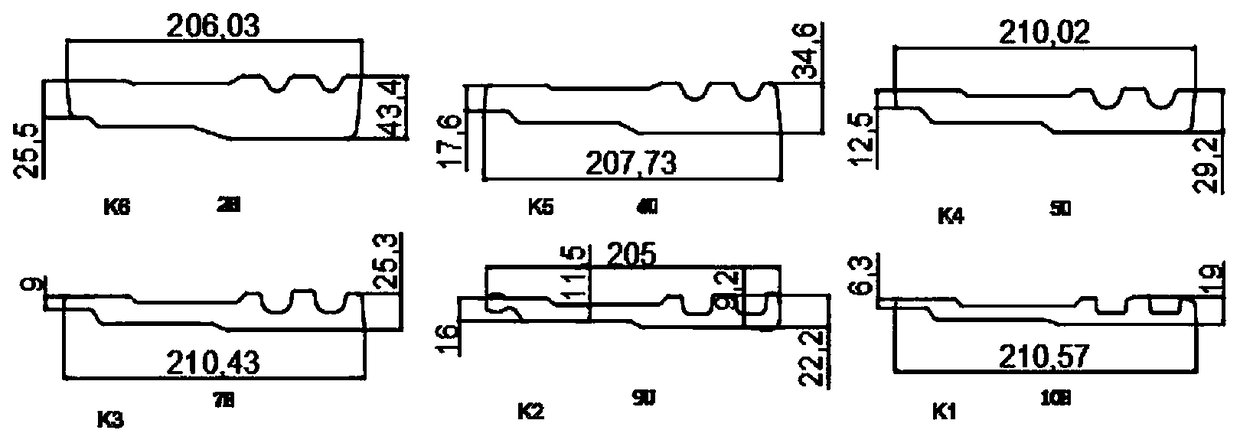

Continuous rolling process of profile steel for double-rubber ring socket steel ring of prestressed concrete pipe

InactiveCN108405606AGuaranteed curvatureSolve the problem of side bending of the headMetal rolling arrangementsProduction lineRubber ring

The invention discloses a continuous rolling process of profile steel for a double-rubber ring socket steel ring of a prestressed concrete pipe. According to the continuous rolling process, (1) the cross-section dimension of a steel billet is 150*150 mm, the length is determined according to the length of a cooling bed of an application production line and the width of a heating furnace, and the initial rolling temperature is 1030 to 1080 DEG C; (2) rolling is performed for 11 passes in the whole line, the strong wide pass is adopted for rough rolling of the first three passes, a rolled pieceis rolled into the shape and size required by the next pass in the fourth and fifth passes, the closed pass is adopted for fine rolling, and the size of a groove of a sealing ring and the size of thetotal width of a finished product are guaranteed by using a width limiting principle; (3) the fine rolling is continuous rolling with six racks, wherein K2 adopts a four-roller universal mill, the rest adopts two-roller horizontal mills, and the lateral bending coefficient of the workpiece of each pass is less than plus or minus 0.01; and (4) an inlet guide of each finishing mill adopts a rollingguide with three groups of guide rollers, the first group include horizontal guide rollers, and the latter two groups include vertical guide rollers. According to the continuous rolling process, the problem of lateral bending of the head of socket steel in a rolling process is solved; compared with an open-train mill, the machine-hour capacity level of the steel product rolling mill is increased by one time.

Owner:XINJIANG BAYI IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com